Ever faced a stubborn wood repair? Can’t seem to find the right adhesive? What if we told you JB Weld might just be your saving grace? Intrigued? Let’s delve into the world of JB Weld on wood together!

JB Weld is one of the most popular epoxy adhesives that use to bond different surfaces like metal, glass, ceramic, PVC, and more.

Because of having excellent bonding capabilities, most woodworkers are interested in using JB Weld on wood.

Therefore, I’ve researched and tested it on many kinds of woodworking projects to see how well it goes with wood.

So, let’s find out, Does JB Weld work on wood?

Yes, JB Weld works effectively on wood. JB Weld KwikWeld creates a strong, permanent bond on wood that can be sanded, drilled, and shaped once fully cured, making it versatile for numerous wood repair and craft projects.

But that’s a quick snapshot of the question.

In this article, we’ll explore deep, Does JB Weld work on wood, how strong JB Weld is on wood, how to use JB Weld on wood, and how to remove JB Weld from wood as well.

Furthermore, I’ll answer some frequently asked questions as well.

Let’s jump in!

Is JB Weld Good for Wood?

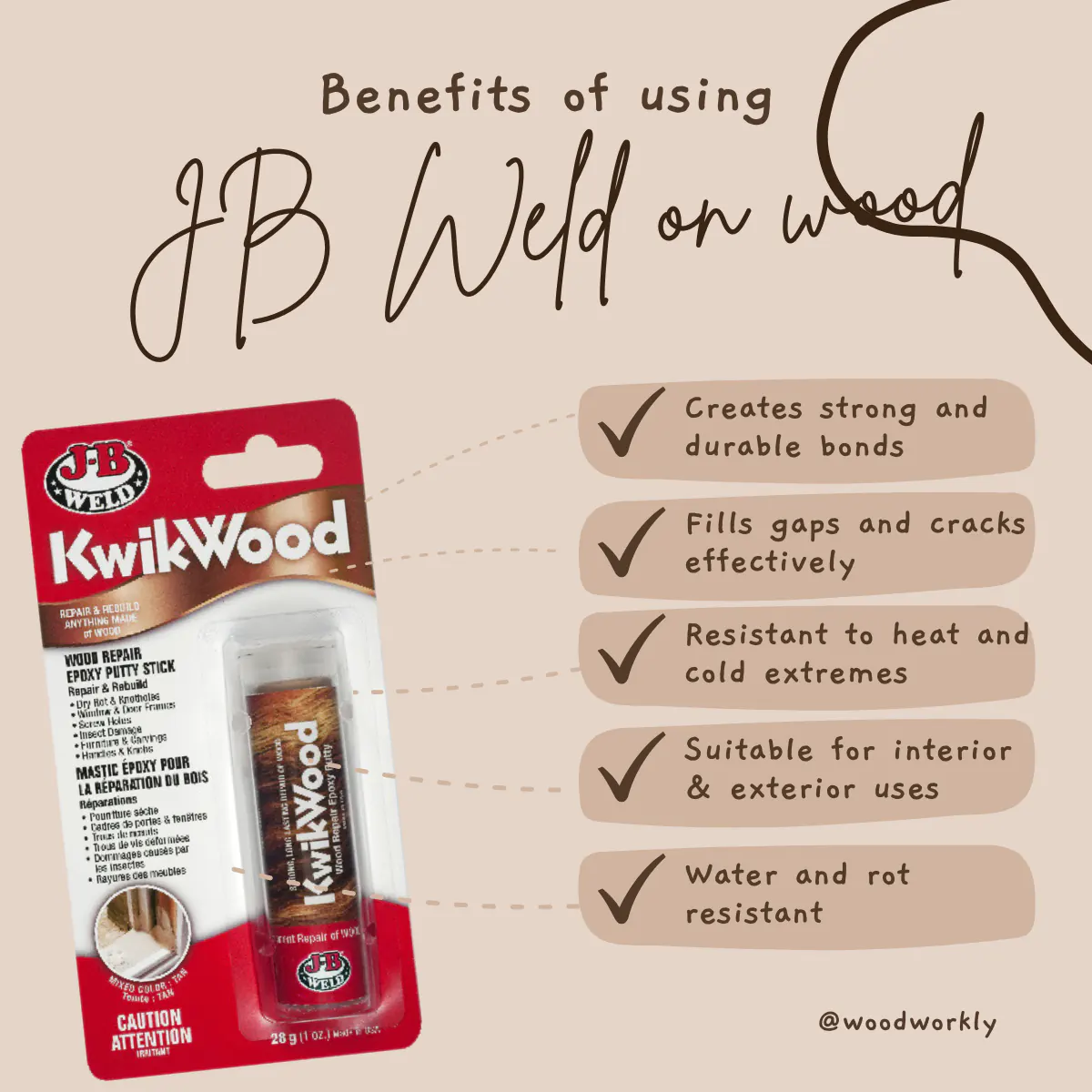

JB Weld is an excellent epoxy adhesive for wood. It can use pretty much for any woodworking project to make super strong, unbreakable bonding that cures and set quickly.

