Ever struggled with cutting MDF? Wondering if a table saw can do the trick without chipping? Let’s unravel this mystery together!

Medium-density fiberboard, also known as MDF, is a manufactured wood type that is used for various projects such as furniture making, cabinets, flooring, doors, and decorative purposes.

When you are working with MDF you may face problems cutting MDF board due to its high density.

I have quite a good knowledge of and experience with working with MDF, having done so for over a decade.

With my experience, I’d like to share what I know. So, can you cut MDF with a table saw?

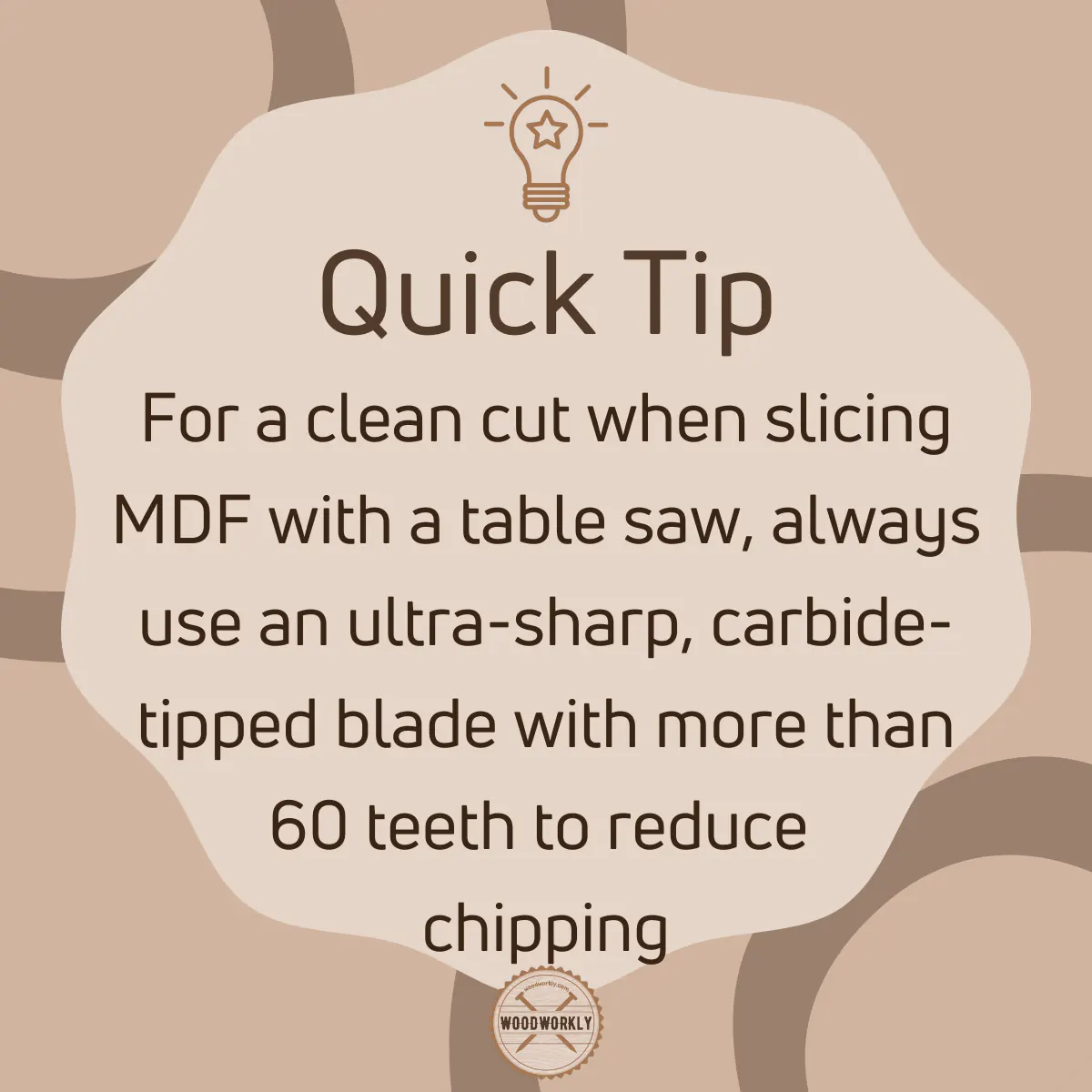

Yes, you can cut MDF with a table saw. To achieve clean and precise cuts, it’s important to use a sharp, carbide-tipped blade with a high tooth count (preferably 60 teeth or more). Proper blade alignment and moderate cutting speed can help prevent chipping.

But there’s a lot to know about working with MDF!

So, in this article, I’ll explore can you cut MDF with a table saw, what saw blade types are best to cut MDF board and how to cut MDF without chipping.

Furthermore, I’ll answer frequently asked questions as well.

So, let’s jump in!

Can You Cut MDF with a Table Saw?

Yes, you absolutely can cut MDF (Medium-Density Fiberboard) with a table saw!

Cutting MDF with a table saw is not only possible, but it’s also one of the most common methods employed by woodworking enthusiasts and professionals alike.

It is an efficient and reliable method when done correctly, especially when making straight cuts.

Understanding MDF

MDF is a type of engineered wood product made from tiny wood fibers glued together under heat and pressure.

It’s known for its strength, consistency, and versatility, and it is commonly used for building furniture, cabinetry, and a host of other indoor and outdoor projects.

However, due to its high glue content and density, cutting MDF can be tricky and requires some specific strategies and tools to avoid damaging the material.

What Saw Blade Should You Use to Cut MDF?

The blade that you use to cut MDF should be carbide-tipped. Otherwise, the high glue content of MDF will dull the steel blade and ruin your table saw.

The number of teeth per inch of the blade which you use to cut MDF should be high to make a perfect cut on the MDF board.

