Tired of the ear-piercing noise from your Dremel? Discover actionable tips to silence it! Ever wondered if a quieter session of creativity and precision is possible? Read on!

The Dremel tool is a popular rotary power tool that comes with lots of accessories.

It can be used for sanding, cutting, polishing, cleaning, sharpening, and for many other endless opportunities in wood carving and metal cutting.

Dremel tools produce a lot of noise due to their high-spinning nature.

I was curious about this and did a deep research with the help of professionals to find a way to make it less noisy.

Thanks to experts I was able to find several quick and easy steps you can take to reduce the noise of almost any dremel.

Let’s discuss, How to make a Dremel quieter?

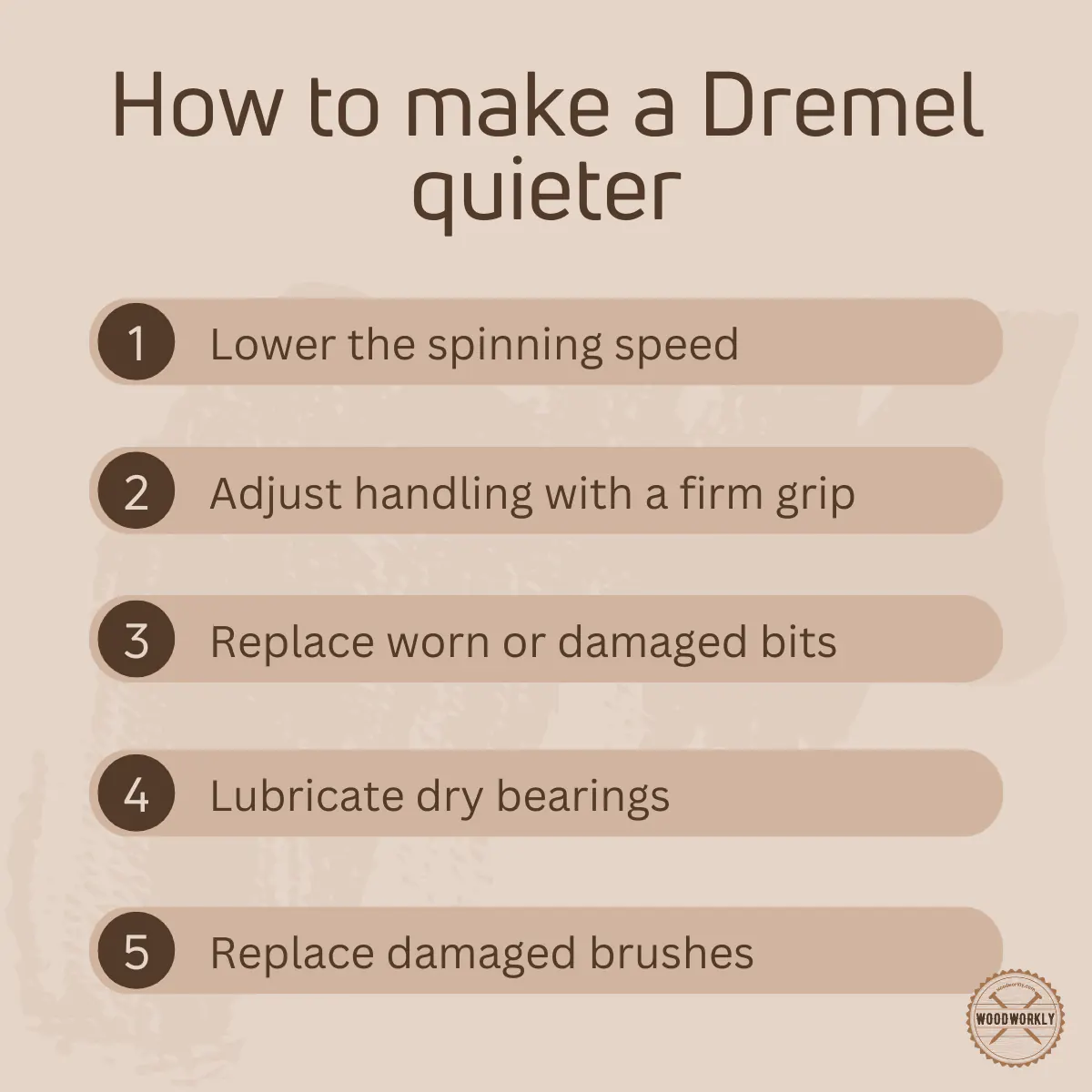

To make a Dremel quieter, lower its spinning speed, improve handling with a firm grip, replace worn bits, lubricate dry bearings, and change damaged brushes. Regular maintenance and proper use can effectively reduce noise levels. Cordless Dremel models or tools like Proxxon can also be quieter alternatives.

