Ever wondered how much weight your wooden table can bear without causing damage? Let’s explore this intriguing topic together, shall we?

Are you curious how much weight can your newly bought or custom-made wood table can hold?

Well, you are not alone. I have faced the same problem when first I built my computer table.

After quite a lot of research on how much weight can hold for each and every wood table type, like computer table, coffee table, dining table, lack table, etc.

And here is what I found.

How much weight can a wood table hold?

A wood table’s weight capacity varies based on its type, design, and the wood used. For instance, a typical coffee table can hold up to 300 lbs (136 kg), a dining table around 330 lbs (150 kg), and a workbench up to 440 lbs (200 kg). However, weight should be evenly distributed.

But that’s just the tip of the iceberg!

So, from this article, I’ll explore all the information you need to know before determining how much weight can your wood table hold.

Furthermore, I’ll answer some frequently asked questions as well.

Let’s jump in!

Maximum Load Capacities of Wood Tables

Computer tables, coffee tables, dining tables, lack tables, and many more other types of tables we use in our households or industries.

So, the maximum load capacity of a wood table varies according to the type of the table.

| Table Type | Maximum Weight Capacity |

| Coffee table | 300 lbs (136 kg) |

| Computer table | 150 lbs (68 kg) |

| Folding kitchen/Dining table | 440 lbs (200 kg) |

| Workbench | 440 lbs (200 kg) |

| Dining table | 330 lbs (150 kg) |

| Dining bench | 550 lbs (250 kg) |

The maximum weights displayed above are average values.

But when you face the question of how much weight can a wood table hold, you have to consider many more factors before determining load capacity.

The conclusions that I got from my research are mentioned below.

Factors that Affect the Maximum Weight of Wood Table

Before you go for custom-made or buy, you need to consider about following factors that affect the maximum loading capacity of the table.

Here’re the factors that affect the maximum loading weight of a wood table,

- Stiffness of the table material

- Maximum Bending strength

- Maximum compressive strength

Let’s discuss them in detail.

1. Stiffness of the Table Material

Stiffness means how much wood deflects when the load is applied to the table perpendicularly.

To know the stiffness of the table material, you don’t need to have a wide knowledge of equations or engineering techniques.

You just need to know Higher stiffness means Higher load capacity. For your ease, I have researched and listed the stiff value of popular wood types we use in making tables.

From that, you can simply determine, how much weight your wood table can hold.

| Table material | Stiffness (Maximum load) / Mpsi |

| Hickory | 2.16 |

| Maple, Hard | 1.83 |

| Maple, Soft | 1.64 |

| Walnut | 1.68 |

| Oak, Red | 1.82 |

| Oak, White | 1.78 |

| Mahogany | 1.40 |

| Birch | 2.01 |

| Fir, Douglas | 1.95 |

| Cherry | 1.49 |

| Cedar | 1.11 |

| Pine | 1.19 |

| Redwood | 1.10 |

*Mpsi = Mega pounds per square inch of the table

From these results, you can select what type of wood should use to make the table. If you’re going to apply to weigh perpendicularly to the table, stiffness is important.

2. Maximum Bending Strength

Maximum bending strength means the amount of weight your table can hold when the load is applied perpendicular to the grain without breaking.

The maximum weight a horizontal beam of the table hold depends on how the weight is applied, span, the build wood type, support of the ends, and cross-sectional area.

The maximum bending strength also varies according to the table material.

Higher bending strength means a Higher load capacity.

Here is the information that I have gathered.

| Table material | Strength (Maximum load) / psi |

| Hickory | 20200 |

| Maple, Hard | 15800 |

| Maple, Soft | 13400 |

| Walnut | 14600 |

| Oak, Red | 14300 |

| Oak, White | 15200 |

| Mahogany | 10700 |

| Birch | 16600 |

| Fir, Douglas | 12400 |

| Cherry | 12300 |

| Cedar | 7500 |

| Pine | 8200 |

| Redwood | 7900 |

*psi = Pounds per square inch of the table

3. Maximum Compressive Strength

The maximum compressive strength depends on the strength of the table legs.

From maximum compressive strength, we can determine how much weight can apply parallel to the grain without breaking.

How many loads can the legs of a table hold before they break. When measuring this value the weight is applied along the axis of the legs through the center.

However, Higher compressive strength means a High amount of load capacity can hold by its wooden legs, which is very important when making legs for a wood table. Here is what I found for legs with the same cross-sectional area.

| Table material | Strength (Maximum load) / psi |

| Hickory | 9210 |

| Maple, Hard | 7830 |

| Maple, Soft | 6540 |

| Walnut | 7580 |

| Oak, Red | 6760 |

| Oak, White | 7440 |

| Mahogany | 6460 |

| Birch | 8170 |

| Fir, Douglas | 7230 |

| Cherry | 7110 |

| Cedar | 4560 |

| Pine | 4460 |

| Redwood | 5220 |

*psi = Pounds per square inch of the table

I know you’re curious about finding out how much weight your wooden table can hold.

