Ever wondered what stands behind the endurance of your favorite wooden furniture – stressed or unstressed joints? Let’s delve in!

The term ‘wood joint’ is popular in woodworking. To join pieces of wood, we employ various types of wood joints and secure them using wood glue.

After the glue is applied, a certain clamping time is necessary to allow for proper adhesion.

Different wood glue products specify varying clamping times for stressed and unstressed joints.

Many people often wonder about the differences between stressed and unstressed joints. So, I did a deep research about this with the help of industry experts.

Here’s what I learned about, Stressed vs Unstressed Joint,

A stressed joint carries a large dynamic load and an unstressed joint carries a small static load. After applying wood glue, stressed joints should clamp for about 24 hours and unstressed joint should clamp for about 30 minutes. Stressed joint needs to be stronger than an unstressed joint to carry the excess load.

But there’s more to know about stressed vs unstressed joint.

In this article, I’ll explore what’s a stressed joint and what is an unstressed joint with their applications and the differences between stressed and unstressed joints as well.

Let’s dive in deeper.

What is a Stressed Joint?

The stressed joint is a wood joint that carries a dynamic high amount of load. There are so many reasons to become a wood joint stressed.

Chairs, tables, cabinetry, floors, and shelves have stressed joints that withstand high pressure from time to time.

To bear that amount of force, the wood joint must need to be strong.

When the stressed joint is properly glued and dried, it becomes stronger than wood fiber.

Stressed joint bond is seldom and able to withstand high forces focus on chairs, tables, cabinets, and doors during the day to day use.

Box joint (finger joint) and Mortise and tenon wood joints are extremely strong and apply for the areas that stress a lot. Therefore, those joints can be considered stressed joints.

When you’re working on wood joints if the position is stressed better to camp the stressed joint for at least 24 hours until the wood glue is completely cured and set.

Most stressed joints require mechanical fasteners with wood glue to reinforce the wood to meet the stress head-on.

The simplest fasteners are screws, nails, dowels, and biscuits. They support stressed joint to face the dynamic load without breaking the joint.

Above fasteners should apply to the stressed joint by cutting a hole and adding metal or wood to the intersection of the wood pieces.

After using both wood glue and fasteners you can see the stressed joint is satisfied and able to withstand high stresses.

Joints that are impacted by high dynamic stress need to be strong without ruining the appearance of the woodwork.

Read to know Why Your Grandpa’s Chair is Stronger Than Yours!

Examples of Stressed Joint

Here’re the wood joins that constantly withstand the dynamic stresses.

- Cabinet joints

- Floor wood joints

- Chairs

- Tables

- Drawers

As you can see, Stressed joints are essentially the superheroes of the woodworking world.

They are designed to bear significant dynamic loads, making them a staple in projects that require a robust and lasting bond.

Think of the sturdy tables, chairs, or cabinets you might have in your home; they most probably leverage the power of stressed joints.

What is an Unstressed Joint?

The unstressed joint is a wood joint that carries a small static load. Unstressed joints are not as strong as stressed joint.

Most of the time wood joint is well enough to carry a load when the joint is unstressed. No need for wood glue or fasteners.

But most woodworking experts recommend using wood glue even when the wood joint is unstressed as extra protection.

The clamping time for the unstressed wood joint is only about 30 minutes.

When you’re working on an unstressed joint like a window frame, window panels which are short clamps, clamping for 30 minutes is well enough and it takes about a maximum of 6 hours to get the wood glue fully cured.

Unstressed wood joints are mostly decorative joints that are not as strong as stressed joints.

Butt joint and miter joints are examples of unstressed wood joints that use for areas with fewer stresses.

Titebond Polyurethane glue should clamp for about 45 minutes and the glue will be cured completely within 6 hours.

Even though we have mentioned 30 minutes clamping/ drying time for unstressed joint and a 24-hour clamping/ drying time for stressed joint, the drying time can differ because of the temperature changes, wood type, wood dryness, and humidity level.

- High temperature, lower humidity, and drier wood speed up the drying time.

- Lower temperature, higher humidity, and wet wood slow down the drying time.

Examples of Unstressed Joint

Here are the unstressed wood joints that carry small static loads,

- Window panels

- Window frames

- Picture frames

- Tabletops

- Boxes

- Crates

Unstressed joints are the unsung heroes that come into play in more delicate scenarios.

They carry smaller static loads, usually finding their place in decorative pieces and structures not exposed to heavy pressures and impacts.

Imagine the beautiful picture frames or decorative window panels gracing your home; these generally involve the use of unstressed joints.