Once the JB Weld bond is fully cured, it can be machined, sanded, painted, tapped, dripped, and stained with no issues.

JB Weld bond with wood has high tensile strength.

Therefore, JB Weld can use for both indoor and outdoor woodworking projects such as doors, fences, furniture, floors, windows and so much more.

JB Weld makes a tight bond between wood surfaces. Here’re some qualities of JB Weld epoxy adhesive on wood,

- JB Weld bond is water resistant and acid resistant. This gives your wood furniture good protection from environmental elements like moisture.

- JB Weld bond has good shock and vibration resistance. This will make your woodwork dimensional stable

- JB Weld can withstand extreme temperatures. This is feature is useful for outdoor furniture to resist temperature fluctuations.

- JB Weld fills gaps and cracks on wood. This is useful for repairing and restoring damaged and rotted wood.

- JB Weld makes a strong bond between wood parts that does not shrink or crack.

As you can see there’re so many advantages of using JB Weld on wood.

It not only helps wood pieces to tight together but also helps to protect their environmental impacts.

JB Weld is great for

- Damaged wood parts

- Rotted wood

- Indoor and outdoor furniture

- Window frames

- Fill cracks and gaps

- Repair and restore woods

Here’re some popular uses of JB Weld products on wood,

- JB Weld liquid hardener prevents wood from rotting

- JB Weld epoxy putty helps to fill gaps in wood

- JB Weld wood restores fill holes and gaps in wood

- JB wood weld bonds to wood tightly without foaming or shrinking when repairing the furniture, windowsills, and more

As you can see, JB Weld can be used pretty much for any woodworking project. This is why it has become so popular in the woodworking world.

So, let’s have a look at how JB Weld works on several woodworking projects and furniture.

JB Weld on Wood Table

JB Weld is useful to repair and restore the wood table to its original strength. Plus, JB Weld is great to attach different wooden parts and other materials to a wood table.

It helps to make an unbreakable strong bond with high impact resistance.

JB Weld helps to increase the dimensional stability of the wood table. Therefore, JB applied wood table can use outdoors as well.

For example, JB Weld is excellent for outdoor dining tables.

When repairing a wood table with JB Weld, you can shape and fill JB Weld to cover up and fill all the gaps and cracks easily.

Sanding and drilling are also possible once the JB Weld layer is cured.

Once the JB Weld layer is cured properly, there’ll be no repairing marks stuck on the surface. Therefore, the wood table will look like new.

If the wood table is rotted, remove the rotted area, apply JB Weld on the affected area and let it dry.

This will restore the wood table to its original appearance with extra strength.

JB Weld on Wood Floor

JB Weld works well on the wood floor. You can apply JB Weld on wood floors for a quick fix because usually it cures within one hour.

It provides a waterproof solution by making a waterproof bond with wood floors. It can fill gaps and cracks on a wood floor that happened due to foot traffic and pet scratches.

JB Weld can use as wood floor filler to restore wood floors.

It makes a strong coating on gaps of wood floors which is scratch resistant, and waterproof and it gives a hard-wearing glossy appearance.

How Strong Is JB Weld on Wood?

