Ever faced a halted project due to a stubborn Ridgid Oscillating Sander that won’t buzz to life? How did you get the power back in your hands? Dive in for proven solutions!

Ridgid Oscillating Sander also known as Oscillating Edge Belt/spindle Sander is a popular power tool among woodworkers that is useful to finish edges, faces, and corners fast and burn-free.

One day when I was working with my Ridgid Oscillating Sander it stopped suddenly and didn’t oscillate anymore. I was so frustrated.

I took it to professionals in my nearest local store and they fixed and repaired it and provide some useful advice to fix some common issues that cause Ridgid Oscillating Sander to stop and how to fix them on my own.

Today, I’ll share with you how they fix my Ridgid Oscillating Sander and the troubleshooting tips I gathered when using it. Let’s find out, why Ridgid Oscillating Sander won’t start.

The Ridgid Oscillating Sander won’t start due to troubles in the motor, bearing problem, sanding sleeve keeps riding up, overheating, poor-quality belt, dust, debris, and starter switch issues. To fix the Ridgid Oscillating Sander won’t start, disassemble it, clean it with compressed air, lubricate the bearings, or send it to the Repair Centre.

But that’s a quick snapshot and there’s a lot more to know about why Ridgid Oscillating Sander won’t start and how to fix it properly.

In this article, we’ll explore why Ridgid Oscillating Sander won’t start, and how to fix all of its issues with some troubleshooting tips.

Furthermore, I’ll answer some frequently asked questions as well.

Let’s dive in!

Why Ridgid Oscillating Sander Won’t Start?

Ridgid Oscillating Sander won’t start due to several reasons. Some are issues that always come with the machine and some are because of how we use it.

If you’re already under the warranty period better to take it to the nearest repair center.

But first, it’s important to identify which part has the issues as a woodworker since some issues can easily fix simple DIY methods.

Here’re some possible reasons why Ridgid Oscillating Sander won’t start,

- Troubles in the motor

- Poor lubrication of the bearings

- Dust and debris

- Low-quality belts

- Overheating

- Starter switch issue

Most of the above issues can be fixed easily, but some aren’t.

