Ever noticed your wooden furniture twisting out of shape? It’s called warping and it can be a real headache. But what if I told you there are ways to prevent it? Curious to find out? Read on!

A few weeks after you bought a wooden board from a local hardware store, you might notice that it has warped and you can no longer use it.

Warping wood is one of the biggest nightmares for any woodworker.

This happens due to the fluctuations of moisture amount inside the wood and the outside world. Basically due to the imbalance.

When I was facing the wood warping problem for the very first time, I was curious to know how to stop it.

Several of my store lumber have been ruined due to warping.

I’ve researched and found really good info and now keep practicing those for years to avoid my lumber from warping.

So, let’s discuss, How to keep wood from warping?

To keep wood from warping, maintain a consistent humidity level in storage, seal the wood using a high-quality sealer or oil, and store lumber properly by “stickering” – placing small sticks between layers for air circulation. Also, let the wood acclimate to its environment before use.

But that’s a quick snapshot and there’s a lot more to know about wood warping.

So, in this article, I’ll dive deep into the hot topic of how to keep wood from warping and discuss the best methods to keep wood from warping in detail.

Furthermore, I’ll discuss what causes wood to warp, how to fix wood warping, and answer some frequently asked questions as well.

So, let’s get going!

What Causes Wood To Warp?

Wood warp happens when the moisture content of the wood changes unevenly throughout the surface.

For example, you have a block of wet wood, and you’ll keep it dry. But when it dries some areas of the board dry faster than other areas causing drier areas to shrink faster.

Because when the wood dries it tends to shrink by releasing its water content. But when some parts of the wood shrink faster, but others don’t that causes the wood to warp.

Here’re the reasons that cause wood to warp,

- High moisture content

- Less moisture content

- Ambient temperature

- Wood type

- Wood thickness

- Woodgrain orientation

- Protective coatings

Wood is a natural material made with fibers with a porous structure. Those pores will absorb and release moisture to the outside environment.

When the environmental humidity is high, wood tends to absorb moisture from outside which causes wood to expand and swell.

When the environmental humidity is low, wood releases its moisture to the outside environment which causes wood to shrink.

Likewise, balancing the moisture level of the outside environment and the moisture content of the inside of wood at a steady state is known as the Equilibrium Moisture Content (EMC).

Wood warping happens mostly when EMC is unstable.

When EMC is stable, wood is neither losing nor gaining moisture.

At a stable EMC moment, moisture losing speed is equal to the moisture-absorbing speed or no moisture release or gain from the outside environment.

How High Moisture Content Causes Wood to Warp?

When the moisture content of wood inside is high, it is already swelled and expanded. If the outside environment has less humidity with less moisture content, wood tries to release water to the outside environment.

When it dries by releasing water into the outside environment, it shrinks back down. This incident happens to stabilize the EMC.

But not all areas of the wood shrink equally by releasing water to the outside environment at an equal rate.

Some areas dry faster and shrink faster while some areas dry slowly and shrink slowly.

When different areas of the wood dry at different rates, this can stress the wood and change its shape permanently.

This is how high moisture content causes wood to warp permanently.

How Less Moisture Content Causes Wood to Warp?

When the wood is dry, it is already shrunken. If the outside environment has high humidity with high moisture content, wood tends to absorb water from the outside environment and expand.

When it gets wet by absorbing water from the outside environment, it will swell.

This happens to stabilize the EMC value between the wood and the atmosphere.

But not all the areas of the wood absorb water at the same rate.

Therefore, some areas get swell faster by absorbing water faster while some areas swell slowly by absorbing water at a slow rate.

When different areas of the wood swell at different rates, this can stress the wood and change its shape permanently which causes the wood to warp.

How Does Ambient Temperature Causes Wood to Warp?

When the outside temperature is high, air can accommodate high, and humidity will also increase.

High environmental humidity affects EMC and the wood need to absorb moisture faster to stabilize EMC with the outside environment.

If the wood is dense and unable to exchange water faster along with the changes of EMC, that causes the wood to warp.

The same thing happens when the outside temperature is low. Air accommodates less and humidity will decrease.