Otherwise, MDF tends to chip. Blades with a higher number of teeth make MDF less favorable to chip.

But on the other hand, when the number of teeth of a blade is high, the blade will produce a high amount of dust which makes the cutting process quite difficult.

So, here’re the two factors that you need to consider before cutting MDF with a table saw,

- Carbide-tipped blade with a higher number of teeth.

- Dust removal process to prevent dust build-up and interfering with the motor.

Things You Need To Know Before Choosing Blade To Cut MDF

Before selecting a blade to cut MDF, there’re several things you need to know. They are,

- Blade size

- Blade teeth count

- Blade type

So, let’s discuss each of the above factors to get a clear idea about how to cut MDF precisely.

1. Blade Size

The blade size of most of the table saws has a diameter of 10 inches. For MDF you need to go with a smaller blade size for best results because of the high-density MDF board.

By selecting a smaller blade size that can handle by saw when cutting MDF you’ll be able to make a clean cut with ease.

Never go for large blade sizes which are hard to handle by table saw.

2. Blade Teeth Count

As we discussed earlier, high teeth count is required for an efficient cutting process.

To deal with a high-density board like MDF, the blade needs to have high teeth count per inch.

The recommended number of teeth count per inch for cutting MDF ranges from 50 to 80 teeth per blade.

3. Blade Type

There’re several blade types that can use for table saws to cut MDF effectively. They are,

- Crosscut blade

- Combination blade

- Composite blade

- ATB blade

So, let’s have. A look at summarized details about the above blade types to select the one that fits you the most.

| Blade Type | Blade Teeth Count | Qualities |

|---|---|---|

| Crosscut blade | 80 – 90 | Use to cut across MDF Produce more sawdust Deliver excellent precise results |

| Combination blade | 32 – 50 | The most common table saw blade type Less refinedPerfect to cut MDF |

| Composite blade | 60 | Perform both ripping and crosscut Excellent to cut MDF Able to make long cuts |

| ATB blade | 50 | Excellent to cut MDF |

As you can see blade type is an important factor you should consider when cutting MDF with a table saw.