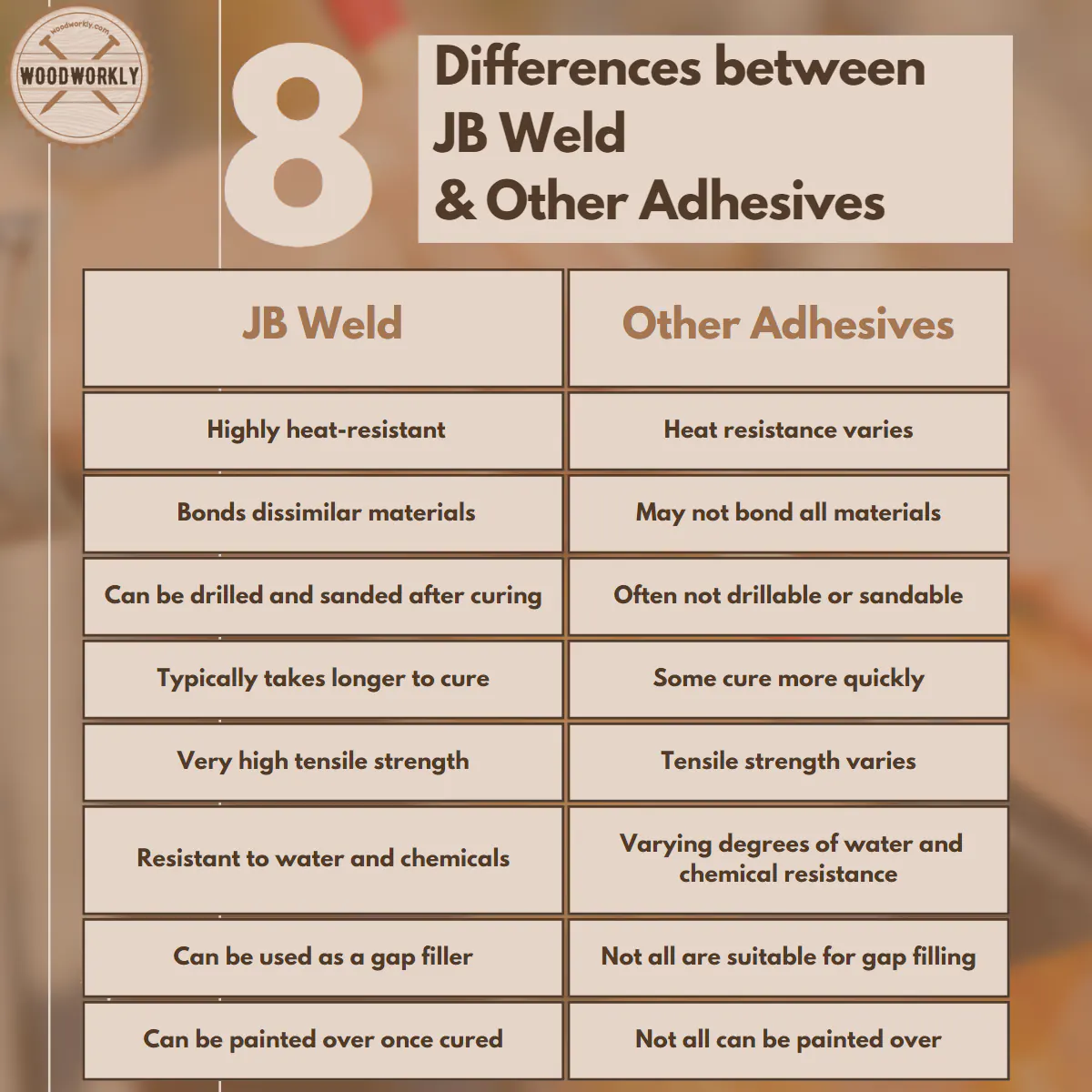

JB Weld is extremely strong on wood. JB Weld makes a strong, unbreakable bond with wood within 6 minutes with a tensile strength of 1,800 PSI.

JB Weld can withstand extremely high-temperature levels. It works well and is strong on wood even at 5000F (2600C).

The maximum threshold temperature of JB Weld is 6000F (3160C) for 10 minutes. As you can see strong bond JB Weld makes with wood furniture is able to withstand any harsh weather conditions.

It gets the maximum strength out of the JB Weld you need to wait until it is fully cured and set. Once it is set overnight and cured JB Weld can easily manage to stay strong up to 6000F.

JB Weld KwikWood is a two-part epoxy that acts as wood putty. Undoubtedly it makes one of the strongest bonds with wood compared to wood putties.

KwikWood hardens quicker than wood putty and makes a bond with a shear strength of 900 PSI.

JB Weld is strongly bonded with wood. Therefore, the bond can easily tolerate woodworking activities.

JB Weld bonds can be drilled, nailed, screwed, stained, painted, and sanded easily without a single crack or split. It won’t shrink, rot or contact outside impacts.

Overall, JB Weld makes a bond with any wood that is significantly stronger than the original bond between wood fibers.

So, let’s find out how to use JB Weld on wood to repair and restore wood properly.

Supplies You Will Need to Restore Wood with JB Weld

- JB Weld Wood Restore Liquid Hardener

- JB Weld Wood Restore Epoxy Putty

- Rotted wood or more

- Screwdriver or paint scraper

- Sandpaper or sanding block (80 or 100 grit)

- Fine grit sandpaper (180 grit to 220 grit)

- Tack cloth

- Paintbrush

- Paint or wood stain

- Latex gloves

- Spreader or mixing stick

Gather the above supplies from quality manufacturers and get ready to use JB weld to restore the wood.

How To Use JB Weld to Restore Wood?

JB Weld is easy to use on wood to repair, restore and fill gaps and cracks. It increases the durability of the wood and wood resistance against moisture and other elements.

There’re 2 main JB Weld products you can use on wood for various tasks like restoring wood, repairing wood, filling gaps and cracks wood, and more. They are,

- JB Weld Wood Restore Liquid Hardener

- JB Weld Wood Restore Premium Epoxy Putty

So, let’s have a look at how to use JB Weld Wood Restore Liquid Hardener and Epoxy Putty on wood to restore properly.

