Ever wondered what’s the best nail for your wood soffit project? The answer might just transform your DIY game. Ready to find out? Let’s get started!

I was curious what are the best nails to use for wood soffit when I was installing wood soffit.

I did some research and was able to find some useful info about nails for wood soffits.

So, let’s find out the best nails to use for wood soffit,

The best nails for wood soffit are galvanized nails, aluminum nails, and stainless steel nails. Galvanized nails resist rust, aluminum nails are light and won’t corrode, while stainless steel nails offer superior strength and durability. Choosing depends on your specific project needs.

Obviously, this depends dramatically on the condition of the soffit, moisture content, the wood type of the soffit, etc.

I’ll explore each and every nail that can use for wood soffit in detail and how to perfectly fit nails to the perfect soffit wood type.

Plus, I’ll answer some frequently asked questions as well.

First of all, Let’s have a look at a brief summary of all types of nails that are good for wood soffits with their characteristics.

Soffit Nails: Galvanized Nails Vs. Aluminum Nails Vs. Stainless Steel Nails

| Nail Type | Soffit wood type | Structure | Handling |

| Galvanized nails | Douglas Fir, (Cedar and Redwood – only for hot-dipped) | 8d and 16d lengths narrow shank, with a large head | Short and easy to use |

| Aluminum nails | Cedar and Redwood | 6d Thin shank | Cannot use for old woods |

| Stainless-steel nails | cedar, redwood, or pressure-treated wood | 8d x 2 3/8 | Best if you live nearby the sea, Can apply for hardwood, Excellent for face nailing |

So, let’s discuss each of the above nail types and their function towards the wood soffit more broadly.

Galvanized Nails for Wood Soffit

Why do we use galvanized nails rather than using regular nails? That is because of corrosion of nails that occurs when they are exposed to different weather conditions especially when they use outside wood construction like the soffit.

Galvanized nails have the ability to resist corrosion. But how?

Nails are made out of iron steel. In the presence of water, iron atoms in the nails release electrons to the oxygen in the air.

To fulfill the space that lost an electron, water combines with iron molecules and forms iron oxides which we called rust.

Imagine if you live in a sea coastal area, this corrosion process is high due to high moisture content in the atmosphere.

To stop this, we use Galvanized nails specially for outdoor wood applications like soffits.

Galvanized nails protect nails from corrosion because of the zinc coating.

When we use zinc-coated galvanized nails to use for soffit the zinc coat will corrode first and because of that, the corrosion of the steel will slow down.

But the disadvantage of zinc-coated galvanized nails is one day, the nail will face corrosion, which can badly affect the soffit. For example, the occurrence of rust.

So, the most durable method of galvanizing technique is hot dipping.

These galvanized nails are called hot-dipped galvanized nails, which are dipped/submerged in molten zinc and coated.

Hot dipped galvanized nails are mainly used for outdoor exposure applications and enable to be used in bad environments such as acid, corrosive, and humid circumstances.

So, this type of galvanized nail is also can use for wood soffits.

The other galvanized nail type is electro-coated nails, which is the cheapest option. These nails are galvanized with the help of an electric current. They are so smooth and glossy.

But the main disadvantage of using these types of nails for the soffit is they are not suitable to use with acidic materials, such as cedar, redwood, etc. Most of the soffits are made out of cedar and redwood.

So, under this circumstance, never select electro-galvanized nails for the installation process.

Also, the galvanized nails with copper flashing. Never use these types of galvanized nails for the soffit, because, with a little amount of moisture they start to corrode really fast.

Conclusion – Use Hot dipped galvanized nails for the installation/ construction or repairing process of the wood soffit. Never use electro-coated galvanized nails or galvanized nails with copper flashing.

Hot dipped galvanized nails with a narrow shank and a large head are soffit nails that are short and easy to handle. They don’t split the thin wood layer and cover the porch ceiling and eave soffits.

We can use hot-dipped galvanized nails for soffits not only because of their off-oxidation ability but also because they have high staying power.

