Ever wondered if Flex Seal is your wood’s best ally or a waste of time? Dive in to unveil the truth!

Flex Seal is a liquid rubber sealant coating that use to avoid corrosion, stop leakages, and repair products and other constructions in your home or working area.

It works pretty well with PVC, copper, metal, glass, and many other materials.

But when it comes to the woodworking world, most people are curious whether Flex Seal works on wood or not.

I did a research about this with the help of professionals and able to gather lots of details.

Now with years of experience, let me tell you how flex seal deal with woods.

So, let’s discuss, Can you use Flex Seal on wood?

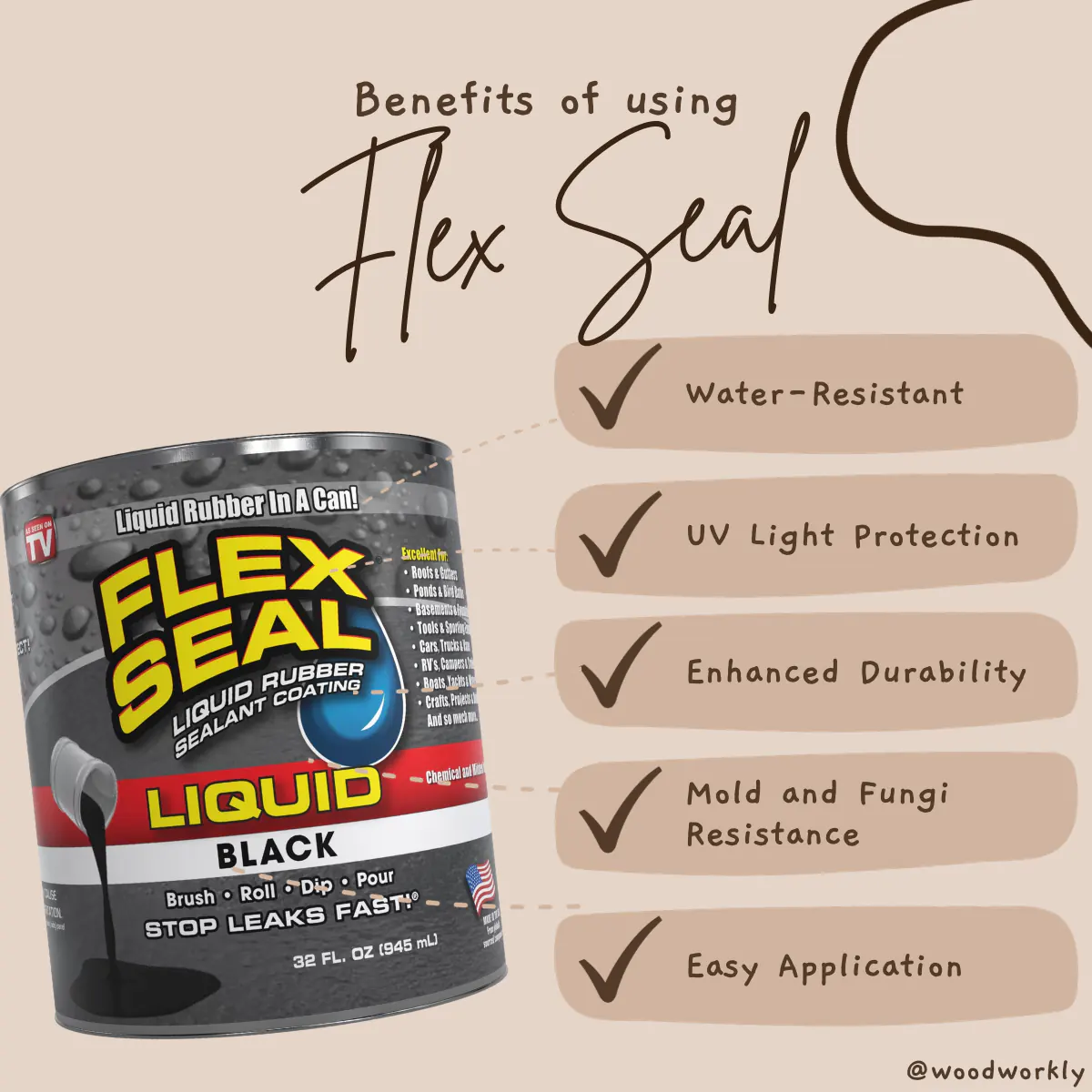

Yes, you can use Flex Seal on wood. It makes the wood waterproof, rot-resistant, and scratch-resistant. Flex Seal coating protects indoor and outdoor furniture from UV light, moisture, and fungi attacks. Flex Seal penetrates through wood fibers and protects the wood inside and seals it.

