Wondering how to extend the life of your pressure-treated wood buried underground? Unearth the secrets to battling moisture and decay, ensuring your wood’s longevity!

Did you know that pressure-treated wood changes when it goes underground? Even though pressure-treated wood doesn’t get eaten by bugs or rot quickly, we still have to take extra care of it when it’s below the ground.

The underground world is a whole different place, and we need to make sure the wood is ready for it!

Think about it like this: if you’re building something outside like a deck, fence, or wall, there is a part of the wood that goes underground to hold everything up.

That underground wood is super important because it keeps everything steady and strong. If it’s not protected, the whole thing can become weak.

I’ve learned a lot about this by talking to experts who know all about wood and how to keep it safe and strong. I want to share those secrets with you!

We have to follow some special steps to make sure the underground wood stays as strong as possible. Are you ready to learn how? I’m excited to share it with you!

So, let’s find out, How to protect pressure-treated wood underground?

To protect pressure treated wood underground, allow it to dry, then apply an all-weather wood sealer. Enhance protection by encasing the wood in concrete, surrounding it with gravel, or wrapping it in plastic to minimize soil and moisture contact, prolonging the wood’s lifespan and integrity.

But there’s a lot more to know!

In fact, you may not know that there are many effective ways to protect pressure-treated wood underground.

In this guide, I hope to explore effective ways to protect pressure-treated wood in underground applications.

Additionally, from understanding the basics of pressure treatment to uncovering the causes of underground wood rot, I’ll give you practical advice, and detailed methods.

Let’s dig in!

Can You Put Pressure-Treated Wood in the Ground?

Yes, pressure-treated wood is designed to withstand exposure to the elements, including soil and moisture.

Did you know that a pressure treatment process increases the durability of wood and makes it suitable for floor contact?

A pressure treatment process involves impregnating the wood with a preservative, usually copper-based, to protect it from decay, insects, and other environmental factors.

It is common to use pressure-treated lumber for underground applications in a variety of outdoor construction projects such as decks, fences, and retaining walls.

However, it is essential to use the right type of pressure-treated wood for specific applications.

There are different levels of treatment, and not all are suitable for direct contact with the floor.

It is important to note that while pressure-treated wood is resistant to decay, it is not completely resistant to weathering.

Regular maintenance and adherence to best practices for installation can significantly extend the life of pressure-treated lumber used in floor contact applications.

Why Do Pressure-Treated Wood Rot Underground?

Pressure-treated wood is generally designed to resist rot and decay, but it can still degrade when used underground due to inadequate treatment levels, moisture accumulation, direct soil contact, biological activities, natural wear and tear, and incomplete coverage.

In my research, I discovered several reasons why pressure-treated wood rots underground.

Here are the reasons why pressure-treated wood rots underground that I have discovered,

1. Inadequate Treatment Levels

Not all pressure-treated wood is created equal. There are different levels of treatment, some of which are not sufficient for long-term contact with soil.

Keep in mind that if wood with a lower level of treatment is used, it may not provide adequate protection against decay.

2. Direct Soil Contact

While pressure-treated wood is treated to resist decay, long-term direct contact with soil can still be a challenge.

In general, soil moisture can trap wood, creating favorable conditions for decay.

Remember that elevating the wood slightly or using proper supports will help minimize direct contact with the soil.

3. Moisture Accumulation

Did you know that even pressure-treated wood can deteriorate if exposed to excessive moisture?

When buried underground, wood can come into contact with water, especially if the surrounding soil has poor drainage.

Then, prolonged exposure to moisture can impair the performance of the preservatives.

4. Biological Activities

In certain environments, the presence of specific microorganisms or fungi in the soil can suppress the resistance of wood to decay.

Some regions have soil conditions more favorable to biological activity that can accelerate wood decay.

5. Natural Wear and Tear

Over time, natural wear and tear can compromise the structural integrity of pressure-treated wood.

Keep in mind that this can be exacerbated by factors such as freeze-thaw cycles, soil movement, or other environmental stresses.