Coarse zinc particles can attach very tightly to any wooden surface they’re being hammered.

Most importantly before you buy a working nail gun, you should select what is the appropriate galvanized nail to attach to the soffit which 8d and 16d lengths are perfect.

If you already got a nail gun which is not working, read my comprehensive guide to fixing a nail gun.

Advantages of Galvanized Nails

- Corrosion Resistance: Galvanized nails are coated with a layer of zinc. This protective layer provides resistance against rust and corrosion, making them suitable for outdoor and marine applications.

- Durability: The zinc coating not only prevents rust but also increases the overall lifespan of the nail. This durability makes galvanized nails a long-lasting solution for many construction and DIY projects.

- Versatility: Galvanized nails come in various sizes and types, making them versatile for different uses, including decking, roofing, siding, and framing. They are also suitable for both indoor and outdoor applications.

- Cost-effective: Compared to other types of nails such as stainless steel, galvanized nails tend to be more affordable while still providing a high level of durability and corrosion resistance.

- Low Maintenance: Once installed, galvanized nails require minimal maintenance due to their resistance to environmental damage and their durability.

- Protection for Wood: When used in wood, galvanized nails can help protect the wood from stains and discoloration that can be caused by rust.

- Improved Adhesion: The zinc coating can help improve the adhesion between the nail and materials like wood or concrete, which can result in stronger, more secure connections.

Aluminum Nails for Wood Soffit

Aluminum nails are the cheapest option you can go with. They have lightweight with very good strength.

The main advantage of using aluminum nails rather than using galvanized nails is, they do not react with cedar or redwood. Because those two are the main wood types we use for soffits.

Also, there are different types of size variations in aluminum nails.

If you live in a very windy area, 1 3/4 cedar soffit nails are the best option because they have annular rings to stop the pullout in very-wind areas.

Standard aluminum nails are very rare which a minimum of 1 3/4” length required for the installation of the soffit.

They have high tensile aluminum alloy and plain shank.

We can use Appleton color-matched nails for a neat and professional job.

You can buy aluminum nails in various types of colors.

Such as Polar White, Herringbone, Wicker, Clay, Ivory, Sandalwood, Charcoal, Sable, Aztec, Brown, Choc. Brown, Nutmeg Brown, Black, Tile Red, Burgundy, Old World Blue, Heron Blue, Pacific Blue, Rustic Blue, Ivy Green, Jade, and Forest Green.

You can match colors according to the color of the wood or the paint of the soffit before the application.

The main disadvantage of using aluminum nails for soffits is they are soft and short, because of that it can be frustrating to drive aluminum nails.

Advantages of Aluminum Nails

- Rust Resistance: Aluminum nails are corrosion-resistant. This makes them a perfect choice for outdoor applications, especially in areas prone to moisture, such as coastal regions.

- Lightweight: Aluminum nails are lightweight, making them easier to work with over extended periods.

- Non-Magnetic: Unlike steel or other types of nails, aluminum nails are non-magnetic. This is a beneficial characteristic when used in certain applications, such as around sensitive electronic equipment.

- Easy to Drive: Aluminum nails are softer than steel nails, so they’re easier to drive into certain materials without splitting or damaging them.

- Compatibility with Aluminum Structures: When used with aluminum siding or construction, aluminum nails are an ideal choice to prevent galvanic corrosion, which can occur when dissimilar metals come into contact with each other.

- Aesthetically Pleasing: Aluminum nails are often used for their aesthetic quality. They can be a perfect match for aluminum siding or trim, providing a seamless look.

- Good Conductor: Aluminum is a good conductor of both heat and electricity. While this may not often be a factor in choosing nails, it can be advantageous in specific applications.