But there’s a lot more to know about making the Dremel quieter!

In this article, I’ll break down how to make a Dremel quieter, why your Dremel is so loud, the loudness of Dremel, and Dremel maintenance tips.

Furthermore, I’ll answer some frequently asked questions as well.

Let’s dive in!

Why Is Your Dremel So Loud?

Usually, Dremels are loud since they are power tools and use for cutting and grinding purposes.

When the Dremel is spinning at a very high speed, they make a lot of noise which can be very difficult for the user especially when the user is not wearing hearing protection.

Dremels make a lot of noise when cutting through wood and metals.

Make sure to wear earbuds to filter the noise when you’re working on wood carving projects using Dremel.

The noise of Dremel comes from bearings when spinning at high RPMs (rotations per minute).

When you’re cutting or shaping wood during carving projects, the noise comes because of small amounts that are slowly ground away by the disk and blade.

Here are the possible reasons why your Dremel is so loud,

- Dremel is spinning at high speed.

- Vibration due to wrong handling

- Wobbling bits of Dremel

- Dry bearings

- Damaged bearings

- Damaged brushes

If your Dremel is squealing that is because of high spinning speed, unnecessary vibration due to wrong handling, wobbling of bits, or dry and damaged bearings.

You can fix the above issues using some maintenance techniques. Other than that Dremel is a powerful tool that makes some noise. That is completely normal.

But if the Dremel is too loud even at low spinning speeds, there might be something wrong you should look at.

I meant, Yes Dremels are noisy, but they aren’t that loud. The noise is almost similar to a small hand drill, dental drill, or saw.

For example, if your neighbors keep complaining about its noise level, defiantly you should take all the possible actions. There’re might be something wrong with the machine itself which is not common.

To get a clear idea about the noise level of your Dremel, let’s see how loud Dremel should be.

How Loud Is Dremel?

Dremel runs at approximately 85 decibels and anything over 85 decibels can cause irreparable harm to your hearing with repeated exposure.

Therefore, be sure to wear hearing protection when working with Dremels for a long.

If your Dremel produces more than 85 decibels, you should take immediate action to stop that by fixing the issues.

Dremels are loud as hairdryers and gas-powered lawnmowers. But Dremels are quieter than circular saws which produce 95 decibels or hammer drills with 110 decibels.

85 decibels is the limit of safe hearing for 8 hours per day.

So, if you notice the Dremel is too loud or over 85 decibels which nearly sounds like a hammer drill or circular saw, take immediate action, and wear protective hearings when using it.

How To Silence A Dremel?

If the Dremel is too loud and nosy, you can silence or reduce the noise level by making some changes. Most of the time Dremels become extremely loud when they’re too old to use.

Dremel is a power tool that you cannot silence 100%. But you can reduce its noise level by fixing some internal issues.

Here are the fixes you should take to silence a Dremel,

- Lower the spinning speed of the Dremel

- Adjust the handling

- Replace bits

- Lubricate bearings

- Replace bearings

- Replace brushes

So, let’s discuss each of the above solutions to find a way to make the Dremel quieter.

1. Lower The Spinning Speed of Dremel To Make It Quieter

When the Dremel is spinning at high speeds, it makes a lot of noise. That’s how power tools work.

Dremel takes electrical energy from a battery or outlet and converts that into the kinetic energy of spinning and releases some energy such as heat and noise.

When the Dremel is spinning at high speed it needs a lot of power. When it grabs a lot of power from the battery or outlet, it spins fast and releases more energy as heat and noise.

This is how high spinning speeds contribute to the loudness of Dremel.

When the RPM (rotations per minute) is high Dremel makes a louder noise since it’s the size of the Dremel is small compared to the power it produces. Dremels make 5000 to 35,000 rotations per minute (RPMs).

Higher RPMs make the cutting and grinding process a lot easier, but at the same time, higher RPMs make a lot of noise.

By reducing the spinning speed of the Dremel you’ll be able to reduce the noise level it produces.

This weakens the efficiency of the cutting process, but it helps the hearing of you and your neighbors.

Please note that you can adjust and reduce the spinning speed of the Dremel only if it’s an adjustable one.

If your Dremel doesn’t have a speed adjusting button or switch, sad to say this method is not for you. Try replacing bearings and changing bits to reduce the noise.

