Ever wondered how many coats of polyurethane will give your woodwork that pristine finish? Let’s find out!

My father had a wooden chair that was given to him by his grandparents, and it was one of the most valuable gifts he had ever received.

Eventually, the chair started deteriorating due to a lack of proper protection against wood degradation.

I decided to preserve this beautiful piece of furniture using polyurethane, but I had no idea how many coats to apply.

So, I did some research with the help of wood-finishing experts and gathered a lot of information about polyurethane coats.

Let’s find out, How Many Coats of Polyurethane?

Apply at least two or three coats of oil-based polyurethane are necessary for long-lasting protection. For water-based polyurethane, apply four to five coats. If your wood is exposing heavy foot traffic, more than three layers are needed. Multiple, thin layers are crucial for an even and flawless finish.

But there’s a lot more to learn.

In this article, I’ll explore how many polyurethane coats should you apply to give ideal protection to the wood, the difference between water-based and oil-based Polyurethane coating, and the benefits and steps of application of polyurethane on different surfaces.

Plus, I’ll share some important tips that I have learned along the journey as well.

So, let’s dive in!

What is Polyurethane?

Scientifically speaking, polyurethane is a synthetic polymer that is made up of a combination of two chemical compounds called urethane and polymer.

Because of its plastic nature, it can be manipulated into different velocities depending on the necessity from a soft and flexible foam nature to a strong, rigid form.

So let’s discuss the types of polyurethane available in the market.

Types of Polyurethane

Polyurethane’s versatile ability arises from the changing chemical composition gained during the manufacturing process.

It has thus become a commonly utilized polymer in the commercial world.

There are various types of polyurethane including Flexible Polyurethane Foam, Rigid Polyurethane Foam, Elastomers, Coatings and Adhesives, Sealants, and many more.

Flexible Polyurethane Foam

This type is used in mattresses, pillows, and automotive interiors due to their lightness, durability, supportiveness, and comfortability nature.

Rigid Polyurethane Foam

This type is commonly used in insulation procedures such as roof and wall insulation, as well as the production of lightweight construction materials.

Elastomers

These are abrasion-resistant, flexible, and long-lasting materials used to produce medical equipment, footwear, gaskets, automobile parts, etc.

Sealant

Because of their flexibility and durability, they are utilized to seal gaps and joints in the automotive and construction industries.

Polyurethane for Coatings and Adhesives

Polyurethane coatings which are in liquid forms and paints are widely used for surface protection, aesthetics, and to gain durability on surfaces such as wood, metals, and concrete.

You can also use polyurethane over painted surfaces.

Polyurethane adhesives provide excellent adhesion to plastics, metals, and wood.

What is Polyurethane Coating?

Polyurethane coating also referred to as polyurethane finish is the application of polyurethane to surfaces such as wood, metal, and concrete to enhance the appearance, protection, and increase durability.

For wood finishing, a liquid form of polyurethane is used.

There are two types of polyurethane finishes available in the market which are oil-based and water-based polyurethane.

Read to know, Is Polyurethane Waterproof? Here’s the Truth!

Water-Based Polyurethane Coating vs. Oil-Based Polyurethane Coating

Oil-based polyurethane coating has been there for the longest time in the market while water-based polyurethane coating became popular recently.

Polyurethane coating is made by combining polyurethane resin with alkyd paint.

Most of the oil-based varnish present in the market contains alkyd.

So mixing polyurethane properly can result in a more durable polyurethane coating.

This combination strengthens the surface’s resistance to heat, scratches, and water.

For a water-based polyurethane coat, use acrylic resins instead of alkyd resins.

Water-based and oil-based Polyurethane coating differ in chemical composition and because of this the surface appearance and also the resistivity level may vary.

However, choosing the right wood surface can bring many benefits.

Water-Based Polyurethane

Water-based polyurethane coatings have been popular for many reasons because of their low odor during application and drying, as well as their environmental friendliness due to their low volatile organic compound composition when compared to oil-based polyurethane.

Water-based polyurethane requires a few hours to dry like 6-12 hours. This is half the time required to dry oil-based polyurethane.

However, water-based polyurethane provides thin coats. So multiple coats, at least three coats are needed to achieve the same level of protection as oil-based polyurethane.

Furthermore, these are more expensive than oil-based Polyurethane.

There is a potential for wood grain raising or swelling with water-based polyurethane.

Therefore, It is better to apply additional sanding between coats.

Oil-Based Polyurethane

Oil-based polyurethane is more popular due to having strong and long-lasting finish to the wooden surface.

