Ever wondered if your engineered wood surfaces could enjoy a refreshed look? Dive in as we explore the do’s and don’ts of painting engineered wood, ensuring your spaces stay stunning!

My mother had been thinking about how to make her old engineered wood cabinet a modern, vibrant makeover that continues to impress for a long time.

So, I did a deep research about this matter and now I have enriched myself with more promising and successful solutions thanks to the advice I got from experts.

If you have the same kind of problem regarding this, you are in the right place! Stay connected with me till the end.

So, let’s find out Can you paint engineered wood?

Yes, you can paint engineered wood, but the process depends on the type of engineered wood and the existing finish. Hardwood veneer types can be sanded and refinished, while laminate engineered wood can be painted after proper surface preparation. Always ensure proper techniques and materials are used for best results.

But there’s a lot more to know.

So, in this article, I’ll explore how to paint engineered wood in detail and will provide some tips I experienced so far for promising results at the end.

Furthermore, I’ll answer some frequently asked questions as well.

Let’s dive in!

Engineered Wood

Engineered wood, also known as composite wood or man-made wood, is a type of wood product formed by binding or fastening together strands, particles, fibers, or veneers of wood with adhesives and, in certain cases, additional materials such as plastics to form a composite material.

Engineered wood is made to give certain structural and aesthetic features, often with better performance and sustainability than natural wood.

This also randomizes the intrinsic properties of solid wood, such as knots and irregular grain, which have little impact on strength.

Here are some common examples of engineered wood.

Plywood

Plywood is created by gluing together numerous thin layers (or “plies”) of wood veneer.

Because of its strength and stability, this cross-layered design is a popular choice for structural and ornamental applications.

Oriented Strand Board (OSB)

OSB is made out of wood strands that are aligned in precise orientations and bound together with adhesive.

It is commonly used in building sheathing for walls, roofs, and subfloors.

Laminate

A man-made product (typically plastic) that has been ‘printed’ to appear to have wood grain.

It enables producers to produce furniture, cabinets, and flooring at a lower cost. Laminates cannot be stained. It’s not made of wood!

Particleboard

Particleboard is formed from wood particles or chips that are bound together by adhesives and compacted into sheets.

It’s used in furniture, cabinetry, and other home furnishings.

Read to know how to finish particle boards with stain.

Laminated Veneer Lumber (LVL)

LVL is created by gluing together veneers of wood with the grain oriented in the same direction.

It is utilized in structural applications such as beams and headers.

Medium-Density Fiberboard (MDF)

MDF is made by combining fine wood fibers with adhesives and then pressing them into sheets.

Read to know, Can You Paint On MDF (EASY Guide!)

Did you know? Engineered wood and manufactured wood are both composite materials made by combining wood particles, fibers, or veneers with adhesives and other additives, resulting in versatile and stable products that are often more affordable and environmentally efficient than solid wood.

Pros and Cons of Engineered Wood

When compared to solid wood, engineered wood has several advantages and downsides.

Understanding these advantages and disadvantages might assist you in making an informed decision when deciding between the two for your unique project.

Pros

- Stable

- Frequently less expensive than solid wood.

- Versatile- used in a variety of applications, including flooring, furniture, cabinetry, and doors.

- Long-lasting and durable- Resistant to strong wear and tear.

- Ease of Installation

- Easy to clean and maintain

Cons

- Engineered wood can only be sanded and polished a limited number of times.

- Not completely resistant to moisture damage.

- Chemicals may be present in the adhesives used to join the layers of engineered wood. Some people may be concerned about off-gassing, particularly in enclosed places.

How Does Paint Work on Engineered Wood?

Paint can be applied to engineered wood surfaces in the same way that it is applied to natural wood surfaces.

However, there are several factors to consider and actions to take to ensure a successful and long-lasting paint job on engineered wood.

Is it Ok to Paint Engineered Wood?

Yes, it is generally acceptable to paint engineered wood surfaces, and it is a practical and aesthetically pleasant solution to enhance and protect these surfaces.

Factors You Need To Consider Before Painting Engineered Wood

Before you begin, many factors must be considered to achieve a successful and long-lasting paint job.

Surface Type

Determine the type of engineered wood with which you are working.

Surface preparation and painting procedures may differ depending on the material, such as plywood, MDF, particleboard, or engineered hardwood.

Priming

Before starting the process, determine whether your surface requires priming.

Using a high-quality primer is often suggested to improve paint adhesion and prevent stains or discolorations from showing through the paint.

Paint Type

Select the correct type of paint for your specific application.

