Struggling with sawdust in your workspace? Ever wondered what type of pipe is best for your dust collection system? Let’s delve into the world of dust collection pipes and make your woodworking journey a breeze!

In the realm of woodworking, producing sawdust is inevitable. Without an efficient dust collection setup, it can seem as though you’re spending more time cleaning than actually working on projects.

When I was first setting up a dust collection system, I wondered, ‘What kind of pipe should I use for dust collection?’

After conducting some research with the help of other woodworking experts, I was able to grab and fit the best dust collection system as per my requirements.

Now with years of experience, here’s what I know about, What kind of pipe to use for dust collection?

Polyvinyl Chloride (PVC) and metal pipes are the best pipes for dust collection. PVC pipes are affordable, lightweight, and easy to connect, while metal pipes, such as aluminum, copper, or steel, are durable and rigid. Both types have pros and cons that should be considered based on the specific setup.

But there’s more to know.

In this article, I’ll explore what kind of pipe to use for dust collection and how to build a dust collection system.

Furthermore, I’ll discuss how to hang the dust collector pipe and the DIY method of the dust collection system.

I’ll answer some frequently asked questions as well.

Let’s get started.

Types Of Dust Collection Pipes with Qualities

There are mainly two types of pipe that can use for dust collection.

- PVC dust collection pipe

- Metal dust collection pipe

Both PVC and metal pipes have their own qualities, advantages, and disadvantages.

By using a branched pipeline system, you’ll be able to collect sawdust generated in different areas.

Especially when your shop has multiple saws, they could each have their own pipeline-like branches.

The pipe size is also a factor you should consider when selecting a type of pipe for dust collection.

A bigger pipe size is needed for saws that create a high amount of sawdust without any loss in suction.

You need to get the most suitable pipe size for your dust collection according to the sawdust amount.

Because when the pipe size is getting bigger and bigger it’ll eventually slow down the power of the central system.

Therefore, always make sure not to go for the biggest pipe size but the most suitable one which balances suction power and power of the central system.

So, let’s discuss the qualities and properties of different kinds of pipes that differ according to their building material.