Here’re the best commercial blades available in the market for cutting MDF,

- DEWALT 10-inch table saw blade

- Freud D1050X Diablo

- DEWALT DW3106P5 saw blade

So, let’s find out how to cut MDF with the knowledge that you’ve already gathered!

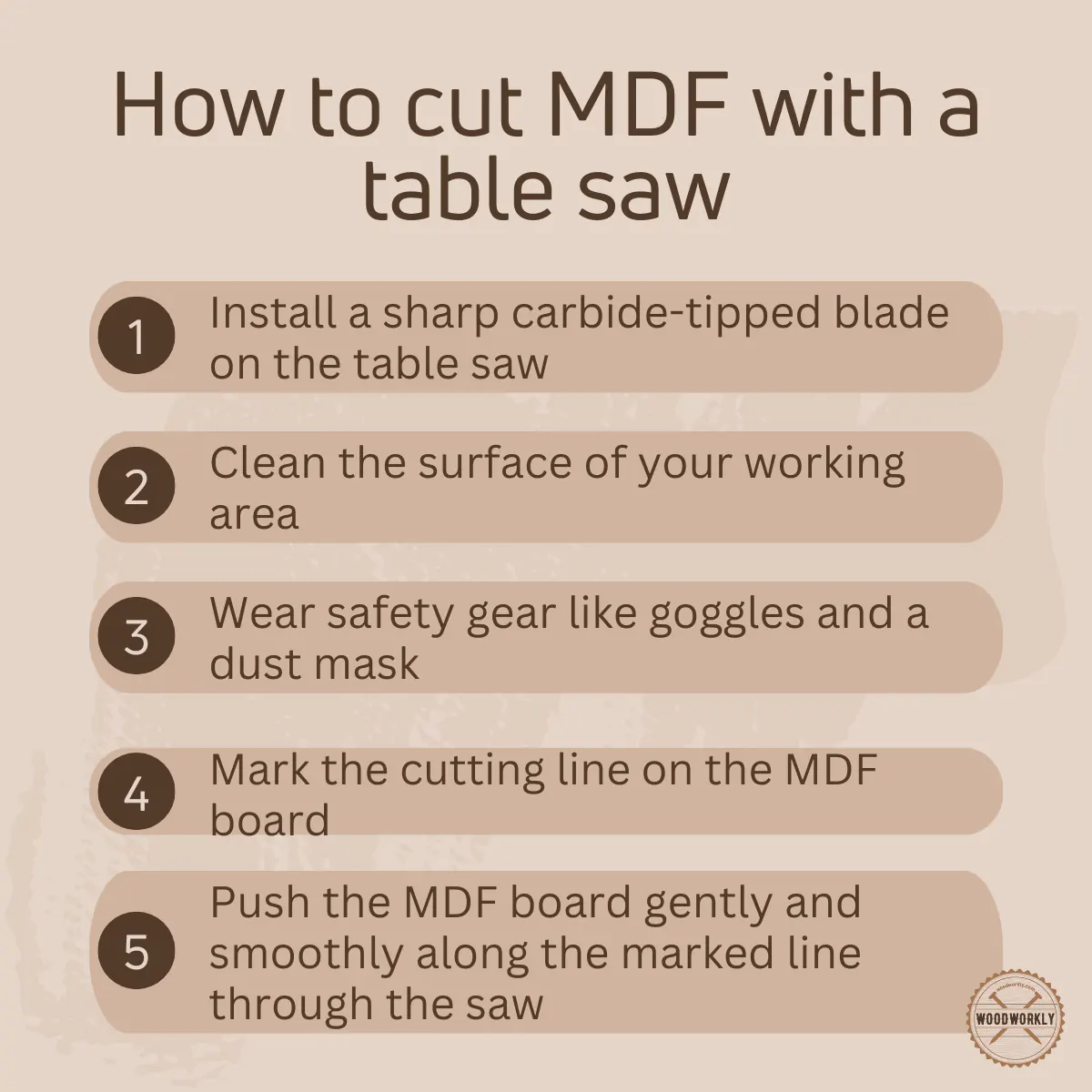

How To Cut MDF On a Table Saw?

