Weighing the pros and cons of Danish oil? Curious to explore its benefits and drawbacks? Delve into the world of Danish oil and make an informed decision for your wood projects!

When it comes to wood finishing, Danish oil is one of the most commonly used types of wood finishing oil, with a wide range of applications.

It is primarily made by blending linseed oil and tung oil with mineral spirits. While there are various types of Danish oil available from different manufacturers in the market, there is no clear mixing ratio between these ingredients.

So, you need to have good knowledge about the danish oil type you going to use for your next woodworking project.

As a full-time, woodworker, I have worked with danish oil to finish most woodwork.

In this article, I’m going to tell you everything you need to know about Danish oil and how to use it.

So, let’s talk about the good things and the bad things about Danish oil when you want to finish a piece of wood.

Danish oil Advantages and Disadvantages

| Advantages | Disadvantages |

| Waterproof oil | Need regular maintenance |

| Dries faster | Less durable |

| Non-toxic | Time-consuming |

| Food safe | Able to use only on bare woods |

| Improves the sheen | Can occur Sudden Ignition |

| Easy to apply | Doesn’t smoothen the Wood Grain |

| Elasticity | |

| Can use as a Primer | |

| Offer scratch resistance | |

| Provide chemical resistance |

But that’s a quick snapshot. Let’s discuss each advantage and disadvantage of danish oil in detail.

First, have a brief look at what is Danish oil with its specifications.

This post contains affiliate links. As an Amazon Associate, I earn from qualifying purchases. I endorse only products I truly recommend. If you make a purchase using one of these links, I may receive compensation at no extra cost to you. For more information, see my disclosure policies.

What Is Danish Oil?

Danish oil is a type of wood finish that contains a blend of finishing oil, varnish, and thinner.

The oil is designed to deeply penetrate the wood, but the exact composition can vary among different manufacturers, making it difficult to define a precise mixing ratio of the ingredients.

Here’re some main properties of Danish oil,

- Hardens upon exposure to air

- Enhance wood color

- Water-resistant

- Food safe

Advantages of Danish Oil

1. Danish Oil Is A Waterproof Oil

Danish oil has excellent resistance to water and other liquids, making it an ideal waterproof coating for woodwork.

The reason Danish oil is so effective is that it’s made by combining small particles that undergo polymerization to form a strong surface after drying.

Danish oil surface is so impenetrable that water molecules can’t get through it, which is why it’s an excellent way to keep your woodwork dry.

The reason for this incredible waterproofing ability is that the particles contained in Danish oil react with atmospheric oxygen to form a highly polymerized, solid structure.

This structure is incredibly strong and impenetrable, making it an ideal way to protect your woodwork from water damage.