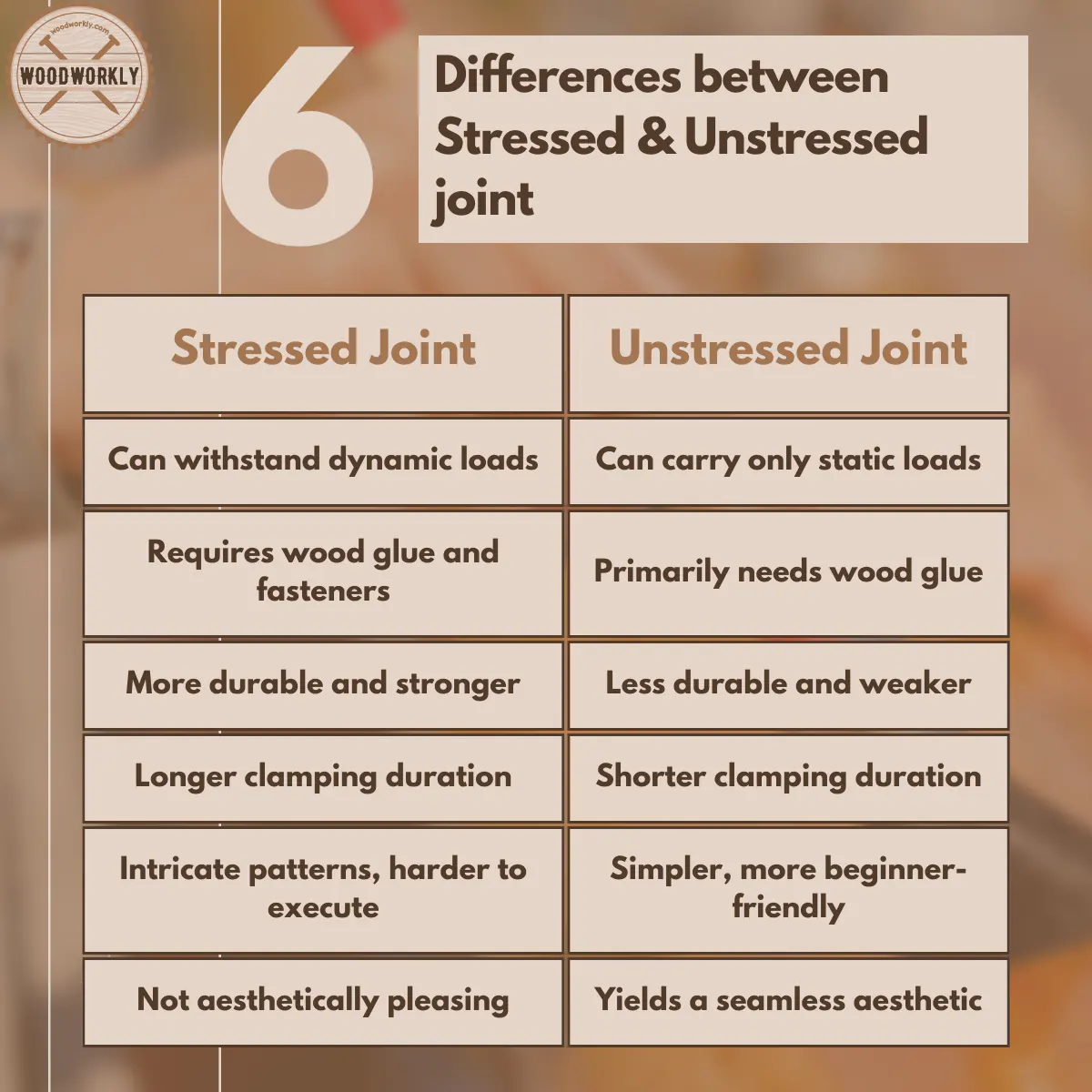

Stressed vs Unstressed Joint Differences

So, let’s find out the differences between the stressed joint and the unstressed joint.

| Stressed Joint | Unstressed Joint |

|---|---|

| Withstand against heavy load | Withstand against small loads |

| Subject to dynamic load | Subject to static load |

| Strong wood joint | Wood joints are not so strong |

| Camping time is 24 hours | Clamping time is 30 minutes |

| Less durable | High durability |

| Need both wood glue and nails | Need only the wood glue |

| Difficult to work with | Easy to work with |

Stressed Joint vs Unstressed Joint Comparision In Depth

Diving into Stressed Joints

Strength and Durability

From personal experience, I can tell you that there’s something truly satisfying about crafting a piece that you know is built to last.

Stressed joints play a crucial role here. Due to their ability to withstand dynamic loads, they promise longevity that makes your hard work pay off for years to come.

Above I mentioned that these joints, when executed properly, could even be stronger than the actual wood fibers, and in my experience, that’s absolutely true.

Techniques and Examples

Building something using stressed joints often involves the use of specific techniques, such as the wedged mortise-and-tenon or box joints.

These not only provide strength but also bring a level of craftsmanship to your piece, showcasing the effort and skill put into the project.

Gluing and Clamping Time

One of the key things to note, and something I’ve learned the hard way, is the importance of giving the glue ample time to cure.

According to the article, a good 24 hours of clamping time is essential to ensure the longevity of the joint.

A Closer Look at Unstressed Joints

Suitability and Usage

Now, let’s chat about unstressed joints. In my journey through woodworking, I’ve found these to be my go-to for projects that are more about aesthetics and less about bearing heavy loads.

They lend themselves wonderfully to pieces where you want the focus to be on the visual appeal, rather than the structural strength.

