Ever found yourself entranced by the beauty of Elm furniture, wondering, “Is Elm actually a hardwood?” Let’s unravel this mystery together!

Elm wood is highly used in furniture, boxes, hockey sticks, and archery bows.

I love to work with elm wood because of its excellent grain pattern and resistance to environmental elements.

When I started to work with Elm, I was always curious about its hardness especially when it come to heavy-duty projects.

So, I did some research, and here’s what I’ve found, Is Elm a hardwood?

Yes, Elm is considered a hardwood. However, it falls under the category of “soft hardwoods,” due to its lower Janka Hardness rating of 830. Despite being softer than other hardwoods, Elm is known for its durability and resistance to splitting.

But that’s just a quick snapshot.

So, in this article, I’ll take a detailed look at whether is Elm hardwood, how hard is Elm, Elmwood’s characteristics, uses of Elmwood and how strong is Elmwood as well.

Furthermore, I’ll answer frequently asked questions as well.

So, let’s jump in!

First of all, let’s have a quick look at what is elm wood.

What is Elm Wood?

Elm wood hails from the family of elm trees, a collection of over 30 species that are known for their rapid growth and significant heights.

They can grow up to 140 feet tall and are celebrated for their ability to provide ample shade, thanks to their wide, branching limbs.

Elm trees, which are deciduous, are primarily divided into two groups: hard elms and soft elms.

Elm Wood: Beauty and Strength

Elm’s interlocked grain not only adds to its visual appeal but also enhances its toughness.

This makes it particularly resistant to splitting, resulting in a high level of durability.

Its impressive shock resistance makes it an ideal choice for furniture pieces and components that are expected to withstand impact and heavy use.

For instance, the steam bending capability of elm is noteworthy.

The wood can be steamed and bent into shape, after which it retains its new form exceptionally well.

This characteristic makes it a preferred choice for supportive furniture components that require structural strength, such as frames, backs, seats, and legs.

The ease with which elm accepts glue and holds nails and screws is another advantage.

It also finishes well and takes stain without much difficulty, making it a versatile option for a wide range of applications.

A Brief Note on Elm Lumber

When it comes to elm lumber, it’s generally modestly priced, although the prevalence of Dutch Elm Disease in the latter half of the 20th century has led to fewer mature trees, impacting its availability.

However, the rapid growth rate of elm trees ensures that it remains a viable source of lumber.

Now let’s move into te the key area which is the hardness of elm wood.

How Hard Is Elm?

Elm wood is harder than any other softwoods on the planet. But it is softer than most of the hardwoods as well.

Therefore, Elm wood is considered as a soft hardwood with both qualities of softwoods and hardwoods.