So, would need to release its moisture at a high rate to stabilize EMC. Otherwise, the wood will stress out because of the EMC imbalance and tend to warp.

How Wood Type Causes Wood to Warp?

Density, hardness, and wood structure can cause wood to warp.

If the wood is highly dense and it cannot match or go parallel with EMC changes the wood will stress out and causes wood to warp.

For example, Cedar has a natural resistance to warping because it has natural chemicals and oils inside the wood.

This oil helps the wood to easily exchange water with the outside environment and balance EMC faster. Therefore, wood doesn’t stress out and no warping happens.

Redwood and Douglas Fir also have similar kinds of oils that protect the wood from warping.

Wide and dense hardwoods are prone to warp. Even some of the softwoods warp because of their wood structure.

Generally, close-grain woods have less tendency to warp than open-grain woods.

Close-grain woods have less spacing between their wood fibers. Therefore, they cannot shrink much as open-grain wood with lots of spaces between wood fibers.

How Wood Thickness Causes Wood to Warp?

Thick pieces of wood take more time to absorb or release moisture from the outside environment. When the wood thickness is high it cannot reach EMC faster.

When the wood has a relatively high moisture content, it shrinks and dries until it reaches equilibrium with a relative outside environmental humidity.

But when wood thickness acts as a barrier, this water exchange process will slow down, and the wood starts to stress by unbaling to adjust for those types of conditions.

As a result of excess stress on the wood, wood warping will happen.

How Wood Grain Orientation Causes Wood to Warp?

Wood logs that are cut perpendicular to the wood grain absorb moisture more quickly than logs that are cut parallel to the wood grain.

Plus, when the wood grain is placed much closer, those woods penetrate less moisture.

As a result of penetrating less moisture content from the wood, it doesn’t shrink much and is less likely to stress up which causes a permanent change in wood.

Therefore, grain direction is highly affected by wood warping.

How Protective Coatings Cause Wood to Warp?

Protective coatings seal the wood and slow down its water absorbance and release rate with the outside environment.

This will reduce or prevent the wood from shrinking or swelling. in other words, protective coatings cut down the direct relationship between wood and the outside environment.

If you apply protective coating only for some areas but others remain without a protective coating, those unprotected areas exchange water with the outside environment and cause wood shrinking and swelling, but protective areas don’t.

As a result of that stress will be generated between wood fibers of protected and unprotected areas.

If the stress build is long-term, the wood will change its shape and adjust accordingly. This incident causes wood to warp.

So, always make sure to apply protective coats like stain, paint, and sealer to the whole wood surface equally with the same number of coatings to prevent wood warping.

Types Of Wood Warping

There’re main five types of wood warping. They are,

- Bow

- Twist or Wind

- Kink

- Crook

- Cup

So, let’s find out each type of wood warping in detail.

| Wood Warping Type | Description |

| Bow | Warp long the length of the wood, not across the face. The shape resembles a bow |

| Twist / Wind | Warp by turning four corners of any face of the wood board. They’ll be no longer on the same plane. The shape resembles a twisted ribbon |

| Kink | Warp the wood edge from a straight line like an elbow. |

| Crook | Warp along one side of the wood. This occurs when only one edge of the wood is exposed to moisture. One edge shrinks while the other edge remains the same which causes warp. |

| Cup | Bend through a straight line across the width of the wood. Bend inwards and results in a curved shape in the middle. |

So, let’s have a look at the top 5 easiest methods to keep the wood from warping.