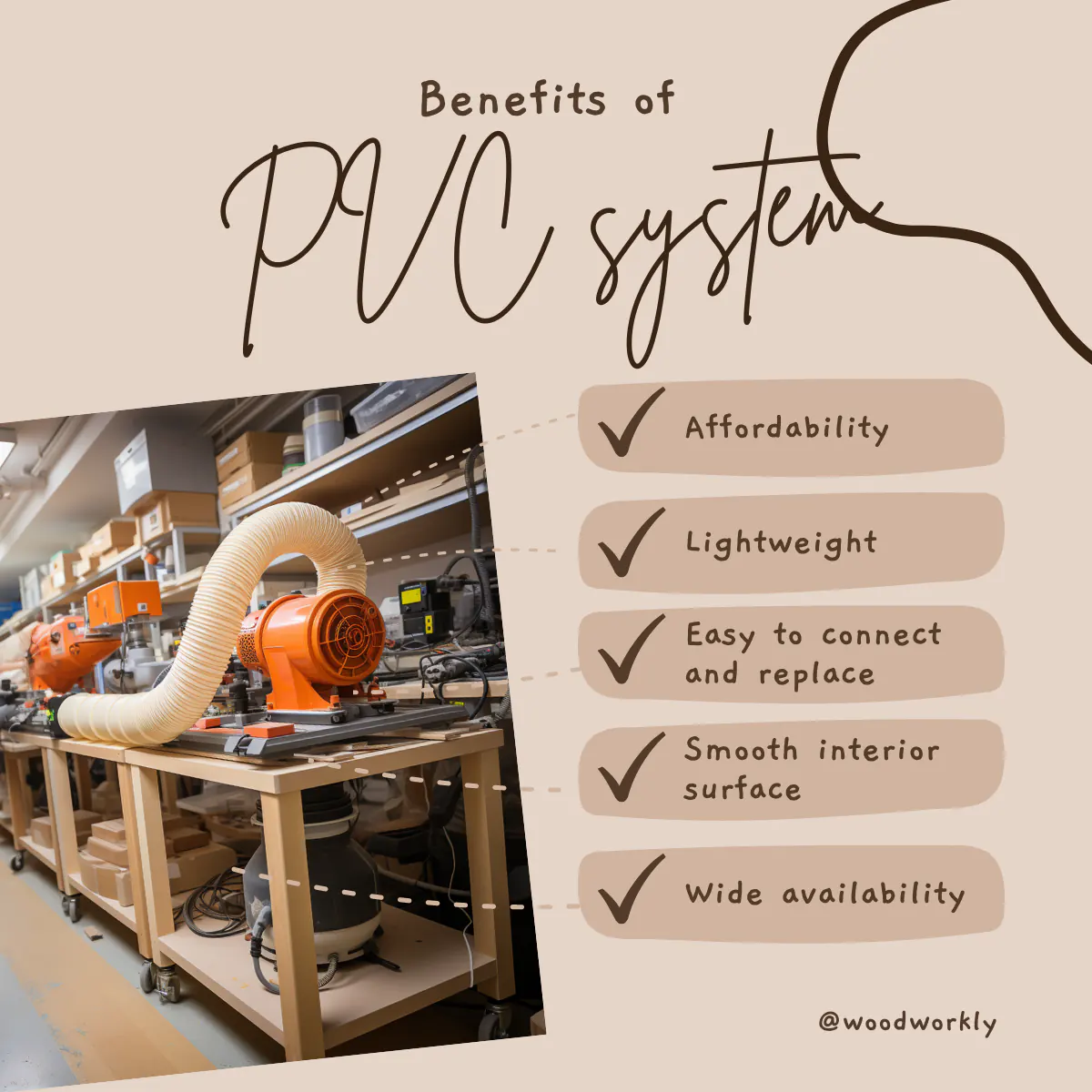

PVC Dust Collection Pipes

PVC is the most common pipe type for dust collection. It is lightweight, easy to use, and most importantly it is cost-effective.

Two types of PVC pipes can use for dust collection pipes. They are,

- 4” PVC pipe

- 6” PVC pipe

The above pipe types differ in pipe size and you have to select one according to the type of job. Be sure to go with the thinnest pipe which is known as “Sewer and Drain”.

Because when the PVC pipe you’re getting is thinner and lighter, easier to work with.

If your, woodworking area creates a relatively low amount of sawdust, better to go with 4” PVC because it doesn’t reduce the power of the central system as 6” PVC pipe does due to the pipe size difference.

But on the other hand, 4” PVC pipe cuts the airflow than 6” PVC pipe.

But if the generating saw dust amount is high, better to stick with a 6” PVC pipe for an effective dust collection process with maximum airflow.

Make sure not to go below 4” pipe sizes, because they will significantly cut off the airflow and reduce the suction power of the dust collection system.

Plus, never use Schedule 40 – Schedule 80 PVC pipes because they are heavy and expensive. When the PVC pipes are heavy, they’re difficult to handle and excess mass is wasted.

They’ll significantly lower the power of the central system due to the extra weight they have. Schedule 40 – Schedule 80 PVC creates low pressure on PVC that reduces the suction power of the dust collection system.

So, I highly advise you to stay away from using Schedule 40 – Schedule 80 PVC for the dust collection system.

Static Discharges of PVC Pipes

PVC is made of plastic. Therefore, static discharge will occur and cause problems.

Even though PVC pipes are grounded, but still problems will occur.

PVC is an insulator and static discharges don’t travel across the pipe so easily.

Only the surfaces of the pipe that are in directly contacted with the wire will be grounded and still buildup static discharges.

If you want to ground the entire PVC pipe system effectively, better to cover the entire PVC pipe system with conductive coating and ground the pipe inside components at the end of the pipe.

You need to focus more on effectively grounding the PVC pipe system. Wood dust is highly combustible, and improperly grounded PVC pipe can act as a source of ignition because of its static buildup.

Moving air causes a significant amount of static electricity.

Pros and Cons of PVC Dust Collection Pipes

Here’re the advantages and disadvantages you’ll get by using PVC as dust collection pipes.

| Pros | Cons |

| Lightweight | Small bending corners reduce the suction power |

| Inexpensive | Buildup static electricity |

| Easy to glue up or tape together | High risk of explosion |

| Easy to change | Plastic tee fittings aren’t suitable for dust removal |

| Smooth interior surface helps maintain airflow. | Plastic pipe elbows are short, which can lead to clogs |

| Extra work is required for grounding. |

Metal Dust Collection Pipes

Metal dust collection pipes are popular in professional woodworking spaces.

Even though metal dust collection pipes are expensive, they won’t develop static discharge as PVC dust collection pipes do.

Corners, elbows, and other fittings are well-designed to increase the suction power by providing space for proper airflow.

Wood dust is explosive with static discharge. So, with metal, there will be zero explosions because metal is not a source of ignition.

Solid metal pipes are expensive but totally worth the money you spend because they are easy to route and install due to their flexibility.