There are main two ways of cutting MDF on a table saw. They are,

- Rip cuts along with the wood lengthwise.

- Crosscut along the direction of the wood grain.

Even though you follow either of the methods, safety comes first.

So, here’re the safety precautions you need to follow before making rip cuts or crosscuts on MDF,

- For your safety, you should always wear protective gear (goggles, ear protection, gloves).

- Unplug the saw until you adjust the MDF against the table

- Use rip fence when making rip cuts

- Use miter gauge for crosscuts

- Keep the MDF board completely flat against the table during the cutting process

So, let’s find out how to make rip cuts on MDF using a table saw.

How To Rip-Cut MDF on a Table Saw?

Ripping is the most common method that uses a table saw.

Because of having a rip fence, you’ll be able to control the MDF while cutting to make the desired cut.

Here’re the steps you need to follow when rip-cutting MDF on a table saw without chipping,

- Unplug the table saw

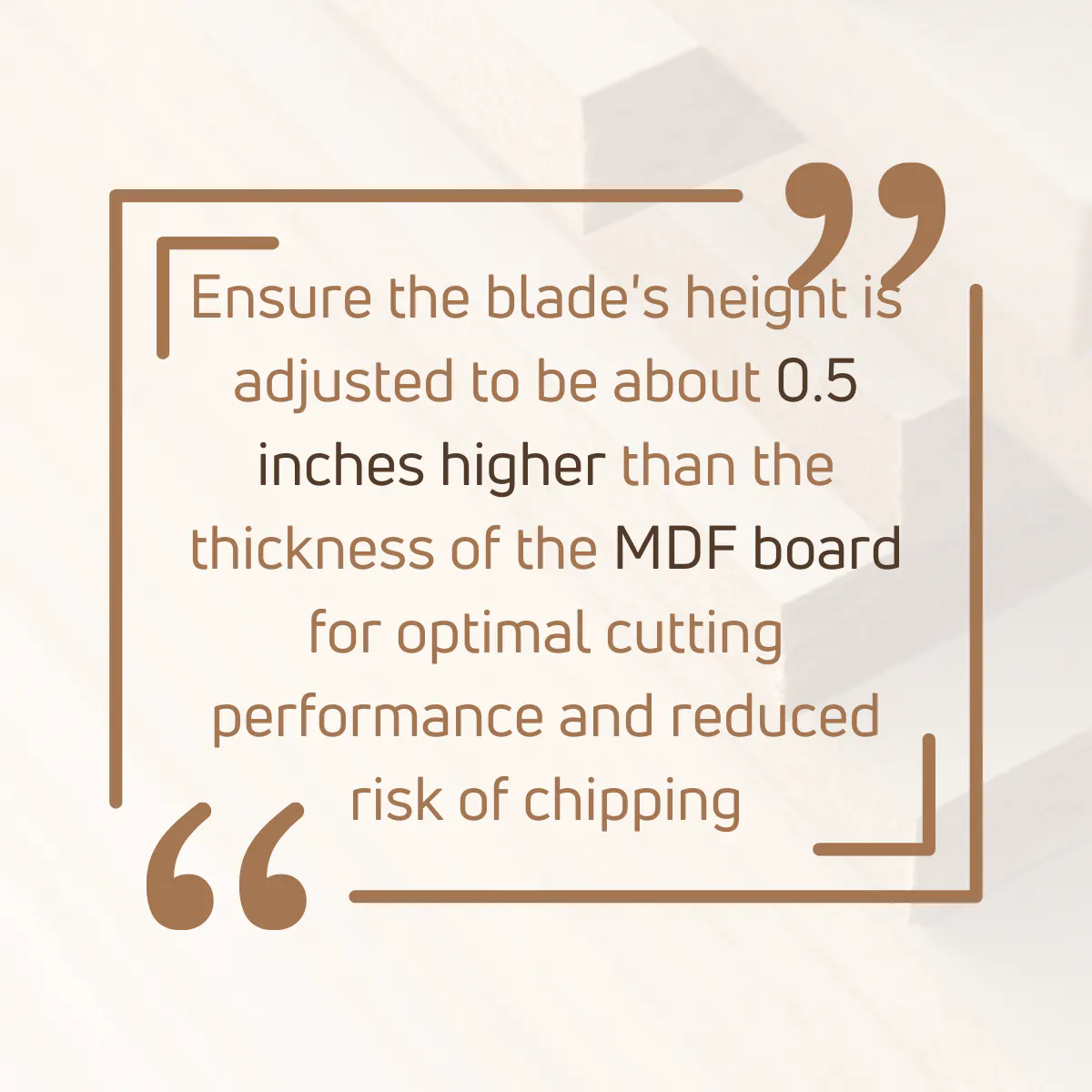

- Attach a suitable blade type with 50 to 80 teeth per blade below the surface of the MDF. Blade height rises no more than ¼” above the height of the MDF board.

- Place the rip fence by releasing the lock and sliding it. This will be helpful to match the inner edge with the desired width of the cut.

- Plugin the table saw

- Place and align the MDF board with the rip fence. But never hit the MDF surface to the blade until it reaches its maximum speed. Otherwise, the MDF will kick back.

- After the blade reaches its maximum speed slowly move the MDF towards the blade. You can use a push stick to keep the fingers away from the blades. If you’re a beginner I highly recommend using a push stick instead of using fingers.

