Ever puzzled over the wood type of Hemlock? Is it hardwood, or could it possibly be a softwood? Let’s journey into the world of Hemlock to unravel this mystery together!

Hemlock is commonly used for making boxes, roofing, crates, light framing, and other construction items.

It is strong with unique qualities and I was curious about its hardness factor.

So, I did some research to find out the hardness level of Hemlock with the help of experts.

Now with years of experience, here’s what I know about, Is Hemlock a hardwood?

No, Hemlock is not a hardwood but a softwood. Despite its strength and durability akin to some hardwoods, it’s classified as a softwood, with a Janka hardness rating of 540 lbf, which increases over time.

But that’s just a quick snapshot.

So, in this article, I’ll take a detailed look at is Hemlock a hardwood, how hard is Hemlock, Hemlock wood characteristics, its uses of Hemlock and how strong is Hemlock wood as well.

Furthermore, I’ll answer some frequently asked questions as well.

Let’s dive in!

First of all, let’s take a quick look at what is hemlock wood.

What is Hemlock Wood?

Hemlock wood originates from the Hemlock tree, a type of coniferous evergreen that’s part of the Pinaceae family.

Named Hemlock because its crushed foliage carries an aroma similar to the poisonous hemlock plant, it’s important to note that the

The Hemlock tree itself is not toxic.

This tree is a substantial contributor to the timber industry, notably due to the wood’s unique qualities and the value of its wood pulp.

Unraveling the Charm of Hemlock Wood

Despite it being categorized as a softwood, Hemlock wood’s characteristics often lead to some confusion, with many even considering it a hardwood.

How does this happen? Well, its strength and durability, coupled with the fact that it hardens over time and has a dense grain, make it as formidable as some hardwoods.

It has a Janka hardness rating of 540 lbf, which surprisingly, is higher than some softwoods.

Moreover, Hemlock wood comes in various species, such as Western Hemlock and Eastern Hemlock, each carrying its unique properties and uses.

For instance, the Eastern Hemlock, also known as the Canadian Hemlock, is utilized for plywood, light framing, and creating pallets, crates, and boxes.

On the other hand, the Western Hemlock is commonly used for doors, windows, ladders, and suspended ceilings.

Hemlock Wood and Its Aesthetic Appeal

In terms of appearance, Hemlock wood showcases a natural beauty with its light reddish-brown heartwood and somewhat lighter sapwood.

Not only does its warm color add a rustic charm to any woodworking project, but it also beautifully absorbs stains, glues, and finishes, contributing to a fantastic end result.

How Hard Is Hemlock?

Hemlock is hardwood and it is harder than most of the softwoods and some of the hardwoods as well.

According to the Janka hardness test values, Hemlock wood has a hardness rating of 540 lbf (2,402 N) which is relatively higher than many other softwoods.

Hemlock is softer than most hardwoods.

Therefore, it is considered a softwood. But when we look at the overall qualities of Hemlock, it has superior qualities to both hardwoods and softwoods.

Hemlock is soft, averagely weak in bending strength, and strong in compression. It has low split resistance and the nail-holding ability is moderate.

Hemlock is mainly used for construction purposes. But because being a softwood, it’s not durable much and requires treatment for external usage.

Hemlock trees are gymnosperms because they don’t have flowers and have cones for the production of seeds.

When we look at the cellular structure of Hemlock, 90% -95% of cells are longitudinal tracheids.

These longitudinal tracheids are able to support and conduct water. A small number of cells of Hemlock differ from one another to make it different than other softwood types.

There’s no vessel, elements of pores structures can be seen in Hemlock because of being a softwood.

Not having vessels and pores is a good indicator to consider Hemlock as a softwood.

When we look at the cross-section of softwoods, resin canals can be seen instead of pores.

Resin canals are tubular-shaped passages that exude resin or pitch to seal off wounds due to mechanical or insect damage.

But in Hemlock, no resin canals can be seen in its cross-section.

In other words, Hemlock has less resistance against insect and mechanical damage than softwoods with resin canals such as Spruce, Pine, and Douglas fir.

Even though Hemlock is considered a softwood due to its structural changes, it is varied substantially in density.

Therefore, Hemlock is used for many construction applications.

Janka hardness rating is a test that measures the resistance of wood against wear and tear. Woods with high resistivity against dents and wear has a high Janka hardness rating.

According to the Janka hardness rating, Hemlock wood has a hardness rating of 540 lbf (2,402 N).

