Ever looked at your rotted wood and wondered, “Could Flex Seal be the quick fix I need?” Let’s dive into the world of Flex Seal and explore how it might just turn your decayed wood woes around!

Flex Seal is a sealer that works pretty well with PVC, copper, metal, and wood.

It is used for repairing and protecting materials from environmental elements like moisture.

Even though we generally use Flex Seal on our fresh woodwork and furniture stuff, have you ever thought about using Flex Seal on rotted wood to avoid wood getting damaged any further?

I did some deep research about this product with the help of professionals that have years of experience with Flex Seal.

So, let’s find out, Can you use Flex Seal on rotted wood?

Yes, you can use Flex Seal on rotted wood to seal and protect it from further damage. However, Flex Seal is not designed to restore severely rotted wood. For best results, apply Flex Seal on dry wood and use multiple coats to create a durable, moisture-resistant barrier.

But that’s a quick snapshot and there’s a lot more to know.

In this article, we’ll explore whether can you use Flex Seal on rotted wood, how to repair rotted wood and apply Flex Seal properly, does Flex Seal waterproof rotted wood, and much more.

Furthermore, I’ll answer some frequently asked questions as well.

Let’s dig in!

Does Flex Seal Work on Rotted Wood?

Yes, you can apply Flex Seal on rotted wood, it seals the wood and doesn’t give moisture a chance to get inside of the wood. But the thing is, the problem has already happened.

The moisture is already inside the wood. You cannot ignore that just by applying Flex Seal paste from the outside.

The Flex Seal will also stop moisture trapped inside of the wood from evaporating. This makes the moisture inside nowhere to go.

So, they’ll soak deep into the wood fibers and rot the wood. This will never stop until the wood gets fully dried. The wood will begin to rot faster than before.

Eventually, after applying Flex Seal on rotted wood, the wood will get into a much worse situation because the moisture will destroy wood from inside.

Therefore, never apply Flex Seal on rotted wood, instead of stopping the wood from rotting, you’re cooperating with the rotting process.

But after repairing the rotted area and then applying Flex Seal over the whole woodwork or furniture, you’ll be able to stop moisture from getting inside of the wood and stop wood rot in the future.

Flex Seal fills gaps and cracks in rotted wood and seals the wood perfectly.

So, let’s have a look at the advantages and disadvantages you’ll get by applying Flex Seal on rotted wood.

Pros and Cons of Using Flex Seal on Rotted Wood

| Pros | Cons |

| Prevent outside moisture from getting inside | Wood starts to rot faster than before |

| Protect wood from UV light | Inside moisture doesn’t evaporate |

| Protect wood from insects and bugs | Ruin the interior structure of the wood |

| Able to use for rotted wood in good condition | Unable to protect the wood that rotted worse |

| Fill cracks and gaps | |

| Seal the wood |

As you can see, you can use Flex Seal on rotted wood only if the wood is not in such a bad condition.

If the rotting is affected to a small area, the other areas of the wood can be protected and sealed with Flex Seal.

But if the wood is rooted so badly, nothing can help you until you repair the wood fully and then apply the Flex Seal.

Let’s have a look at the things you need to have before restoring rotted wood with Flex Seal.

Supplies You Will Need to Apply Flex Seal on Rotted Wood

- Flex Seal product

- Rotted wood

- Damp cloths

- 220 grit sandpaper

- Gloves

- Hammer

- Paintbrush

How To Use Flex Seal on Rotted Wood?

You can only apply Flex Seal on rotted wood by repairing the rotted area first and then applying the Flex Seal over the wood.

So, let’s see how it should be done.

Here’re the steps you need to follow when using Flex Seal on rotted wood,

- Let the wood dry completely

- Remove rotted area

- Clean the wood

- Sand and remove sawdust

- Spray or apply Flex Seal

- Let it dry and cure

So, let’s discuss each of the above steps one by one to get a clear idea about using Flex Seal on rotted wood,