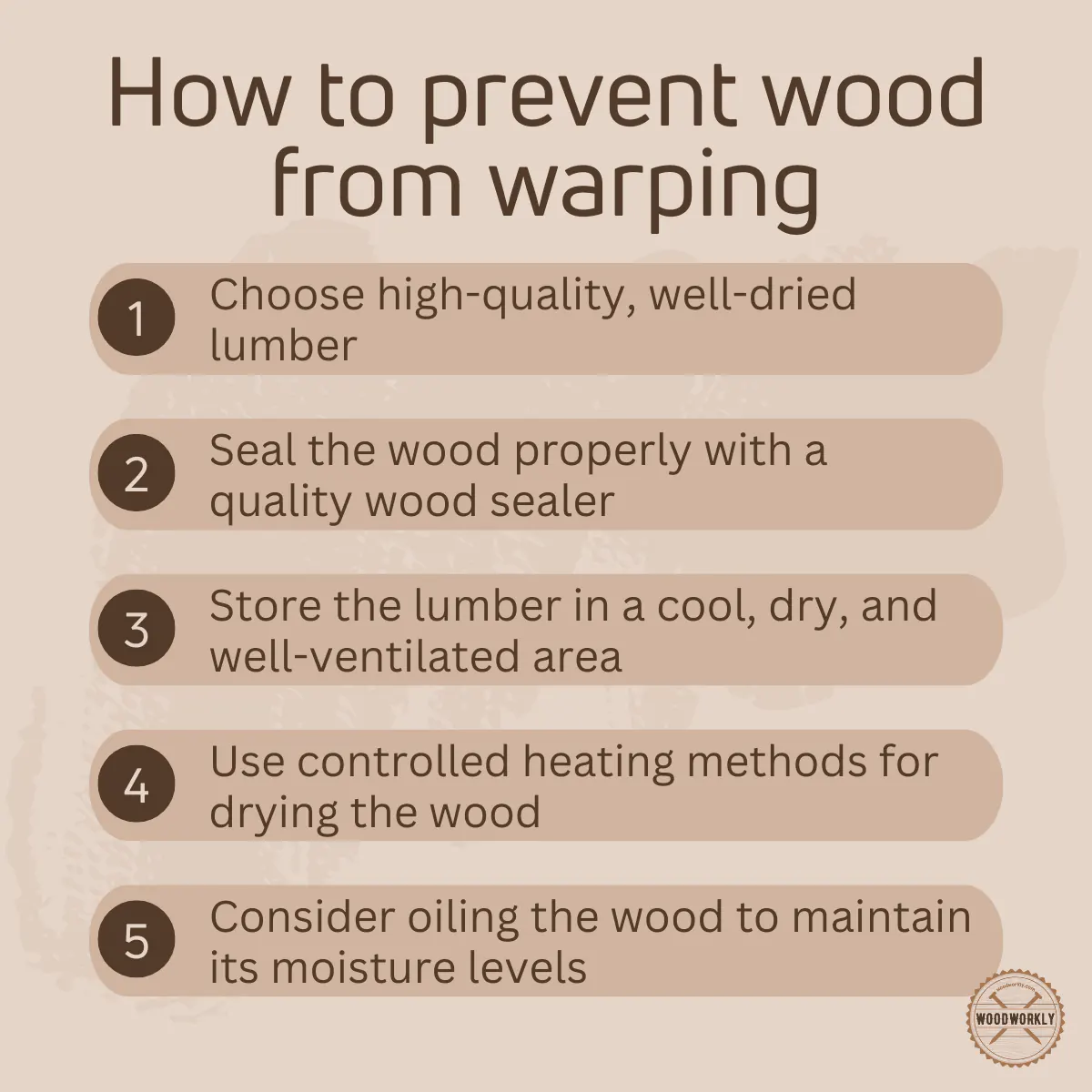

How to Keep Wood from Warping – Top 6 Methods

There’re several ways to you try out to stop wood warping. Try the one that suits you the most to protect your valuable furniture and woodwork.

Here’re the methods to prevent the wood from warping,

- Store wood in a clean and dry storage area with proper storage techniques

- Monitor moisture content

- Cure the wood properly

- Seal the wood

- Acclimate wood before installation

- Control the cutting of boards with sawing techniques

By following the above 5 methods, you’ll be able to protect your loving furniture, woodwork, and lumber from warping.

So, let’s discuss each of the above methods separately.

1. Store Wood Using Storage Techniques

To keep wood from warping you should keep wood in a clean and dry storage area.

The way you stack wood is one of the main things for how it will change when it adjusts to EMC.

Because wood warping mostly happens by exposure to moisture.

By preventing the wood from getting in contact with moisture, you’ll be able to keep wood from warping.