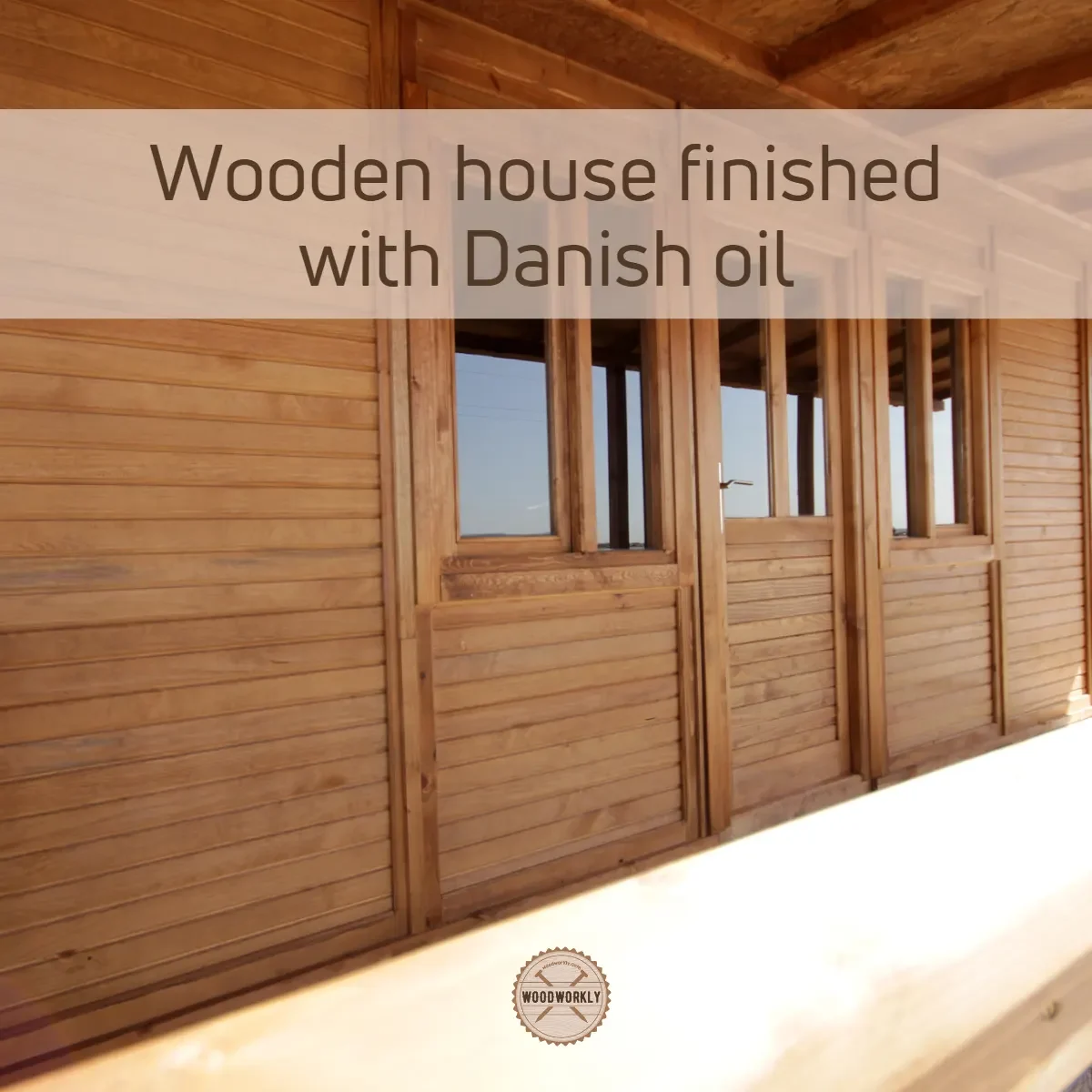

Danish oil creates a surface that is impenetrable to moisture, making it an ideal finish for outdoor furniture.

After years of experience working with Danish oil, I’ve learned that it’s not only water-resistant but also resistant to alcohol and acid.

2. Danish Oil Dries faster

Danish oil has the ability to dry faster than many other finishing oils available in the market.

The average time Danish oil takes to dry is around 6 hours. But this time can vary drastically on the environmental temperature and humidity.

If it’s colder weather, you could have to wait longer till the danish oil coating is completely dried. Colder weather and high humidity delay the drying time.

Warmer weather and when the humidity is low the drying time is shorter.

It is important to follow the manufacturer’s instructions for application and drying time.

After applying Danish oil, you should wait at least 6 to 8 hours before applying a second coat, if desired. It is also recommended to allow the wood to dry for at least 24 hours before using or handling it.

Apart from that, the drying time of Danish oil can differ from manufacturer to manufacturer.

So, my advice you to keep a minimum of 3 days for the completion of the drying process of danish oil after applying the coat 2-3 times.

3. Non-toxic

Danish oil is completely non-toxic. You can apply it to children’s toys or any other household furniture without any problem. Danish oil is safe for babies’ toys and accessories.

There are no toxic additives and ingredients available in danish oil. Once it’s fully cured you can use it anywhere you wish.

But I recommend you don’t use the furniture until the danish oil coat is fully cured for better safety. Because many wood finishers are toxic in liquid or uncured states.

So, keep in mind that “non-toxic once cured”. Danish wood is safe to use on toys and kitchen furniture and other kitchen accessories.

4. Food Safe

Danish oil is food-safe. You can apply danish oil over any wooden tool, furniture, or kitchenware.

It is completely safe to apply Danish oil on cutting boards, kitchen cupboards, salad bowls, and banisters without any issues since it won’t react with foods.

Danish oil can use on butcher blocks as well.

But wait for the application to use until the oil is fully cured. This is because of its polymerization ability, once it gets fully cured, it doesn’t release anything outside or to the foods.

It can take days or weeks the completion of the curing process. But you should wait because if you use the kitchen item with uncured danish oil, definitely the oil will get mixed with the food and cause a lot of trouble.

So, patience is the key.

Danish oil bonds with the wood and become essentially inert.

In my experience, once I applied danish oil to the cutting board and kept it for around 30 days until it fully cured.

As long as you keep waiting, the result will be so useful.

5. Improves the Sheen

Applying danish oil, not only gives good protection to the furniture but also improves the look.

Danish oil has the ability to absorb the wood and give protection for any exterior defects and protect the interior without getting any damage.

The extra sheen, and glossiness help to increase the beauty and the appearance of the furniture.

The low sheen and the darker color given by danish oil add a unique look to the wood. It also gives good chemical and heat resistance to the wood by remaining extra glamour.

The sticky oil that is left on the wooden surface after rubbing the surface is the reason for its silky sheen.

If you want to have a soft sheen or rustic finish, such as decorative tables, clocks, jewelry boxes, and picture frames, which don’t require tough rough coating, Danish oil is the best solution.

Danish oil enables you to refinish the wood easily.