1. Let the Wood Dry Completely

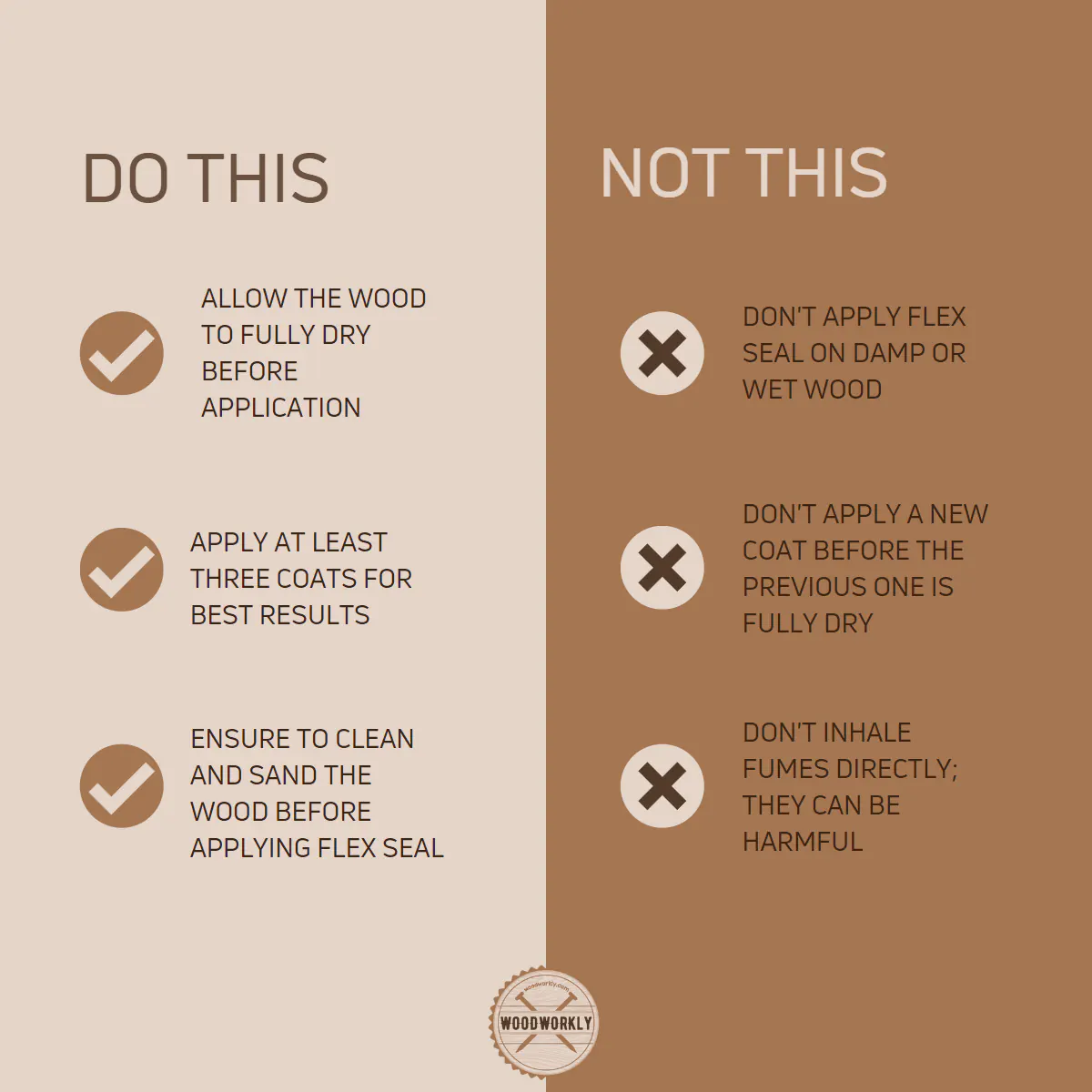

First of all, let the rotted wood dry completely to evaporate the moisture inside.

This can take days or weeks depending on the wood type and moisture content inside.

Place the rotted woodwork or furniture in a well-ventilated dry area and let it dry out completely. Because rotted areas will be easily removed when the wood dries.

2. Remove the Rotted Area

First, you need to identify whether the wood is rotten and what areas you should focus on the most.

Now claw out the rotted area using the hammer. Place the claw of the hammer at the base area of the rot and apply pressure to pull the claw towards you to remove the rotted surface.

Do the same procedure with the hammer again and again until the rotted area removes completely because it is so difficult to apply Flex Seal on rotted surfaces.

Make sure not to apply too much pressure on the hammer because that can damage the healthy wood parts.

Only the unstable wood needs to be removed.

Read to know, Stop Pressure Treated Wood Rot! (EASY Guide!)

3. Clean the Wood

After removing the unstable rotted wood areas clean dust and debris off the whole wood surface with damp cloths.