2. Adjust The Handling To Reduce The Noise of Dremel

Dremels are loud and that’s completely normal at some point. But what if I told you there’s a method of handling the Dremel you can make it much quieter than before.

When you’re handling the Dremel, holding it in a comfortable position can be challenging since there’s no specific handle.

Some people tend to make walnut handles for Dremel and attach them to the Dremel body to make the Dremel easier to handle like this.

But on the other hand, this wrong handling technique can damage the productivity of Dremel a lot.

Because of not having a good grid around the Dremel body, it will eventually make a lot of noise when working.

Therefore, apart from going for the comforts, you should focus on making Dremel quieter by using proper handling techniques.

To make the Dremel silent, adjust your handling by using a firm grip around the central casing and try to handle the body of the Dremel by squeezing and compressing the central casing.

Holding the Dremel using a fine grip reduces the vibration when cutting and grinding and lowers the noise level.

Or try to hold Dremel with both hands with confidence. The target of this technique is to reduce the individual movement of Dremel’s body to reduce the vibration.

3. Replace Bits To Make The Dremel Quieter

Dremel has a wide range of drill bits. Due to the constant usage of drill bits, they tend to wear and tear over time.

Wearing and tearing of drill bits make the Dremel wobble. Wobble Dremel produces a loud nice that’s well above the normal range.

If your Dremel is too loud, you should immediately check the status of the drill bits. Immediately replace the damaged bits due to wear and tear with new ones to make the Dremel quieter.

You can replace drill bits of Dremel by reading the instruction manual that comes with Dremel. Turn into the “Changing Accessories” page and follow the instructions mentioned.

This differs according to the type of Dremel model.

You can purchase drill bits from any local hardware store or contact the manufacturer.

4. Lubricate Bearings to Make The Dremel Quieter

Most of the time Dremel makes a loud noise when working due to the dry bearings. Working with Dremel for a long time makes the bearings dry and worn.

If your bearings are in good shape Dremel makes less noise. So, the status of the bearings is a good indicator to identify the loud noise of the Dremel tool.

Dremel bearings need to be regularly greased or lubricated to prevent them from drying out. Regular usage makes bearings dry and eventually, they’ll damage due to high friction.

Therefore, make sure to grease or lubricate bearings regularly to keep your Dremel healthy without making high-pitch squealing.

Use light machine oil (silicon-based or grease) to lubricate bearings properly and to reduce the noise level of Dremel. Never use WD-40 or any other oils to lubricate bearings since they’re good for chain saws, not for Dremel bearings.

Here’s how to lubricate Dremel bearings properly to make them quieter,

- Put drops of light machine oil to the place that meets the shaft with bearings using a fine nozzle.

- Then spin the shaft using one hand.

- Now monitor how the bearing absorbs the machine oil inside

- Add another drop of machine oil through the nozzle and let it absorb into the bearing

- Repeat this until the bearing gets saturated with machine oil

- Stop the lubrication process once the machine oil sits off the surface or when the bearing stops sucking the oil in.

- Finally, clean the excess oil on the bearing surface with a cotton bud

After lubricating the bearing, let the Dremel run at a slow speed and check for high-pitch squealing. If the issue was due to the dried bearing, this should sort by now.

5. Replace Bearings

If your bearings are totally damaged and unable to restore by lubrication or too far gone the best step you should take to make the Dremel quieter is to replace the bearings with new ones.

Damaged bearing is a common issue for old Dremels. You should replace them at least once to give Dremel a fresh start in silence.

You can purchase new bearings from almost any local hardware store or contact the manufacturer for the locations.