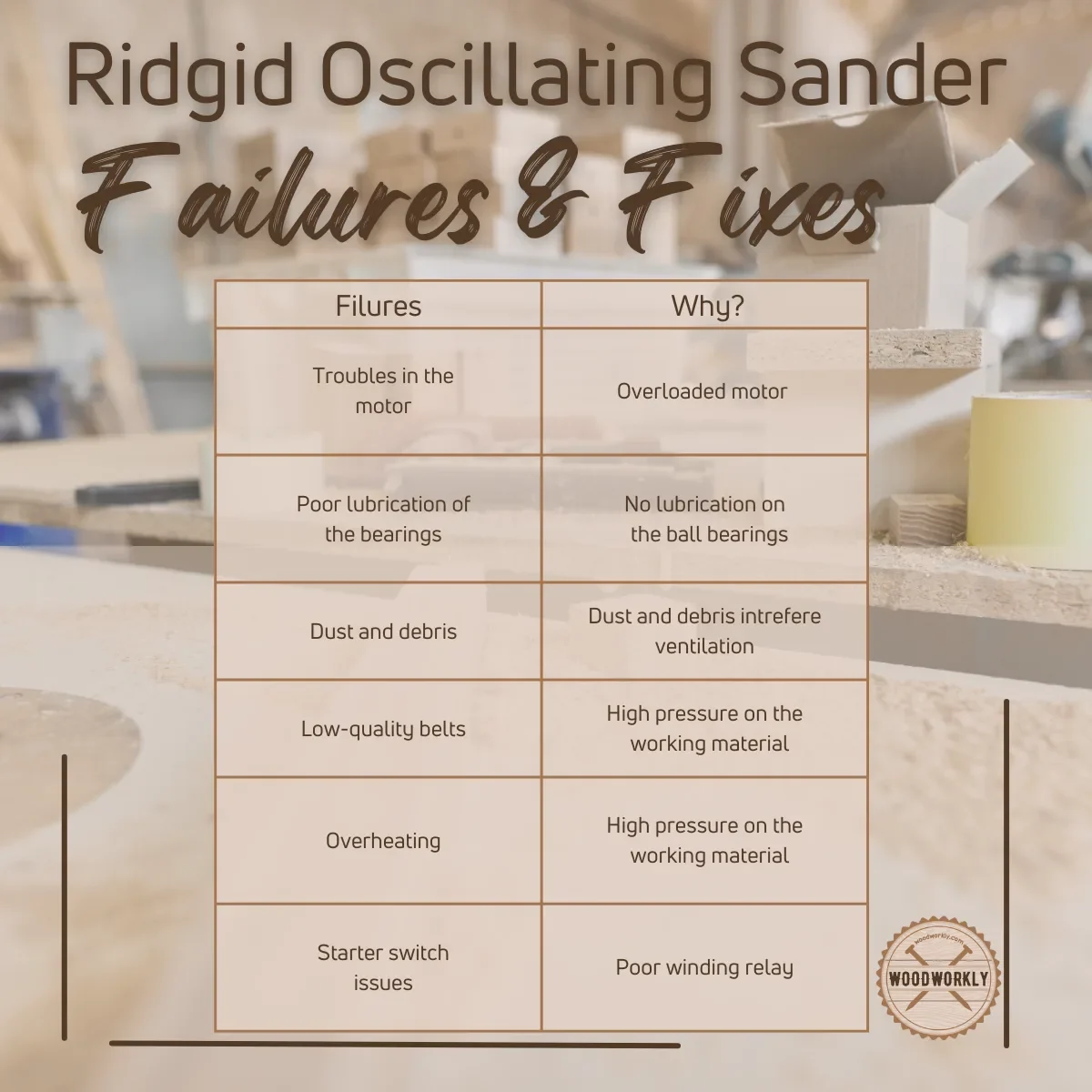

Here’re the reasons that could affect the following issues of the Ridgid Oscillating Sander.

| Reason For Ridgid Oscillating Sander Failure | Why? |

| Troubles in the motor | Overloaded motor due to making too many starts and stops in a short time, low voltage, lose or incorrect connections, |

| Poor lubrication of the bearings | The lubrication of the ball bearings is gone |

| Dust and debris | Dust and debris go into the ventilation and interfere, sawdust collects on the inside table recess |

| Low-quality belts | High pressure on the working material, spindle knob is too loose |

| Overheating | High pressure on the working material |

| Starter switch issues | Poor winding relay, damaged switch |

Sometimes you’ll have to take the machine to the nearest Repair Centre if you couldn’t identify the issues.

But first, it’s wise to try dissembling and cleaning it properly since many troubles can occur when dust and debris interfere with the working parts inside.

Let’s see how to fix Ridgid Oscillating Sander to make it work again.

How To Fix Ridgid Oscillating Sander Won’t Start?

Most of the Ridgid Oscillating Sander problems can fix by cleaning the motor, and belts and by shifting the area.

Overheating, dust, debris, and poor or high voltages are the first things you should look at when an electrical machine won’t start.

Some parts of the Ridgid Oscillating Sander can be replaced with new parts and most of the problems may fix with that. But never replace parts blindly without knowing the root cause of the issue.