I recommend you apply nearly 3 coats of danish oil with proper drying to get an excellent sheen out of most wood types.

But this totally depends on the type of wood you’re using.

6. Easy to Apply

You can easily apply danish oil on any type of wood with a brush or a cloth. Make sure to apply through the grain direction for better results. It can easily penetrate the wood.

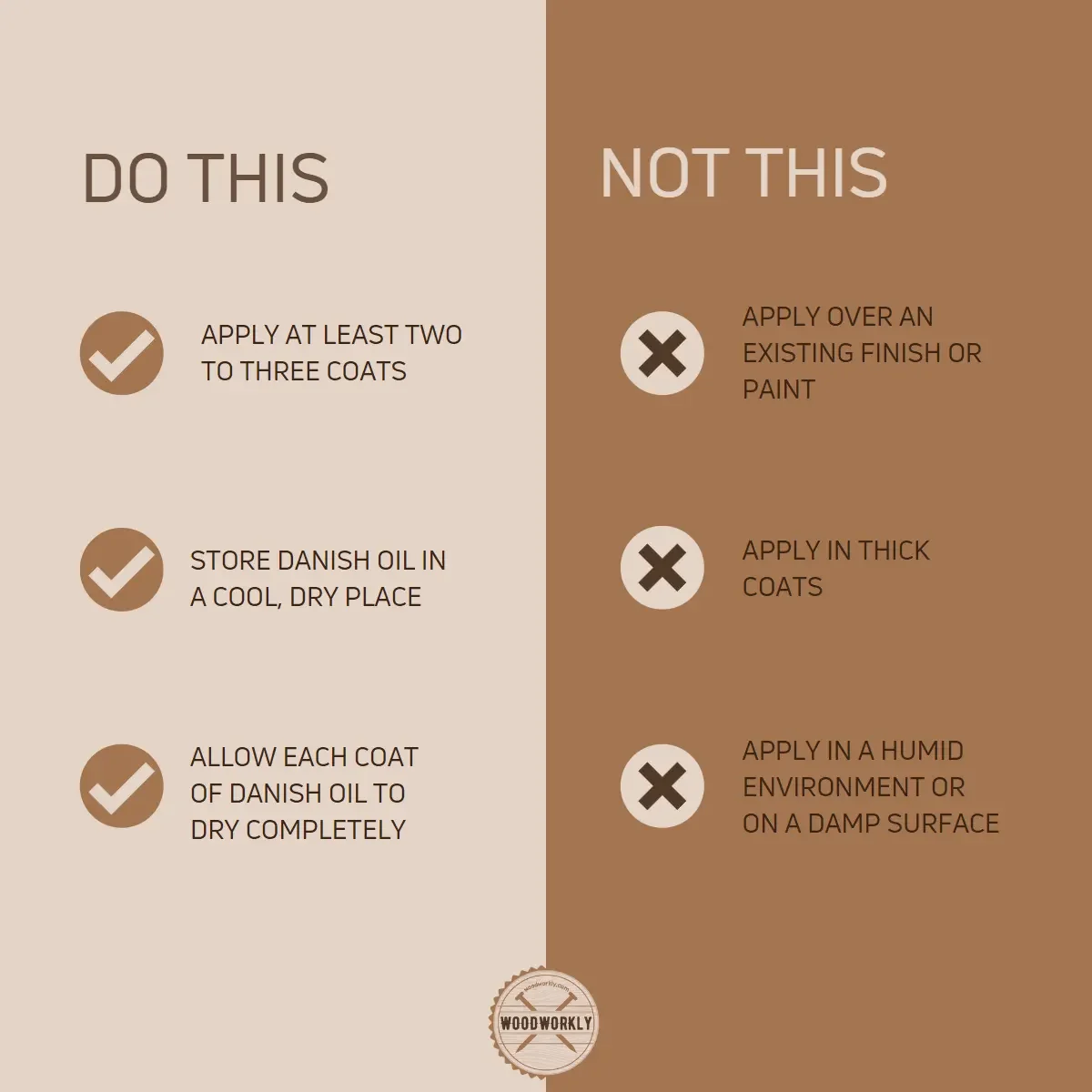

Apply nearly 3 coats to get better results according to the wood type.

After each coat leaves the surface to dry completely for at least more than 6 hours. When you feel the surface is completely dried and smooth by touching, do the second coating and repeat drying the process.

Here I have listed down the summarized steps of How is Danish oil applied.

- Sand the wood with 220 grit until the surface is nice and smooth

- Remove the sanding dust

- Apply the first coat with a brush or cloth through the grain direction

- Let the oils soak well

- Rub the wood with a rag to get the sheen and smooth surface

- Leave the wood for several hours to dry

- Once you feel the wood is completely dried, apply the second coat after rubbing the surface with 600 grit sandpaper after dipping it in danish oil.

- Let the surface dry for a minimum of 2-3 days.