- Slice through the MDF

So, let’s find out how to crosscut MDF using a table saw.

How To Crosscut MDF on a Table Saw?

Never use a rip fence when you’re crosscutting MDF.

Because rip fence only stabilizes long lengths and cannot use for narrow cuttings of MDF. Therefore, we use a miter gauge for crosscuts.

The miter gauge stabilizes the MDF and bar which fits into deep grooves of the surface of the table.

So, it is better to purchase a miter gauge if you’re planning to crosscut MDF on a table saw.

Here’re the steps you need to follow when cross-cutting MDF on a table saw without chipping,

- Unplug the table saw

- Attach suitable blade type with 50 to 80 teeth per blade below the surface of MDF. Blade height rises no more than ¼” above the height of the MDF board.

- Place the miter gauge either angled or straight.

- Place and align the MDF along the edge of the miter gauge using clamps.

- Plugin the table saw

- Let the MDF touch blade once it hits the maximum speed. Otherwise, the MDF will kick back.

- After the blade reaches its maximum speed slowly slide the miter gauge and MDF through the blade. You can use a push stick to keep the fingers away from the blades. If you’re a beginner I highly recommend using a push stick instead of using fingers.

Hope you have gained good knowledge about how to cut MDF on a table saw.

By following the above procedure you’ll be able to cut MDF without chipping.

Other Woodworking Tools That Can Use to Cut MDF

Rather than a table saw, here’re a list of other tools that can be used to cut MDF precisely.