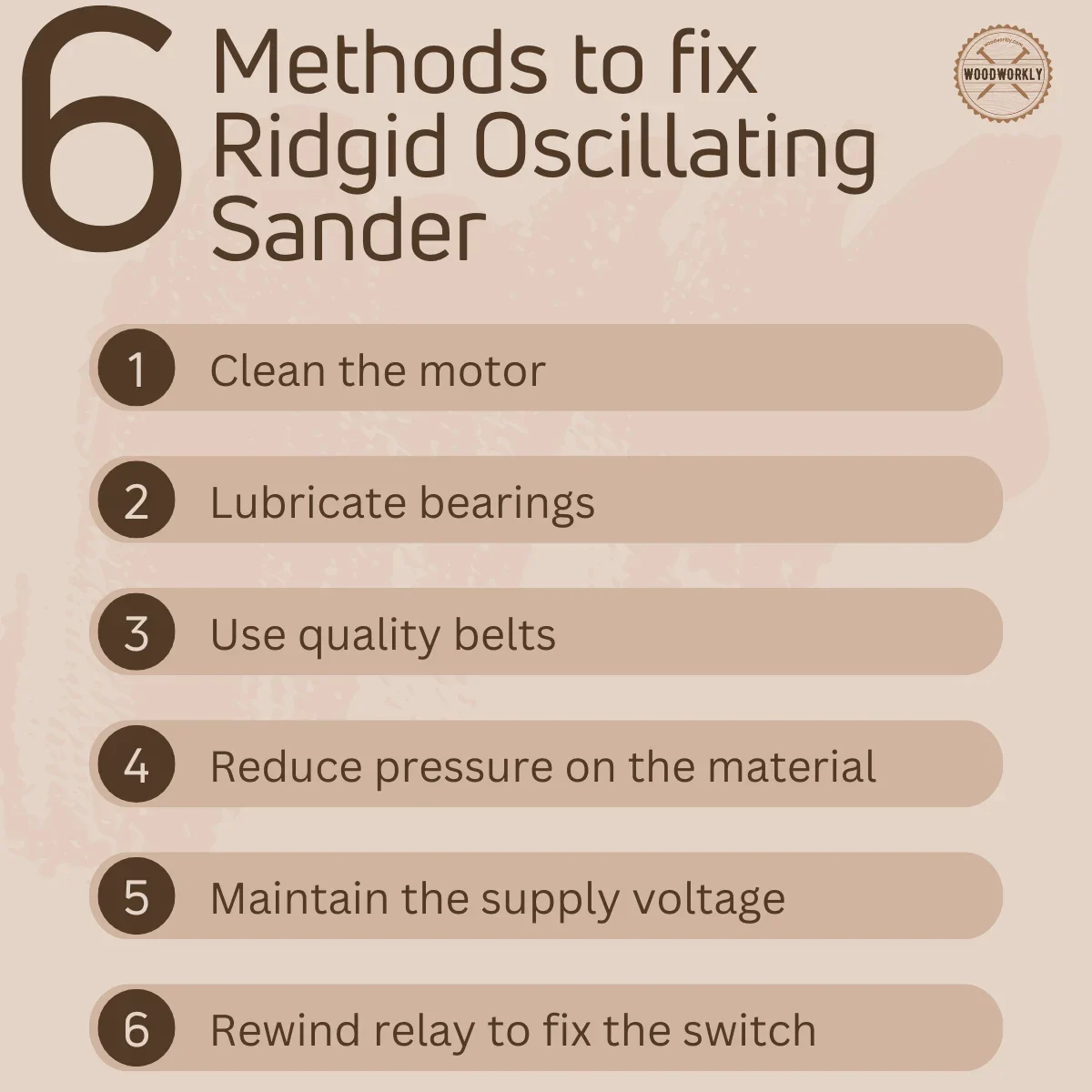

Here’re the common fixes you can try to fix Ridgid Oscillating Sander won’t start,

- Clean the motor

- Lubricate bearings

- Use quality belts

- Reduce pressure on the working material

- Maintain the supply voltage and connections

- Wind relay properly to start the switch

Let’s discuss each of the above fixes in detail to get a clear idea of troubleshooting Ridgid Oscillating Sander properly.

1. Clean The Motor

Most of the Ridgid Oscillating Sander won’t start when dust and debris accumulate inside the inner parts.

The motor stops working when dust and debris go inside. Even though Ridgid Oscillating Sander is equipped with a proper dust collection system, it’s important to keep the area clean.

Keep the motor clean by blowing it out frequently or by vacuuming it. Accumulation of dust can make it overheat, interfere with the motor ventilation system and reduce functionality.

Plus, dissemble the Ridgid Oscillating Sander from time to time according to your usage and clean the inside components properly to remove dust and debris which cause many troubles.

Follow the instruction manual to see how Ridgid Oscillating Sander dissembles and assembles properly when cleaning.