The simple apply and reapply is one of the main reasons for danish oil to become such a popular wood finishing oil.

7. Elastic ability

Think of your wood contracts or expands because of any reason, the best finish you can go for that type of wood is danish oil.

Danish oil has a unique stretching ability. The elasticity of danish oil doesn’t go even when it is fully cured and turned into a solid polymerized structure.

Because of its wonderful elastic properties, once it applies to wood, it can expand and contract along with wood without affecting the finish. The protection will remain the same.

Some woods expand and contract under temperature fluctuations. For those woods, danish oil is the best finishing oil you can go with.

Due to its elastic properties, danish oil can have great compatibility with wood which is not common on other finishing oils available in the market.

There will be no scratches, cracking, or dull spots that will remain on the wood due to expansion with the danish oil coating.

8. Can Use as a Primer

Because of being a hard drying oil, Danish oil can use as a primer or sealer. It can apply on bare wood before applying the finishers.

You can paint over danish oil with any oil-based paint once the danish oil layer is completely cured.

By using danish oil as a primer, the efficiency of the wood paint will increase and give extra protection to the wooden surface from cracking and scratching.

Danish oil gives better adhesion chemically and physically by bonding perfectly with the paint you are going to use.

As we have discussed the advantages of danish oil, let’s turn the table to talk about the disadvantages of danish oil.

When it comes to danish oil advantages and disadvantages, there are lots of advantages of danish oil than its disadvantages, which make the oil so special.

Disadvantages of Danish Oil

1. Need Regular Maintenance

Careful and consistent maintenance is essential thing when it comes to danish oil. This of one of the main drawbacks of danish oil, because regular cleaning is very time-consuming.

If you’re going to apply a danish oil wood finisher, make sure to clean the furniture regularly to keep its appearance the same as earlier. This will give refreshment to the wood as well.

The polymeric oil structure of danish oil works as a magnet for dust particles. Even though they don’t penetrate inside, they stick on top of the wood, and that makes the wood dull.

So, make sure to keep the surface clean to keep the shine forever.

To clean the surface, use the polish of shammy cloth. Wipe the dull areas. To repair the cracks and scratches, reapply the danish oil coatings.

The re-application of 2-3 coats is recommended every year. This will keep the wood naturally fresh.

After working with Danish oil keep it in a clean dry environment to prevent it from going bad.

2. Less Durability

When it comes to durability, even though Danish out compatibilized perfectly with the wood itself, it doesn’t give a durable finish as we expect.

There are many other wood finishing oils available in the market that give better durability results than danish oil.

Because of its low durability, the resistance to scratches and cracks over time will be reduced.

With dirt and other defects, the scratches will easily appear over time. Reapplication will be needed.

Paint and Varnish which we use as finishes for our household furniture, give better protection to the wood than Danish oil because of having high durability.

Also, tung oil gives better durability than danish oil as well.

So, I recommend you think twice before applying danish oil as a finisher for the items that we use mostly in our day-to-day lives.

As I discussed earlier, danish oil finish works like a magnet to outside dust particles. They stick on the wood and don’t go away naturally.

So, you need to clean the wood regularly to keep the sheen continuously.

Here I have listed, Durable wood finishes than Danish oil,

- Polyurethane

- Varnish

- Paint

- Tung oil

These durability issues are mostly depending on the types of ingredients danish oil has. Because the ingredients and blending ratios can differ manufacturer-wise.

So, always go for the top quality danish oil for better protection and durability.

3. Time Consuming

Patience is key when working with danish oil. Because, after applying each coat you must wait for 2-3 days until it’s completely dried before applying the next coat.

This drying time is mostly depending on the type of danish oil you’re using for the purpose and the item type.

For example, I had to keep my cutting board for over a month after applying danish oil to complete the curing and drying process.

During each coating, sanding is required with 600-grit sandpaper. Also, I recommend applying at least 2-3 coatings for most woodwork. So, this requires a lot of time and patience.

So, if you’re going to apply danish oil to an item that you commonly use, please keep an alternative item ready, because you won’t be able to use the previous item for days until the coatings are fully dried and smooth.

4. Can only Apply to Bare woods

The application and efficiency are limited on Danish oil. Danish oil gives proper perfect finishing with bare, untreated wood surfaces. But it’s limited to that purpose.

Danish oil quickly absorbs into porous woods. The oil can penetrate easily through the porous structure.

This is a major problem, because once the oil gets inside the porous wood, the strength of the wood will lose, and cracks and scratches can happen easily.

So, I recommend paying extra attention when using danish oil as a finisher for porous woods such as,

Alder, basswood, birch, maple, and willow.

By applying danish oil, the tone of the wood surface can change. It lows the sheen of the wood and darkens the color.

So, make sure to test the wood with danish oil before directly heading into the application.

Also, danish oil is not suitable for woods that are used for cutting.