This type can produce thicker, amber-like hue coats and needs to apply fewer coats like two or three coats to get the desired appearance.

Oil-based polyurethane takes a longer time to dry due to its thickness.

Moreover, since it contains a higher amount of volatile organic compounds it has a stronger odor than water-based polyurethane.

So, if you wish to apply oil-based polyurethane, your wood surface should be in a well-ventilated area, to prevent suffocation.

This oil-based polyurethane coating may require multiple days Because, to apply multiple coats, the previous layer needs to be completely dry.

The drying time is relatively longer than water-based Polyurethane.

Is One Coat of Polyurethane Enough?

In most cases, one coat of polyurethane may not be enough to get a smooth, even finish and adequate protection. Because you will see brush marks after applying the first coat.

For example, if you use a water-based polyurethane, most of the time you require a second coat.

If you don’t know the exact number of coats that need to apply, don’t need to worry about that.

Now there is a solution to that. Some manufacturers have developed one-coat polyurethane or triple-thick poly!

However, since both products are thicker than oil-based polyurethane, it is much more difficult to apply than the three-time application of normal Polyurethane.

So, I don’t think single-coat polyurethane will work and you may not get the desired finish.

How Many Coats of Oil-Based Polyurethane?

Normally, it requires three or four coats of oil-based polyurethane. The first coat is needed to seal the surface and for good adherence.

The second coat will increase the durability. Applying the third and fourth coats will ensure a long-lasting and strong barrier.

If you need a glossy appearance, you can apply more coats.

Although oil-based polyurethane is thick, you may require many coats to ensure entire surface protection.

Tips for Applying Oil-Based Polyurethane Coating

- Choose a high-quality brush or applicator pad to minimize any brush marks and drips.

- Apply thin layers rather than one thick coat. To get a smooth, durable finish, multiple thin coats are required.

- Thinning of Polyurethane will reduce the time required for the drying process.

- Don’t apply too many coats on the surface. Because it will take a long time to dry and may appear fine at first, but there is a chance that it will become yellow or peel.

- During the application process, brush should be done along the wood grain but not against it, to ensure even output.

How Many Coats of Water Based Polyurethane

You need to apply at least three coats of water-based polyurethane coats to get even smoother appeal and protection.

The main reason that requires multiple coats is that water-based polyurethane is thinner.

If you are going to apply Water Based Polyurethane into areas with high footprint traffic, you should use more layers to ensure long-term protection.

Tips for Applying Water-Based Polyurethane Coating

- Use a brand new, bristle brush when applying polyurethane.

- Don’t sand too hard after applying a water-based polyurethane coat. Otherwise, dried polyurethane may be completely removed.

- Be generous when applying the polyurethane.