Make sure there’s no dust or debris between the working material and its supports. This can interfere with the workability of the sanding drum and make it slow down.

Clean sanding belt assembly regularly by removing sawdust from the inside table recess.

Better if you can clean the dust outside the machine after each usage and clean the inner areas at least once per two months.

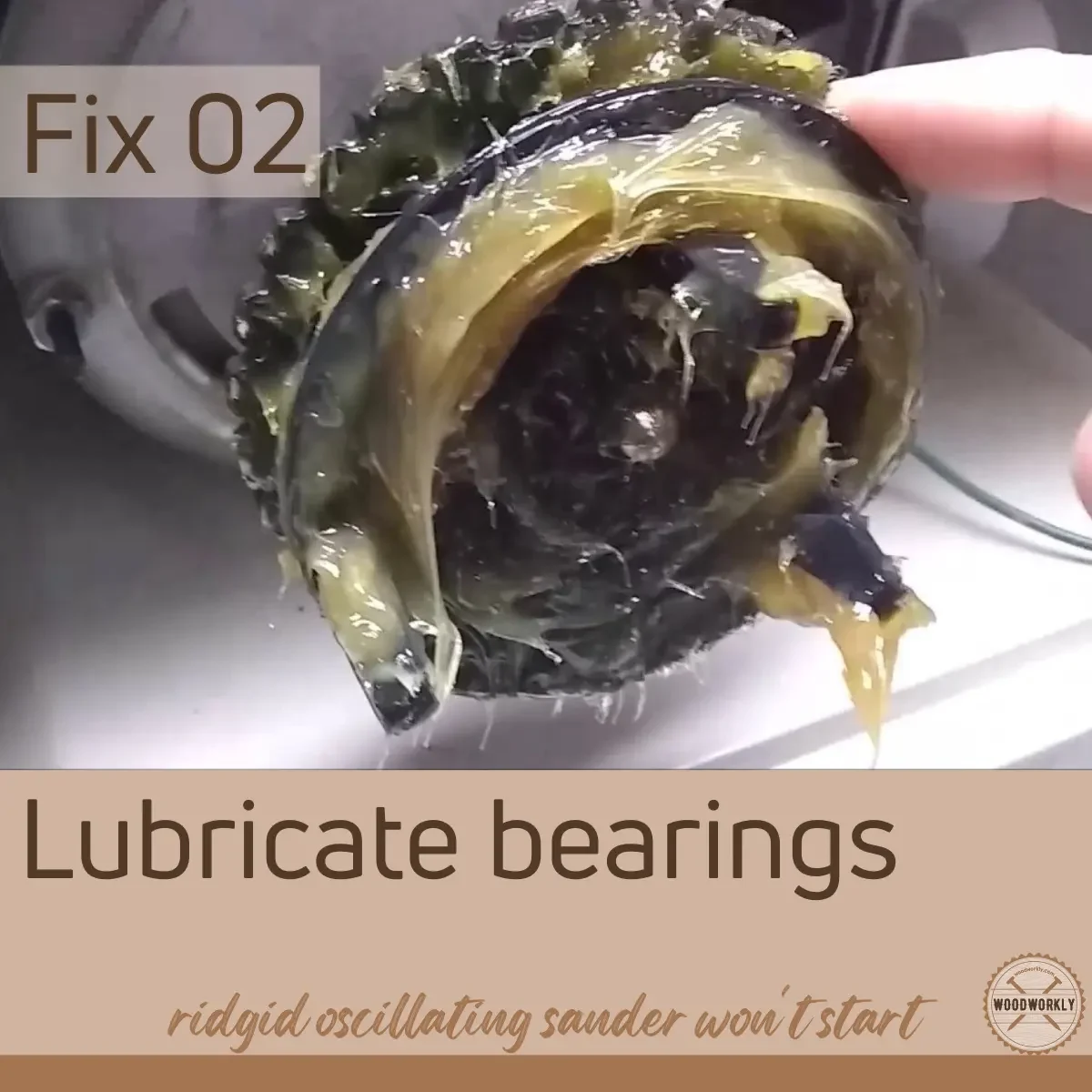

2. Lubricate Bearings

According to the instructions manual of Ridgid Oscillating Sander, all the bearings are self-lubricating, and we don’t need to lubricate them.