Here’re the steps you need to follow to restore wood using JB Weld Liquid Hardener and Epoxy Putty,

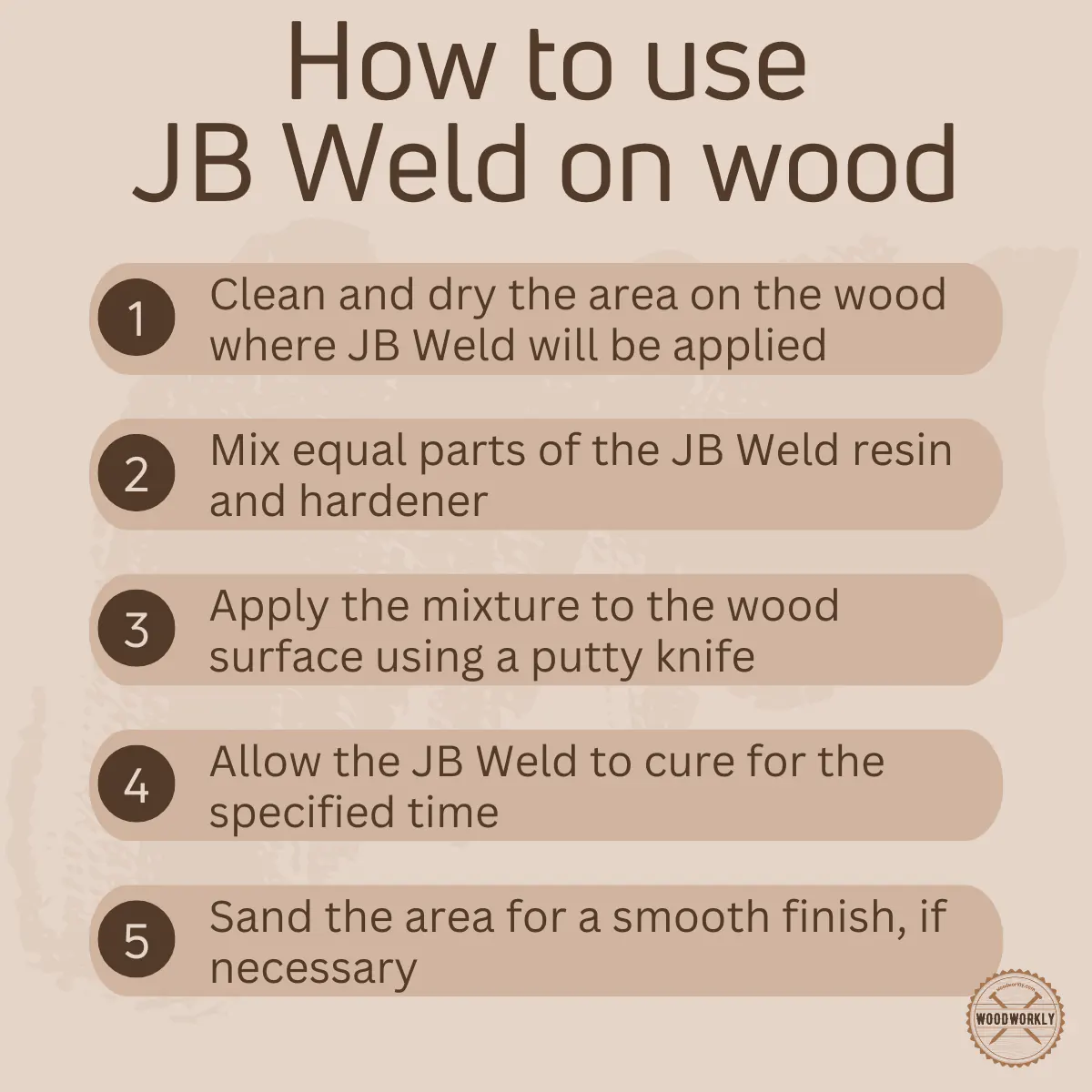

- Dry and clean the wood

- Remove rotted area

- Seal wood with JB Weld Liquid Hardener

- Let it dry and Cure

- Mix and prepare JB Weld Epoxy Putty

- Apply JB Weld Epoxy Putty

- Let it dry and cure

Let’s discuss each of the above steps separately to get a clear idea of restoring wood with JB Weld.

1. Dry and Clean the Wood

The wood must be clean and completely dry before removing the rotted area. Otherwise, it’s difficult to remove the rotted areas from the surface.

First let the wood completely dry out by keeping it in a dry, moisture-free environment.

If you live in a dry climate, this will take a few days, but for the people who live in a wet climate can take around 2 – 3 weeks.