They are,

- Jigsaw for curved cuts

- Circular saw

- Hole saw to drill holes

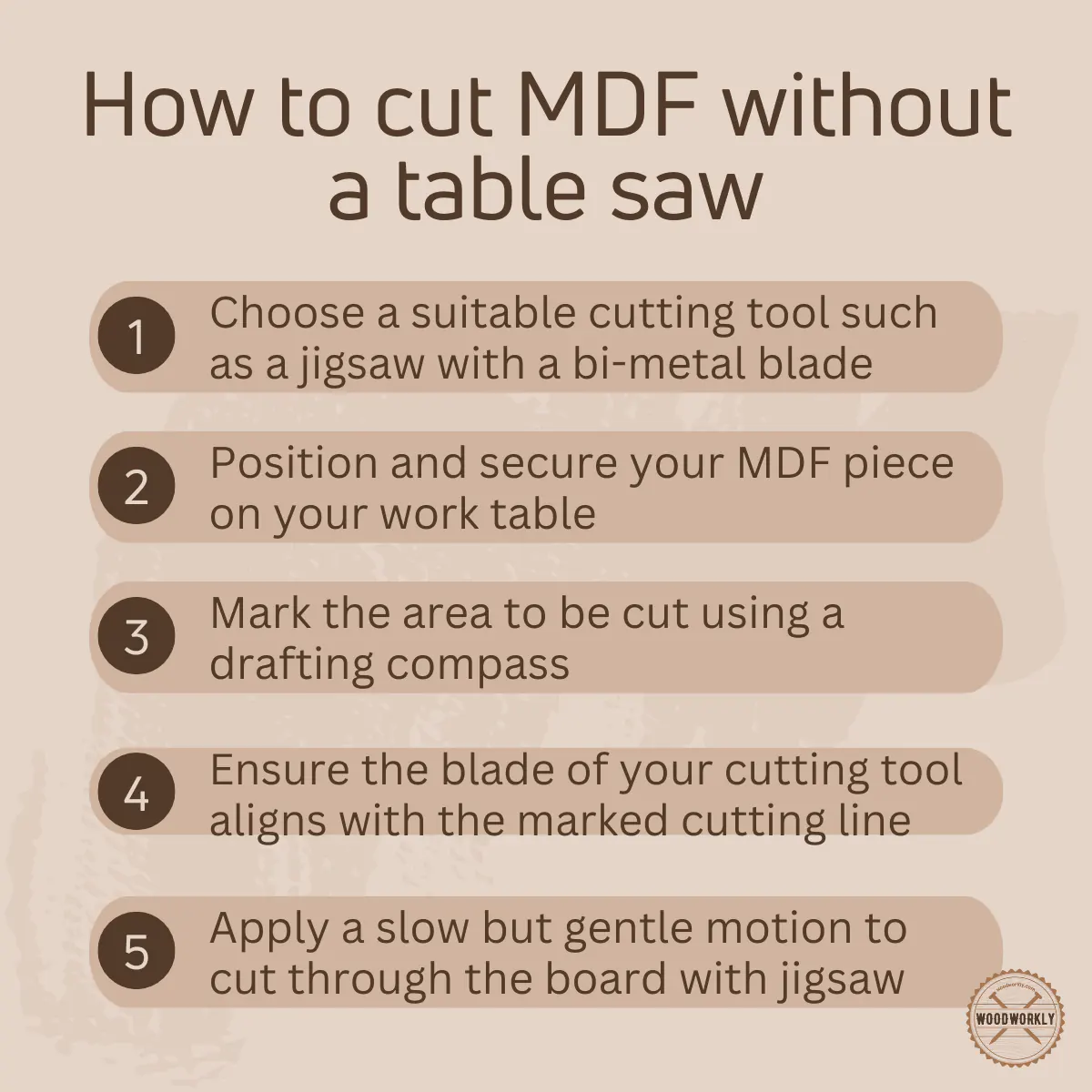

Cutting Wood Without a Table Saw

Sure, a table saw is an invaluable tool in a woodworker’s kit, but what if you don’t have access to one?

Well, fear not, because there are indeed many ways to slice that proverbial, or in this case, literal, piece of wood.

Embracing the Versatility of a Circular Saw

A circular saw can be an excellent substitute for a table saw.

They’re portable, powerful, and can make both straight and angled cuts with precision.

With the right setup, a circular saw can mimic a lot of the functions of a table saw.

Here’s the procedure of cutting MDF with a circular saw,

- Mark Your Cut: Measure and mark your cut line with a ruler or a straight edge.