Here’re the wood storage techniques you need to follow to store wood properly,

- Place woodpiles onto flat foundations

- All boards and stickers that are placed need to have a uniform thickness when placed in the same layer

- Stickers should align vertically and lay flat

- Spaces between woodpiles are essential for proper ventilation

- Weights need to be placed on wood plies to avoid cupping

- Cover the wood with a material that protects wood from vapor to keep the wood dry in humid areas. Use vapor-impermeable material to avoid wood from absorbing moisture from the outside environment, especially in humid places.

- Store wood in a clean dry area with a high humidity level (80% or more)

Always make to focus on the humidity of the outside environment, because if the wood absorbs a high amount of water from outside, it’ll stress out and warp easily.

2. Monitor Moisture Content

To keep wood from warping, the moisture content of the wood needs to monitor frequently.

Plus, you have to make sure the storage area is also free from moisture and humidity.

Testing moisture content is crucial to producing high-quality wood.

The humidity of the storage area can be measured by using hygrometers and the moisture content of the wood can be measured by using prong meters from the surface to the inner area of the wood.

You should measure the moisture content of the wood surface and interior both because those measurements can vary by one to two percent.

But both values have to be in a pretty low state to consider them free from moisture and water. If the moisture content of the surface and interior are too different, the wood drying process needs correcting.

For example, if the surface of the wood is dry and the interior is wet, that means the kiln is operated at too high a temperature causing surface to dry faster than the interior.

This will stress out the wood and leads to wood warping.

The moisture content of the wood needs to be measured at each production stage.

Because if wood warping happens, it is easier to detect which production stage is responsible for that.

Follow the below guidelines to take accurate measurements of the relative humidity of the storage area,

- Avoid places with restricted airflows like corners and alcoves.

- Check the sensory element of the relative humidity meter before taking measurements to make sure it has not been damaged.

- Take multiple relative humidity readings and take the average value of it to get the most accurate result.

- Seal or stain the ends of the wood to prevent them from warping. Because wood ends dry faster than in other areas. By sealing endings, they won’t dry faster than the rest of the wood.

The below table shows how the moisture content of wood should vary along with the relative humidity of the outside environment.

| Relative Humidity of Outside | Moisture Content of the Wood |

| 0% | 0% |

| 25% | 5% |

| 50% | 9% |

| 75% | 14% |

| 99% | 23% – 30% |

If the moisture content of the wood and the relative humidity of the storage area is too different than the values of the above table, the wood is already stressed out and tends to warp.

3. Cure the Wood Properly

Curing the wood properly is important to protect the wood from warping. Curing will increase the wood’s durability.

By curing you need to make sure the woods are completely dry before storing them in a storage area.

Follow the below instructions to cure wood properly,

- Never allow woods to dry slowly because their moisture content stays there for long enough that resulting in wood warping

- Never expose drying wood to moisture or water

- Over-drying should be avoided because that will lead to cracks and splits

4. Seal the Wood

sealing wood can help prevent warping, a common issue that plagues woodworking projects. Warping refers to the distortion of wood fibers due to changes in moisture levels and humidity. When we seal wood, we add a protective layer that safeguards it from these damaging environmental factors.

Understanding Wood Warping

To understand why sealing works, we must first comprehend what causes wood to warp.

Wood is hygroscopic, which means it absorbs and releases moisture based on its surroundings.

If it absorbs too much moisture, it expands and warps.

On the flip side, if it’s exposed to dry conditions for too long, it shrinks and warps.

This characteristic of wood makes it highly susceptible to warping when left unprotected.

How Sealing Helps Prevent Warping

Sealing wood serves as a protective barrier, safeguarding the wood from changes due to moisture and humidity.

When we seal wood, we’re essentially applying a coat that shields the wood from the elements.

This protective layer minimizes the absorption and release of moisture, thus helping to maintain the wood’s shape and integrity.

Consider it as an umbrella for your wood: just as an umbrella shields you from rain and keeps you dry, a good quality sealant protects your wood from absorbing excess moisture or drying out too quickly.

Best Wood Sealer to Prevent Warping

Choosing the right sealer for your wood can significantly affect the durability, beauty, and longevity of your project.