Airflows, and sunlight, help to eliminate moisture from the wood and dry out, especially the rotted area.

Once the wood is completely dry, clean it using a lint-free soft cloth to remove dust and debris.

Never use soapy water or any other solution when cleaning because the wood needs to be in dry mode.

2. Remove The Rotted Area

Once the wood is completely dry, take the screwdriver or paint scraper and carefully remove the rotted area.

By removing the rotted area, the drying process of the wood will be much faster.

If the wood is still not completely dry out, you can use a heat gun to dry out to dry them manually.

All the impacted wood fibers, loose and unstable wood should be removed with a screwdriver or scraper.

If any remained on the surface while we are applying the JB Weld, that’ll cause so many troubles because rotted areas don’t hold them well.

When removing the decayed, very soft or loose wood keep the wood always dry.

Once you’re done removing the impacted areas, clean the wood well to get rid of dust, dirt, or loose paint residue.

Likewise, proper surface preparation should be done before using JB Weld on wood to get the maximum out of it.

3. Seal Wood with JB Weld Liquid Hardener

Now shake the JB Weld Liquid Hardener bottle well and apply it to the impacted area using the paintbrush.

There should be no rotted areas anymore when you’re applying to JB Weld.

When you’re applying JB Weld Liquid Hardener on wood, don’t dry to thin the liquid. Thick coats help to cover up the wood well and make a strong and tight bond with the surface.

Saturate and soften wood thoroughly with JB Weld Liquid Hardener without missing any spots.

Apply several coats of JB Weld Liquid Hardener until you get a shiny glossy surface with an extra strong bond.

But make sure to let the previously applied coat dry out completely before applying another coat of JB Weld Liquid Hardener on top of it.

4. Let It Dry and Cure

After applying several coats of JB Weld Liquid Hardener, let the wood dry and cure completely before moving on to the next step.

Usually, JB Weld Liquid Hardener hardens and dries within 2 – 4 hours.

After applying JB Weld Liquid Hardener let it dry and cure for about 8 hours.

Once the JB Weld coats are fully dried and cured, clean the surface well and move on to the filling process with JB Weld Epoxy Putty.

5. Mix and Prepare JB Weld Epoxy Putty

While the JB Weld Liquid Hardener coats are drying out you get enough time to prepare and mix JB Weld Epoxy Putty before moving on to the application step.

Tip:

Make sure to seal the wood first with JB Weld Liquid Hardener or Premium Liquid Epoxy before applying JB Weld Epoxy Putty because there should be no rotted areas and the surface needs to be well prepared to stick wood putty well on to the surface.

Wear gloves and mix equal amounts of Part A and Part B Epoxy Putty using a 1:1 mixing ratio.

Mix both parts well using the mixing stick or by gloved finger until uniform color appears.

Once you get the uniform color by mixing A, and B parts using a 1:1 ratio, you’re good to move into the application step.

6. Apply JB Weld Epoxy Putty

Now apply prepared Epoxy Putty to the impacted areas and fill evenly without missing any spots.

The wood needs to be completely repaired. Therefore, shape the wood putties using your hand and shape them before filling the gaps and cracks of the wood.

Press the Epoxy Putty firmly when filling to get the surface as you want. You should do the application process without leaving Epoxy Putty for too long because it tends to harden quickly.

Apply wood putty until you get the desired appearance of the wood.

7. Let It Dry and Cure

Once you’re done with applying wood putty and get the desired appearance as you want, let JB Weld Epoxy Putty hardens and dries for 2 – 4 hours.

After leaving it for 2 – 4 hours, Epoxy putty is completely hardened, and it won’t crack or shrink. After it is fully dried and cured you can sand, drill, or screw the surface with no issues.

For better protection, I recommend applying wood stain or paint once you’re fully done with the wood restoration process with JB Weld products.

You can apply any type of wood stain evenly throughout the wood, including the restored areas without making any wood stain mistakes.

That’s how you should restore rotted wood with JB Weld.

Have you ever thought of bonding metal and wood? Don’t worry! JB weld gets you covered. Let’s see how it is done in detail!