Consider whether you need interior or exterior paint, as well as whether latex/acrylic or oil-based paint is more suited to your needs.

It may be influenced by the location and intended use of the painted surface.

Color and Finish

Choose a paint color and finish (e.g., matte, satin, or gloss) that match with your aesthetic choices and the overall style of the project.

Ventilation

Make sure the area where you’re painting has adequate airflow. It helps t drying and avoids paint fumes from being inhaled.

Open windows and utilize fans to help with air circulation when painting indoors.

Environmental Condition

Keep in mind that painting should be avoided during particularly hot, cold, or wet weather because it can influence the application and drying of the paint.

Supplies You Will Need to Paint Engineered Wood

First, gather all the tools and materials mentioned below.

Tools

- Engineered wood furniture

- Paintbrushes or a paint sprayer

Materials

- Sandpapers

- Tack cloth or a damp cloth

- High-quality primer

- A suitable paint

- Clear polyurethane or varnish (optional)

- Safety gear (protective gloves, mask, safety goggles)

Make sure to collect the above supplies from quality manufacturers to achieve promising results.

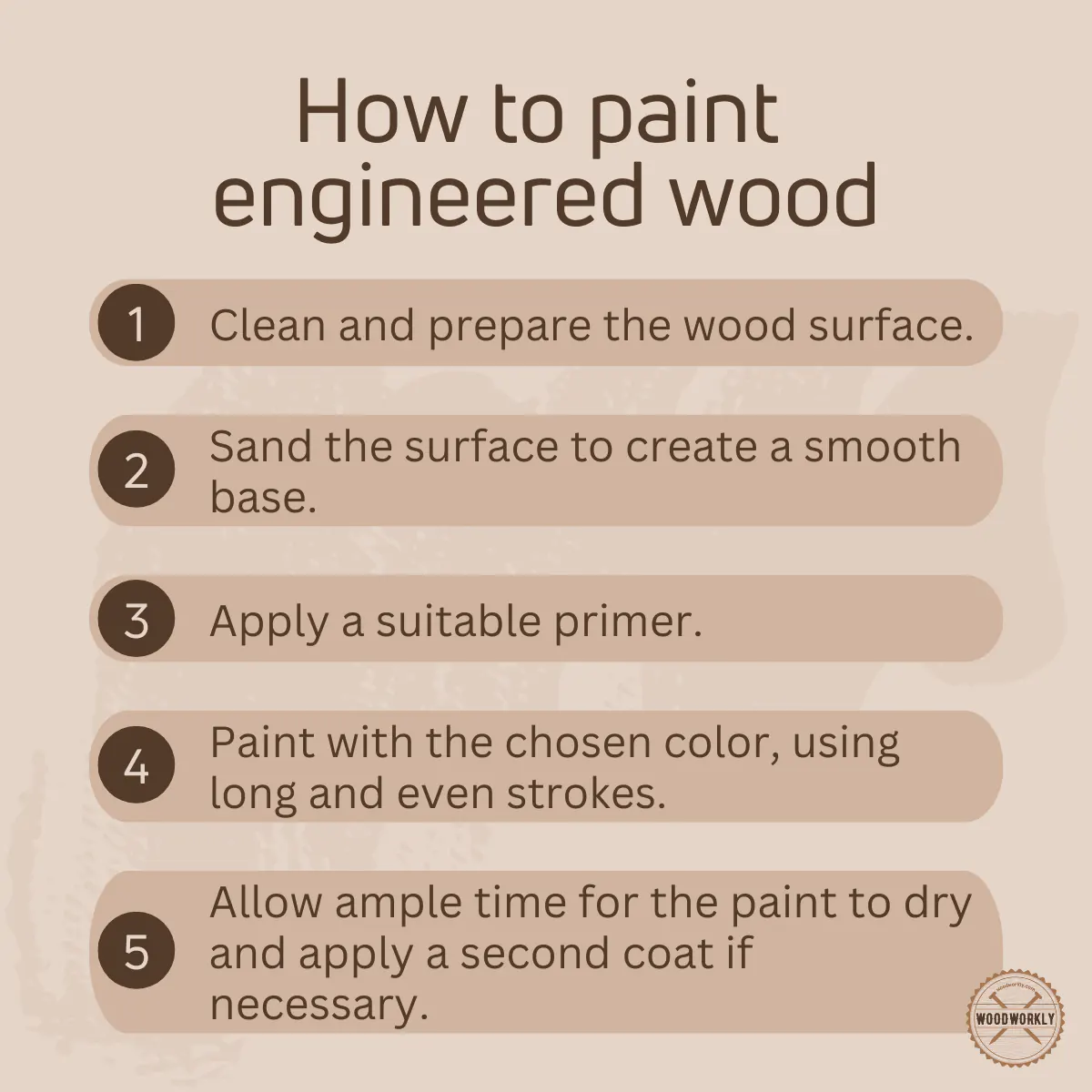

How to Paint Engineered Wood Furniture?