But if your Ridgid Oscillating Sander is too old, and won’t work well, better to dissemble it and check for bearings.

Bearings need to be saturated with oil. If it is not the heat and dryness will build up and reduce the functionality of the bearings which leads to the Ridgid Oscillating Sander won’t start or spinning slowly.

You can identify that when the machine is vibrating abnormally. Try to dissemble the machine and lube the bailer bushing in the top bearing.

Never lube bearings if your Ridgid Oscillating Sander is new since I’m 100% sure it comes with good lubrication.

Try only when your machine is too old and the warranty period is expired already. Worth to give a shot before being a new one.

3. Use Quality Belts

Using poor-quality belts can damage the Ridgid Oscillating Sander over time which can cause it stops working.

Have you noticed the “thump”, “thump sound noise comes from the Ridgid Oscillating Sander? That’s when the quality of the belts is not so good.

Replace the belts immediately with quality ones such as Norton belts at HoMe to avoid your Ridgid Oscillating Sander from damaging any further.

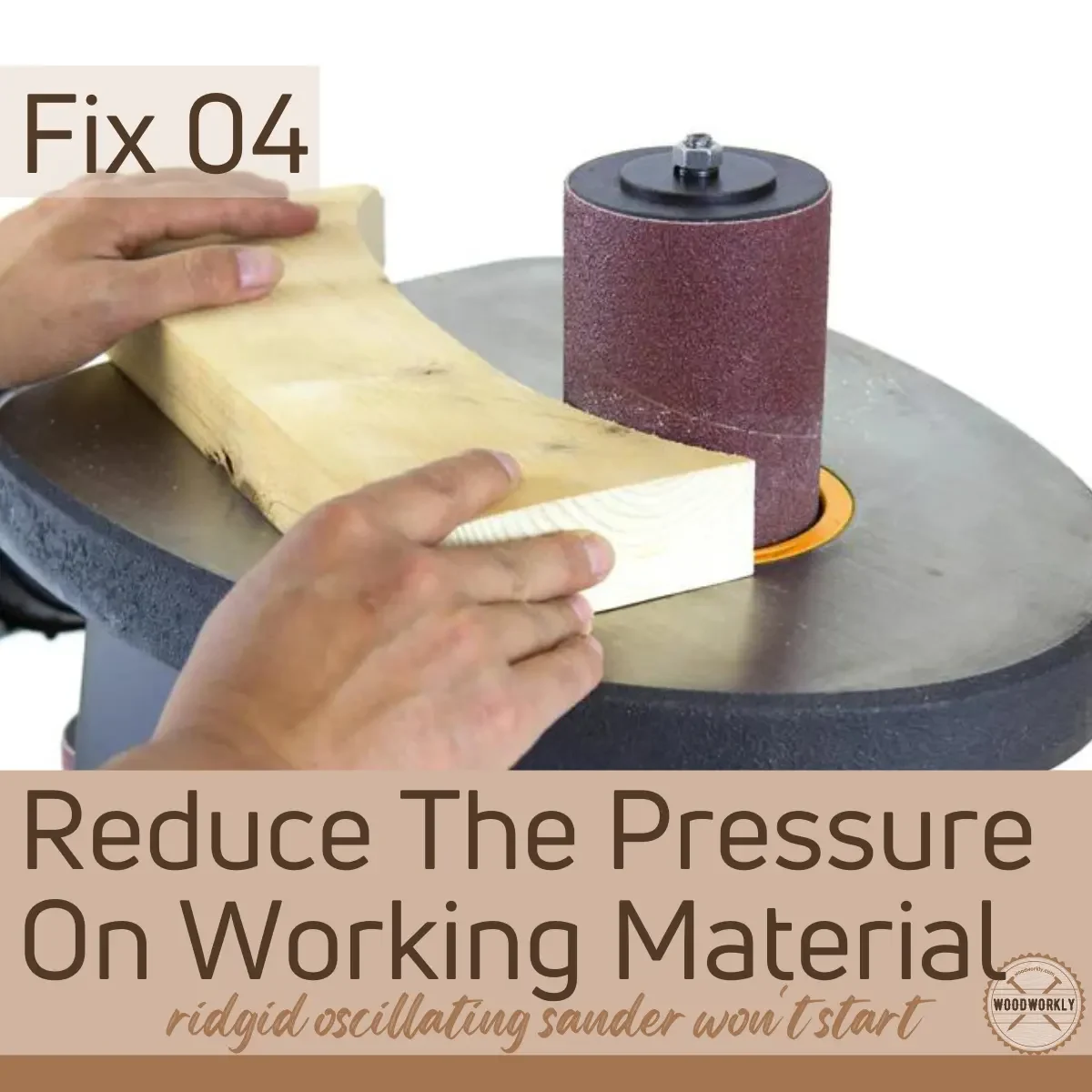

4. Reduce The Pressure On Working Material

When you apply too much pressure on the material when working Ridgid Oscillating Sander it can cause several issues in the machine such as,

- The motor starts to overheat

- The sanding belt or drum slows down or slips off

When the motor starts to overheat, its performance gets affected and slows down or causes sudden stops in Ridgid Oscillating Sander.

When the sanding belt or drum slips off the machine will randomly stop.

Therefore, make sure not to apply too much pressure on the workpiece. This is a really simple fix to avoid your Ridgid Oscillating Sander from random stops.

5. Maintain Supply Voltage And Connections

The supply voltage can have a big effect on the workability of the Ridgid Oscillating Sander. The supply voltage should not be too high or too low.

Plus, the connection wires should not be too long which can damage the inner parts of the Ridgid Oscillating Sander due to less voltage supply.