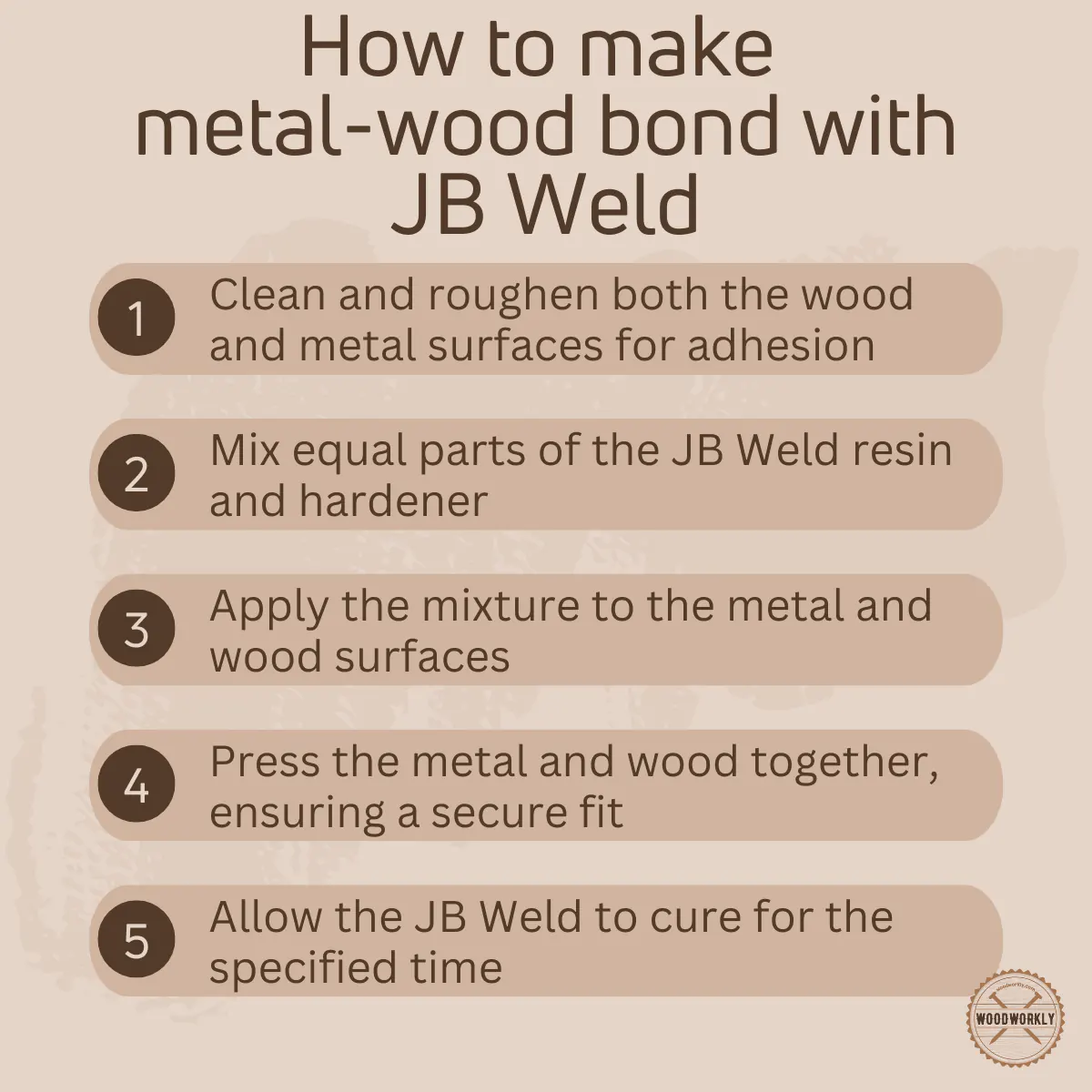

JB Weld Metal to Wood: A Step by Step Guide

Having a versatile adhesive at hand can be a lifesaver when you’re in a DIY fix or need a quick repair.

JB Weld is one such adhesive, renowned for its strong bond and ability to stick to almost any surface, including wood and metal.

So, here’re the steps you need to follow when bonding metal and wood with JB weld,

- Gather your materials

- Prepare the surface

- Mixing JB weld

- Applying JB weld

- Bonding metal to wood

- Let it cure

Let’s have a look at each of the above steps in detail to bond metal to wood or wood to metal properly.

Step 1: Gather Your Materials

Before you start, make sure you have everything you need:

- JB Weld adhesive (consider the original JB Weld or KwikWeld for faster drying)

- Metal and wood pieces to join

- Sandpaper (120-grit)

- A clean, dry cloth

- Disposable container and a stick for mixing

- Gloves for protection

Step 2: Prepare the Surfaces

To ensure a solid bond, it’s essential to prep both the wood and metal surfaces.

Wood Preparation

Remove any dust, grease, paint, or oil from the wood surface. This might require a little gentle scrubbing.

Once it’s clean, ensure the wood is completely dry before proceeding.

If needed, use masking tape to section off areas where you don’t want the glue to adhere.

Metal Preparation

As with wood, ensure the metal surface is free of dust, oil, paint, or rust. Then, use 120-grit sandpaper to lightly roughen the surface.

This gives the JB Weld a better “grip” on the metal.

Step 3: Mixing the JB Weld

JB Weld typically comes in two tubes – the epoxy resin and the hardener. The recommended mixing ratio is 1:1.