6. Incomplete Coverage

If the pressure treatment process does not sufficiently penetrate all parts of the wood, areas that are not adequately treated are likely to rot.

This is likely to occur at cutting edges or drill holes where the cure has not fully reached.

In addition, it is essential to follow the manufacturer’s guidelines for installation and maintenance to maximize the durability of pressure-treated wood in underground applications.

Methods to Protect Pressure-Treated Wood Underground

Did you know that pressure-treated wood is designed to withstand environmental challenges?

When using pressure-treated wood in underground applications it is important to implement safety measures to ensure its longevity and resistance to decay.

There are simple and effective ways to protect pressurized wood when used underground.

Here are some ways you can protect pressure-treated wood underground,

1. Select Specially Labeled Pressure-Treated Wood

If you want to touch the floor it is very important to choose specially labeled pressure-treated wood.

These types of wood undergo a high level of preservative treatment and are more resistant to decay when in direct contact with the soil.

2. Raise the Pressure-Treated Wood to the Floor Surface

Whenever possible, lift the pressure-treated wood above the floor surface. This minimizes direct contact with the soil and reduces the risk of moisture absorption and decay.

Concrete blocks, gravel or other suitable supports can be used to achieve this elevation.

3. Improve Drainage

Ensure proper drainage around the timber installation site. Poor drainage can cause water to accumulate, exposing wood to prolonged moisture.

Grading the soil away from wood or using materials such as gravel can facilitate efficient drainage.

4. Seal Cutting Edge

Apply a high-quality wood sealant to any cut edges or drilled holes in pressure-treated wood.

These areas are more vulnerable to moisture penetration and sealing them provides additional protection against decay.

5. Regular Maintenance

Conduct regular inspections of pressure-treated lumber to detect signs of wear, damage, or decay.

Address problems such as cracks or splits quickly and apply appropriate treatments or sealants as needed.

Implementing these simple methods will not only protect stressed timber from decay but also contribute to the overall stability and durability of structures or installations placed underground.

By combining proper wood selection with preventative measures, the resistance of pressure-treated wood to challenges presented by soil and environmental factors can be improved.

How to Protect Pressure-Treated Wood Underground?

It is a very simple step to be aware of how to protect pressure-treated wood underground.

Preserving pressure-treated wood when used underground involves a series of strategic steps to ensure its longevity and resistance to decay.

Follow these detailed instructions to effectively protect pressure-treated wood in such environments.

I have listed for you a few steps on how to protect pressure-treated wood underground.