The best sealers provide an excellent barrier against moisture, hence preventing warping and extending the life of your wooden structures.

Let’s explore some top choices in the market and share a few personal experiences that might help you make the right decision for your projects.

Polyurethane

Polyurethane sealers are a top pick among woodworkers due to their high durability and impressive resistance to water, heat, and sunlight.

They are available in both oil-based and water-based variants.

Oil-based polyurethane offers superior water resistance and durability but tends to yellow over time.

In contrast, water-based polyurethane doesn’t yellow, dries faster, and is easier to clean up, but it might not provide the same level of protection as the oil-based version.

Spar Urethane

Spar urethane is another fantastic option, especially for outdoor wooden projects.

It’s similar to polyurethane but has added ingredients that make it more resistant to sunlight, water, and temperature changes, making it an ideal choice for protecting wood from warping.

Tung Oil

Tung oil is a natural product that penetrates the wood fibers and hardens to provide a durable and water-resistant finish.

It brings out the natural beauty of the wood, making it a favorite for projects where aesthetics are a key consideration.

However, it’s worth noting that Tung oil may require more frequent reapplication compared to polyurethanes or spar urethane.

How to Seal Wood with Sealants to Prevent Warping?

Here’re the steps you need to follow when preventing wood from warping by applying sealants,

- Choose a high-quality wood sealer suitable for your project, considering factors like the type of wood and the intended use of the finished piece.

- Prepare the wood surface by sanding it smoothly to ensure better adhesion of the sealer.

- Clean the wood surface thoroughly to remove any dust, dirt, or grease that could interfere with the sealer’s application.

- Apply the first coat of sealer using a brush or sprayer, ensuring to cover all surfaces evenly.

- Allow the first coat of sealer to dry completely, as per the manufacturer’s instructions.

- After the first coat is dry, lightly sand the surface to ensure an even and smooth finish.

- Wipe away any dust or residue left from sanding before applying the second coat.

- Apply a second coat of sealer, just as you did the first, allowing it to dry completely.

- Repeat the process of light sanding and additional coats until you reach the desired level of protection.

- Once the final coat is dry, your wood should be well-sealed and ready to resist warping due to moisture exposure.

Personal Experience with Wood Sealers

In my woodworking journey, I’ve had the opportunity to use various types of sealers.

One of my most memorable experiences was when I built a custom outdoor bench for a client.

I chose spar urethane for this project because of its superior resistance to outdoor elements.

The bench has been outside for more than two years now, exposed to sun, rain, and winter, yet it still stands sturdy and warp-free.

The client is delighted with how it has held up.

On another occasion, I made a coffee table from reclaimed oak.

I wanted to highlight the natural grain and color of the wood, so I opted for Tung oil.

The oil enhanced the wood’s natural beauty and provided a good level of protection.

While it did require reapplication after a year, the depth and richness it gave the wood were worth the effort.

5. Acclimate Wood Before Installation

Your wood should always acclimate before the installation.

By acclimation, you can get your wood close to the EMC value as possible with environmental humidity.

For example, if you’re working on woodwork or furniture that will be shipped to another area that has a different climate, humidity, and other weather condition should acclimate the whole woodwork by treating it with wood stain, paint, or sealer.

By applying protective coatings, you will be able to stop its moisture exchange relationship with the outside environment and stop wood warping permanently.

The woodwork can be used in any area you want where it’ll be exposed to different moisture levels indoors and outdoors.

6. Control the Cutting of Boards With Sawing Techniques

It is so much more difficult to control the cutting direction of the wood and avoid wood warping in the future. There’re main 3 cutting methods boards. They are,

- Rift sawn

- Quartersawn

- Flatsawn

Rift-sawn creates the most stable wood but the wastage is high. In Rift-sawn wood, logs are cut perpendicular to the growth rings of the wood.

Flatsawn creates unstable wood but the wastage is less. In Flat sawn cut the lumber flat by ignoring the wood grain.

To have high stability and less wastage you should go with the Quartersawn method which gets closer to the wood grain by making it less wasteful and highly stable with less likely to warp.