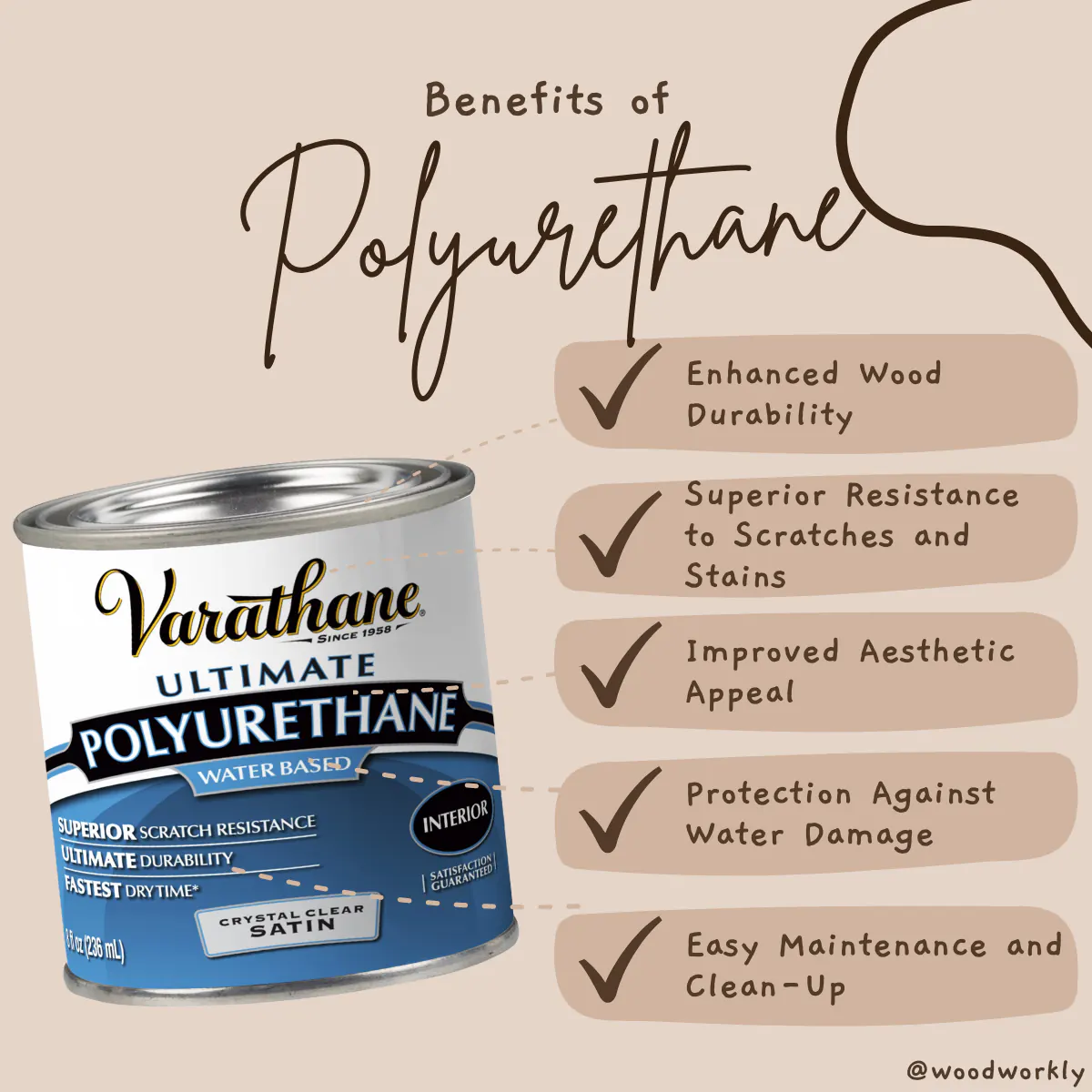

Benefits of Using a Polyurethane Coating

Polyurethane coating has become popular due to various benefits.

Provide Extra Protection to Your Surface

Polyurethane coating serves as a transparent and smooth surface to your wood with protection against various chemicals such as oils, acids, and various solvents.

Also, this provides Water resistance to frequent water spilling while making it more suitable to coat outdoor applications.

Check out the Best Exterior Polyurethane (Tested & Reviewed!)

Furthermore, polyurethane coating gives resistivity to abrasions and surface damages that frequently occur in flooring, countertops as well as coastal structures, etc.

Not only that, If you have outdoor wooden decks with frequent exposure to UV, apply polyurethane with UV resistivity.

High Versatility

As mentioned above, the high level of versatility of polyurethane makes it.

It can apply a wide range of surfaces made up of steel, wood, stone, and many more.

Enhanced Appearance

Polyurethane coating can enhance the natural beauty of the wood while making it more smooth.

If you apply it to the stone, it gives a glossy, reflective finish that looks amazing under light.

When Polyurethane is on metal it gives a shiny appearance along with easy cleaning ability.

You need to choose according to your preference as it is available in different sheens to increase the desired aesthetic effect on your surface.

Safety

After the curing process, it doesn’t emit any vapor that harms the health and it is exposed to high temperatures or humidity for a long time as well.

But keep in mind, when spraying it is necessary to wear a respirator and necessary safety gear.

Durability

Polyurethane coating provides exceptional durability by making a tough, protective layer to the wood surfaces even with high furniture and foot traffic.

Easy Maintenance

Surfaces coated with polyurethane are relatively easy to clean and maintain.

They can be cleaned with mild soap and water, reducing the need for tedious maintenance.

How to Apply Polyurethane Coating?

Here is the procedure you need to follow when applying polyurethane coating,

- Gather all necessary tools and materials.

- Prepare and clean the wood surface.

- Stir the polyurethane.

- Apply the first coat.

- Allow the surface to dry.

- Sand the surface.

- Apply the second coat.

So, let’s discuss each of the above steps in detail to apply polyurethane coating properly on any wood without messing things up.

1. Gather All Necessary Tools and Materials.

Here are the supplies you need to collect before the application of polyurethane,

- Safety goggles and protective gloves

- Respirator mask

- Oil-based and water-based Polyurethane coating- Based on your preference

- Paintbrush

- Stir stick

- Sandpaper

- Clean and damp cloth

2. Prepare and Clean the Wood Surface

First, you need to make sure the surface is free from dust, dirt, and debris.