5. Can Occur Sudden Ignition

When danish oil is exposed to the air, it reacts with atmospheric oxygen and makes the surface harden. This is an advantage.

But on the other side, danish oil is a highly volatile extremely flammable liquid blend with hydrocarbons distilled on petroleum oil.

But when it comes to exothermic conditions, danish oil is flammable and you must be careful when working with danish oil surfaces when the fire is near.

Because the oily surface can easily catch on fire. When the oily rags are dry, the heat produces. They can react with oxygen and lead to spontaneous combustion which leads to fire and can do destruction.

To avoid this, you need to pay extra attention to the rags that you use. It’s beaten to dry the rags before disposing or you can soak the rags in water.

6. Doesn’t Smoothen the Wood Grain

Danish oil doesn’t have the ability to smoothen the wood grain naturally. So, after each coating, wet sanding is required to get a smooth surface. The brush marks also will be removed because of wet sanding.

So, you need to have proper guidance before finishing the surface with danish oil because it is a type of finisher either can enhance the quality of the wood or ruin the whole wood just in seconds of misuse.

So, as I discussed above there are lots of advantages and disadvantages of using danish oil as a finisher.

In my point of view, Danish oil is a great finisher that can improve the properties of the wood in every aspect if you use it with proper guidance.

To cover everything you need to know about Danish oil advantages and disadvantages, I have listed down frequently asked questions about danish oil.

What is Danish Oil Use For?

Danish oil is a versatile popular choice when it comes to wood finishing.

Danish oil is commonly used for,

- Wood tool handles

- Kitchen worktops

- Cutting boards

- Butcher bench

- Food utensils

- Other household furniture

It dries hard and gives better protection and a better appearance than most of the wood finishes available in the market.

What Are The Advantages Of Danish Oil?

- Danish oil waterproofing oil

- Dries faster

- Non-toxic

- Food safe

- Improves the sheen

- Easy to apply

- Elasticity

- Can use as a Primer

- Offer scratch resistance

- Provide chemical resistance

What Are The Disadvantages Of Danish Oil?

- Danish oil needs regular maintenance

- Less durable

- Time-consuming

- Able to use only on bare woods

- Can occur Sudden Ignition

- Doesn’t smoothen the Wood Grain

How Long Does Danish Oil Finish Last?

Danish oil finish last for more than a decade or even above 20 years if the finishing surface is properly maintained.

For best practice, apply Danish oil finish at least once per two years to keep the surface fresh with excellent protection from the outside world.

It is important to note that Danish oil finish does not provide a hard, protective surface like varnish or polyurethane, and it may require more frequent reapplication in high-traffic areas or areas exposed to water and moisture.

Is Danish Oil Enough To Protect Wood?

Yes, Danish oil is enough to protect the wood from moisture, harsh chemicals, acid, alcohol, and scratches.

Danish oil makes a protective coat over any wood which isolates wood underneath from the outside environment.

This helps the wood to get protected from extreme weather conditions such as rain, snow, and heat exposure.

Danish oil is enough to protect both interior and exterior wood furniture and woodwork for a long time.