But that’s a quick snapshot and there’s a lot more to know about Flex Seal on wood.

In this article, I’ll explore can you use Flex Seal on wood, how Flex Seal work on wood decks, posts, floor, fences, and other woodworks, how to use Flex Seal on wood and so much more.

Furthermore, I’ll answer some frequently asked questions about using Flex Seal on wood as well.

Let’s jump in!

Does Flex Seal Work on Wood?

Yes, Flex Seal works so well on wood. It makes a coating that protects wood from rotting, moisture, scratches, and direct sunlight.

Spraying Flex Seal, will make a rubberized watertight barrier on the wood surface.

Flex Seal works great on wood. It is easy to use. It finishes any woodworking project or furniture better than most finishing products.

Flex Seal is better and easy to use than epoxy which is known as one of the most popular wood finishing products.

Usually, Flex Seal works better on dry wood than wet wood, because Flex Seal does not stick well on wet wood.

Therefore, make sure to apply Flex Seal always when the surface is dry. Therefore, think twice before applying Flex Seal on rotten wood.

Generally, 2 -3 coats of Flex Seal are recommended to apply on wood. Each coat of Flex Seal treats the wood in different ways.

First coat of Flex Seal on wood

Once you apply the first coat of Flex Seal on the wood surface, it will penetrate through the wood fibers and protect the wood from the inside.

Second coat of Flex Seal on wood

The second coat of Flex Seal bonds with the first coat and seals the wood.

Third coat of Flex Seal on wood

The third coat of Flex Seal sits on the second coat and provides water-resistant, wood warmth, and scratch-resistant qualities to the wood.

As you can see Flex Seal is a complete package that helps the wood to get protected from environmental elements such as moisture, UV light, fungi attacks, moldings, and many more.

Flex Seal protects wood from rotting and decaying as well.

So, let’s have a look at sing Flex Seal on different furniture and woodworks and how it works on them.

Flex Seal on Wood Decks

You can use Flex Seal on any type of wood deck. Flex Seal makes the wood deck water-resistant and prevents it from rotting.

If seal and fill cracks and splits of wood decks.

The drying time of Flex Seal on a wood deck is around 2 to 3 hours and the curing time is around 24 hours.

But this can differ according to the area where your wood deck is placed. If it is in a less humid area, the Flex Seal will dry faster.

Once the Flex Seal is completely dried, you can paint the surface. Flex Seal is paintable but unfortunately not sustainable.

The only issue with using Flex Seal on the wood deck is the cost. Three coats of Flex Seal use on the wood deck for maximum results and gallon sizes are expensive compared to their coverage area.

Therefore, you can easily replace the previous deck with a new one with the money you spend to buy Flex Seal.

Flex Seal on Wood Posts

You can use Flex Seal on wood posts. Wood posts are outdoor woodworks that can be protected by applying Flex Seal from water and direct sunlight.

Flex Seal makes a coating that makes wood posts water-resistant and rot-resistant.

UV light can harm the structure of wood posts and darken them. The UV stabilizers contained in Flex Seal are useful to protect from UV light.

Some Flex Seal products have fungus and mold inhibitors that are useful to protect themselves from fungi attacks.

However, Flex Seal helps wood posts to get protected from any kind of outdoor environmental elements and increase their lifetime.

Flex Seal on Wood Floor

Flex Seal is not a good choice for the wood floor because it does not hold foot traffic so long. Yes, it seals and protects wood from cracks and moisture, but over time it will peel off due to the foot traffic.

Epoxy is a better choice for wood floors rather than Flex Seal with proper surface preparation.

Flex Seal adds flexibility to the wood floors rather than drying them completely. This makes it perfect for making baseboard out of composite instead of wood.