Due to the heavily loaded circuits, the supply voltage will be low. Due to that the motor of Ridgid Oscillating Sander won’t be able to generate full power and fails especially when it reaches full speed.

Heavy-loaded circuits slow the spinning speed of the motor.

The motor tends to stall resulting in circuit breakers or blown fuses due to the sudden voltage drops and rises. Better to check your voltage supply with a qualified electrician to prevent the motor from getting damaged.

Maintain the following specifications when supplying power to the motor of the Ridgid Oscillating Sander.

| Motor Type | Relay start A-C motor |

| Rated H.P | 3/8 |

| Amperes | 5.0 A |

| Voltage | 110 V – 120 V |

| Frequency (Hertz) | 60 |

| RPM | 1725 |

| Phase | Single |

| Rotation of Shaft | Clockwise |

When your Ridgid Oscillating Sander won’t work check the plug whether it is properly connected to the outlet or not.

The local cord should be from a quality brand to provide an uninterruptable power supply to the Ridgid Oscillating Sander.

The use of any extension cord reduces the power to the sander. Therefore, better if you don’t use an extension cord for Ridgid Oscillating Sander.

6. Wind Relay Properly To Start Switch

When your Ridgid Oscillating Sander is not working properly dissemble and check the starter switch. In the starter switch, there’s a relay that winds up with wire.

The relay switch draws up extra power as it is starting up. It creates extra magnetism and draws up the little cylinder that makes extra contact with the motor starter.

It needs to have more windings to create good magnetism to provide extra power. But sometimes you’ll notice the windings are not enough in the relay switch to create that extra power.

This makes Ridgid Oscillating Sander stop and reduces the spinning speed.

To fix that, you can wind the relay switch with enough wire to create good magnetism upon working with extra power. Proper winding of the relay switch fixes Ridgid Oscillating Sander from stropping.

Rewind it with the original wire or use a wire from an old transformer. Rewind properly and test your Ridgid Oscillating Sander.

That’s it, folks! Now you know how to fix Ridgid Oscillating Sander won’t start using the correct methods. Give it a try before taking it to the repair center.