Make sure to provide 4,500 feet per minute velocity in the dust collection system to get sufficient suction power and minimize dust explosion.

Metal dust collection pipes come in various sizes.

If your, woodworking projects create a low amount of sawdust, 4” metal pipes will do the job. Because it doesn’t reduce the power of the central system as 6” metal pipes do.

But on the other hand, 4” metal pipe cuts the airflow than 6” metal pipe.

But if the generating saw dust amount is high, better to stick with 6” metal pipes for an effective dust collection process.

Pros and Cons of Metal Dust Collection Pipes

Here’re the advantages and disadvantages you’ll get by using metal pipes as dust collection pipes.

| Pros | Cons |

| No static discharges buildups | Significantly Expensive than PVC |

| No dust explosion happens | Heavy |

| Fittings can be easily fabricated | Difficult to handle |

| Safe | Can be susceptible to rust over time. |

| Professional | Requires additional protection or treatment to prevent corrosion. |

Cheapest Pipe for Dust Collection

Finding the right pipe for your dust collection system can seem like a daunting task, especially when budget constraints come into play.

PVC and ABS pipes are cost-effective solutions that can efficiently support your dust collection needs.

However, if you’re on the hunt for a more budget-friendly option that doesn’t compromise the efficiency of your dust collection system, you’re in the right place.

We’ve compiled some information about the cheapest pipe for dust collection that still guarantees a good performance.

PVC: A Cost-effective Option

Polyvinyl Chloride, better known as PVC, is widely recognized as the most affordable option for dust collection systems.

PVC pipes are lightweight, easy to work with, and cost-effective, which makes them an ideal choice for many woodworkers, particularly hobbyists and those working in small to medium-sized workshops.

While PVC pipes are cheaper and easier to work with, they have their drawbacks.

The main concern is the potential for static electricity build-up, which could lead to a dust explosion.

However, this risk can be mitigated by properly grounding your PVC dust collection system, typically by running copper wire along or around the pipe throughout your system.

ABS: Another Affordable Choice

Acrylonitrile Butadiene Styrene, or ABS, is another affordable option to consider for your dust collection system.

Similar to PVC in many ways, ABS pipes are resistant to physical damage, able to withstand extreme temperatures without warping or deforming, and are also easy to work with.

They are also often used in industrial settings, which is a testament to their durability.

While ABS pipes might be slightly more expensive than PVC, they are still a budget-friendly option that provides durability and effectiveness for dust collection systems.

How To Hang Dust Collector Pipe?

Most people nowadays use brackets to hang dust collector pipes. Those brackets have a radius the same as the pipes.

So, they can mount on the wall and all the dust collection will sit there and when you feel to modify the system, all you have to do is pick up the pipe, cut it, and move it where you need to.

Therefore, brackets have become the best tool to hang dust collector pipes.

To hang dust collector pipes, you can use both formal hangers or brackets. They are strong, inexpensive, and easy to install.

Hang dust collector pipes using brackets are not really clamped down and secured, but it is not going anywhere because the radius of the brackets extends o the halfway point of the pipe.

So, it will never move at all. But it allows the flexibility to be modified down the road.

Here’s a comprehensive guide on how to hang dust collector pipes properly to ensure optimal performance and durability.

Selecting the Right Materials

First, let’s cover the basic materials you’ll need. These might include galvanized wire, metal strapping, nylon cable ties, stainless steel band clamps, or a suspension system.

Each of these materials offers unique advantages and the choice largely depends on your specific needs, the weight of the pipes, and the structure of your workspace.

Traditional Wire Hanging Method

The simplest and most traditional method to hang dust collector pipes is by using galvanized wire.

To use this method, you attach the wire to the ceiling or metal pipe, then around the ducting area.

It’s a simple and effective solution that has stood the test of time, and works well especially for lightweight PVC or ABS pipes.

Metal Strapping

For a more robust and secure setup, consider using perforated rolls of galvanized sheet metal plumber strapping.

Cut the strap long enough to make a “U” shape that can mount flush with the ceiling.

Secure both ends of the strap with screws, then bolt the strap around your duct.

This method is particularly suitable for heavier metal dust collector pipes.

Using Nylon Cable Ties

Nylon cable ties provide a quick and convenient solution. They are easy to install with screw-in mounts.

Use 2 inches screws to secure the heavy-duty nylon, then thread the long nylon cable ties into the mounting brackets.

This method is popular due to its speed, convenience, and effectiveness for a wide variety of pipe materials.