It’s not a wise decision to spend money on sealer for a wood floor that cannot barefoot traffic well.

Flex Seal on Wood Fence

Same as wood posts, Flex Seal is perfect for wood fences.

It protects the wood fence from UV light and makes a coating that provides water-resistant and scratch-resistant abilities to the wood.

Apply Flex Seal on the wood fence when it is fully dried because Flex Seal does not work well against wet surfaces.

Try to buy Flex Seal products that contain UV and fungi inhibitors, because UV light and fungi attacks are the worst enemies of exterior woodworking projects.

Flex Seal on Wood Siding

Flex Seal works well on wood siding. The only issue is the expensiveness of the product.

Because an outdoor woodworking project like finishing wood siding with Flex Seal has high coverage area plus it requires a lot.

Therefore, make sure to apply Flex Seal correctly on wood siding with one shot, otherwise, it can be a waste of money and time.

Epoxy paint is cheaper and does a better job at finishing wood siding than Flex Seal does.

Now you have a crystal-clear idea about how Flex Seal works on wood decks, siding, fences, posts, and floors.

So, let’s focus on how to apply Flex Seal correctly on wood with the simplest method, Flex Seal is an expensive product and there should be no wastage when using it. Let’s see how to do that!

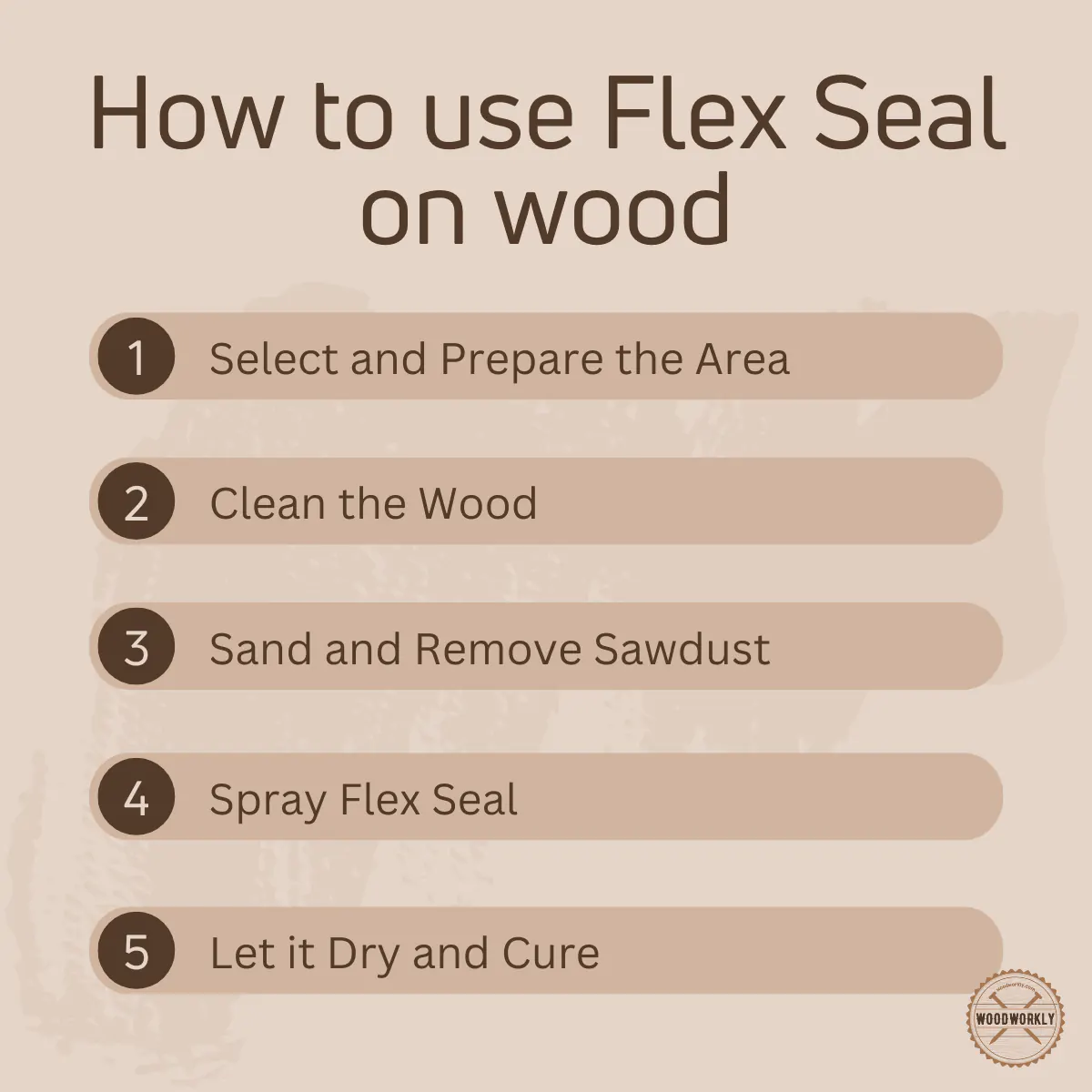

How To Use Flex Seal on Wood?

Flex Seal is easy to use on wood. it makes a protective coating over wood with 2 – 3 coatings that help to increase the durability and the wood resistance against, moisture, UV light, and fungi attacks.

So, let’s have a look at how to use Flex Seal on wood perfectly.

Supplies You Will Need,

- Flex Seal product

- Woodwork or furniture

- Damp cloths

- 220 grit sandpaper

- Gloves

Here are the steps you need to follow when using Flex Seal on wood,

- Select and prepare the area

- Clean the wood

- Sand and remove sawdust

- Spray Flex Seal

- Let it dry and cure

So, let’s discuss each of the above steps in detail to get a clear idea of using Flex Seal on wood.

Tip:

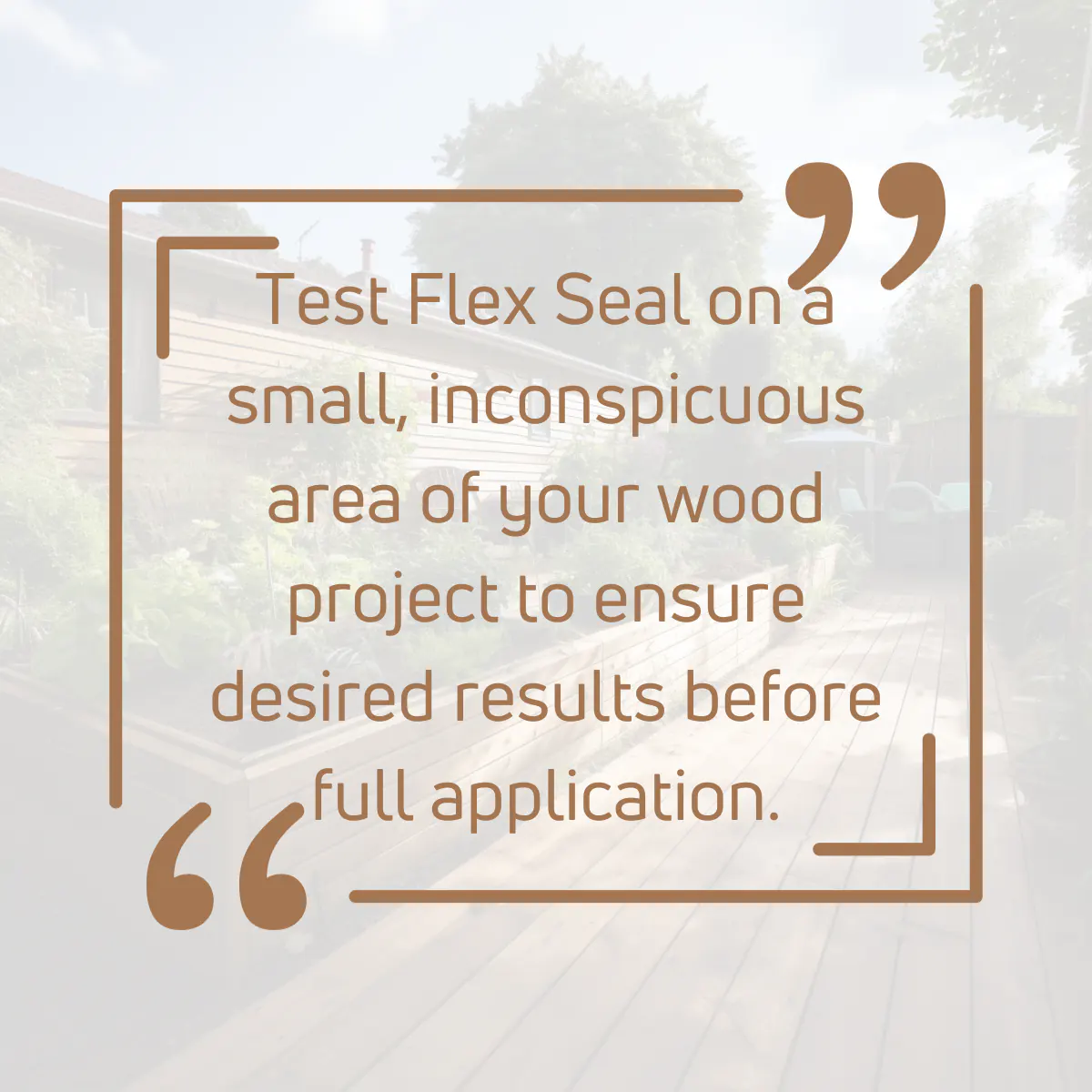

Before using Flex Seal directly on main woodwork or furniture, better to test it out with a scrap wood piece from the same wood to check how Flex Seal goes with your wood.

When you get satisfactory results with scarp wood, try the same procedure for the main project to get the best results without making any mistakes.

1. Select and Prepare the Area

Area preparation is really important before applying Flex Seal on wood.

Find a well-ventilated area with good air circulation because Flex Seal is a highly chemical compound that can cause breathing issues.

Your garage is an excellent place to use Flex Seal on wood with doors open. Other than that you can use a room with windows open and a fan running.

Plus, you can use the backyard for this project only if the weather is good with no rain, snow, sleet, or dew.

If you want to spray only a selected area of woodwork or furniture, cover other areas with a drop cloth.

This will prevent spraying Flex Seal on unnecessary areas.

Make sure to use an area with enough space to gain the best results.

2. Clean The Wood

Cleaning is an essential part of any wood finishing project because if dust and debris get trapped inside the Flex Seal coat, we are unable to get the maximum performance out of it.

Wipe down the whole wood surface with a clean rag without missing any spots. Or you can use a cleaning solution to clean the surface.

You can use soapy water as a cleaning solution. Mix dish soap and water well and dip clean rag, soak it in the soap water and wipe the entire surface to eliminate dust and debris.

After cleaning the wood, let it dry completely before moving to the next step.

Even though Flex Seal works on a wet surface, I highly recommend you apply it on a dry surface for excellent results.