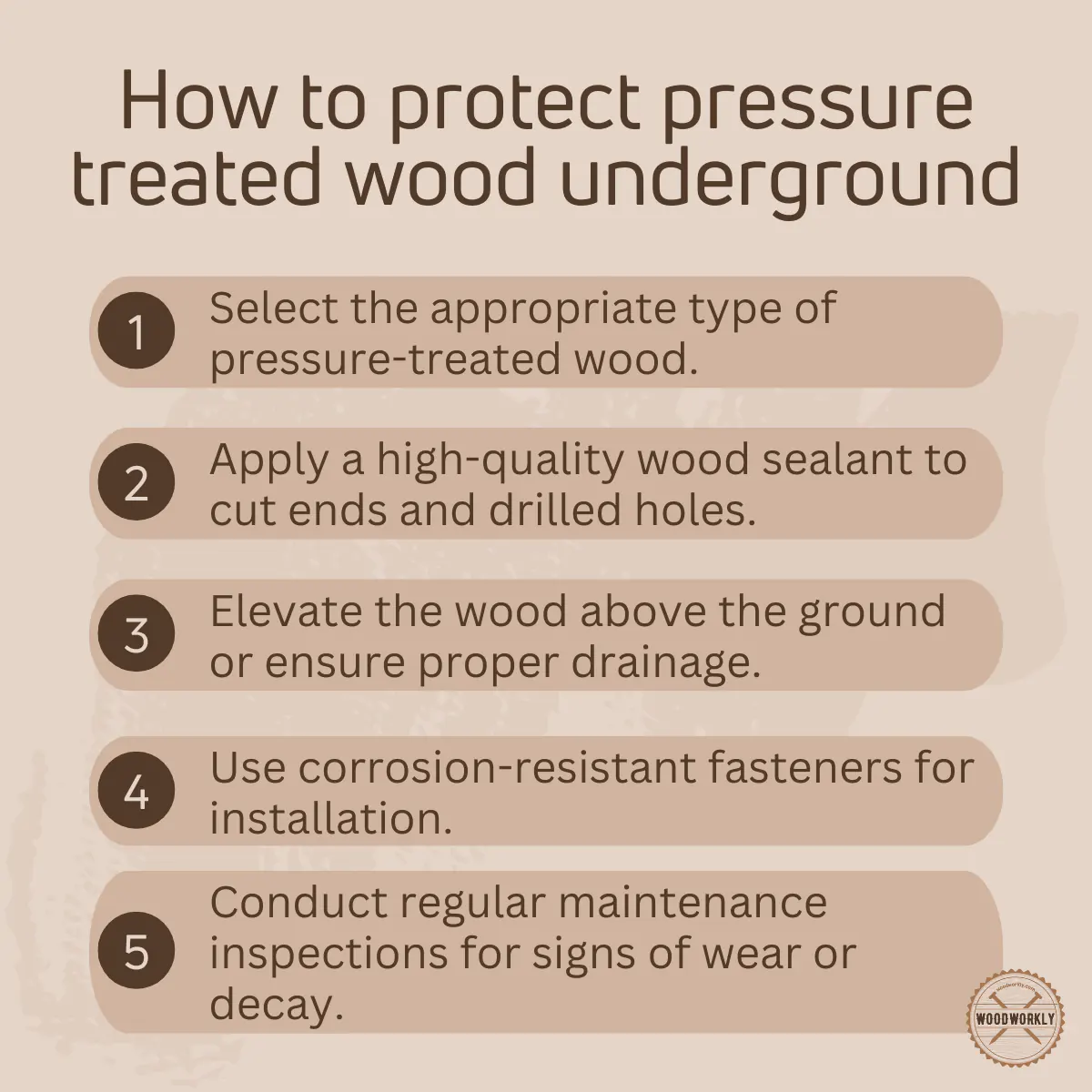

- Choose the Right Type of Pressure-Treated Wood

- Elevate the Wood Above the Ground

- Ensure Proper Drainage

- Apply Sealant to Cut Ends and Drilled Holes

- Use Corrosion Resistant Fasteners

- Install Safety Barriers

- Regular Maintenance Inspections

- Avoid Direct Soil Contact in High-Risk Areas

- Monitor Vegetation Around the Wood

- Follow Manufacturer Guidelines

Let us now talk about these steps in detail.

1. Choose the Right Type of Pressure-Treated Wood

Opt for pressure-treated wood specifically designed to touch the ground first.

This type of wood has a high level of preservatives and has been able to provide greater protection against decay and insects.

2. Elevate the Wood above Ground

To minimize direct contact with the soil here, raise the pressure-loaded lumber above the floor surface.

This can be achieved using concrete blocks, treated wood supports or other suitable materials.

3. Ensure Proper Drainage

In this step, an implementation is carried out to promote proper drainage around the wood.

You can use well-draining soil to prevent water pooling and consider adding gravel or crushed stone under and around the wood.

4. Apply Sealant to Cut Ends and Drilled Holes

Before installation, apply a high-quality wood sealant to all cut edges and drill holes. This will help you create a protective barrier.

It also prevents water seepage into vulnerable areas and helps to reduce the wood’s resistance to decay.

5. Use Corrosion Resistant Fasteners

In this step, I advise you to choose fasteners made of corrosion-resistant materials such as galvanized or stainless steel.

This prevents the fasteners from corroding over time, maintaining their structural integrity and not compromising the wood.

6. Install Safety Barriers

Here I advise you to integrate protective barriers such as plastic or rubber sheeting between the stressed wood and the surrounding soil.