Because dust and debris get trapped inside the Flex Seal coat you won’t be able to achieve maximum performance.

Wipe down the entire surface with a clean rag without missing any spots.

Make sure not to use cleaning solutions to clean the wood because, after removing the rotted area, there’s a high possibility of absorbing water into the wood because wood interior fibers are widely open to the outside world.

Therefore, better to do clean and dry without using water.

4. Sand and remove Sawdust

After cleaning the wood properly, sand the entire surface with 220-grit sandpaper to make the surface smooth.

After removing the rotted area, the surface will be so random and dull.

Therefore, sanding is highly recommended to make the surface ready to accept Flex Seal evenly.

Sand along the direction of the wood grain to avoid wood from scratching.

Use finer-grade sandpapers because higher-grade ones can damage the sensitive areas of the wood.

Once you’re done with sanding clean the whole surface with a damp cloth to remove sawdust.

Now you have a nice, smooth, and clean surface to accept Flex Seal without no issues.

5. Spray or Apply Flex Seal

Shake the flex spray can vigorously for about a minute and aim the nozzle of the spray at the cracks and gaps of your previously rotted wood furniture.

Then spray Flex Seal in sweeping motion by keeping a distance of 10 – 12 inches.

Flex Seal fills cracks and gaps of rotted wood and makes sure to spray slowly until fills all the gaps and cracks.

Make sure not to miss any spots because once the Flex Seal is settled in, it’s a bit difficult to identify the missing spots.

When spraying Flex Seal, you’ll notice it can perfectly fill up the rotted areas without showing any difference from the healthy areas of the wood.

Therefore, Flex Seal works really well in rotted wood once the wood is fully repaired.