Easy to Work With

For those of you just starting out, you’ll find that working with unstressed joints can be a great entry point.

They’re easier to understand and execute compared to their stressed counterparts, making them beginner-friendly.

Examples and Appearance

Using unstressed joints doesn’t mean compromising on the beauty of your piece. In fact, it’s quite the opposite.

Structures involving these joints, like miter or butt joints, often result in a seamless and visually pleasing outcome, hiding away the intricacies of the joint within the workpiece.

Gluing Time

An added advantage here is the quicker drying time. You won’t have to wait a whole day to see your creation come to life.

Generally, you’re looking at about 30 minutes to 6 hours of drying time, although this can vary depending on several factors including the type of glue you use and the environmental conditions.

Types of Stress

Stresses are the forces that divide wood joints into stressed and unstressed joints.

There are main 4 types of stresses that impact wood joints. They are,

- Compression

- Tension

- Racking

- Vertical shear

Among the above stresses racking is the most destructive stress. Those stress may tear the wood joint apart.

To withstand against above stresses wood joint, need to be strong and tightened with wood glue and fasteners.

The stressed wood joint can withstand against above stress, but if the applied stress is too much, stressed joints may also tend to break down.

- Compression stress – Forces are joined together

- Tension stress – Forces pull apart. Happens when an overloaded shelf is joined to a carcass with dado joints. The weight on the shelf pulls the shelf out of the dado.

- Vertical shear stress – Occurs when two halves of a wood joint slide against each other. This commonly happens with butt joints.

- Racking – Twisting and bending forces. This is the toughest stress for a wood joint. Even a stressed joint is hard to endure.

Tip:

As per recommendations for experts, never stress a new joint for at least 24 hours. Because the wood pieces are subjected to high stress at once, the wood fibers tend to break on their own.

Congrats folks! Now you know stressed joint vs unstressed joint with their in-detail comparison based on my experience with them and based on experts’ opinions that I’ve collected during my research.

So, let’s answer some frequently asked questions.

FAQs

What are stressed and unstressed wood joints used for?

Stressed joints are typically used in furniture and structures that need to bear heavy loads and pressure, like cabinetry and flooring, while unstressed joints are used in lighter, decorative pieces such as picture frames and window panels.

What is the primary difference between stressed and unstressed joints?

The main difference is the load-bearing capacity; stressed joints can handle dynamic loads and are therefore used in structures that need to be more durable, whereas unstressed joints are used for static loads and generally find their place in decorative or non-load-bearing applications.

Can I use wood glue for unstressed joints?

Yes, although unstressed joints don’t necessarily require adhesives or fasteners, using wood glue can reinforce the connections and provide an extra layer of security against potential breaks or loosening over time.

What are some examples of stressed joints?

Some popular examples of stressed joints include wedged mortise-and-tenon joints and box joints, known for their strength and ability to withstand significant impact and pressure.

What is the recommended clamping time for stressed joints?

For stressed joints, it’s advised to allow a clamping time of at least 24 hours to ensure that the glue cures properly, providing a strong and durable bond that can withstand heavy loads.

Are unstressed joints easier to work with for beginners?

Absolutely, unstressed joints are generally easier to work with, making them a great starting point for woodworking beginners due to their simpler patterns and less demanding requirements regarding glues and fasteners.

What kind of appearance can I expect from unstressed joints?

Unstressed joints are known for offering a more seamless and aesthetic appearance, allowing you to easily hide the joint within the workpiece and focus on the visual appeal of the project.

What factors can influence the drying time of wood glue in unstressed joints?

The drying time for glue in unstressed joints can be influenced by environmental factors such as temperature and humidity, with higher temperatures and low humidity generally allowing for faster curing times.

Can stressed joints be stronger than the actual wood fibers?

Yes, when executed properly with the right adhesives and fasteners, stressed joints can indeed be stronger than the actual wood fibers, offering a truly robust and long-lasting connection.

What are some suitable fasteners for stressed joints?

Suitable fasteners for stressed joints include nails, screws, dowels, and biscuits, which work together with wood glue to create a joint capable of withstanding heavy loads and high pressure.

Did I cover all you wanted to know about Stressed vs Unstressed Joint with Differences?

In this article, I have deeply discussed stressed vs unstressed joint, what is meant by stressed wood joint, what is meant by unstressed wood joint, the camping times of each wood joint, and the major differences between stressed and unstressed wood joints as well.

Stressed joints are designed to withstand heavy dynamic loads, commonly found in furniture and cabinetry, utilizing strong adhesives and fasteners for durable connections. Unstressed joints, on the other hand, bear lighter static loads and are usually used in decorative pieces, requiring lesser or no adhesives and offering a more aesthetic, seamless look.

Furthermore, I have discussed the uses of both stressed and unstressed joints and talked about the wood stress types and how their impact on the wood joints.

Hope you have gained pretty good knowledge about stressed vs unstressed joint with their differences.

So, let’s head into your next woodworking project and make sure to apply the correct wood joint for the correct position to avoid getting problems in the future.

Enjoy woodworking!