Don’t worry! I’ll teach you to calculate it by yourself like a pro!

How to Calculate How Much Weight a Table Can Hold

Understanding how much weight a table can hold is crucial for safety and durability.

To make an accurate calculation, you’ll need to take into account several important factors such as the type of wood used, its stiffness, bending strength, and compressive strength.

Let’s break down each of these factors and how they contribute to the weight-bearing capacity of your table.

1. Understanding the Type of Wood

The type of wood used in the construction of the table plays a significant role in how much weight it can bear.

For instance, hardwoods like hickory, birch, or hard maple, are generally stronger and more durable than softwoods like pine or cedar.

The article you provided shared some insightful data on various wood types and their stiffness, bending, and compressive strength.

Based on that information, hickory seems to be the sturdiest with the highest values in all three categories.

2. Analyzing the Stiffness of the Wood

Stiffness, or rigidity, refers to the ability of the wood to resist deformation or bending when heavy weight is applied.

The higher the stiffness, the greater the weight the table can hold without bending or sagging.

For example, a table made of hickory, which has a stiffness of 2.16 Mpsi can withstand a greater load compared to a table made of cherry, with a stiffness of 1.49 Mpsi.

3. Evaluating Bending Strength

Bending strength is another critical factor. It refers to the maximum amount of bending or deflection the table can withstand without breaking or collapsing.

Like stiffness, the higher the bending strength, the more weight the table can hold.

To illustrate, let’s look at two types of wood: birch and pine.

Birch, with a bending strength of 16,600 psi, can support more weight than pine, which has a bending strength of just 8,200 psi.

4. Compressive Strength Matters Too

Compressive strength refers to the ability of the table, particularly the table legs, to handle a heavy load without breaking or collapsing.

High compressive strength equals greater load capacity.

So, a table made from walnut (compressive strength of 7580 psi) will be able to bear more weight than one made from cedar (compressive strength of 4560 psi).

While these factors and values provide a solid starting point, remember that other factors can also influence a table’s weight capacity, like design, construction quality, and maintenance.

Additionally, calculating the exact weight-bearing capacity of a table can be complex and might require professional expertise.

If you find that your table can’t hold the weight you need it to, don’t worry. There are ways to increase its weight capacity.