6. Replace Brushes

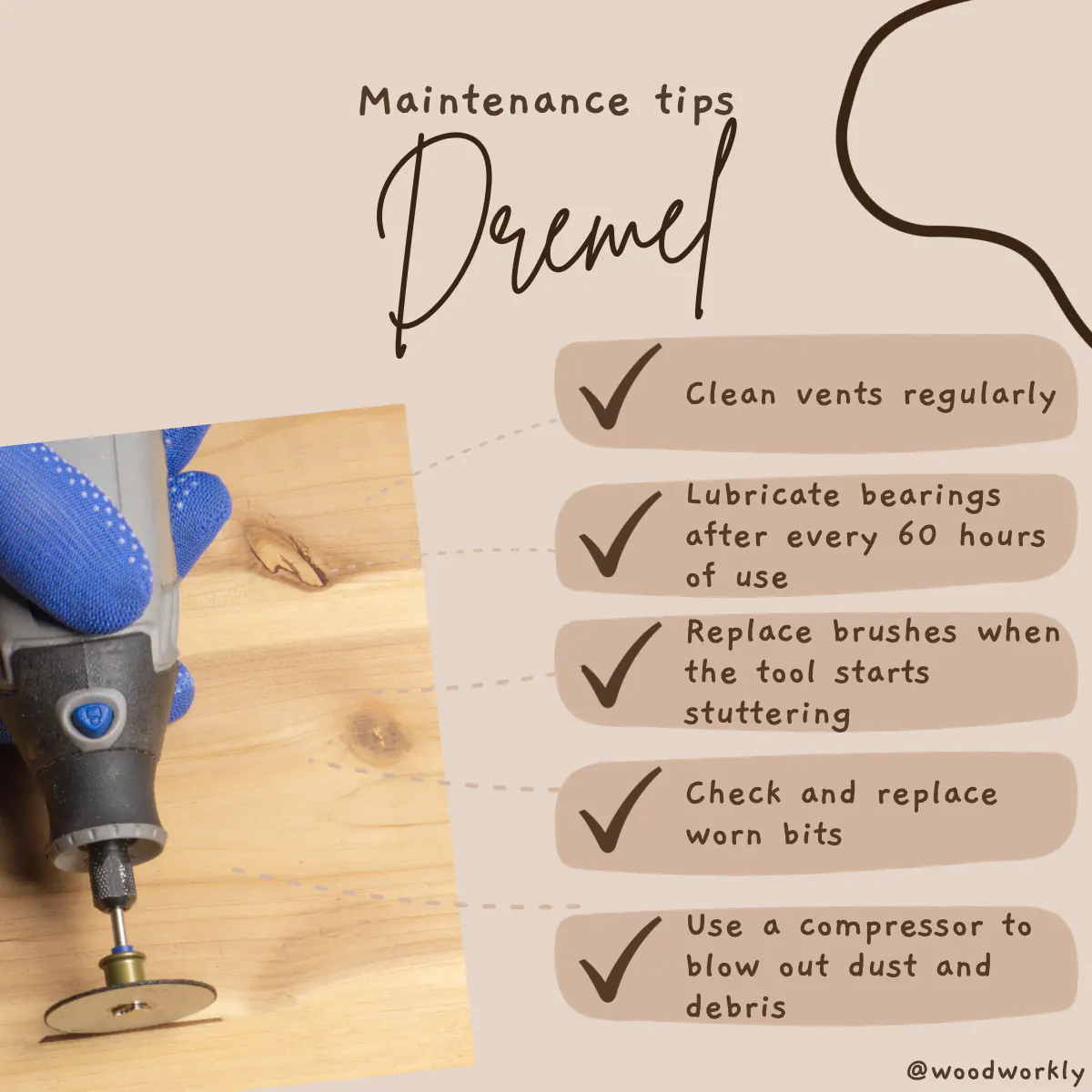

Dremel recommends replacing brushes once after 60 hours of total use. Dremel makes a loud noise when the brushes are damaged or worn off.

Therefore, replace bushes from time to time to work with Dremel with less noise.

That’s how to make Dremel quieter in a few simple steps.

With proper maintenance, you can keep Dremels fresh as new for years with no loud noise.

Let’s see some maintenance tips to keep your Dremel healthy forever.

Dremel Maintenance Tips

Follow the maintenance tips below from time to time to keep your Dremel healthy and to stop making trouble like loud noises.

- Clean the Dremel regularly with a paintbrush to remove dust. Make sure to focus more on the inlet and exhaust vents on both sides.

- Use a compressor to blow up all the dust on the vents.

- Change brushes when you notice Dremel is stuttering while engraving.

- Dissemble the unit with a 4300 flat screwdriver and replace the worn-out brush with a new rectangular shape brush.

- To repair the flex shaft, remove the mini attachment that you have out of the box and clean the inner and outer collet to remove debris and sawdust.

- Remove the cable of the flex shaft and monitor two square ends and clean them

- Reinsert the cable into the flex shaft properly

- Add a few drops of light machine oil down the shaft and hang it from the table to let the oil make it all the way down.

- Make sure not to add too much oil since they will seep out of your handpiece

- Reattach the flex shaft properly to the Dremel

- After applying new brushes hang your Dremel onto the table clamp and spin it at 30000 to 35000 RPM for at least 10 minutes. This helps brushes to bed onto the motor.

What If Nothing Went Good?