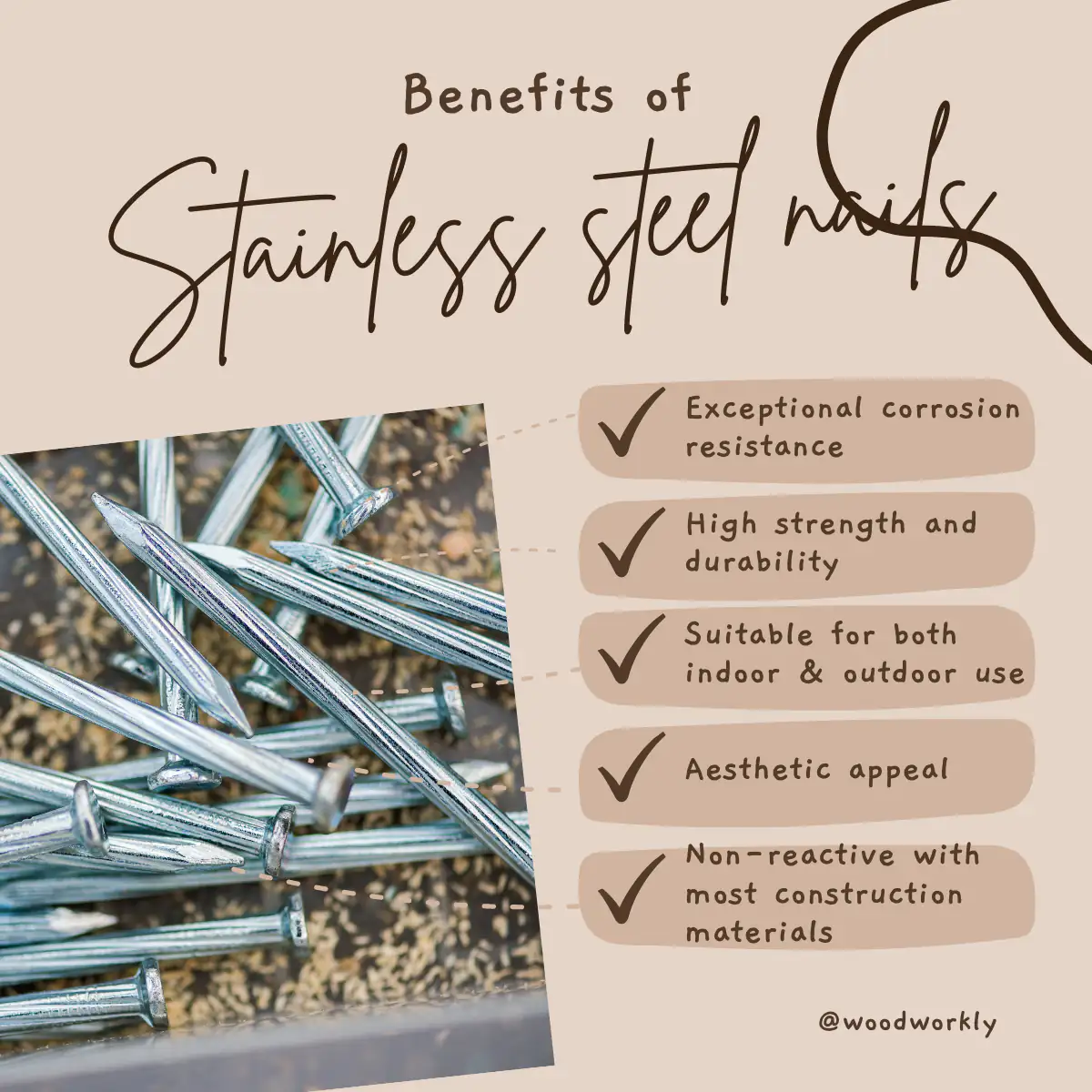

Stainless Steel Nails for Wood Soffit

Stainless steel nails are ideal for attaching wood soffit. They drive better than aluminum nails which we discussed above.

Because of their structural design, they are great for exterior applications. They can use for soffits that are made out of cedarwood, redwood, and also pressured wood.

The main advantage of using stainless nails is they don’t corrode. Because of that, their lifetime is very much higher than using galvanized nails and aluminum nails.