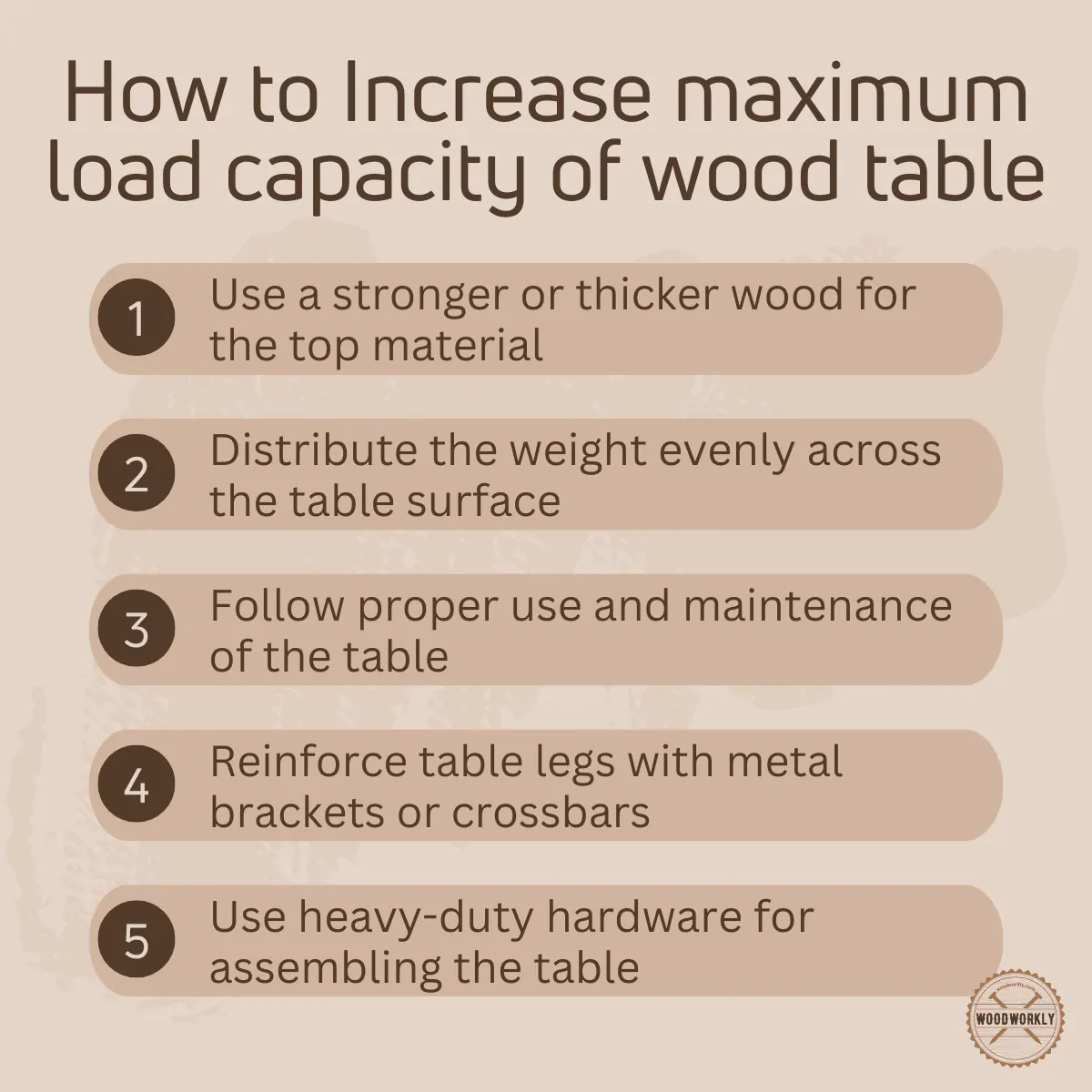

How To Increase The Maximum Load Capacity of Wood table?

Are you afraid of the loading capacity of your wood table, because the weight of your instruments is higher than the loading capacity of a wood table according to the website?

Well, this is a situation that you have to conclude by brainstorming.

Same when you custom-make a wood table with not much considering its maximum load and finally you found the maximum load of its wood material is lesser than your required value.

After years of working with wood, I have a very clear idea about those numerical values of maximum weight.

There is a 90% chance the table that you bought/ custom-made wood table will hold at least twice the maximum load capacity.

But it is important to increase the maximum load capacity of the wood table because at some point overloading can damage the table very soon.

To increase the maximum weight a wood table can hold, you have to mainly focus on its top material.

Because that can be the weak point of the table. Applying a huge amount of load over the middle of the table could overload/overstress the top and it can cause to break the table.

The simplest way to fix the top layer is by putting more weight directly over the legs without centering the weight to one specific area. Spread the weight all over the table evenly.

But if you really need to increase the strength of the center of the top layer without spreading the weight.

How can I make my table hold more weight?

You can affix ribbing from top to bottom of the table to spread the weight evenly.

But this cannot be done if there is not enough material on top of the layer to attach to or when it’s a very thin wood material.

If your wood top layer is very thin, it can show some lateral movement with the applied weight.

With the application of lateral force in different directions, the fasteners/joints which hold the legs tightly will fail and the table can be completely useless. This happens especially because the table is made out of wood.

To prevent lateral movements with load, you can attach one side of the table to a wall as a support.

This will be your best bet because the maximum loading capacity definitely will be increased.

How To Reinforce A Table To Hold More Weight?

We all have that one table in our house – the one that we love but that wobbles just a little bit too much or bows under the weight of a large Thanksgiving turkey.

If you’re in this situation, don’t fret!

Here’re the steps you need to take to reinforce a table to hold more weight,

- Strengthening the tabletop

- Reinforce table legs

- Adding additional support

- Proper usage and maintenance

Let’s discuss them in detail to reinforce your table as you wish without letting it break due to the load.

1. Strengthening the Tabletop

The first point of attention should be your tabletop. If it’s too thin or made from a softer wood, it might not withstand heavy loads. Here are a couple of ideas on how to reinforce it:

Use a Thicker or Stronger Wood

You can replace your existing tabletop with a thicker one or use a stronger wood type. Hardwoods like hickory or birch have higher stiffness and bending strength than softwoods and can handle a greater load.

Add More Layers

If you can’t replace the tabletop or don’t have a stronger type of wood at hand, you can add more layers to the existing top. This could be additional layers of the same wood, or a layer of plywood underneath for extra support.

2. Reinforcing the Table Legs

Your table legs play a critical role in supporting the weight of the table. They need to be sturdy and well-attached. Here’s how you can reinforce them:

Attach Metal Brackets or Braces

Metal brackets or L-shaped corner braces can be attached to the legs to provide additional support. Choose heavy-duty brackets and screws to ensure maximum stability.