Ridgid Oscillating Sander Troubleshooting

The following chart helps you to identify the most common troubles you’ll identify on Ridgid Oscillating Sander upon singing and how to fix those quickly.

| Symptom | Reason | Solution |

| The motor fails upon full power and is unable to achieve full speed | Low voltage supplies due to the overloaded circuit, Issues in the motor relay, Overloading of power company facilities | Avoid using Ridgid Oscillating Sander on heavily loaded circuits, Check voltage by a qualified electrician, Replace the relay |

| Loud noise | Failures in the gearbox of motor | Contact the Repair Centre |

| Overheating motor | Motor overloading | Reduce pressure on the working material |

| Motor stalls | Failures in the motor relay, the Supply voltage being too low, Incorrect circuit breakers and fuses in the power line | Install correct fuses and circuit breakers, Check voltage by a qualified electrician, Replace the relay |

| The motor won’t start | The on/Off switch is damaged, the Motor is burned out, and Low voltage | Replace the damaged parts of the motor, Contact the Repair Centre |

| The fuse or Circuit breaker opens frequently | Overloaded motor, Incorrect circuit breakers and fuses in the power line, the relay is not opening | Feed work slower, Contact the Repair Centre, Replace the relay |

| The sanding belt or drum slips out and slows down | Too much pressure on the working material, Loosed spindle knob | Reduce pressure on working material, Tighten or replace spindle knob |

| Sandpaper doesn’t remove the material | Sawdust accumulated on sandpaper | Clean or replace the sandpaper |

| Wood burns when sanding | The sanding drum is glazed | Replace the sandpaper |

| The spindle does not go full ¾” travel | Sawdust accumulated under the lower drum washer, Fan is not installed, Gearbox is damaged | Remove sawdust from lower drum washer, Install fan, Contact Repair Centre |

Now you know how to fix it and what actions you should take when Ridgid Oscillating Sander not working properly.

Let’s answer some frequently asked questions.