Wearing your gloves, squeeze out equal amounts of both the resin and hardener into your disposable container.

Then, use a stick to mix them together until they blend into a uniform color.

Tip: Be mindful that the mixed JB Weld starts setting after about five minutes, so you should apply it soon after mixing.

Step 4: Applying the JB Weld

With the mixed JB Weld, apply a layer on either the wood or metal surface (or both if necessary).

The amount you need will depend on the size of the surfaces you’re bonding. Ensure you have enough to cover the surface evenly.

Step 5: Bonding Metal and Wood

Once the JB Weld is applied, press the metal and wood pieces together. If possible, clamp the pieces together to secure the bond.

If you can’t use a clamp, applying consistent pressure by hand for a few minutes can also work.

Step 6: Curing

Now, you play the waiting game. JB Weld sets in about 4-6 hours, but for a complete cure, you should ideally wait for around 15-24 hours.

During this curing time, ensure the bonded pieces are left undisturbed, preferably in a warm, dry area.

And voila! You’ve successfully used JB Weld to bond metal to wood. This quick and effective solution works for all sorts of home repairs, crafting projects, and more.

However, always remember to take necessary precautions when handling adhesives, and refer to the manufacturer’s instructions to get the best results.

Note: While JB Weld forms a strong bond, remember that it’s not a substitute for mechanical fastening in load-bearing scenarios.

JB Weld’s versatility is what makes it a staple in many DIY enthusiasts’ toolkits.

Whether it’s a quick fix for a broken toy or a lasting repair on your wooden furniture, JB Weld can do the job.

How To Remove JB Weld from Wood?

Usually, it is difficult to remove JB Weld from wood once it is fully hardened and cured.

But you can remove JB Weld from wood by heating it above 6000F maximum threshold temperature. It will get soft around the threshold temperature level.

But heating JB Weld to extreme temperature can damage the wood and you should do this carefully without damaging the wood.

Other than that, use an angle grinder to remove JB Weld from wood. this also should be done carefully without damaging the wood underneath.

If you need to know more details about removing JB weld from wood, read my comprehensive guide about, How to remove JB weld from wood!

Now you have a clear idea of using JB Weld on wood.

How Long Does JB Weld Take to Dry on Wood?

JB Weld takes 2 – 4 hours to dry on wood. JB Weld dries quickly when the area is well-ventilated,

Drying time can differ according to the environmental humidity and the dryness of the wood.

This is why drying is so important before applying JB products to wood.

What Is the Cure Time of JB Weld?

JB Weld cures within 4 – 6 hours. In my personal experience, it is usually cured properly 6 to 24 hours after the application.

The curing time for JB Weld Wood Epoxy primarily depends on the specific product and the conditions in which it is applied.

For instance, the widely-used JB Weld KwikWeld has a cure time of 4-6 hours.

However, for it to be completely cured and to achieve its maximum strength, it is recommended that you leave it undisturbed for about 15 to 24 hours.

Different JB Weld products have different set and cure times.

For example, the original JB Weld, known for its strength and durability, takes around 20-25 minutes to set, but it requires around 15-24 hours to cure fully.

Factors Affecting the Cure Time

Temperature

Cure times can be influenced by environmental factors such as temperature. Epoxy resins tend to cure faster at higher temperatures.

For instance, if you’re working in a warm environment, JB Weld may cure more quickly. Conversely, colder temperatures may extend the curing time.

Humidity

Moisture in the air, or humidity, can also affect the curing process.

High humidity can slow down the curing process, while low humidity might speed it up.

How to Tell If JB Weld is Cured?

Touching is a simple but effective way to check if your JB Weld application is cured.

After the expected curing time, gently touch the surface of the glue. If it’s no longer tacky and doesn’t indent under pressure, it’s likely cured.

However, do remember that it’s always better to err on the side of caution and give it a bit more time if you’re unsure.

Why is Cure Time Important?

Understanding and respecting the cure time of JB Weld is crucial to achieving a strong and durable bond.

If the epoxy is disturbed before it has fully cured, it can weaken the bond, leading to less effective results.

For example, if you’re repairing a chair leg with JB Weld, you would want to let the epoxy cure fully before you apply any weight to the chair.

Not doing so could result in the bond breaking or not forming properly.

Being patient with the curing process can be a game-changer when it comes to the longevity and effectiveness of your repair work.

Remember, rushing the process might give you a quick fix, but for a durable and reliable bond, giving JB Weld the right amount of time to cure is absolutely essential.

During this time the wood should not get in contact with water, dust, or any other elements.

Once the coats are fully cured, they can sand, stain, paint, and drill without shrinking or cracking the surface.

Staining and painting are possible once the JB Weld Wood Restore is completely dried and cured.