You can buy a box of stainless steel before attaching the soffit a box of 200 nails for about $9 only. Which are long-lasting and cheaper than aluminum nails as well.

If your soffit is made out of cedar, redwood, or pressured wood, the perfect dimension of stainless steel nail you should use is 8d x 2 3/8 stainless steel nail.

You can attach nails to the wood layer without splitting and they are perfect for the Douglas fir soffit as well.

Also, you can buy stainless steel nails in various types of colors in the market like aluminum nails according to the color of the soffit.

They are white smooth, black, dark bronze, brown, burgundy, forest green, cozy cottage, navy blue, Eldridge grey, pewter, almond, wicker, clay, etc.

By using stainless steel you can avoid the main disadvantage of using aluminum nails, which is bending. Stainless steel nails don’t bend easily.

As a summary, let’s see what are the advantages of using stainless steel nails rather than other nail types for soffit installation.

Advantages Of Stainless Steel Nails

- High corrosion resistance

- Affordable price

- High life expectancy. (No need to repair for a long period of time)

- Streaking and staining are minimal

- Very strong

- High tensile strength

- The load-bearing capacity is 20% higher than plain steel nails.

- Nontoxic – You are applying this for a soffit so it needs to be environmentally and health-friendly.

- 100% recyclable.

Overall, however, stainless steel nails have a good life cycle arrangement, compared with other types of soffit nails.

What Nails to Use for Fascia Board?

- Aluminum Nails: Aluminum nails are corrosion-resistant and are a great choice if you’re installing aluminum or vinyl fascia boards. However, they’re softer than other types of nails, which means they might bend during installation if not handled carefully.

- Stainless Steel Nails: Stainless steel nails are durable, sturdy, and highly resistant to rust. They’re suitable for attaching wooden fascia boards. Although they tend to be more expensive, their longevity can make them cost-effective in the long run.

- Galvanized Nails: These are steel nails that have been coated with a layer of zinc to make them resistant to rust. They’re cheaper than stainless steel nails but not quite as resistant to corrosion. They’re a decent choice for climates that aren’t excessively damp.

- Copper Nails: Copper nails are incredibly resistant to corrosion and are a suitable choice for attaching wooden fascia boards. They’re often used in coastal areas where salt air might cause other types of nails to rust.

- Roofing Nails: These nails come in various materials, including aluminum, stainless steel, and galvanized steel. They have a broad, flat head and a sharp, pointed tip, making them suitable for fascia board installation.

What Kind of Nails to Use on Plywood Soffit?

- Galvanized Finish Nails: Galvanized finish nails are a great choice for plywood soffits because they resist rust and corrosion. Their heads are small, so they can be driven flush with or slightly below the surface of the wood for a neat appearance.

- Stainless Steel Nails: Stainless steel nails are another excellent option, particularly if you live in a coastal area where salt air can cause other types of nails to corrode rapidly. They’re more expensive than other options, but their durability makes them a good investment.

- Aluminum Nails: Aluminum nails are also resistant to rust and are suitable for use with aluminum or vinyl soffit materials. However, they tend to be softer than other types of nails and may not be the best choice if your soffit will need to withstand heavy winds or other harsh conditions.

- Roofing Nails: While not typically used for soffits, roofing nails can be used if you’re in a pinch. They have larger heads and longer shanks, which can help ensure a secure hold.

Now you know what nail type you should go with for soffits. Let’s see what nail gun you should go with for promising results.

what nail gun to use for soffit?

Here are a few options that are suitable for this type of project:

- Brad Nailer: A Brad nailer uses 18-gauge nails, typically between 5/8 inch and 2 inches long. This type of nail gun is ideal for precise, detail-oriented work where the nail head needs to be hidden. It’s also great for materials that might split with larger nails, making it an excellent choice for soffits.

- Finish Nailer: A finish nailer uses thicker and longer nails (15 or 16-gauge), and it’s more powerful than a brad nailer. If you’re dealing with thicker soffit materials or need more holding power, a finish nailer might be your best bet.