Woods that are cut from the heart of the trees are more stable and resistant to wood warping and shrinking.

Straight grain woods with 1/32-inch (0.79 mm) space between grain lines are less likely to warp.

So, that’s all about the top 5 methods how to keep wood from warping.

Now I’m going to share with you some useful tips to prevent wood from warping which I have learned from experience.

Tips To Keep Wood from Warping

- Never expose wood to excess moisture or water.

- Avoid fast drying and always go for a slow drying process because the drying speed of the wood surface and interior cannot be too different.

- Always use fresh woods to make woodwork and furniture

- Apply a good finisher to every woodwork to avoid wood warping. Never leave without applying a protective coating.

- Avoid excess drying because that will lead to wood crack and splitting.

How To Fix Warped Wood?

Fixing warped wood is possible. Fixing wood warping is somewhat different than keeping wood from warping. Fixing wood warping is easy if you follow the correct procedure.

Before fixing warped wood, you need to have a clear idea of how wood warping happens. It happens due to the fluctuations in moisture content between relative humidity and the wood interior.

So, by adding or releasing moisture you’ll be able to clamp wood into its original shape.

You can fix warped wood with the help of moisture and heat. Heat speeds up the moisture absorption rate of the wood.

Iron is equipment that uses moisture and heat which is useful to fix warped wood.

Here’re some popular methods of fixing warped wood,

- Spray down the wood and let the wood absorb moisture. Once the water has been absorbed, camp the wood in a fixed position and let it dry. When the wood dries it will eventually regain its original shape.

- Take a wet towel and place it on the warped area. Then take the hot iron and place it on the wet towel and allow the wood to steam. This will generate heat and moisture at the same time. heat will increase the moisture absorption speed and relax wood fibers quickly to gain their original position. Then clamp the wood and let allow to dry.

- Warp wood in damp towels and leave it under direct sunlight for two-three days. Sun’s warmth relax the wood fibers and helps to regain the original non-warped shape of the wood.

- The steam machine can affect the whole wood area once to fix warping. It has a boiling water tank and water is fed to the wood through-hole-filled surface.

- Ironing machines function like steaming machines except they only heat the wood. Wet wood is placed on a heated ironing machine to relax wood fibers and clamp them until it reaches their original shape.

The wet towel method and steam machine method are the most popular method to fix warped wood because they use heat and moisture both to un-warp wood.

When you are working with ironing machines and steam machines to fix warped wood, you should be careful not to burn or damage wood because of excess heat.

How to Store Lumber to Prevent Warping

Every now and then, I get asked: “How can I store lumber so that it doesn’t warp?”

Over the years, I’ve learned a thing or two about properly storing lumber to maintain its quality and avoid warping.

Let’s delve into this subject so you can save yourself from future headaches.

Correctly Stacking Your Lumber

One of the first things to consider when storing lumber is how it’s stacked. You want to make sure it’s flat and supported along its entire length.

This is called “stickering,” and it can be a real game-changer.

Here’s a personal anecdote. I once had a stack of beautiful oak boards that I stored improperly.

One end was supported, but the other wasn’t.

Over time, the unsupported ends sagged, and my beautiful boards warped. After that experience, I always ensure my lumber is properly supported.

A Tip for Stickering

When stickering, place thin pieces of wood, known as “stickers,” between each layer of lumber.

These stickers create spaces for air to circulate around the lumber and distribute weight evenly.

Each sticker should be directly above the one below it for the best support.

Control the Environment

Consider where you’re storing your lumber. Ideally, it should be a cool, dry place with consistent temperature and humidity.

Rapid changes can cause the wood to expand and contract, leading to warping.

I learned this lesson the hard way when I stored some lumber in my shed, which unfortunately was subject to significant temperature and humidity fluctuations.

The lumber warped in no time. Now, I store my lumber indoors where the environment is more stable.

Properly Seal the Ends

Sealing the ends of your lumber pieces can go a long way in preventing warping.

The ends of boards tend to dry out faster than the middle, which can lead to splitting and warping.

By applying a coat of wax or a specially-designed end grain sealer, you can slow down this process and help keep your lumber straight and true.