So, sand the surface to remove any old finishes and imperfections. Otherwise, it may form lumps and bubbles under the polyurethane.

3. Stir the Polyurethane

Use a clean stir stick to mix the product to ensure equal distribution of the compounds in the mixture.

Prevent vigorous shaking, because it can introduce bubbles.

4. Apply the First Coat

Use a bristle brush to apply the Polyurethane layer.

In the first coat, there is no need to thin out the mixture and this will allow Polyurethane to properly adhere to the wood surface.

If your wood is previously Polyurethane coated, you need to thin it out the product.

How to Apply Oil-Based Polyurethane

Because of its thickness, an oil-based polyurethane ether foam brush or bristle brush can be used to apply it.

Dip the brush directly into the mixture to avoid form formation and apply evenly.

Tap into the tin’s middle to remove extra polyurethane.

How to Apply Water-Based Polyurethane

Because water-based polyurethane is thinner, apply with a cloth or a foam.

Always avoid wood grain rising from the wood surface.

5. Allow the Surface to Dry

Allow the first coat to dry well. Follow manufacturers’ manufacturer-recommended drying time.

Normally, oil-based polyurethane takes 24-36 hours to dry while water-based Polyurethane takes less time than oil-based Polyurethane and it will be around 6-12 hours.

6. Lightly Sand the Surface

After the first coat gets dry, use light grit sandpaper (e.g., 220-grit) to lightly sand the surface.

Light sanding helps to build a good adhesion between polyurethane coats without occurring any layer separations.

Then make sure to wipe away all the dust and debris by using a cloth.

7. Apply the Second Coat

After sanding and cleaning the surface, you can apply the second coat. Depending on your project the second coat can be the final coat.

But for better outcomes or to remove any brush lines, you may apply multiple coats.

Let each coat dry before applying the next layer. You can sand lightly in between layers as you desire a smooth finish.

Number of Polyurethane Coats for Different Products

The number of polyurethane coats depends on,

- The type of surface

- Desired finish

- Type of Polyurethane used

- Environmental conditions

Now I’m going to explain to you how many polyurethane coats you should go with for different woodworking applications.

Number of Polyurethane Coats By Surface

If your wood surface is new, it may require 2-3 layers of polyurethane for furniture, and for hardwoods, it is three to four layers.

If you wish to recoat already coated furniture, you will only need 1-2 layers.

For concrete floors, 2-3 layers of polyurethane may be required to gain protection and enhance the appearance with a glossy texture.

Typically, 2-3 coats may be enough to finish metal furniture for better protection against corrosion.

For wood furniture, it is enough to apply two coats of polyurethane to gain the desired outcome.

But if your furniture is subjected to frequent routines like chairs, and tables additional layers of polyurethane are required.

So let’s see the number of coats needed for wood furniture with different surfaces.

How Many Coats Of Polyurethane For Outdoor Furniture

Outdoor furniture is frequently exposed to various weather conditions including sunlight, rain, temperature fluctuations, UV rays, etc.

For those, you can apply three coats of water-based polyurethane with UV-resistant quality.

How Many Coats Of Polyurethane on Doors

The number of coats needed widely depends on the material that the door is made of and the place where the door is.

If your door is an interior one, two coats may be enough, and for an exterior one three or four coats of polyurethane is enough to get a good outcome.

Metal and fiberglass doors require only one to two coats because they are strong on their own and naturally resist corrosion and scratches.

How Many Coats Of Polyurethane on Stained Wood

Apply 2-3 coats of water-based polyurethane to stained oil-based furniture. Furthermore, it may tend to raise wood grain due to water-based polyurethane.

Then, apply more coats to gain a smooth finish.

How Many Coats Of Polyurethane On Wood Floors

Wood floors are constantly exposed to foot traffic.

If you are going to use water-based poly on wood floors, better to apply three to four coats of polyurethane check for the desired shine, and apply more coated if required.

How Many Coats Of Polyurethane On Kitchen Table

Kitchen tables are constantly exposed to liquid spills, heat damage, scratching, and other hazards.

As a result, kitchen table requires increased protection and durability. To withstand tough conditions, three coats of polyurethane need to be applied on the kitchen table.

How Many Coats Of Polyurethane On Cabinets

Apply three or more coats on your cabinet to make it look new and professional. More layers may result in better finishing.

Bathroom cabinets are often subject to moisture and humidity. To withstand it, you need to apply more than three coats.

How Many Coats Of Polyurethane On Stairs

Stairs typically show signs of wear and tear. Since stairs need strong protection, apply three coats of polyurethane on stairs.