These barriers act as an additional protective layer against direct soil contact.

7. Regular Maintenance Inspections

Here, establish a regular maintenance schedule to check the pressure-treated wood for signs of wear damage or decay.

Fix problems quickly by replacing damaged parts or applying additional sealant as needed.

8. Avoid Direct Soil Contact in High-Risk Areas

Consider avoiding direct ground contact altogether during this step, especially in areas with aggressive soil conditions.

Use alternative construction methods such as concrete footings or piers to elevate the timber and protect it from adverse soil effects.

9. Monitor Vegetation Around the Wood

Keep the area around the stressed wood free of debris and vegetation.

Don’t forget that plants and organic matter can hold moisture against wood and contribute to decay over time.

10. Follow Manufacturer Guidelines

Finally, follow the manufacturer’s guidelines for installation and maintenance.

These guidelines provide specific recommendations based on the type of pressure-treated wood used to ensure optimal performance and durability.

Keep in mind that by following these steps correctly, you can create a comprehensive strategy for protecting pressure-treated wood when used underground.

This approach addresses the various factors that can contribute to decay and ensures that the wood is durable and resilient in challenging soil environments.

How Long Does Pressure-Treated Wood Last Underground without Any Treatment

You already know that pressure-treated wood is a popular choice for outdoor projects due to its resistance to rot and insects.

When used underground without any additional treatment, the lifespan of pressure-treated wood can vary depending on factors such as environmental conditions, type of wood and specific preservatives used in the treatment.

In general, pressure-treated wood is designed to resist decay and deterioration, but it is not affected by moisture and soil.

Without additional treatment or protection, pressure-treated lumber can remain underground for 20 to 25 years or more under favorable conditions.

However, factors such as high moisture levels, poor drainage and aggressive soil conditions can accelerate the deterioration process.

In harsh environments, the life of untreated pressure-treated lumber can be shortened.

Read to know, Stop Pressure Treated Wood Rot! (EASY Guide!)

To maximize the longevity of pressure-treated wood underground, it’s recommended to follow best practices, such as using wood specifically designed for ground contact, elevating the wood above the ground when possible, ensuring proper drainage, and conducting regular inspections for signs of wear or decay.

Read to know, Best Methods to Protect Outdoor Wood Furniture

Additionally, applying sealant to cut ends and drilled holes and using corrosion-resistant fasteners can further enhance the wood’s durability.

How Long Does Pressure-Treated Wood Last Underground After Treating

You already know that pressure-treated wood is treated with preservatives to increase its resistance to decay, insects, and other environmental factors.

When used underground and properly treated, the life of pressure lumber can be significantly extended. Typically, treated wood can last 40 to 75 years or more in underground applications.

The durability of pressure-treated wood after treatment depends on various factors such as the type of wood, the specific preservatives used, soil conditions and local climate.

In general, pressure-treated wood is more durable and resilient compared to untreated wood, making it suitable for long-term use in contact with the floor.

To maximize the effectiveness of the treatment and extend the life of pressure-treated wood, it is important to follow best practices.

This includes using specially designed pressure-treated wood for ground contact, ensuring proper installation with good drainage, and regular inspections for wear or decay.

The wood’s resistance to moisture and decay can be further improved by applying additional protection measures, such as using a high-quality wood preservative or sealant.

Regular maintenance, such as recoating the wood with preservatives as needed, contributes to the sustained durability of pressure-treated wood in underground applications.

Tips for Protecting Pressure-Treated Wood Underground

Here are some tips I use to protect underground pressure-treated wood.

- Always opt for pressure-treated wood that is specially designed to touch the floor. This type of wood has a high level of preservatives and offers greater protection against decay and insects.

- Don’t forget to minimize direct contact with the soil by always elevating pressure-treated above the ground. To achieve this, concrete blocks, treated wood supports or similar materials can be used.

- Promote good drainage around the wood by using well-draining soil and incorporating materials such as gravel. This will prevent water accumulation and reduce the risk of decay.