Consider Orientation

Believe it or not, the orientation of your lumber stack can affect how well it stays warp-free.

For the best results, try to orient the stack so that the lumber’s growth rings curve downward.

This simple tip can really make a difference in preventing warping.

Finally, patience is a virtue when it comes to storing lumber. Let your lumber acclimate to the environment before using it.

This allows it to reach equilibrium with the surrounding air humidity, reducing the chances of warping when you start working with it.

What Wood Does Not Warp?

Most of the woods warp when they are exposed to moisture. But some woods are warp-resistant because of chemicals and oils inside the wood.

Woods warps the least are,

- Cedar

- Redwood

- Douglas Fir

- Cherry

- Walnut

- Yellow Poplar

The above woods are excellent for outdoor woodworking projects and they have good weather-resistant as well.

How To Keep Wood from Warping After Cutting?

Here’re the steps you can take to keep wood from warping after cutting.

- Wood layers align vertically

- Store wood in a clean, dry, cool area

- Supply plenty of ventilation

- Lumber should place on a flat solid surface

- Heavyweights should place on top of the wood to prevent warping

Following the above steps after cutting wood will prevent the wood from warping.

The above methods help the wood to reach Equilibrium Moisture Content (EMC) by drying quickly.

This whole process takes 2 -3 days to complete.

During the drying process, wood should not be exposed to rain or high-moisture environments.

How To Keep Wood from Warping After Painting?

Here’re the steps you can take to keep wood from warping after painting.

1. Sealing the Edges of the Wood.

Because edges are the areas that are highly exposed to the outside environment and they’re the area that highly exchanges water and moisture with the outside world and initiates the wood warping.

Because wood is stressed out due to imbalances of moisture exchange rates all over the wood that leads to warping.

By sealing those areas, their moisture absorption and release rates will slow down and prevent wood warping.

2. Seal the Whole Wood Surface

After the painting is done, you can apply a protective layer all over the wood without missing any spots to build a permanent barrier to water between the outside environment and the wood itself.

Before sealing check the moisture content of the wood and make sure it’s around the 8% – 10% range.

Otherwise, if the moisture content is high, the wood will start rotting inside.

8% – 10% moisture content is ideal for sealing.

By sealing the whole area moisture no longer get in contact with wood and no warp will happen.

3. Let the Wood Dry Completely

After the application of paint, varnish, shellac, and other finishers, the wood has been exposed to plenty of moisture, and it tends to warp.

By letting the wood dry completely, the water will evaporate, and the wood mostly will get back to its original shape by un-warping.

How to Dry Wood Without Warping

Here’re the steps you can take to dry wood without warping,

- Allow partial drying to exchange moisture quickly and regain its original shape

- Avoid slow-drying processes because they will warp the wood even more.

- Don’t do over-drying because over-drying will evaporate water excessively and the wood will shrink excessively. This can lead to wood cracking and splitting.

Does Oiling Wood Prevent Warping?

Oiling wood is an age-old technique used by carpenters, woodworkers, and DIY enthusiasts to protect, preserve, and enhance the natural beauty of wooden objects.

But the question here is – can oiling actually prevent the wood from warping?

Let’s explore this together, touching on some of my personal experiences along the way.

The Role of Oil in Wood Preservation

Wood oils, such as linseed oil, teak oil, and the aforementioned tung oil, penetrate the wood fibers and harden, creating a moisture barrier that helps protect the wood from warping.

They achieve this by filling the pores of the wood, reducing its ability to absorb water and therefore its tendency to expand and contract, which leads to warping.

Linseed Oil: A Personal Story

A few years ago, I restored an antique wooden dresser that had seen better days.

I wanted to maintain its natural look and charm, so I decided to use linseed oil.

I noticed that, in addition to giving the wood a beautiful, rich sheen, the linseed oil helped stabilize the wood, protecting it from the changes in humidity in my house.

This prevented any further warping or distortion in the wood, ensuring the dresser remained in excellent condition.

A Note on Outdoor Wood Projects

For outdoor projects, it’s important to consider the type of oil you’re using.