Painting engineered wood furniture is an excellent method to refresh its appearance and give it a new appearance.

Here’s a step-by-step guide for painting engineered wood furniture,

- Clean the Furniture

- Sand the Surface and clean again

- Apply Primer

- Paint the Furniture

- Allow to Dry

- Apply a Clear Coat (Optional)

Now, I’ll discuss each step in detail.

1. Clean the Furniture

Using a tack cloth or a moist cloth, remove any dirt, dust, or grime from the furniture.

If the furniture is very dirty, it may be necessary to wash it with a mild detergent and water and allow it to dry fully.

2. Sand the Surface and Clean it Again

Sand the entire surface of the furniture lightly with medium-grit sandpaper. This gently roughens the surface, which promotes greater paint adhesion.

Sand in the direction of the grain of the wood. After that, polish the surface with a fine-grit sandpaper.

If you are planning to paint previously painted engineered hardwood floors, use a pad sander, but for larger rooms, you might want to use a floor buffer and sanding screen. This will smooth out and remove the old finish.

Use a tack cloth or a moist towel to remove any sanding dust and debris after sanding. Before continuing the process, make sure the surface is clean and dry.

3. Apply Primer

Use a high-quality paintbrush or roller to apply a high-quality primer to the furniture which improves paint adhesion and offers an even basis for the paint color.

After drying the first coat of primer, apply the second coat. I always recommend sanding between primer coats.

4. Paint the Furniture

After the primer has dried, apply a topcoat using high-quality latex or acrylic paint. Using a paintbrush or a paint sprayer, apply thin, even coats.

Always paint in the direction of the wood grain to maintain a natural appearance.

Depending on the paint and color, two or more coats may be required to obtain the desired smoothness and finish.

Once you’re done with painting, read to know How to Clean Acrylic Paint Brushes.

5. Allow to Dry

Allow the coat to dry before moving on to the next step. Follow the manufacturer’s recommended drying time.

6. Apply a Clear Coat (Optional)

Apply a clear polyurethane or varnish as a coating to the painted furniture to offer further protection and gloss.

This is especially crucial if your furniture has high-traffic regions.

Best Paint to Use on Engineered Wood

The best paint to use on engineered wood depends on the application and the desired finish.

Acrylic or Latex Paint

Interior uses of latex or acrylic paints on engineered wood furniture, cabinetry, and walls are frequent.

They are simple to clean, dry quickly, and produce fewer fumes. These paints come in a variety of colors and finishes, ranging from matte to high gloss.

Oil-Based Paint

Oil-based paints are extremely durable and can be used both inside and outside.

They are frequently used in high-traffic areas and on surfaces that need additional protection, such as doors, trim, and outdoor furniture.

However, it takes longer to dry and release more odors, so sufficient ventilation is essential.

Acrylic Enamel Paint

Acrylic enamel paints are a long-lasting, high-gloss choice. They have a strong, glossy finish that is scratch and stain-resistant. They are appropriate for both inside and external use.

Chalk Paint

To gain a distressed or vintage look on engineered wood surfaces, chalk paint is a common option.

It sticks effectively to most surfaces and does not require significant priming. For further protection, it is usually coated with a wax or varnish after painting.

How Long Does Paint Last on Engineered Wood?

Exterior paint on engineered wood surfaces can last anywhere from 5 to 15 years if properly maintained.

Interior paint on engineered wood surfaces often has a longer lifespan, frequently lasting 10 years or more, depending on factors such as cleaning.

The durability of paint on engineered wood can vary greatly based on various factors, including paint quality, preparation and application, level of exposure to the environment, and amount of wear and tear.

High-quality paints are more durable and last longer. They often have higher adhesion, fade resistance, and weather resistance. In general, higher-quality paints may last longer than lower-quality alternatives.

If your surface is thoroughly cleaned, sanded, and primed, the paint sticks better and is less prone to peel or chip.

Regular upkeep can help the painted surface last longer. This includes cleaning the surface on a regular basis and performing touch-ups or repainting as necessary to address symptoms of wear and degradation.