- Set Up a Guide: Attach a straight edge guide (a straight piece of wood or metal will do) along the line to ensure a straight cut.

- Position the Saw: Line up the blade with your mark and adjust the blade depth to just below the thickness of your wood.

- Make Your Cut: Keeping the saw’s base plate flush against your guide, slowly push the saw through your wood.

The Compact and Curvaceous Jigsaw

When it comes to making curved cuts without a table saw, the jigsaw is your best friend.

With a thin, reciprocating blade, a jigsaw can navigate tight turns and complex shapes that a table saw or circular saw couldn’t handle.

Here’s how to use a jigsaw for curved cuts,

- Trace Your Cut: Draw your desired shape directly onto the wood. This will serve as your guide when cutting.

- Position the Jigsaw: Align the jigsaw blade at your cut’s starting point.

- Start Cutting: Slowly follow your marked path with the jigsaw, taking care to not force the blade too hard or go too fast, as this can lead to rough cuts or broken blades.

Hand Saw: The Classic Alternative

Even in the era of power tools, nothing beats the simplicity and satisfaction of a good old-fashioned hand saw.

They’re affordable, easy to use, and need no electricity.

They come in a variety of types, like the rip saw for cutting along the grain, the crosscut saw for cutting across the grain, and the hacksaw for cutting metal.

Here’re the steps you need to follow when cutting MDF with a hand saw,

- Mark Your Cut: Use a square or ruler to draw a straight line where you want to cut.

- Position Your Saw: Hold the saw at an angle to the wood, with the teeth just at the edge of the line you’ve drawn.

- Start Sawing: Begin sawing, using long, smooth strokes. Let the saw do the work – there’s no need to apply too much downward pressure.

Congrats folks! Now you know the best way to cut MDF and Can you cut MDF with a table saw properly?

So, let’s answer some frequently asked questions.

FAQs

What kind of blade should I use to cut MDF with a table saw?

To achieve clean, precise cuts on MDF, it is recommended to use a carbide-tipped blade with a higher tooth count, preferably 60 teeth or more. These blades stay sharp for longer and reduce chipping.

Can I make curved cuts on MDF using a table saw?

While table saws are excellent for making straight cuts, making curved cuts on MDF is best done with a jigsaw or band saw, as these tools offer more flexibility for intricate shapes.

What causes chipping when cutting MDF?

Chipping often occurs due to dull blades, high cutting speeds, or incorrect blade alignment. Using a sharp, carbide-tipped blade and maintaining a moderate cutting speed can minimize chipping.

Do I need any specific safety gear when cutting MDF with a table saw?

Yes, it’s essential to wear safety goggles to protect your eyes from debris and a dust mask to prevent inhalation of the fine dust particles MDF produces when cut.

Is MDF harder to cut than other types of wood?

MDF’s density and high glue content can make it more challenging to cut than softer woods, but with a sharp, carbide-tipped blade and proper technique, cutting MDF can be just as straightforward.

Is it necessary to clean my table saw before cutting MDF?

Yes, cleaning your table saw helps to remove any dust or debris that could potentially interfere with your work or scratch the MDF laminate.

Did I cover all you wanted to know about, Can You Cut MDF With A Table Saw?

In this article, I have deeply discussed whether can you cut MDF with a table saw and how to do that.

I have answered what saw blades should you use to cut MDF and what factors you should look at before buying the perfect blade type to cut MDF according to your purpose.

MDF can be cut with a table saw with the appropriate blade type. The blade should be carbide tipped and the table saw should have a vacuum removal system to prevent dust from building up. The wrong type of blade will dull the table saw because of the high glue content of MDF.

Because safety always comes first.

Furthermore, I have answered some frequently asked questions as well.

Hope you have gained pretty good knowledge and found answers to the question, can you cut MDF with a table saw?

So, let’s start your next woodworking project with MDF, and don’t forget to give it a try with a table saw after reading the entire guidelines above. Enjoy woodworking!