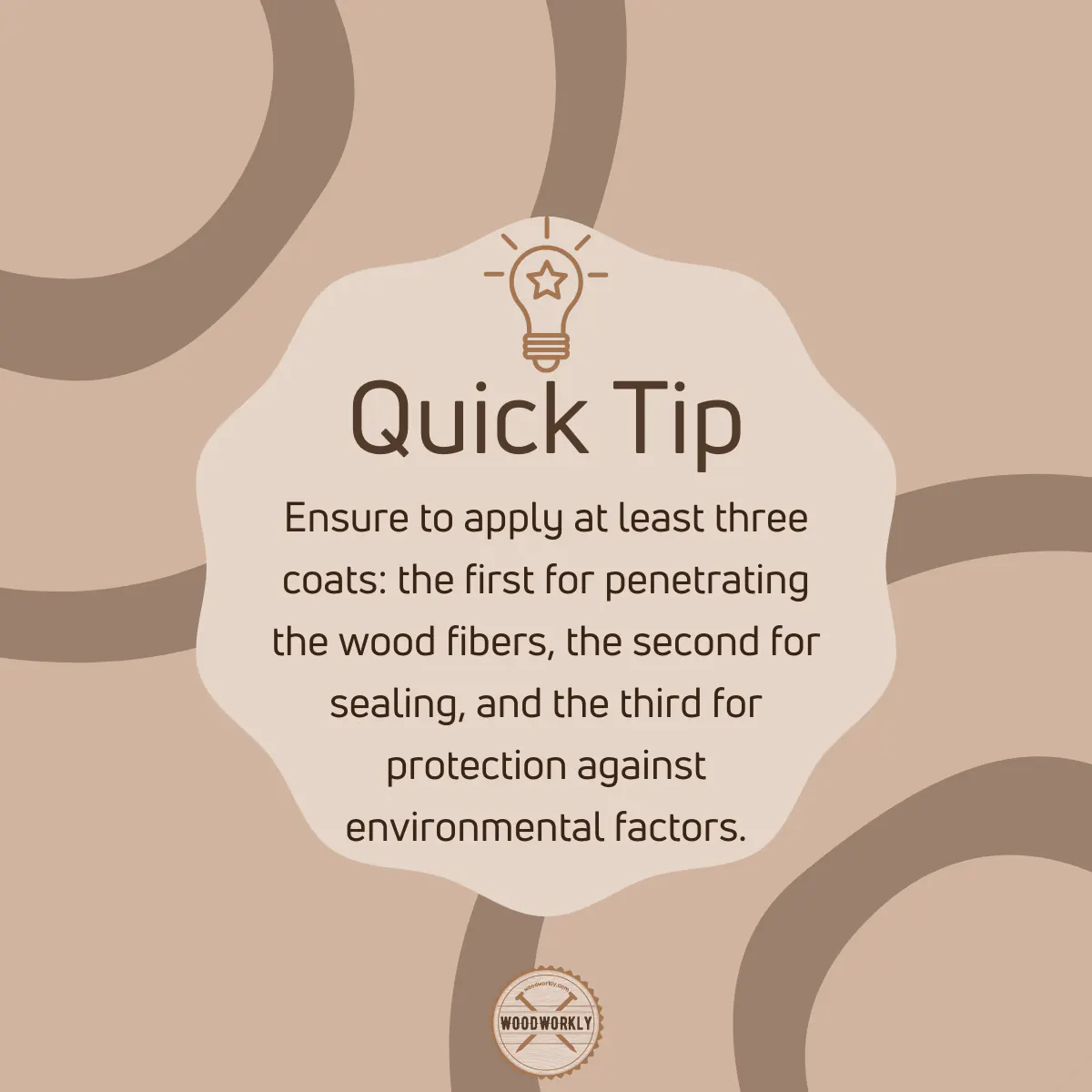

Apply 3 coats of Flex Seal on rotted wood to get the results you want.

The first coat of Flex Seal penetrates through wood fibers and the second coat of Flex Seal bonds with the first coat and seals the wood.

The third coat of Flex Seal is useful to protect the wood from UV light, moisture, and other environmental elements.

6. Let it Dry and Cure

Let the Flex Seal settle and dry for about 24 hours before applying the next coat of Flex Seal.

After applying all the coatings of Flex Seal let the rotted wood dry for about 24 hours and allow it to cure for about 48 hours before using it.

Never apply another coat of Flex Seal once the previous cost is still wet because the trapped moisture between two layers of Flex Seal can penetrate through wood fibers and can cause wood to rot.

Then you’ll have to start everything from the beginning and the appearance of the woodwork will be ruined as well.

Drying time and curing time can vary due to the wood type, environmental humidity, and climate changes.

Usually, it takes more time to apply Flex Seal on healthy wood than apply Flex Seal on rotted wood because of the high drying time.

That’s it, folks! Now you know how to use Flex Seal on rotted wood correctly without making any errors.

Make sure to do the job correctly from the first attempt because Flex Seal is significantly higher than other finishers like epoxy.

Congrats folks! now you know how to use Flex Seal on rotted wood.

Now I’m going to share with you some useful tips which I’ve learned from professionals and from my own experience.

They’ll help you to make the rotted wood repair project lot easier.

Tips for Using Flex Seal on Rotted Wood

Rotted wood can be an eyesore and even a structural risk.

But with a little patience, a can of Flex Seal, and these handy tips, you’ll be well on your way to giving that old wood a new lease of life.

Understand the Limits of Flex Seal

Before diving into the actual process, remember that while Flex Seal is indeed an incredible product, it’s not a magic wand.

It works wonderfully for sealing, protecting, and preventing further damage, but it’s not designed to restore severely rotted wood.

If the rot has deeply penetrated the wood, you might need to consult a professional or replace the damaged parts.

Make Sure the Wood is Completely Dry

An essential tip when using Flex Seal on rotted wood is to ensure the wood is thoroughly dry before starting the application process.

Any residual moisture can lead to issues down the line as it can become trapped beneath the sealant, potentially leading to more decay.

Remove as Much Rot as Possible

Don’t just spray Flex Seal on rotted wood and hope for the best. Instead, be proactive and remove as much of the rotted sections as you can.

This process might involve using a hammer or chisel to get rid of the visibly rotted areas, but the extra work will pay off in the end.

Preparation is Key

When it comes to applying Flex Seal, the old adage holds true: preparation is half the battle.

Thoroughly clean and sand the surface of the wood to create a smooth area for the Flex Seal to adhere to.

This step will make the application process easier and more effective.

Multiple Coats for Maximum Protection

Don’t skimp on coats. Applying multiple coats of Flex Seal offers more protection and creates a more durable barrier against moisture and pests.

Remember, the first coat penetrates the wood fibers and seals them, the second coat strengthens this seal, and the third coat offers additional environmental protection.

So, ensure you’re giving your wood the protection it deserves.

Patience Pays Off

Let each layer of Flex Seal dry completely before applying the next one.

While it might be tempting to rush the process, remember that the drying and curing stage is crucial for the success of this project.