3. Sand and Remove Dust

After cleaning the wood properly, and the entire surface with 220 grit sandpaper to eliminate surface randomness and make the surface ready to accept Flex Seal evenly.

Sand along the direction of the wood grain, if possible, to prevent surface scratching.

Never use higher-grade sandpapers because they might harm the wood and ruin the appearance of the furniture.

Once you’re done with sanding, clean the whole surface with clean rags to remove sawdust.

When you feel the surface is nice, smooth, and clean, you’re good to start the spraying step.

4. Spray Flex Seal

Now you have reached the most important step in using Flex Seal on wood. Shake your Flex Seal can well vigorously for about a minute and aim the nozzle of the spray at the woodwork or furniture.

Then, spray Flex Seal in sweeping motion by keeping a distance of 10 to 12 inches.

Don’t spray too fast, identify, and focus more attention on cracks and gaps on the wood surface and spray them slowly and evenly.

Make sure not to miss any spots during spraying because it’s a little bit difficult to identify the missing spots once it is fully applied.

Apply 3 coats of Flex Seal on wood to get the maximum outcome. The first coat of Flex Seal penetrates through wood fibers, the second coat will bond with the first coat and seal the wood.

The third coat makes a coating that protects wood from scratches, moisture, UV light, and other environmental elements.

5. Let It Dry and Cure

Make sure to let the Flex Seal settle and dry on the wood surface between coats for about 24 hours before applying the next coat of Flex Seal.

After applying all the coats of Flex Seal, let the wood dry for 24 hours and allow it to cure for about 48 hours before using it.