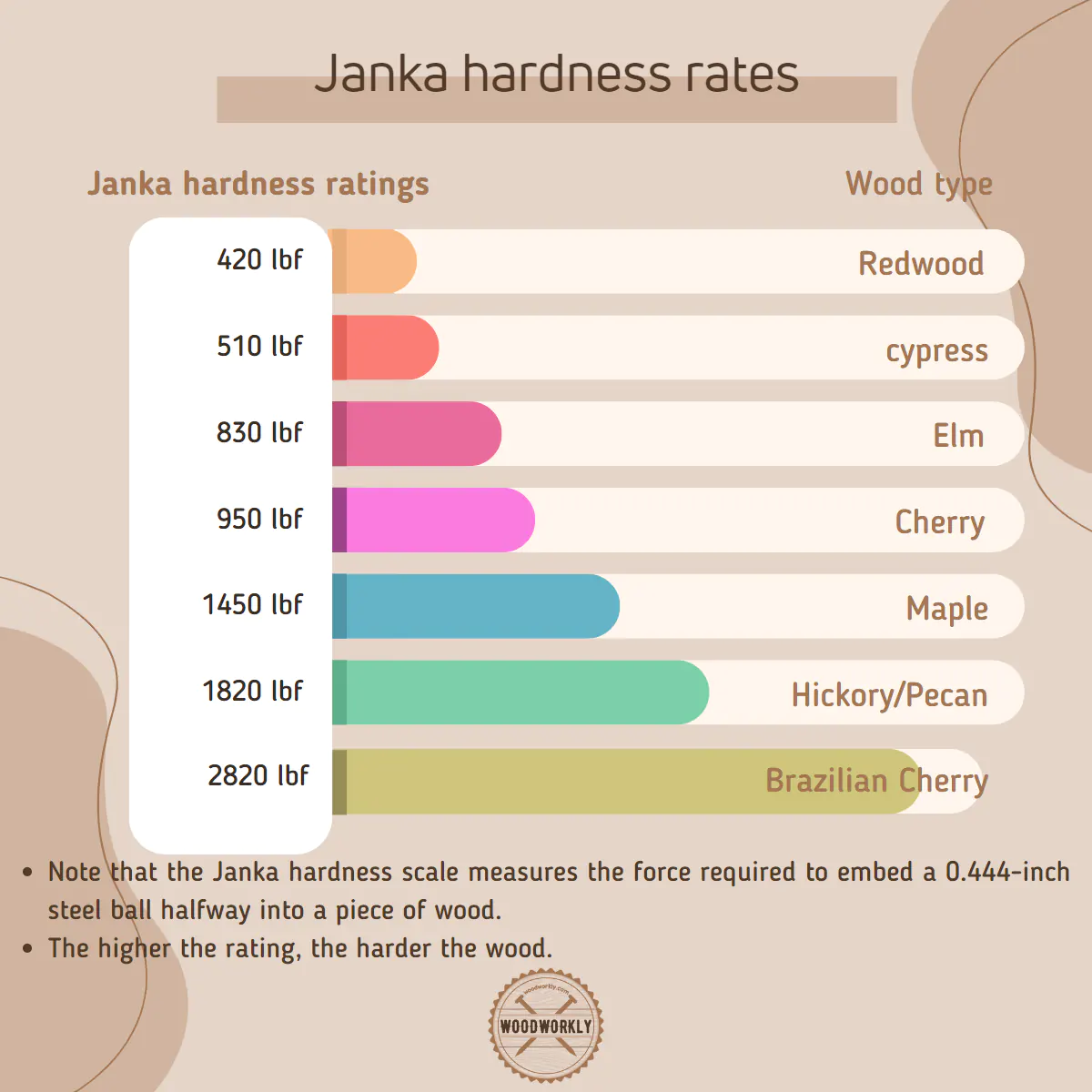

According to the Janka hardness ratings, Elm wood has a hardness rating of 830 lbf (3,692 N) which is higher than most softwoods such as,

- Cypress with a hardness rating of 510 lbf (2,268 N)

- Pine with a hardness rating of 380 lbf (1,690 N)

- Redwood with a hardness rating of 420 lbf (1,868 N)

But Elm wood is softer thanmany hardwoods. Such as,

- Ash with a hardness rating of 1,320 lbf (5,872 N)

- Beech with a hardness rating of 1,300 lbf (5,783 N)

- Cherry with a hardness rating of 950 lbf (4,225 N)

- Maple with a hardness rating of 1,450 lbf (6,450 N)

The Janka hardness scale is a standard measurement that use to find out the hardness values of the wood.

It resembles the resistance of a particular wood to dent and wear. For example, if some wood has high resistance to wear and dent, that means the wood has a high hardness rating.

As you can see the hardness of Elm wood is less than most of the hardwoods.

Normally woods from a deciduous tree that lose leaves in fall are known as hardwoods.

Elm wood also belongs to a deciduous tree, but the difference is that Elm wood itself is softer than other wood types that come from hardwood trees.

Therefore, Elm wood is classified as a soft hardwood that belongs to the category of in-between hardwoods and softwoods.

As a soft hardwood Elm is harder, denser, and stronger than most of the softwoods, but less hard, less dense, and weaker than most of the hardwoods.

When we look at the in-depth structure of Elm wood, the pores structure of Elm wood consists of straight or wavy tangential bands.

That means the pores are aligned in horizontal orientation. This pattern type is rare and specialized to all the Elmwood species.

Overall, Elm wood has a ring-porous structure with distinct figures and wood grain patterns.

The spaces and diameters of pores fibers are higher than hardwoods and less than softwoods.

According to that, the number of fibers in a unit volume of Elm wood is higher than softwoods.