Stainless Steel Band Clamps

If you’re dealing with heavier dust collection pipes, stainless steel band clamps offer an excellent solution.

These clamps are designed to mount duct pipes securely.

To use this method, you clamp the pipes and secure them using a deck screw. This method is perfect for those seeking a firm and solid mount.

Suspension System

The suspension system is a more advanced method, utilizing a metal cable that can be adjusted to fit the hanging requirements.

This method makes your installation quicker and easier, especially for larger dust collection systems.

It provides excellent support and flexibility, allowing for easy adjustments if needed.

In all cases, the hanging method should be chosen based on the specific requirements of your dust collection system, the type of pipe being used, and the structure of your workspace.

Regardless of the method you choose, always ensure that the installation is secure and stable, to ensure efficient dust collection and a safer work environment.

Now let’s talk about how to make and fit dust collection by yourself. The DIY guide that I use is here.

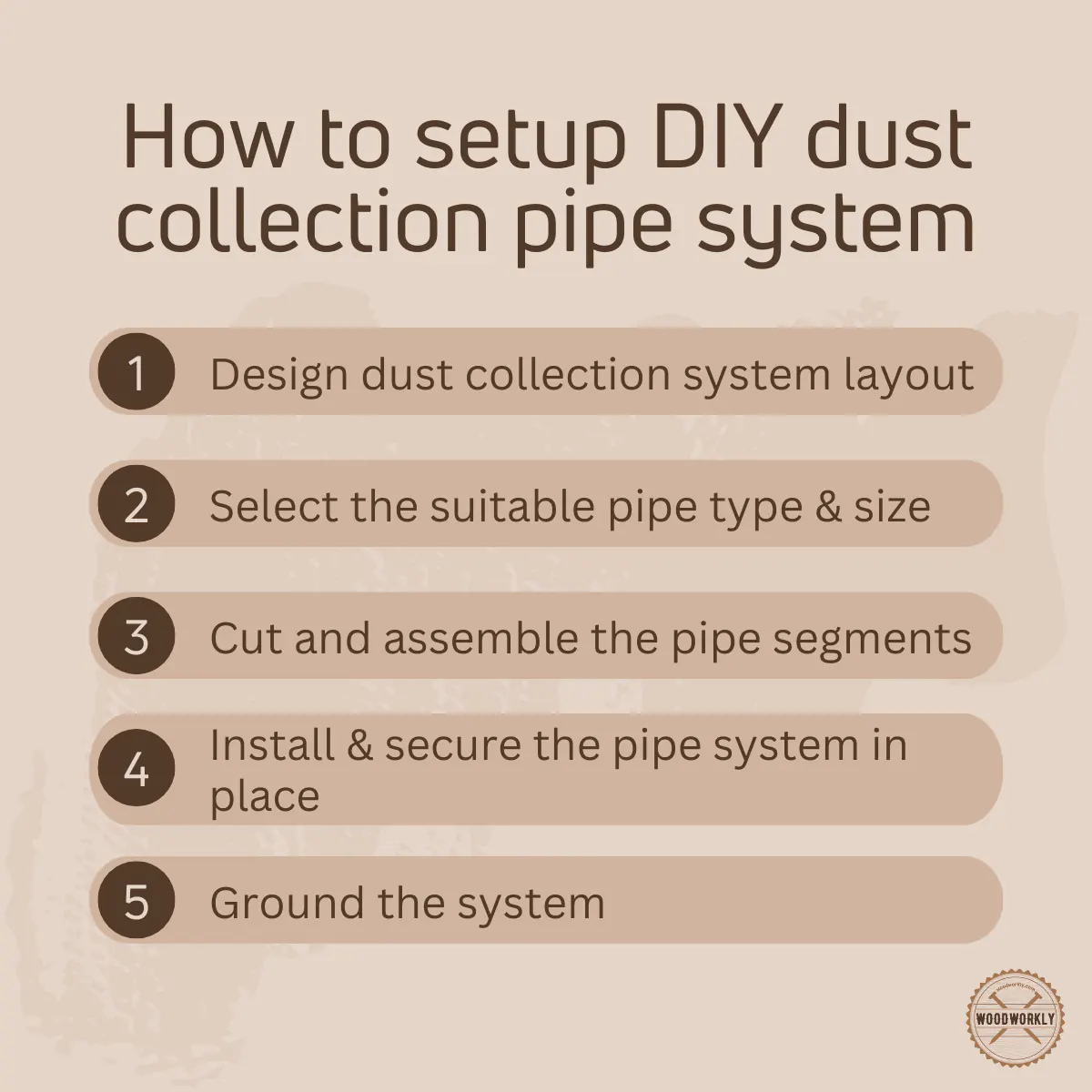

DIY Dust Collection System

Creating a dust-free workspace is vital, not only to maintain the cleanliness of your workshop but also to ensure your health and safety.