Paint may decay faster if it is exposed to severe conditions such as extreme temperatures, humidity, rain, or sunshine. Exterior surfaces are frequently subjected to greater wear and tear.

Can You Change The Color Of The Engineered Wood Floors

Engineered wood floors can be colored, although the process may vary depending on the type of finish used on the surface.

Engineered wood floors are typically pre-finished, which protects the surface from damage and improves its appearance.

You can modify the color of your hardwood veneer-engineered wood flooring by refinishing it. Sanding down the previous finish and then putting a fresh stain and finish

If you have a laminate-engineered wood floor, the color of the flooring cannot be changed by refinishing.

One option is to add an area rug or carpet. The other alternative is to completely replace the flooring with a new color or pattern.

Tips for Painting Engineered Wood Properly

Here are some valuable tips that you’ll need for a successful engineered wood painting process.

- Make sure to remove any removable hardware parts such as knobs, handles attached to your furniture using a screwdriver before starting the process. This will make painting easier and result in a cleaner finish.

- Don’t sand too much. Because engineered wood type can be a thin material, use caution to avoid damaging the top layer.

- Applying a thick layer of paint might result in drips, uneven coverage, and prolonged drying times.

- To prevent the drip marks when using a synthetic brush, begin strokes in the center of the piece and work outward. Drips are more common on the edges and corners, therefore having less paint on the brush as you approach the sides.

- Work according to the wet edge. It means, that when you finish a section, begin the following section by overlapping it by roughly 20% onto the freshly painted section.

- Don’t try to correct imperfections that you see after the paint has dried slightly. This will ruin your paint. To repair it, the paint must be entirely dried. Then the problems will be resolved by allowing it to dry, buffing it out, and then painting another coat

That’s it folks! Now you know about painting engineered without making any mistakes.

So, let’s answer some frequently asked questions.

FAQs

Is it necessary to sand engineered wood before painting?

Yes, it is necessary to sand engineered wood before painting to ensure proper adhesion of the paint, but care must be taken to not sand too much as engineered wood typically has a thin top layer.

Can you change the color of engineered hardwood floors?

Yes, you can change the color of engineered hardwood floors by sanding down the existing finish and applying a new stain and finish, though this depends on the thickness of the veneer and the number of times the floor has been refinished previously.

Can you paint LP SmartSide engineered wood siding?

Yes, LP SmartSide engineered wood siding can be painted, and it is recommended to use acrylic latex coatings designed specifically for wood composites. The factory-primed surfaces should be painted, and any cut edges should be primed and painted to protect the substrate.

Is it recommended to back prime LP SmartSide engineered wood products?

No, it is not recommended to back prime LP SmartSide engineered wood products. The back side of the siding and trim is better left unpainted, as back priming has not shown to be beneficial for these specific products.

What types of stains can be used on engineered wood?

Transparent stains are not recommended for engineered wood. However, there are new acrylic latex paints available that can replicate the appearance of a semi-transparent stain.

Can you refinish laminate engineered wood flooring?

No, you cannot refinish laminate engineered wood flooring by traditional sanding and restaining methods due to its construction. The surface is a photographic layer rather than real wood, but you can paint over it with proper preparation.

How many times can you refinish engineered hardwood floors?

The number of times you can refinish engineered hardwood floors depends on the thickness of the veneer layer. Thicker veneer layers allow for more refinishing sessions, with a general guideline being one less than the veneer thickness in millimeters.

What should be considered before deciding to paint or refinish engineered wood floors?

Before deciding to paint or refinish engineered wood floors, consider the thickness of the veneer layer, the number of times the floor has been refinished, and the overall condition of the floor.

Can you change the color of engineered wood without sanding?

Yes, you can change the color of engineered wood without sanding by using methods like glazing, which adds a tinted finish over the existing one. However, this method may not be as permanent as refinishing, and the glaze color will mix with the existing stain.

Did I cover all you wanted to know about: Can You Paint Engineered Wood

In this article, I deeply discussed whether can you paint engineered wood, things you need to consider when painting engineered wood, and the painting procedure in detail.

Furthermore, I’ve answered some frequently asked questions.

You can paint engineered wood and painting gives new life to your furniture and surfaces. You can achieve an amazing and long-lasting finish with the correct techniques and materials. However, the success of the process depends on several factors such as the surface type and age, expected surface finish, paint type, and so on.

Hope you learned everything you wanted to know about the painting engineered wood including expert tips!

Now it’s time for you to practice the above procedure with scrap engineered wood for several times and then head into the main project like a pro!