Is JB Weld Stronger Than Epoxy?

Yes, JB Weld is stronger than epoxy. JB Weld makes a stronger bond with an impact resistance of 1,800 PSI which can tolerate up to 5000F with no issues.

It bonds tightly with wood fibers and makes bonds stronger than Epoxy.

You already know how to use JB weld on wood and what tips you need to follow. Now, let’s see what you should not use JB weld on.

What Should You Not Use J-B Weld On?

J-B Weld, with its strength and versatility, is a beloved staple in the toolbox of many DIY enthusiasts and professionals alike.

However, it’s important to note that while this adhesive is powerful and works well with many materials, there are some situations and materials where it might not be the best choice.

Let’s explore some of those scenarios.

High-Temperature Environments

While J-B Weld is known for its ability to withstand high temperatures (J-B Weld KwikWeld, for example, can withstand up to 230 degrees Fahrenheit), it’s not meant for extreme heat environments.

So, using J-B Weld on parts that consistently encounter extremely high temperatures, like the inside of an engine combustion chamber, may not be a good idea.

In such cases, a specialized high-temperature adhesive would be a more suitable choice.

Flexible or Soft Materials

Another scenario where J-B Weld may not be the best choice is when dealing with soft or flexible materials.

J-B Weld cures to a hard and rigid finish, so it’s not ideal for bonding materials that need to maintain flexibility, like some rubbers or flexible plastics.

Food and Water Safe Applications

Even though J-B Weld is resistant to water and many chemicals once it’s fully cured, it’s not generally recommended for use in applications that come in direct contact with food, drink, or potable water.

Large Gap Filling

While J-B Weld is fantastic for bonding two surfaces together, it is not designed to fill large gaps or holes.

It is a bonding agent, not a gap filler. Therefore, if you have a significant void to fill, you might need to consider another solution, such as a specialized filler.

Cosmetic Applications

J-B Weld is known for its strength rather than its looks. It typically dries to a dark grey color and can be noticeable if used on lighter materials.

If you’re working on a project where appearance is important, consider a different adhesive or filler that matches the color of the material or can be painted over easily.

Moving Parts

When it comes to moving parts, especially those with high rotational speed, it’s not advisable to use J-B Weld.

The forces exerted might not be something J-B Weld can handle and therefore could result in the failure of the bond.

J-B Weld is a versatile adhesive with many uses, but it’s not a one-size-fits-all solution.

It’s essential to consider the specific requirements of your project and select the right tool for the job.

When used appropriately, J-B Weld can provide a durable, long-lasting bond. But recognizing where it might not be the best fit is key to achieving the best possible result.

That’s it, folks! Hope you were able to learn everything you wanted to know about, Does JB Weld work on wood in detail?

Let’s answer some frequently asked questions as well.

FAQs

Can I paint over J-B Weld on wood?

Yes, J-B Weld can be painted over once it has fully cured. However, bear in mind that it dries to a dark grey color, so a primer might be needed for lighter paint colors.

Is J-B Weld waterproof? Can it be used on wood in wet conditions?

Yes, once fully cured, J-B Weld is waterproof and resistant to many chemicals, making it suitable for use on wood in wet conditions.

Is J-B Weld suitable for all types of wood?

J-B Weld works well with most types of wood, but the surface needs to be clean, dry, and free from dust, grease, and oil for optimal adhesion.

Can J-B Weld be used to fill gaps or holes in wood?

While J-B Weld is an excellent adhesive, it’s not designed to fill large gaps or holes. For significant voids in wood, a specialized filler might be a better choice.

How can I remove J-B Weld from wood if needed?

Removing cured J-B Weld can be challenging due to its strong adhesion. Mechanical means, such as sanding or scraping, are typically the most effective, but care should be taken not to damage the underlying wood.

Did I cover all you wanted to know about: Does JB Weld Work on Wood?

In this article we have deeply talked about does JB Weld work on wood and it goes with different woodworking and furniture applications including wood table and floors.

We have discussed how strong JB Weld is and how to use JB Weld on wood without getting into trouble with simple easy steps.

JB Weld works well on any type of wood. It makes a quick setting, strong, nearly unbreakable bond with wood surfaces. JB Weld is used for wood bonding and repair and restoring damaged and rotted wood. It cures quickly on wood and is able to drill, sand and paint. JB Weld works great for indoor and outdoor woodworks.

By applying JB Weld, you will get a strong bond that can tolerate any temperature level and it can withstand harsh weather conditions.

Therefore, JB Weld is useful for both indoor and outdoor woodworks and furniture.

Furthermore, we have answered some frequently, asked questions about JB Weld on wood.

Hope you have gained good knowledge about how JB Weld works on wood and how to use it to get the maximum out of it.

Try it on your own and be the one that does wood restoration better than professionals!