Use Stronger Wood for the Legs

If you have the resources and skills, consider replacing your table legs with ones made of a stronger wood type. The compressive strength of the wood used for the legs significantly affects the overall load capacity of the table.

3. Adding Additional Support

Sometimes, merely reinforcing the top and legs might not be enough. You might need to add extra support to the structure.

Install Support Beams or Crossbars

Support beams or crossbars between the legs can help distribute the weight more evenly and increase the table’s load-bearing capacity. For example, adding a beam across the center of the table, connecting opposite legs, can add a lot of support.

Attach a Ribbing

Attaching a ribbing vertically along the entire length of the table can also help distribute the weight evenly. This can be a bit more complex to do, but it’s a great solution, especially for longer tables that tend to sag in the middle.

4. Proper Usage and Maintenance

Last but not least, the way you use and maintain your table can impact its weight-bearing capacity. Try to distribute the weight evenly across the table surface and avoid placing very heavy items in the middle of the table where it’s most likely to sag. Regularly check for any signs of damage and repair them promptly to preserve the table’s structural integrity.

While these tips can help you reinforce your table to hold more weight, please remember that every table has its limits.

Overloading a table beyond its capacity, even after reinforcement, can result in damage and potential injury.

If you’re unsure, it’s always best to consult with a professional.

That’s it, folks! Now you know everything you wanted to know about how much weight can a wood table hold.

Let’s see some related questions you might get when working on increasing the load capacities of your wood tables.

What wood can hold the most weight?

Hickory holds the most weight due to its high bending strength (20,200 psi) and compressive strength (9,210 psi), making it the top choice for heavy-duty tables.

Honestly, this is one of the best materials that can hold a very large amount of weight with excellent support.

How thick should coffee table legs be?

Around ¾” thick and 4″ wide. You can get better strength if thicken it more.

How should I make a table base?

I highly recommend using T-style table bases, because they can provide excellent support over the huge surface to hold a large amount of weight.

How much weight can a pedestal table hold?

A pedestal table can hold weights up to 200 lbs. This can vary on the wood type used to make the pedestal table and the weight of the legs.

So, let’s answer some frequently asked questions as well.

FAQs

How much weight can a typical dining table hold?

A standard dining table is typically designed to safely support approximately 330 lbs or 150 kg. However, it’s important to remember that weight should be evenly distributed and not concentrated in one spot.

Does the type of wood affect how much weight a table can hold?

Yes, The type of wood greatly impacts a table’s weight capacity. For instance, hickory, known for its high stiffness and compressive strength, can bear more weight than softer woods like pine or cedar.

How can I increase the weight capacity of my table?

You can reinforce your table by using stronger or thicker wood for the top, attaching metal brackets to the legs, or adding support beams or crossbars. Also, proper usage and regular maintenance can help maintain its load-bearing capacity.

How much weight can a coffee table hold?

A coffee table can generally hold up to 300 lbs or 136 kg. However, it’s essential to evenly distribute the weight across the table surface to avoid causing any damage.

How can I calculate the weight-bearing capacity of my wood table?

Calculating the weight-bearing capacity of a wood table involves considering the wood type’s stiffness, bending strength, and compressive strength, as well as the table’s design and usage.

Can I make my table legs thicker to increase its weight capacity?

Yes, making your table legs thicker can enhance their ability to bear heavier loads, but remember that the type of wood used also plays a significant role in determining the legs’ strength.

Can I place heavy objects directly on my wooden table?

It’s advisable to avoid placing extremely heavy objects directly on your wooden table. If needed, distribute the weight evenly and ensure it doesn’t exceed the table’s weight limit to prevent damage.

What happens if I overload my wood table?

Overloading your wood table can lead to structural damage like warping, bending, or even collapsing, which could potentially cause injuries. It’s always best to adhere to the table’s weight capacity.

Can a workbench hold more weight than a dining table?

Generally, a workbench is designed to hold more weight than a dining table. Typically, a workbench can safely support around 440 lbs or 200 kg due to its robust design and materials used.

Did I cover all you wanted to know about: How Much Weight Can A Wood Table Hold

In this article, I’ve deeply discussed, How much weight can a wood table hold with in-depth information about all types of wood tables.

All the facts we discussed were gathered from experts in the field.

The weight a wood table can hold depends on factors like wood type, construction, and design. On average, a coffee table can bear 300 lbs, a dining table 330 lbs, and a workbench 440 lbs. However, proper weight distribution is crucial to avoid damage.

Furthermore, I’ve answered some frequently asked questions as well.

Hope you gathered good information about the weight capacities of all popular wood table types including, dining tables, coffee tables, computer tables and many more.

Use fresh, quality hardwoods for wood tables to gain maximum weight capacity.