While commercial dust collection systems are widely available, they can often be quite costly. Fortunately, you can create your own DIY dust collection system without breaking the bank.

Here’s a simple guide to help you set up your very own system at home.

Planning Your Dust Collection System

First and foremost, sketch a layout of your workspace, marking the placement of every machine that generates dust.

This will allow you to determine the optimal path for your ductwork and will ensure you account for every source of dust.

Choosing the Right Materials

PVC and ABS pipes are excellent choices for your dust collection ductwork due to their affordability, availability, and ease of use.

As discussed earlier, 4-inch and 6-inch diameters are most common for dust collection systems, with the latter providing maximum and continuous airflow.

Constructing Your Dust Collection System

Building the Main Trunk

The backbone of your dust collection system will be the main trunk – the pipe that runs through your shop and connects all your machines.

Start by setting up your main trunk pipe along the path you’ve sketched in your workspace layout.

Connecting Your Tools

Next, branch lines should be installed to connect each tool to the main trunk. It’s crucial to create branches as short and straight as possible to maintain optimal airflow.

Remember, every bend or curve in your system reduces the efficiency of your dust collector.

Installing Blast Gates

To control the suction to specific machines when not in use, install blast gates on each branch line.

These gates can be opened or closed depending on which tools are being used, maximizing the efficiency of your system.

Addressing Static Electricity

Remember, both PVC and ABS are prone to static build-up, which can potentially ignite dust particles, causing a dangerous explosion.

To prevent this, you need to ground your system properly.

Run a copper wire along or around the pipe throughout your pipeline system to disperse the built-up static electricity.

Hanging Your Pipes

Depending on the specifics of your workspace, there are several methods you can use to hang your pipes, including galvanized wire, metal strapping, nylon cable ties, stainless steel band clamps, and even suspension systems.

Choose the method that best suits your needs and capabilities.

Ensuring Proper Airflow

Finally, you need to ensure that your dust collection system is properly balanced to allow for correct airflow.

A poorly balanced system might result in inefficient dust collection or even damage your dust collector.

To ensure proper balance, the size of your main trunk and branch lines, as well as the placement of your dust collector, should be taken into account.

Can You Use ABS Pipe for Dust Collection?

Yes, ABS pipes are perfect for dust collection. But you need to make sure the ABS pipe system is properly grounded to avoid creating static discharge because combustion can take place under ideal conditions.

ABS pipes are easy to install and inexpensive. Better to with size 6”.

Plus, avoid 90-degree fittings and use 45-degree fittings to have good suction power throughout the system.

That’s it, folks! Now you know all you need to know about, what kind of pipe to use for dust collection.

Let’s answer some frequently asked questions.

FAQs

Are larger diameter pipes better for dust collection systems?

While larger pipes, like 6-inch PVC, can collect a high amount of sawdust with maximum airflow, they can also slow down the power of the central system. On the other hand, a 4-inch pipe might provide more efficient use of the central system’s power.

What is the risk of static electricity in PVC pipes?

PVC pipes can build up static electricity, which, if not properly grounded, could potentially ignite dust particles causing a dust explosion. It’s crucial to ground the system with copper wire to disperse built-up static electricity and prevent this hazard.

What is the most affordable pipe option for a dust collection system?

PVC pipes are often the most affordable option for dust collection systems. They are lightweight, easy to connect, and widely available, making them a popular choice for DIY projects.

Did I cover all you wanted to know about What Kind of Pipe to Use for Dust Collection?

From this article, I have answered what kind of pipe to use for dust collection by taking metal and PVC pipes.

I have talked about the pros and cons of each kind of pipe and answered some frequently asked questions as well.

PVC and metal pipes are used for dust collection. It’s a matter of personal preference. PVC pipes are commonly used for dust collection because it’s light, easy to glue up or tape together, and inexpensive. Metal pipes offer high strength, and superior rigidity, and minimize static discharge in dust collection pipes.

Dust collection pipes are useful especially when you’re working with hand tools since you’ll be closely working in a dusty environment.

Now you know what kind of pipe to use for dust collection that matches exactly your purposes.

So, let’s begin to install your new dust collection system with your favorite pipe type. Enjoy woodworking!

I was kind of in doubt of what type of pipe to use but with this information it’s clear that I’LL use metal pipe .Thank you !