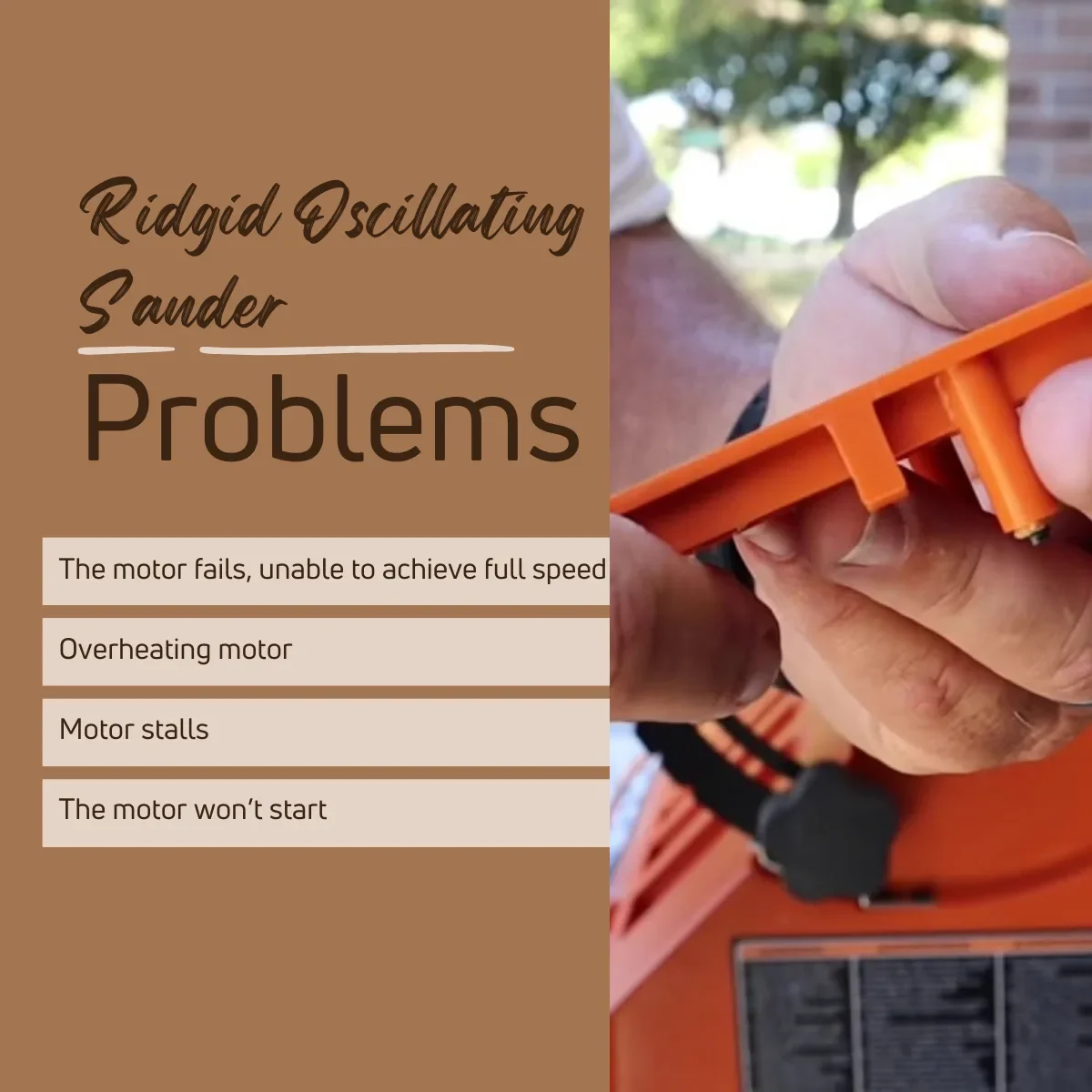

What Are the Ridgid Oscillating Sander Problems?

Ridgid Oscillating Sander is an awesome machine that is recommended by woodworkers for so long. But as with every other material, this sander also has some common issues.

Here’re some popular common problems of Ridgid Oscillating Sander,

- The motor fails upon full power and is unable to achieve full speed

- Loud noise

- Overheating motor

- Motor stalls

- The motor won’t start

- The fuse or Circuit breaker opens frequently

- The sanding belt or drum slips out and slows down

- Sandpaper doesn’t remove the material

- Wood burns when sanding

- The spindle does not go full ¾” travel

Most of the above problems can be fixed by removing dust and debris after dissembling. Other than that take the Ridgid Oscillating Sander to the nearest Repair Centre to get the problems fixed.

Why Ridgid Oscillating Sander Does Not Spin?

Ridgid Oscillating Sander does not spin when the relay switch is broken, when the motor is damaged, or when the belt is in poor quality.

First try to clear the ventilations of the motor to remove dust, debris, and sawdust from the machine, try to replace the relay or belt and notice whether it spins well.

If nothing worked,

Take Ridgid Oscillating Sander to the nearest Repair Centre to fix the not spinning issue.

Why Ridgid Oscillating Sander Is Stuck?

Ridgid Oscillating Sander stuck due to the failures in the motor. To fix the stuck Ridgid Oscillating Sander,

- Avoid using Ridgid Oscillating Sander on heavily loaded circuits

- Check voltage by a qualified electrician

- Replace the relay

- Contact the Repair Centre

- Reduce pressure on the working material

- Install correct fuses and circuit breakers,

- Replace the damaged parts of the motor

Did I cover all you wanted to know about: How To Fix Ridgid Oscillating Sander won’t Start?

In this article, we deeply discussed, why Ridgid Oscillating Sander won’t start and how to fix that properly using 6 different methods. We have discussed how to troubleshoot some common issues of the Ridgid Oscillating Sander before taking it to the Repair Centre.

You can fix Ridgid Oscillating Sander won’t start by cleaning the motor, lubricating the bearings, using quality belts, reducing pressure on working material, maintaining the supply voltage and connections, and wind relay properly to start the switch. Finally, take it to the Repair Centre for troubleshooting.

Furthermore, I’ve answered some frequently asked questions as well.

Hope you learned everything you wanted to know about, how to fix Ridgid Oscillating Sander won’t start in many ways.

Apply techniques you learned to fix your broken Ridgid Oscillating Sander and be good at fixing your tools like a pro.