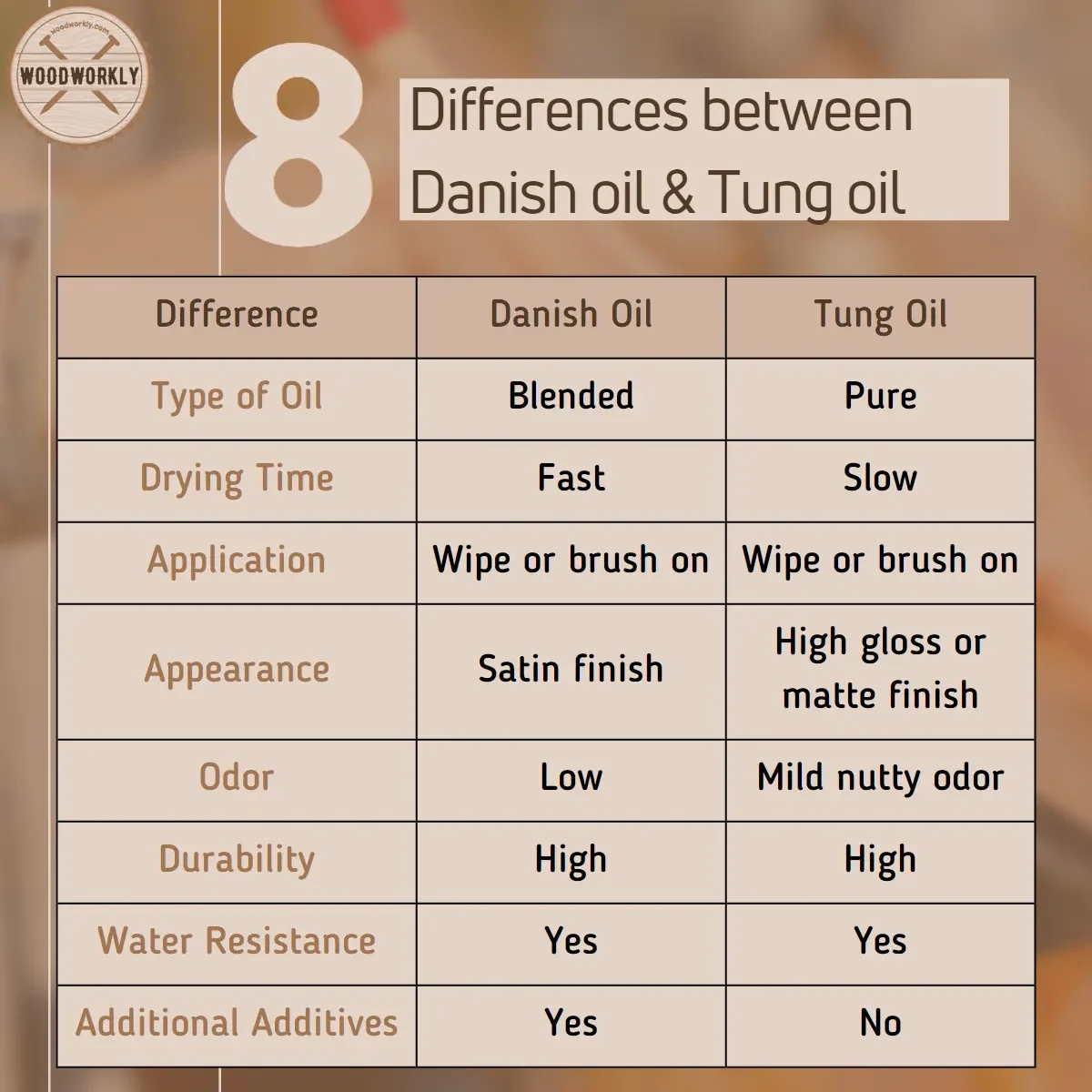

What’s Better Danish Oil Or Tung Oil?

Danish oil is better than Tung oil because it dries faster than Tung oil and Danish oil is able to make a harder and tougher protective coat than tung oil makes over the wood.

On the other hand, Tung oil is better than Danish oil only because it’s 100% natural and eco-friendly since it is made of the seed from the nut of the tung tree.

Tung oil already consists of Danish oil since Danish oil already got its qualities, but with qualities from Linseed oil and mineral spirits as well.