This means the density of Elm wood is higher than softwood which is why Elm is denser than softwoods.

Likewise, the number of fibers in a unit volume of Elm wood is lower than hardwoods.

This means the density of Elm wood is lower than hardwood which is why Elm is less dense than hardwoods.

Because of being in middle between hardwoods and softwoods, Elm wood has hardwood characteristics and softwood characteristics both of which are helpful in the woodworking field.

So, according to the Janka hardness rating, Elm wood has a hardness rating of 830 lbf (3,692 N).

Hardness Of Elm Compared to Other Woods

So, to get an idea about how hard Elm wood is you can follow the following Janka hardness rating scale to compare the hardness of Elm wood with other popular wood types.

| Wood species | Hardness value |

| Brazilian Walnut | 3,684 lbf (16,390 N) |

| Red Mahogany, Turpentine | 2,697 lbf (12,000 N) |

| Brazilian Cherry, Jatoba | 2,350 lbf (10,500 N) |

| Golden Teak | 2,330 lbf (10,400 N) |

| Purpleheart | 1,860 lbf (8,300 N) |

| Hickory, Pecan, Satinwood | 1,820 lbf (8,100 N) |

| Rosewood | 1,780 lbf (7,900 N) |

| African Padauk | 1,725 lbf (7,670 N) |

| Wenge, Red Pine, Hornbeam | 1,630 lbf (7,300 N) |

| Hard Maple | 1,450 lbf (6,450 N) |

| White Oak | 1,360 lbf (6,000 N) |

| Ash (White) | 1,320 lbf (5,900 N) |

| American Beech | 1,300 lbf (5,800 N) |

| Red Oak (Northern) | 1,290 lbf (5,700 N) |

| Yellow Birch / Baltic Birch | 1,260 lbf (5,600 N) |

| Heart Pine | 1,225 lbf (5,450 N) |

| Teak | 1,155 lbf (5,140 N) |

| Black Walnut, North American Walnut | 1,010 lbf (4,500 N) |

| Cherry | 995 lbf (4,430 N) |

| Black Cherry, Imbuia | 950 lbf (4,226 N) |

| Soft Maple | 950 lbf (4,226 N) |

| Cedar | 900 lbf (4,003 N) |

| Elm | 830 lbf (3,692 N) |

| Southern Yellow Pine (Loblolly and Shortleaf) | 690 lbf (3,100 N) |

| Douglas Fir | 660 lbf (2,900 N) |

| Hemlock | 540 lbf (2,402 N) |

| Redwood | 420 lbf (1,868 N) |

| Pine | 380 lbf (1,690 N) |

As you can see Elm wood is softer than many other hardwoods and harder than some popular softwoods.

Being a soft hardwood is like having the qualities of hardwood and softwood both but none of them are at their finest.

Elm Wood Characteristics

| Color | Brownish and off-white |

| Density | 500 kg/m3 |

| Hardness | 830 lbf (3,692 N) |

| Stiffness | 1.34 Mpsi |

| Wood Type | Soft Hardwood |

| Applications | Furniture, boxes, hockey sticks |

Elmwood is a light to medium brownish wood with interlocked grain pattern. It has an uneven coarse texture.

The interlocked grain pattern makes it so hard to split. Therefore, Elm wood is considered one of the best split-resistant wood.

The ring-porous structure is one or two pores wide in diameter and growth rings are distinct with normal gaps.

Because of being a soft hardwood with less density and hardness, Elm wood is not durable against insect attacks and other environmental elements.

Therefore, keeping Elm wood furniture outside without applying proper sealer is not recommended.

Most of the hardwoods with less hardness are easy to work with. Because most of them have a straight wood grain pattern.

But surprisingly Elm wood contains interlocked grain pattern, and this makes it so hard to work with and the workability of Elm wood is significantly low.

As a woodworker, I don’t recommend Elm wood for a beginner in woodworking because screwing, nailing, and sawing are a little bit difficult with Elm wood.

Apart from those aspects, here’re some qualities of Elm wood that are useful in woodworking.