- Cordless Nailer: A cordless nail gun offers freedom of movement without being tethered to an air compressor. If your project involves climbing on ladders or working in tight corners, a cordless nailer can be a convenient choice.

- Pneumatic Nailer: Pneumatic nail guns are powered by air compressors. They are highly durable and powerful, which can be beneficial for larger projects. However, they require a separate air compressor, which can limit mobility.

Remember to consider the thickness and type of your soffit material when choosing a nail gun.

When nailing soffits, it’s usually best to use shorter nails (about 1 1/4 inch is often sufficient) to avoid penetrating too deeply and causing damage.

Always follow the manufacturer’s instructions for both the nail gun and the soffit materials.

How To Nail Wood Soffit?

Nailing wood soffit may seem like a daunting task if you’re new to it.

However, with the right tools and knowledge, it can be a straightforward and satisfying DIY project.

Let’s dive into it.

Understand the Materials and Tools You’ll Need

Before starting, it’s crucial to gather all the necessary materials and tools.

For wood soffit installation, you’ll need trim nails that are corrosion-resistant, such as stainless steel or hot dip galvanized nails.

These nails have slightly larger heads that help hold the siding in place.

Tools-wise, you should have a nail gun or an air compressor on hand.

These tools help apply the right amount of pressure when nailing the soffit in place, preventing damage to the framework or framing of the soffit.

Measure and Cut the Soffit Boards

The first step is to measure and cut the wood soffit boards according to your needs. Make sure they fit securely around the outside of your house.

If you find it necessary to make some precise cuts for a snug fit, a jigsaw can be handy.

Pre-drill the Holes and Fasten the Boards

After measuring and cutting the boards, pre-drill small holes before nailing them in.

This pre-drilling helps to prevent the splitting of the wood. Afterward, use your nail gun or air compressor to securely fasten the boards to the structure beneath them.

Be sure to apply the right amount of pressure when nailing, as too much force can damage the framework or framing of the soffit.

When choosing the nail size, remember that it should be appropriate for the job. If the nails are too long, they could come out the other side, which isn’t ideal.

Add Decorative Trim (Optional)

If you’re considering adding decorative trim to your soffit for aesthetic appeal or to cover any exposed edges or seams, you can attach the trim using finish nails.

Here, an air nailer or a hammer would be helpful to carefully drive the nails.

Just remember, these nails should be long enough to penetrate the thickness of the trim.

Apply an Exterior Sealant or Paint

Lastly, consider applying an exterior sealant or paint to your soffits.

This step is essential as it not only enhances the look of your soffits but also improves their durability, protecting them from harsh elements.

As a friendly reminder, always remember to use safety glasses when nailing the soffit. This practice ensures your safety while you’re nailing.

Practice Makes Perfect

Installing wood soffit can seem intimidating at first, especially if you’re a DIY beginner. But remember, practice makes perfect.

As you gain more experience and become familiar with the tools and materials, you’ll find that nailing wood soffit isn’t as tough as it initially seemed.

How To Attach Soffit To A Fascia Board?

If you’ve ever found yourself puzzled about how to attach a soffit to a fascia board, then this guide is for you.

As someone who’s been through this process several times, I can assure you that the task is not as complex as it might initially seem.

So, let’s go through the process together, step by step.

1. Gather the Necessary Materials and Tools

First things first: you will need to gather all the necessary materials and tools.

These typically include soffit panels, fascia boards, a tape measure, a circular saw, a drill with screwdriver bits, and some corrosion-resistant screws.

A ladder will be necessary too, as you’ll need to reach the eaves of your roof.

2. Measure and Cut the Soffit Panels

The second step is to accurately measure the length and width of the space where the soffit will be installed.

It’s always a good idea to measure twice to avoid any mishaps.

Once you have these measurements, you can cut the soffit panels to the correct size using a circular saw.

Don’t forget to wear safety goggles to protect your eyes from dust and debris!