Hardness Of Hemlock Compared to Other Woods

I’ve created a chart to indicate the hardness of Hemlock compared to other popular woods that we commonly use.

| Wood species | Hardness value |

| Brazilian Walnut | 3,684 lbf (16,390 N) |

| Red Mahogany, Turpentine | 2,697 lbf (12,000 N) |

| Brazilian Cherry, Jatoba | 2,350 lbf (10,500 N) |

| Golden Teak | 2,330 lbf (10,400 N) |

| Hickory, Pecan, Satinwood | 1,820 lbf (8,100 N) |

| Hard Maple, Sugar Maple | 1,450 lbf (6,400 N) |

| White Oak | 1,360 lbf (6,000 N) |

| Ash (White) | 1,320 lbf (5,900 N) |

| American Beech | 1,300 lbf (5,800 N) |

| Red Oak (Northern) | 1,290 lbf (5,700 N) |

| Yellow Birch / Baltic birch | 1,260 lbf (5,600 N) |

| Teak | 1,155 lbf (5,140 N) |

| Black Walnut, North American Walnut | 1,010 lbf (4,500 N) |

| Cherry | 995 lbf (4,430 N) |

| Black Cherry, Imbuia | 950 lbf (4,200 N) |

| Red Maple | 950 lbf (4,200 N) |

| Douglas Fir | 710 lbf (3,158 N) |

| Silver Maple | 700 lbf (3,100 N) |

| Hemlock | 540 lbf (2,402 N) |

| Black Spruce | 520 lbf (2,313 N) |

| Redwood | 420 lbf (1,868 N) |

| Engelmann Spruce | 390 lbf (1,735 N) |

| Sugar Pine | 380 lbf (1,690 N) |

As you can see, the hardness of Hemlock is pretty low compared to other types of wood.

So, let’s find out the characteristic qualities of Hemlock to overcome the lower of Hemlock to become one of the most superior wood types in the world.

Hemlock Wood Characteristics

When we look at the characteristic features of Hemlock, there’re main two types of Hemlock that we use in our day-to-day lives.

- Eastern Hemlock

- Western Hemlock

Western Hemlock is spread through the northwest coast of North America and eastern Hemlock is spread through eastern North America.

The heartwood of both kinds of wood is light reddish-brown and sapwood is lighter in color. Growth rings are conspicuous and placed in a nice grain pattern.

Even though Hemlock is considered a softwood, it has a straight grain with an even texture pattern that makes the wood harder and denser.

But because of having no resin canals to seal off wood against insect attacks, Hemlock is prone to insect attacks.

The durability of Hemlock is also significantly lower than most hardwoods and softwoods as well.

The workability of Hemlock is pretty good. But because of having qualities of softwoods and some late hardwoods, sanding tends to create uneven surfaces and dips.

Finishing Hemlock with wood glues and stains is so much easy.

Hemlock is more resistant to warping and twisting than most other woods like Pine.

It does not decolorate or warp easily against temperature variations like many other kinds of wood.

Most importantly, Hemlock can be used as one of the best alternative woods to hardwoods because of having versatile hardwood features at a cheaper price.

For indoor woodworking projects, Hemlock is essential, and it has superior strength as well.

In summary, here’re the main qualities of Hemlock wood,

- Softwood

- High workability

- Lightweight

- Easy to cut

- Easy to finish (painting and staining)

- Affordable

- Resistant to warp

- Strong

As you can see not all softwoods are less strong and have poor qualities than hardwoods.

Hemlock is one of the best examples of softwood with excellent qualities.

Hemlock Wood Properties

| Color | Pale yellowish-brown |

| Density | 500 kg/m3 |

| Hardness | 540 lbf (2,402 N) |

| Stiffness | 1.63 Mpsi |

| Wood Type | Softwood |

| Applications | Framing, Roofing, Sheathing, Shutters |

So, let’s have a look at the uses of Hemlock wood which are good to know how its hardness is important in those applications.

What Is Hemlock Good For?

Hemlock is one of the best alternative softwoods that can use for hardwood applications on many occasions due to its superior qualities.

Here’re the applications of Hemlock,

- Boxes

- Crates

- Pallets

- Framing

- Plywood

- Construction purposes

- Roofing

As you can see Hemlock is one of the best affordable wood options for your most indoor woodworking projects.

It is easy to finish and works well with woodworking tools.

Make sure to finish Hemlock wood applications with good stain or paint. Hemlock is less resistant to insects and mechanical damage.

Therefore, having a good seal is a must for the durability of Hemlock wood applications.

How Strong Is Hemlock?

Hemlock is a moderately strong wood type. Hemlock has a compressive strength of 7,200 psi and a bending strength of 11,300 psi which is relatively less than most hardwoods but higher than most softwoods.

The strength of Hemlock wood is highly dependent on the wood grain.

If knots are available, they’ll significantly reduce the strength of Hemlock wood and the wood tend to split and crack so easily.

Hemlock wood with a smooth grain is quite strong.

Strong Hemlock wood is extremely resistant to wear and tear.