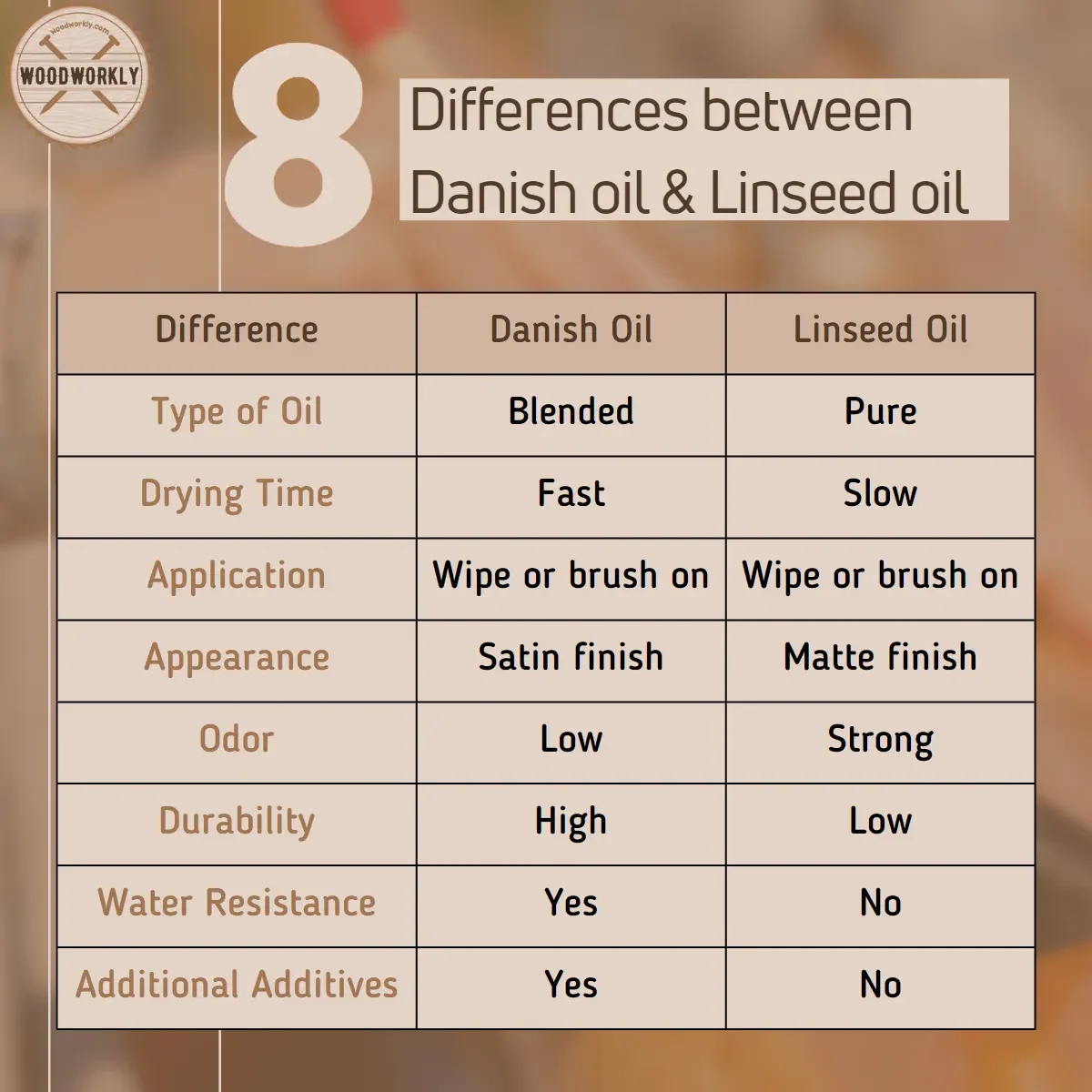

What’s Better Danish Oil Or Linseed Oil?

Danish oil is considered superior to linseed oil due to its faster drying time and more effective performance on untreated new wood.

Additionally, certain Danish oil products contain UV filters that aid in safeguarding outdoor furniture from harmful UV light, which is not offered by linseed oil.

How many Coats of Danish Oil should you Use?

An average minimum of 3 coats of Danish oil recommends for most of the wood types. Apply thin coats of Danish oil for promising results.

The number of coats you should apply depends on the type of wood you are going to use and the type of danish wood.

Three layers of Danish oil are generally recommended because they provide a more durable and long-lasting finish than just two layers.

Three layers of Danish oil provide better penetration and coverage.

Are 2 coats of Danish Oil enough?

Two coats of Danish oil are not enough instead use three coats of Danish oil for ideal results since two coats of Danish oil may result in an uneven finish.

When applied, the first coat of Danish oil may be absorbed into the wood’s surface, leaving a relatively thin layer of oil on top.

The second coat may penetrate further into the wood, but it may not be enough to provide complete coverage and protection.

Applying additional coats of Danish oil can help to build up the finish, fill in any gaps, and provide greater protection against wear and tear.

How Do You Maintain Danish Oil?

I usually follow the below steps to maintain the Danish oil finish,

- Dust and clean the surface regularly: Dust your woodwork regularly using a soft, dry cloth or a microfiber cloth to prevent dust buildup. For more thorough cleaning, use a damp cloth or sponge to wipe the surface clean, and avoid using harsh chemicals or abrasive cleaners that can damage the finish.

- Reapply Danish oil as needed: Over time, the Danish oil finish may wear off or become dull, especially in high-traffic areas or areas exposed to water and moisture. When this happens, you can reapply Danish oil to restore the finish and protect the wood. Apply a thin, even coat of Danish oil using a brush or cloth, and allow it to dry completely before using the woodwork.

- Sand and refinish once per two years: If the woodwork has deep scratches, dents, or other damage, you may need to sand it down and refinish it with Danish oil. Sand the wood with fine-grit sandpaper, wipe it clean with a damp cloth and then apply Danish oil as usual.

- Protect the finish from heat and sunlight: Danish oil can be sensitive to heat and sunlight, which can cause it to break down and fade over time. To protect the finish, keep the woodwork away from direct sunlight and heat sources, such as radiators or fireplaces.

Do You Need To Sand After Danish Oil?

Yes, Light sanding between each coat of Danish oil is recommended to smoothen the surface remove any imperfections, and build a good adhesion between the layers.

Sanding gives adhesive properties to the existing Danish oil coat which helps the next coat to stick well onto the existing one.

Make sure to lightly sand to avoid leaving scratch marks on the Danish oil surface and sand along the direction of the wood grain for a super smooth finish.

Will Danish Oil Prevent Cracking?

Yes, Danish oil prevents wood from cracking and splitting under harsh weather conditions and humidity changes.

Danish oil protects wood from outside impacts and keeps the wood fresh as new for a long time with no cracks and scratches.

Danish oil can help to minimize the risk of cracking by keeping the wood well-moisturized and flexible.

This can help to prevent the wood from drying out and becoming brittle, which is a common cause of cracking.

Do I Need Polyurethane After Danish Oil?