- Split-resistant and high flexibility

- Attractive

- Heartwood

- Smooth texture

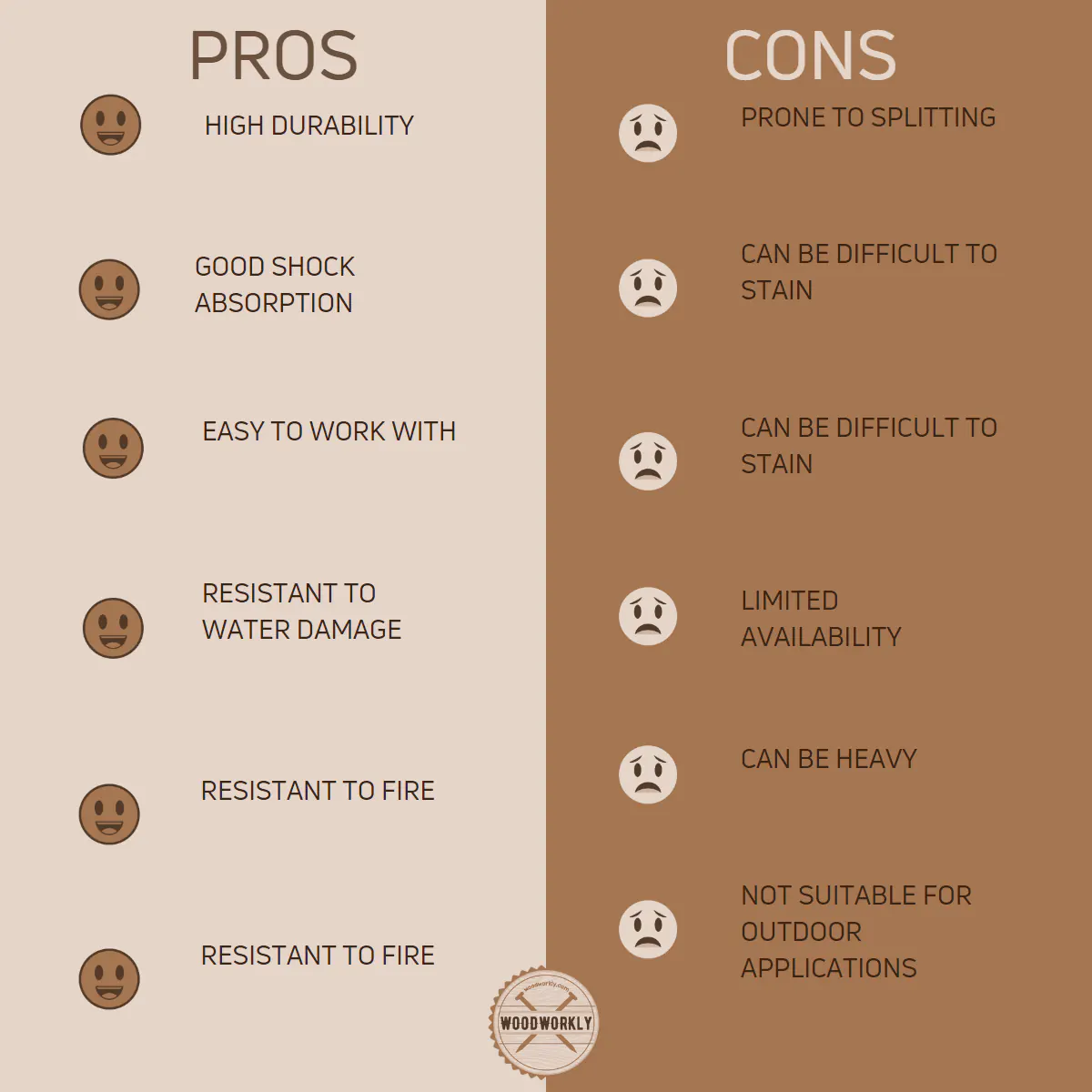

So, let’s have a look at the advantages and disadvantages of using Elm wood

Pros and Cons of Elm Wood

| Pros | Cons |

| Split Resistant | Poor Workability |

| Smooth texture | Less resistant to insect attacks |

| Attractive | Poor dimensional stability |

| Excellent flexibility | Difficult to dry |

| Strong | Moderately priced |

| Harder and denser than softwoods | Prone to fungal attacks |

As you can see, Elm needs good protection and proper maintenance with care. Otherwise, the wood will be easily destroyed because of moisture and bugs.