3. Install Soffit “J” Channel

After you’ve cut the soffit panels, you’ll need to install the soffit “J” channel.

This is a piece of metal or vinyl that’s shaped like the letter “J” and serves as a receptacle for the soffit panels.

Secure the “J” channel to the wall and the bottom edge of the fascia board using corrosion-resistant screws, ensuring its level.

4. Slide the Soffit Panels Into Place

Once your “J” channel is secured, you can begin sliding the soffit panels into place.

Start from one end and work your way down, making sure each panel is secure before moving on to the next.

5. Screw the Soffit Panels to the Fascia Board

Now, this is where you’ll need your drill. After you’ve inserted the soffit panels into the “J” channel, fasten them to the underside of the fascia board using the corrosion-resistant screws.

It’s recommended to pre-drill the holes to avoid damaging the soffit panels.

Remember, the screws should be tight enough to hold the soffit panels in place, but not so tight that they cause the panel to warp.

6. Apply the Finishing Touches

Lastly, make sure to inspect your work thoroughly.

Ensure that the panels are securely attached and that there are no gaps between the soffit and the fascia board.

That’s it, folks! Hope you were able to learn everything you wanted to know about what nails to use for wood soffit and how to attach them.

Let’s answer some frequently asked questions.

My Wood Soffit Is Made Out Of Pressured Wood, What Nail Should I Use?

Use Stainless steel nails for pressured wood. Never use galvanized nails with copper flashing, because the wood layer can be split and they react with the cedar and redwood.

Are Galvanized Nails Toxic?

Galvanized nails have zinc coating around the steel. So, with time some amount of zinc and lead particles can detach from the metal surface. Zinc is a poison.

What Type Of Nail Gun For Fascia?

A 15-degree nail gun is great for fascia. it can install all types of nails with no issues.

What size nails should I use for wood soffit?

For wood soffit installation, typically 1 1/4 inch galvanized nails are ideal. They’re long enough to hold the soffit securely without penetrating too deeply and potentially causing damage.

Can I use screws instead of nails for my wood soffit?

Yes, you can use screws, particularly if you want a more robust hold. However, installation might take longer due to the added time to drive screws compared to shooting nails with a nail gun.

Do I need a specific type of nail for wood soffit?

Yes, you should use galvanized nails for your wood soffit as they resist rust and corrosion, which is essential given the exposure to outdoor conditions.

How many nails do I need for each soffit panel?

Typically, you should place a nail every 12 to 16 inches along each soffit panel. The exact number may vary depending on the panel’s size and the specific installation guidelines.

Is it possible to over-nail the wood soffit?

Yes, it’s possible to over-nail, which can cause damage. To avoid this, use the appropriate nail size and be mindful not to drive the nails too deeply.

Can I use non-galvanized nails for my wood soffit?

It’s not recommended because non-galvanized nails are more susceptible to rust and corrosion, which could compromise the integrity of your soffit over time.

What are some safety precautions when nailing wood soffit?

Always wear protective gear like safety glasses and gloves when operating a nail gun, and be sure to work on a secure ladder or scaffolding if your soffit is high off the ground.

Did I cover all you wanted to know about Best Nails To Use For Wood Soffit?

In this article, I have deeply discussed the best nails to use for wood soffit and we went talked about all 3 types of nails in detail with tips.

When it comes to securing wood soffit, galvanized, aluminum, and stainless steel nails are top choices. Galvanized nails are rust-resistant, aluminum nails won’t corrode and are lightweight, and stainless steel nails provide excellent strength. Consider your project’s requirements to make the best choice.

Furthermore, I’ve answered some frequently asked questions as well.

Hope you learned everything you wanted to know about the best nails to use for wood soffit.

Try to use them in your next wood soffit installation project and experience the difference.

This really answered my downside, thanks!

You’re most welcome. Happy to help you.

My brother recommended I might like this web site. He was entirely right. This post actually made my day. You can not imagine just how much time I had spent for this information! Thanks!