Not all oils offer the same level of protection against elements such as water, UV rays, and temperature changes, which can all contribute to warping.

Teak oil, for example, is often used for outdoor furniture because it provides excellent water and UV resistance.

Oiling Isn’t a One-Time Task

It’s essential to remember that oiling wood is not a one-time task, but rather an ongoing maintenance requirement.

Over time, oil finishes can start to wear off and will need to be reapplied to maintain their protective qualities.

Regular oiling ensures the wood remains hydrated, protecting it from drying out and warping over time.

So, Now you have a clear understanding about, how to keep wood from warping with all the possibilities.

So, let’s answer some frequently asked questions as well.

FAQs

Can warped wood be fixed?

Yes, it’s often possible to fix warped wood, usually through a process of applying moisture and heat, then using clamps or weights to reshape the wood as it dries. However, prevention is easier than the cure.

How does sealing help prevent wood warping?

Sealing wood with a good-quality sealer helps to lock in the wood’s internal moisture and protect it from external moisture, temperature, and humidity changes, thereby reducing the chances of warping.

How does oiling prevent wood from warping?

Oiling wood serves a similar function to sealing. It penetrates the wood and slows down the rate of moisture absorption and loss, helping to keep the wood stable and preventing warping.

What type of sealer is best for preventing wood warping?

Polyurethane sealers, particularly those that are water-resistant, are highly effective at preventing wood warping. Marine-grade sealers are also an excellent choice for high-humidity or outdoor conditions.

How should I stack my lumber to prevent warping?

Lumber should be stickered – that is, stacked with small sticks placed between the layers for air circulation and weight distribution – and supported along its entire length to prevent warping.

Why is the storage environment important in preventing wood warping?

A stable storage environment with consistent temperature and humidity levels helps prevent the wood from expanding and contracting due to environmental changes, which can lead to warping.

What is end grain sealing and why does it matter?

End grain sealing involves applying a coat of wax or special sealant to the ends of lumber. It helps slow down the drying process at the ends of the boards, which can prevent splitting and warping.

Can the orientation of wood growth rings affect warping?

Yes, when stacking lumber, orienting the stack so that the wood’s growth rings curve downward can help reduce warping.

How can I keep thin wood from warping?

To prevent thin wood from warping, ensure it’s properly dried and sealed with a quality wood sealer. Thin wood can warp easily due to its size, so proper storage, like laying it flat and supporting it evenly, is also crucial.

How can I prevent 4×4 posts from warping?

To prevent 4×4 posts from warping, use wood that’s been pressure-treated or properly seasoned and sealed. Also, orienting the growth rings in a specific direction – perpendicular to the face of the post – can help reduce warping.

How can I keep a 6×6 post from warping?

To prevent 6×6 posts from warping use pressure-treated or properly seasoned and sealed wood. Good installation practices, such as setting the post in concrete and ensuring good drainage, can also help prevent warping.

How long does it take for wood to warp?

The time it takes for wood to warp can vary greatly depending on factors like the type of wood, its thickness, and the conditions it’s exposed to. Warping can occur anywhere from a few days to several months after exposure to adverse conditions.

Did I cover all you wanted to know about How To Keep Wood From Warping?

In this article, I have widely discussed how to keep wood from warping and what are the best 5 methods you can easily use to avoid wood warping.

Those are the methods that woodworkers follow for any small or large woodworking project which works perfectly.

You can keep wood from warping by keeping wood in a clean, dry storage area with proper storage techniques, monitoring the moisture content of the wood, curing the wood properly, acclimating wood before installation, and controlling the cutting of boards. Those methods will help you to keep wood from warping when cutting, painting, and drying.

Furthermore, I’ve talked about how to fix warped wood with some pro tips to keep wood from warping.

Those tips are so helpful for both beginner and advanced woodworker to protect their loving woodwork from moisture.

Ultimately sealing the whole wood is the best option to get a life protected from warping.

Also, I’ve answered some frequently asked questions as well.

Hope you have gained good knowledge about wood warping and what actions you should take to stop it.

So, let’s head into applying protection to your lumber, furniture, and woodwork from warping with this knowledge. Have fun in woodworking!