Moreover, rushing might lead to trapping moisture in the wood, which can further accelerate decay.

Regular Maintenance and Inspection

Finally, regular inspection and maintenance are key.

After treating the rotted wood with Flex Seal, make sure to regularly check the treated areas for signs of new rot or decay.

The sooner you spot potential issues, the easier they’ll be to fix.

And there you have it! With these tips in hand, you’re now well-prepared to tackle that rotted wood with Flex Seal.

Just remember, Flex Seal is an excellent tool for managing rot, but it’s not a definitive cure for severely rotted wood.

How Long Does Flex Seal Take to Dry On rotted Wood?

Flex Seal takes 2 – 3 hours to dry on rotted wood while it takes around 24 hours to fully cure.

But drying time is hugely dependent on the wood type, humidity, climate changes, thickness of the Flex Seal coating, and many more.

How Do You Know If Wood Is Rotting?

You can identify whether the wood is rotting or not by inspecting its surface. Mushroom-like fungus area with spore dust indicates that the wood is rotting.

The smell is also different from the musty smell.

Other than that, the wood discoloration, change in size, cracks, and splintering are good indications to identify the wood is rotting.

Here’s the list of signs of rotting wood,

- Discoloration: Wood affected by rot will often change color, becoming darker or lighter than the surrounding wood. This could be a sign of either wet or dry rot.

- Soft or Spongy Texture: A clear sign of rot is if the wood feels soft or spongy when touched. A probe or screwdriver can easily penetrate rot-infested wood.

- Shrinkage: As the wood breaks down from the rot, it can begin to shrink in size. This can result in noticeable gaps or cracks in the woodwork.

- Musty Odor: A musty, damp smell often accompanies wood rot. This is more noticeable in closed, less ventilated areas.

- Visible Fungal Growth: This might look like a white or grey cotton-like growth on the wood or could be a mushroom-like body. If you see this, the wood is suffering from a severe rot infestation.

- Wood Dust or ‘Frass’: Wood dust or frass is often a sign of an insect infestation, which can lead to rot. It’s essentially the excrement of wood-boring insects and is usually found near the entry holes they create.

- Uneven or Warped Surfaces: As the wood structure weakens due to rot, it may warp or buckle, resulting in uneven surfaces.

- Crumbling Wood: If the wood crumbles easily when touched or poked, it is likely rotted and should be replaced or treated.

Hope you learned everything you wanted to know about using flex seal on rotted wood.

So, let’s answer some frequently asked questions as well.

FAQs

Can Flex Seal repair severely rotted wood?

While Flex Seal can help seal and protect rotted wood from further damage, it isn’t designed to restore severely rotted wood. If the wood is extensively decayed, it may need replacement or professional intervention.

How many coats of Flex Seal should I apply on rotted wood?

For the best results, it’s recommended to apply at least three coats of Flex Seal on rotted wood. Each coat serves a distinct purpose: penetration, sealing, and environmental protection.

Can I apply Flex Seal on damp wood?

For optimal results, it’s best to apply Flex Seal on dry wood. Applying it on damp wood can trap moisture beneath the sealant, potentially leading to further rot.

Is Flex Seal the best sealant for rotted wood?

While Flex Seal is a great option for sealing and protecting rotted wood, it may not be the best choice for restoring it. Epoxy is often considered the best sealant for rotted wood due to its ability to fill cracks and create a hard, durable surface.

Can Flex Seal prevent wood from rotting?

Yes, Flex Seal can help prevent wood from rotting by creating a moisture-resistant barrier. However, it should be used as a preventative measure on healthy wood or mild rot, not on severely rotted wood.

Did I cover all you wanted to know about: Can You Use Flex Seal on Rotted Wood?

In this article, we have deeply explored whether can you use Flex Seal on rotted wood, what are the pros and cons you’ll get by applying Flex Seal on rotted wood, and how to prepare rotted wood for Flex Seal.

Flex Seal works well on rotted wood only after the rotted area is repaired. Other than that, you should never apply Flex Seal on rotted wood because it’ll seal the wood while the moisture inside which will cause wood to rot faster than before. Repairing is a must before Flex Seal.

Furthermore, I’ve answered some frequently asked questions as well.

Hope you have gained good knowledge about using Flex Seal correctly on rotted wood with the most simple and accurate method.

Keep practicing to become a pro at using Flex Seal to repair your rotted wood projects!