Never apply seal coat when the previous coat is still wet because it can ruin the wood appearance and waste the Flex Seal.

The drying time and curing time can differ according to the environmental humidity, wood type, and climate changes.

If you need more info about Flex Seal, read the manufacturer’s guidelines.

How Long Does Flex Seal Last on Wood?

Flex Seal last on wood for around 30 years because it does not deteriorate, fade, dry, crack, or yellow.

Flex Seal is better in durability than any other wood sealer on the market. By applying Flex Seal using proper methods, you’ll be able to use your loving indoor or outdoor woodwork or furniture over decades.

How Long Does Flex Seal Take to Dry On Wood?

Flex Seal takes 2 – 3 hours to dry on wood while it takes around 24 hours to fully cure.

But the drying time is hugely dependent on wood type, environmental humidity, the thickness of the coating, and temperature levels.

Even though Flex Seal works well on wet surfaces, better to apply it on dry surfaces to get the maximum out of it. It.

Therefore, drying is so important when using Flex Seal on wood.

Does Flex Seal Work on Plywood?

Flex Seal does not work well on plywood because Flex Seal is only water-resistant, not waterproof.

That means under high humidity and extremely high moisture conditions, the water has the ability to penetrate through the plywood, especially when using it outside.

Therefore, better not to use Flex Seal on plywood.

Does Flex Seal Work on Treated Wood?

Yes, Flex Seal works well on treated wood. Apply 3 coats of Flex Seal on treated wood for the best.

Flex Seal protects treated wood from moisture, UV light, and fungi attacks. It stops the wood from rotting and decaying and increases the durability of the treated wood.

Does Flex Seal Work on Painted Wood?

Yes, Flex Seal works well on painted wood, but the paint coatings need to be completely dried before applying Flex Seal on top of that.

Flex Seal works great on both latex paints and oil-based paints.

Drying between each coating is highly necessary to avoid getting a blotchy, splotchy, or tacky surface.

Other than that, you can peel off the paint layer completely and apply Flex Seal liquid on the wood after sanding and smoothing the surface to provide better protection to the wood.

That’s its folks! Now you know how to use Flex Seal on any wood properly without making any mistakes. Flex Seal is expensive enough to do the job correctly with a shot.

So, let’s answer some frequently asked questions about using Flex Seal on wood.

FAQs

How Many Coats Of Flex Seal Do I Need?

Typically, applying 2-3 coats of Flex Seal ensures optimal wood protection. Each coat performs a distinct function, contributing to the wood’s overall resilience and longevity.

How long does Flex Seal take to dry on wood?

Flex Seal typically takes 2-3 hours to dry and around 24 hours to fully cure on wood, although these times can vary depending on environmental conditions.

Is Flex Seal effective on treated wood?

Flex Seal works well on treated wood, protecting it from environmental elements when applied in 3 coats to ensure optimal effectiveness and durability.

Can Flex Seal be used on plywood?

Flex Seal is not recommended for plywood as it is porous and might not provide a strong, adequate seal, especially in highly humid or wet conditions.

How to apply Flex Seal on wood?

Flex Seal is applied by cleaning and preparing the wood surface, spraying 2-3 coats of the product while ensuring each coat dries before applying the next, and then allowing a full cure.

Does Flex Seal last long on wood?

Flex Seal can last for several years on wood when properly applied, offering a durable seal that withstands various environmental conditions and wear.

Did I cover all you wanted to know about: Can You Use Flex Seal on Wood?

In this article, I have deeply discussed, the can you use Flex Seal on wood by taking common examples like using Flex Seal on wood decks, posts, fences, floors, and sidings. Then we talked about how to use Flex Seal on wood with the simplest and most accurate method.

Flex Seal can be applied to wood, offering protection from moisture, UV light, and fungi. It creates a durable, rubberized, waterproof coating. Apply 2-3 coats for optimal results. Not recommended for plywood or high-traffic wood floors.

Furthermore, I’ve answered some frequently asked questions about using Flex Seal on wood as well.

How you have sharpened your knowledge about Flex Seal from his article.

So, let’s begin and finish your next woodworking project with Flex Seal to get more practical knowledge of using it. Keep practicing!