- Before installation, apply a high-quality wood sealant to the ends and holes. This creates a protective barrier, preventing water from seeping into vulnerable areas.

- Choose fasteners made of corrosion-resistant materials such as galvanized or stainless steel. This prevents fastener corrosion while maintaining structural integrity.

- Combine plastic or rubber membranes between the pressure-treated wood and the soil. These barriers act as an additional protective layer against direct soil contact.

- Make it a habit to always inspect the wood for signs of rot, wear, damage or decay . Address any problems immediately to prevent deterioration over time.

- In areas with aggressive soil conditions, don’t forget to consider alternatives such as concrete footings to minimize direct ground contact.

- Keep the area around pressurized wood free of debris and vegetation that can trap moisture and contribute to rot.

- Follow the manufacturer’s recommendations for installation and maintenance to ensure optimal performance and durability.

By incorporating these tips I’ve mentioned, you can create a comprehensive strategy for protecting pressure-treated wood when used underground.

These measures help to minimize the impact of environmental factors and ensure that the wood is durable and resilient over a long period of time.

That’s it folks! Now you know how to protect pressure treated wood underground effectively using the right methods!

So, let’s answer some frequently asked questions.

FAQs

Can pressure-treated wood be directly buried underground?

Yes, pressure-treated wood can be buried underground, but additional protection such as sealing or encasing in concrete enhances its durability and longevity, preventing moisture damage.

Does pressure-treated wood need additional sealing if placed underground?

Yes, applying an all-weather wood sealer to pressure-treated wood before placing it underground helps prevent moisture damage, extending the wood’s lifespan.

How long does pressure-treated wood last underground without additional treatment?

Without additional treatment, pressure-treated wood can last 7-10 years underground, but factors like moisture and soil conditions can affect its lifespan.

Is it necessary to let pressure-treated wood dry before sealing it?

Yes, it’s essential to let pressure-treated wood dry thoroughly before applying sealer to ensure effective protection and prevent the sealer from peeling off.

Can concrete or gravel be used to protect pressure-treated wood underground?

Yes, encasing pressure-treated wood in concrete or surrounding it with gravel can effectively reduce direct soil contact and moisture absorption, enhancing its durability.

What type of sealer is best for protecting pressure-treated wood underground?

Ready Seal 520 Exterior Stain and Sealer is a recommended option, known for its ease of application and effectiveness in protecting both above and underground wood.

How do I apply a sealer to pressure-treated wood intended for underground use?

Clean the wood surface, let it dry, and then apply the sealer with a paintbrush or sprayer, ensuring all parts, including cut ends and drilled holes, are covered.

What types of wood are naturally resistant to moisture and suitable for underground use?

Black Locust, White Cedar, Cypress, and Redwood are naturally moisture-resistant and can be suitable options for underground applications, especially in moist environments.

Are there specific chemicals used in treating wood for underground use?

Yes, chemicals like Chromated Copper Arsenate (CCA) and Alkaline Copper Quaternary (ACQ) are commonly used to enhance wood’s resistance to decay and insect damage.

Is it safe to use pressure-treated wood for vegetable gardens or other areas in contact with food?

Avoid using pressure-treated wood in areas that come into contact with food, as the chemicals used in the treatment process can potentially leach into the soil and plants.

Didi I cover all you wanted to know about: How To Protect Pressure Treated Wood Underground

In this article, I’ve deeply discussed how to protect pressure treated wood underground using different methods in detail.

To safeguard pressure-treated wood underground, elevate it above the ground, promote proper drainage, and choose wood labeled for ground contact. Apply a wood sealant to cut ends, use corrosion-resistant fasteners, and conduct regular inspections for signs of wear or decay.

Furthermore, I’ve answered some frequently asked questions.

Hope you’ve learned everything you wanted to know about how to protect pressure treated wood underground including experts’ tips and techniques.

Now it’s time for you to select the method that suits you the most and protect your pressure-treated wood furniture before placing it underground to increase its lifespan! Happy wood finishing!