Because of its high compressive and bending strengths, Hemlock wood is an excellent choice for construction purposes like building horizontal components and longer spans.

Is Hemlock Good for Building?

Hemlock is an excellent wood for building materials. It is mostly used for horizontal components, frames, roofing, flooring, and stairs.

Hemlock is a light and strong wood with good dimensional stability.

With proper finishing Hemlock, any woodworking project is possible with Hemlock.

It is strong, resistant to warp, one of the best alternative wood types of hardwoods, no discoloration occurs due to weather fluctuations, is affordable, easy to finish, and great for lamination.

Because of those reasons, Hemlock is great for building materials.

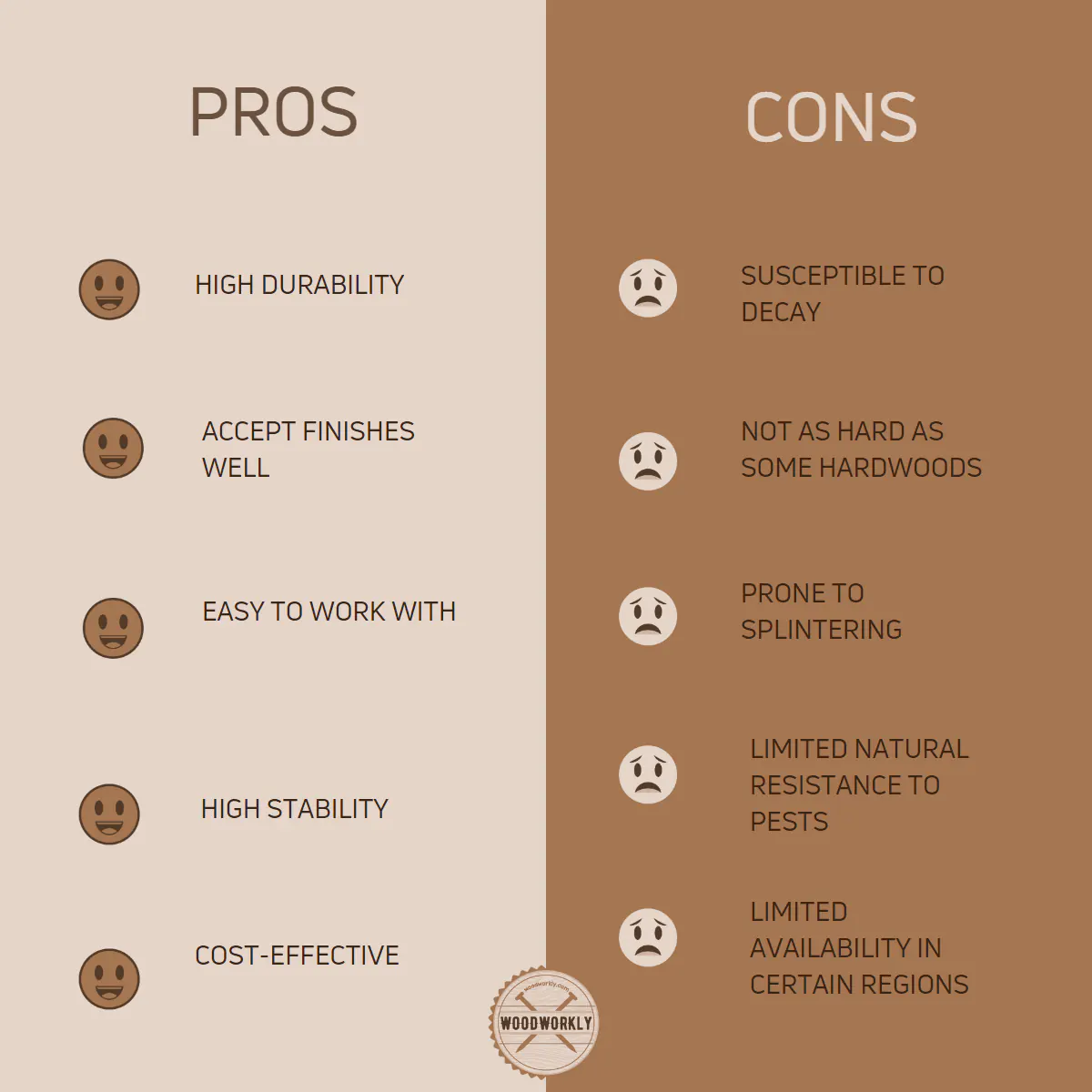

Here’re the pros and cons of Hemlock to use as a building material,

| Pros | Cons |

| High strength | Poor durability |

| Affordable | Prone to insect attacks |

| Easy to finish (hold paints well) | Split and crack easily |

| Warp resistant | Softwood |

| High stability | |

| Lightweight | |

| No discoloration happen |

As you can see there are lots of advantages of Hemlock wood for building purposes.