What if you did everything you could and still your Dremel is too loud? Frustrating right?

In that case, your Dremel may have some manufacturing faults inside or your Dremel is too old to use.

Most of the items inside are damaged, worn off, or rusted. That’s why it makes high pitch squeal.

Take the Dremel to the shop you bought if it is new and nothing worked well. take help from professionals.

But if your Dremel is too old and still makes loud noise even after the repair, It’s time to move for a new Dremel.

When you’re looking for a new Dremel, you can also go for Proxxon which provides the same task as Dremel but with less noise level.

Proxxon works nicer and quieter than Dremel.

But this is based on your personal preference, if you’re a Dremel fan who worked with it for many years, never think twice about getting a new one. Simple as that!

So, that’s it, folks! Hope you got a good knowledge about, how to make a Dremel quieter with all the maintenance tips and techniques.

Is There A Quiet Dremel Tool?

No, there’s no quiet Dremel tool. Usually, cordless Dremel tools are quieter than corded Dremels. But overall, all the Dremels are noisy and none of them is 100% quiet.

Or you can use an extension wand from Dremel to make the Dremel quieter. Put the motor in an insulated box and run the cord outside of the box to make it less loud when working.

Wear some quality earplugs when working with Dremels for too long. Play some music, audiobooks, or podcasts to reduce the stress that builds up when working in a noisy environment.

Never work more than 6 hours with Dremels without wearing earplugs since the loud noise can exceed the maximum safe hearing limit and can damage your eardrums over time.

If you really want to work in a quiet environment, better to move to the woodworking and wood carving hand tools. They are quiet and maintenances are also easier and cheaper than power tools.

Can I Oil My Dremel?

Yes, you can oil Dremel after 60 hours of use to lubricate bearings, and brushes and to lubricate the flex shaft. Make sure to clean Dremel vents properly before oiling them.

Oiling Dremel prevents bearings from wearing off, stops Dremel from wobbling, and stops Dremel from squealing. Plus, oiling helps to increase the lifetime of Dremel.

Proper maintenance is a must to keep power tools healthy.

How Long Does A Dremel Last?

With proper maintenance, Dremel will last for more than a decade. Dremel batteries will last for 3 years of continuous daily usage.

Dremel itself can last for many years. But proper maintenance and regular cleaning are a must.

Usually, all the Dremels come with a 2-year warranty. Manufacturers provide excellent customer support during that period for any issues.

Let’s answer some frequently asked questions as well.

FAQs

Why is my Dremel so loud?

Dremel tools are inherently loud due to their high-speed operation and mechanical components, like bearings and brushes, which can generate noise. Wear and tear, improper handling, or inadequate maintenance can exacerbate the noise issue.

Can lowering the Dremel’s spinning speed make it quieter?

Yes, reducing the Dremel’s spinning speed can decrease the noise level. However, this might affect the tool’s efficiency in cutting and grinding tasks.

How does proper handling affect the noise level of a Dremel?

Holding the Dremel with a firm grip can minimize vibration and noise. Proper handling techniques involve squeezing and compressing the central casing area to reduce sound emission.

How often should I lubricate my Dremel to keep it quiet?

You should oil your Dremel after every 60 hours of use. Regular lubrication helps in maintaining the efficiency of bearings and brushes, leading to quieter operation.

How long does a Dremel typically last with proper maintenance?

With appropriate care and maintenance, a Dremel can last for over a decade. Regular cleaning, lubrication, and replacement of worn parts are crucial to prolonging its lifespan and keeping the noise down.

What if my Dremel is still loud despite maintenance and repairs?

If the noise persists, there might be a manufacturing defect, or the tool may be too old and worn. Consider seeking professional help or replacing it with a new, quieter model or an alternative like Proxxon.

Did I cover all you wanted to know about: How To Make A Dremel Quieter?

In this article, we deeply discussed, how to make a Dremel quieter, why your Dremel is so loud, and what steps you should take to stop that with all the maintenance tips and tricks of Dremel.

You can make Dremel quieter by lowering the spinning speed, adjusting the handling by squeezing and compressing the central casing area with a firm grip, and by lubricating or replacing the bearings. Cordless Dremel is quieter than the plugin Dremel. Proxxon has a brushless motor and works quieter than the Dremel.

Furthermore, I’ve answered some frequently asked questions as well.

Hope you knew everything you wanted to know about, how to make a Dremel quieter with well-researched facts.

Making Dremels 100% is impossible since it is a power tool, and they dissipate some energy as heat and noise. That’s how they work.