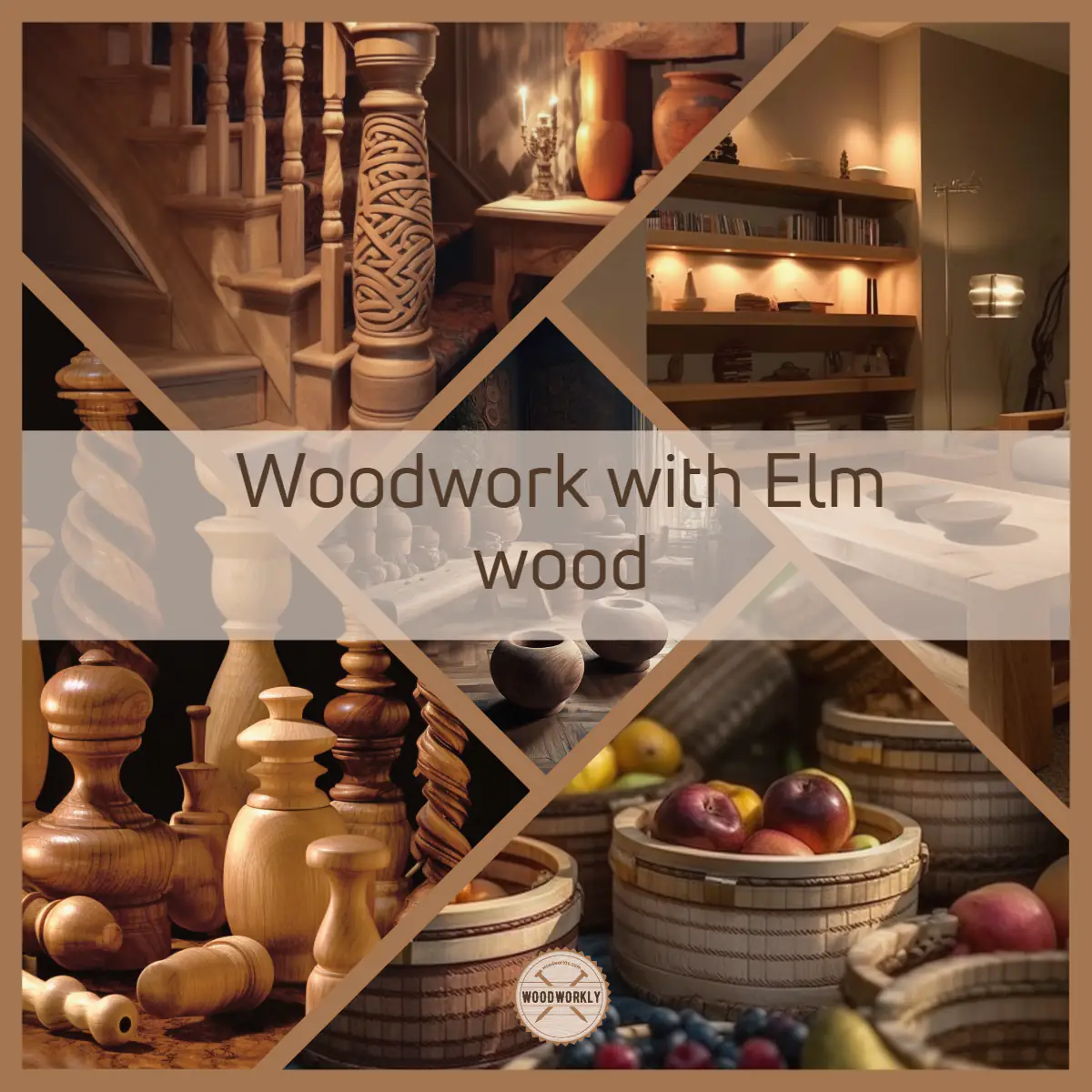

What Is Elm Wood Used For?

Elmwood is commonly used for the following applications. Such as,

- Furniture making

- Hockey sticks

- Boxes

- Archery bows

- Veneer

- Baskets

- Decorative paneling

- Stair treads

Because of having qualities of hardwood and softwood both can use overall any woodworking application without any hesitation.