Most of the disadvantages can be minimized by applying a good finisher and giving proper maintenance regularly.

So, let’s compare Hemlock with other popular woods that we daily use.

Is Hemlock Harder Than Pine?

Hemlock is harder than Pine.

Both Pine and Hemlock are softwoods, but due to their structural properties, Hemlock is slightly harder and stronger than Pine.

According to the Janka hardness ratings,

| Wood Type | Hardness |

| Hemlock | 540 lbf |

| Sugar Pine | 380 lbf |

| White Pine | 380 lbf |

Even though Hemlock wood is only slightly harder than Pine, in the real-world Hemlock wood is clearly the winner due to its great strengths and superior hardwood qualities.

Is Hemlock Harder Than Poplar?

No, Hemlock is less hard than Poplar.

Hemlock is a softwood and Poplar is a hardwood. So, Poplar wood is harder, denser, and stronger than Hemlock on any day.

According to the Janka hardness ratings,

| Wood Type | Hardness |

| Poplar | 540 lbf |

| Hemlock | 540 lbf |

As you can see Poplar and Hemlock both have the same hardness ratings.

But because of the cell fiber structure, density, and stiffness, Poplar is way harder and stronger than Hemlock.

But Hemlock is also significantly strong, and this is why it is considered one of the best wood that can be used as a hardwood.

Is Hemlock Harder Than Cedar?

Hemlock is harder than Cedar. Both red Cedar and white Cedar are softwoods and softer and less dense than Hemlock.

According to the Janka hardness ratings,

| Wood Type | Hardness |

| Red Cedar | 350 lbf |

| White Cedar | 320 lbf |

| Hemlock | 540 lbf |

As you can see in terms of hardness Hemlock is way harder than Cedar.

Hemlock has good dimensional stability with excellent compressive and bending strength as well.

Is Hemlock Stronger Than Oak?

Oak is stronger than Hemlock. Oak is considered hardwood while Hemlock is softwood. so, in terms of strength mostly softwoods cannot compete with hardwoods.

According to the Janka hardness ratings, Oak is harder than Hemlock with a hardness of 1,290 lbf while Hemlock is 540 lbf.

In terms of their compressive and bending strengths,

| Wood Type | Compressive Strength | Bending Strength |

| Hemlock | 7,200 psi | 11,300 psi |

| Oak | 6,760 lbf | 14,300 psi |

As you can see Hemlock has better compressive strength than Oakwood. but in terms of flexural strength (bending strength), Oakwood is clearly a winner.

Even though theoretical values indicate Oak is slightly stronger than Hemlock, in the real-world Hemlock is no way near stronger than Oakwood.

Oakwood is a superior wood with some exceptional qualities that can use for any indoor and outdoor woodworking project.

So, let’s answer some frequently asked questions.

FAQs

What are the different types of Hemlock?

There are several species of Hemlock, with the most popular ones being the Eastern Hemlock (also known as Canadian Hemlock) and the Western Hemlock.

Is Hemlock wood good for outdoor use?

Generally, Hemlock is not recommended for outdoor use due to its susceptibility to rot, decay, and insect attacks.

Does Hemlock wood accept stains and finishes well?

Yes, Hemlock wood is highly receptive to stains, glues, and finishes, which contributes to its popularity in woodworking projects.

Is Hemlock wood resistant to insects and decay?

Unfortunately, Hemlock wood lacks resistance to decay and is susceptible to insect attacks, requiring regular maintenance when used in certain environments.

How does Hemlock wood change over time?

Hemlock wood tends to increase in hardness over time, becoming even stronger and making it a long-lasting choice for many woodworking projects.

Is Hemlock wood suitable for high-traffic areas?

Given its susceptibility to denting and scratching, Hemlock may not be the best choice for high-traffic areas unless it receives regular maintenance.

Can Hemlock be used for furniture making?

Yes, due to its workability, strength, and attractive finish, Hemlock wood is a suitable choice for crafting cabinets and other types of furniture.

Did I cover all you wanted to know about: Is Hemlock A Hardwood?

In this article I’ve deeply discussed is Hemlock a hardwood and how hard Hemlock is by considering its structural properties and day-to-day applications.

Hemlock is not a hardwood. Hemlock is a softwood. Hemlock wood has a hardness rating of 540 lbf (2,402 N) which is higher than most softwoods. It grows harder with age. Even though Hemlock is a softwood, it is stronger than many hardwoods because of its dense grain.

Furthermore, I have answered some frequently asked questions as well.

Hope you have gained pretty good knowledge about whether is Hemlock a hardwood and how can we use it for building purposes.

So, let’s begin your next woodworking project with Hemlock wood. Have fun woodworking!