Furthermore, the stairs should not be slippery. To enhance safety, polyurethane with anti-slip compounds is suitable.

Now I’m going to share with you some tips and tricks that I’ve learned by working with polyurethane for a long time.

These will help you to get a nice and even polyurethane finish without making any polyurethane mistakes.

Tips For Applying Polyurethane Coating

I remember the first time I took on a project that involved applying a polyurethane coat; the anticipation, the learning curve, and oh, the satisfaction of seeing the final outcome.

Let me share with you some tips that I’ve gathered from personal experiences and the golden nuggets of wisdom shared by other experts online.

Choose Your Tools Wisely

First, let’s talk about what my uncle always emphasized – having the right tools.

A smooth application starts with using the right brushes or rollers.

You know, the synthetic brushes have worked wonders for me, especially for water-based polyurethane.

Personal Tip: Always invest in a high-quality brush. It might be a bit pricey but believe me, it’s worth every penny.

You wouldn’t want to spoil your project with streaks or brush hairs, would you?

Read to know, How to Clean Polyurethane Brush!

Timing and Environment

Setting up the right environment is often an overlooked yet critical aspect.

I learned this the hard way when I had to redo my living room floor because the humidity messed up the first coating.

A Little Anecdote: There was this one time when I decided to work late into the night, thinking the cool temperature would be an advantage.

But the dew that settled overnight affected the finish, leaving it with an uneven sheen.

Now I know – always check the weather and make sure to work in controlled conditions, ideally between 50-90 degrees Fahrenheit.

Sanding is Your Best Friend

Remember that time you prepared a meal and realized that the prep work took longer than the actual cooking?

Well, polyurethane application is somewhat similar. Sanding, akin to chopping your veggies finely, is vital.

A smooth, well-sanded surface will not only look better, but it will also ensure the polyurethane adheres well.

Expert Tip: Sand gently between coats with a fine-grit sandpaper to get that glass-like finish.

Patience Pays Off

Patience, my dear friend, is indeed a virtue in the world of polyurethane coatings. Allow ample time for each layer to dry before you apply the next one.

It’s tempting to rush, I know. I’ve been there, hurrying through the process only to end up with a surface that wasn’t quite what I envisioned.

Heartfelt Advice: Take a step back, enjoy a cup of coffee, and give it the time it deserves. A well-dried coat is key to achieving a splendid finish.

Cleanup and Maintenance

Lastly, let’s chat about the aftermath. Cleanup is as important as the application process itself.

A well-maintained brush can serve you for many projects down the line.

Personal Experience: In my early days, I would use the same brush repeatedly without giving it a proper cleanup, which led to a deteriorated finish over time.

Now, I make sure to clean my tools meticulously, ensuring they’re ready for the next project.

Congrats folks! Now you know how many coats of polyurethane should you apply on different occasions.

So, let’s answer some frequently asked questions.

FAQs

Can I Get Away with Just One Coat of Polyurethane?

No, One coat of polyurethane generally doesn’t offer sufficient protection. Trust me, adding at least one more coat will give you that rich, lasting finish that you’re yearning for!

Is Three Coats of Polyurethane Too Much?

Three coats of polyurethane aren’t “too much” by any standard; in fact, it’s just perfect for giving that depth and glossy touch to your wooden treasures. Imagine the sheen under your living room lights; splendid, isn’t it?

How Long Should I Wait Between Coats?

Typically, you should wait 4-6 hours between coats. Yes, it might test your patience, but remember, good things take time and you’re just setting the stage for a masterpiece!

What Happens if I Don’t Sand Between Coats?

While it might seem like a time-saver, failing to sand between coats can result in an uneven finish and poor adhesion of subsequent coats. Just a little light sanding, and you’re all set for a flawless finish!

Can I Mix Different Types of Polyurethane for Different Coats?

Mixing different types of polyurethane for different coats isn’t advised. Keeping a uniform type ensures consistency and that perfect, smooth finish we’re all after!

Did I cover all you wanted to know about: How Many Coats of Polyurethane

In this article, I’ve deeply explored how many coats of polyurethane should you apply on different applications and how the number of polyurethane coats depends on the type of polyurethane.

For a durable and smooth finish, apply at least 2-3 coats of polyurethane. Sand lightly between coats to ensure optimal adhesion and a flawless result. Allow adequate drying time between applications to achieve the best results.

Furthermore, I’ve answered some frequently asked questions as well.

you learned everything you wanted to know about, how many coats of polyurethane need to be applied on any indoor purpose. Give them a try and become a pro at wood finishing!