But I advise you not to go with Elm wood for outdoor woodworking projects due to its high prone to bugs and insects.

How Strong Is Elm Wood?

Elm wood is stronger than most softwoods and weaker than most hardwoods.

The compressive strength is moderately high, and the bending strength of Elm wood is significantly high due to its high flexibility and split resistance.

| Compressive Strength | 5,520 psi |

| Bending Strength | 11,800 psi |

| Stiffness | 1.34 Mpsi |

As you can see, Elm wood has high bending strength which is second to cherry, beech, and hard Maple only.

Congrats folks! Now you know exactly whether Is elm a hardwood or softwood with its key characteristic features.

Now let’s compare the hardness of elm with other popular woods which we use the most.

Is Elm Harder Than Oak?

Oak is significantly harder than Elm. Both red Oak and White Oak are harder, stronger, and denser than Elm wood.

According to the Janka hardness ratings, you can get an idea about the hardness of Elm wood compared to Oak wood.

| Red Oak | 1,290 lbf |

| White Oak | 1,360 lbf |

| Elm | 830 lbf |

As you can see, Elm wood is twice as much weaker and softer than Oak wood.

Is Elm Harder Than Pine?

Elm is harder than sugar Pine and White Pine. But Elm wood has a similar hardness to the Yellow Pine.

Elm wood is harder, stronger, and denser than sugar Pine, White Pine both and similar in density and strength to Yellow Pine.

According to the Janka hardness ratings, you can see the hardness of Elm wood compared to Pine.

| Sugar Pine | 380 lbf |

| White Pine | 380 lbf |

| Yellow Pine | 870 lbf |

| Elm | 830 lbf |

Is Elm Harder Than Maple?

Maple is significantly harder than Elm. Both hard Maple and soft Maple are harder, denser, and stronger than Maple wood.

According to the Janka hardness scale,

| Hard Maple | 1,450 lbf |

| Soft Maple | 950 lbf |

| Elm | 830 lbf |

As you can see why Elm wood is considered soft hardwood. The hardness is lower than the soft Maple as well.

Is Elm Harder Than Birch?

Birch is much harder than Elm. The most popular one, yellow Birch is harder, denser, and stronger than Elm wood.

According to the Janka hardness ratings,

| Yellow Birch | 1,260 lbf |

| Elm | 830 lbf |

Hope you have gained the answer to the hardness of Elm wood question by the above comparison with other popular wood types.

So, let’s find answers to frequently asked questions.

FAQs

What are the distinguishing characteristics of elm wood?

Elm wood is known for its heartwood colors ranging from light to medium reddish-brown and a paler off-white sapwood. Its standout feature is its unique, interlocking grain pattern that gives it a distinctive swirl and wave effect.

What other uses does elm wood have?

Aside from furniture, elm wood is used in various applications due to its toughness, such as butcher blocks, chair seats, spindles, tool handles, hockey sticks, bats, and even in shipbuilding and pier construction.

Is elm wood expensive?

Elm lumber is modestly priced, although the availability can be affected by the impact of Dutch Elm Disease, which has reduced the number of mature trees.

What types of elm trees are there?

There are over 30 species of elm trees, primarily divided into two groups: hard elms and soft elms. Some of the most well-known are the American elm, the slippery or red elm, and the English Elm.

Did I cover all you wanted to know about: Is Elm A Hardwood?

In this article, I have deeply discussed whether is Elm a hardwood and how hard Elm wood is with characteristic qualities of Elm wood.

Furthermore, I dug into the structural changes of Elm wood to see why Elm wood considered a soft hardwood even though it is originated from a deciduous tree.

Elm is a soft hardwood with a Janka hardness rating of 830 lbf (3,692 N). Elm tree is a hardwood tree that loses leaves in the fall. But Elm wood is softer than other woods that come from hardwood trees. Therefore, even though Elm is from a hardwood tree, the wood itself considered as a soft hardwood

Hope you have gained good knowledge about the hardness of Elm wood and its unique features.

So, let’s start your next woodworking project with Elm wood. Enjoy woodworking!