Applying polyurethane over danish oil is not necessary because Danish oil is a self-sufficient wood finish that can provide both protection and a beautiful appearance to wood.

But polyurethane helps to protect Danish oil coats and the wood underneath from moisture, wear, and other impacts by sealing it.

Polyurethane makes the Danish oil coat more durable and makes it useful especially for outdoor environments.

Polyurethane makes Danish oil coats more waterproof and enhances the natural beauty of the wood by bringing out its natural color and grain.

Is Danish Oil Good for Oak?

Danish oil work well on Oak with no issues. It protects Oakwood from environmental impacts while enhancing the wood’s appearance.

Danish oil is perfect for oak wood furniture. Danish oil avoids cracking, scratching, and stains and enhances the sheen of oak wood with an attractive appearance.

When it comes to oak wood floors, danish oil is mostly used to get a modern look.

Can you use Danish Oil on Pine?

Danish oil work perfectly on pine. Pinewood furniture, paneling, flooring, cabinetry, and framing are the common applications we use danish on as a pinewood finisher. It gives better durability with enhancing appearance.

It protects the wood from cracking, scratching, and stains.

Normally the color of pine wood tends to go away over time, but by applying danish oil coating over the surface, the color will remain the same for a long time with regular maintenance.

Can You Use Danish Oil On Maple?

Danish oil works so well on Maple. Danish oil protects maple wood furniture and woodwork from weather elements and improves the wood’s appearance.

Apply thin Danish oil coats on Maple for better and even penetration.

You can read more about using Danish oil on Maple through this article.

Can you Wax Over Danish Oil?

Don’t use wax over danish oil. Wax doesn’t give any protection. It attracts dirt.

Three coatings of danish oil are completely enough to protect the wood from any kind of external effects.

What Is The Danish Oil Cure Time?

Danish oil takes around 2 to 3 weeks to fully cure. Curing time refers to the time it takes for the oil to harden and fully cure.

This can take several days to a few weeks, depending on the conditions. During the curing process, the oil will continue to harden and provide increased protection to the wood.

What Are The Best Danish Oil?

Here are some of the best Danish oil products that are best to use for any project,

- Watco Danish Oil

- Tried & True Danish Oil

- Rustins Danish Oil

- Minwax Danish Oil

- General Finishes Danish Oil

Can You Paint Over Danish Oil?

Yes, it is possible to paint over Danish oil, but there are some important factors to consider before doing so.

It is essential to ensure that the Danish oil has fully cured before attempting to paint over it.

This is because any residual oil that has not fully dried may seep through the paint and cause adhesion issues.

Should I Use Danish Oil Or Varnish?

Danish oil is best suited for indoor use on decorative objects, while the varnish is ideal for outdoor use and high-traffic surfaces that require maximum protection.

Choosing between the two depends on the specific needs and desired outcome of the project.

Does Danish Oil Darken Wood?

Yes, Danish oil can darken wood as it penetrates into the grain, enhancing the wood’s natural beauty and color.

The degree of darkening will depend on factors such as the wood’s type, porosity, and the number of coats of Danish oil applied.

Typically, Danish oil will produce a richer, deeper color than other clear finishes such as shellac or lacquer.

It is important to remember that the wood’s color will continue to change over time as it is exposed to light and air.

Therefore, the initial darkening caused by Danish oil may fade over time, and the wood may revert to its natural color or take on a different hue entirely.

To minimize the darkening effect of Danish oil, it is advisable to test the finish on a small, inconspicuous area of the wood to determine how it will affect the wood’s color.

Additionally, you can choose a lighter shade of Danish oil or apply fewer coats to achieve a lighter finish.

Did I cover all you wanted to know about: Danish Oil Advantages and Disadvantages

In this article, I have widely discussed the danish oil advantages and disadvantages that I have learned with years of woodworking and working with different finishing oils available in the market.

Danish oil is a great oil in terms of protection, and appeal and it gives good strength to the wood as well.

Always make sure not to use the wood until it’s fully cured and dried.

Pay more attention when applying danish oil over porous wood. Make sure to apply the danish oil only over bare wood.

I have discussed the qualities of danish oil that make it perfect for any type of woodworking project.

The advantages of Danish oil are waterproofing oil, fast drying, non-toxic, improves the sheen, easy to apply, and elasticity. Disadvantages of Danish oil are high maintenance, poor durability, time-consuming and sudden Ignition.

Ultimately, I have answered all the possible questions that can occur when you’re working with danish oil.

Hope you learned everything about danish oil’s pros and cons, now you can have a clear idea to take the final decision according to your personal preferences.

Can I use this for a small dining room table or should I try something else. I’ve never done anything like this so recommend something easy please.

Hi Cheryl!

Yes, Of course, Danish oil works perfectly for any indoor woodworking project, including dining room tables.

Thanks for all of the info on Danish oil.