Ever considered using hemlock wood for your next project? Think again! Let’s delve into why this timber might not be your best choice.

Hemlock is an affordable softwood with excellent resistance to warp. It has good dimensional strength compared to other softwoods and uses as a construction material for barns, sheds, and garages.

But when I was working on heavy-duty projects, I identified some disadvantages of Hemlock and tried to find methods to fix them with the help of experts.

Most of them worked really well.

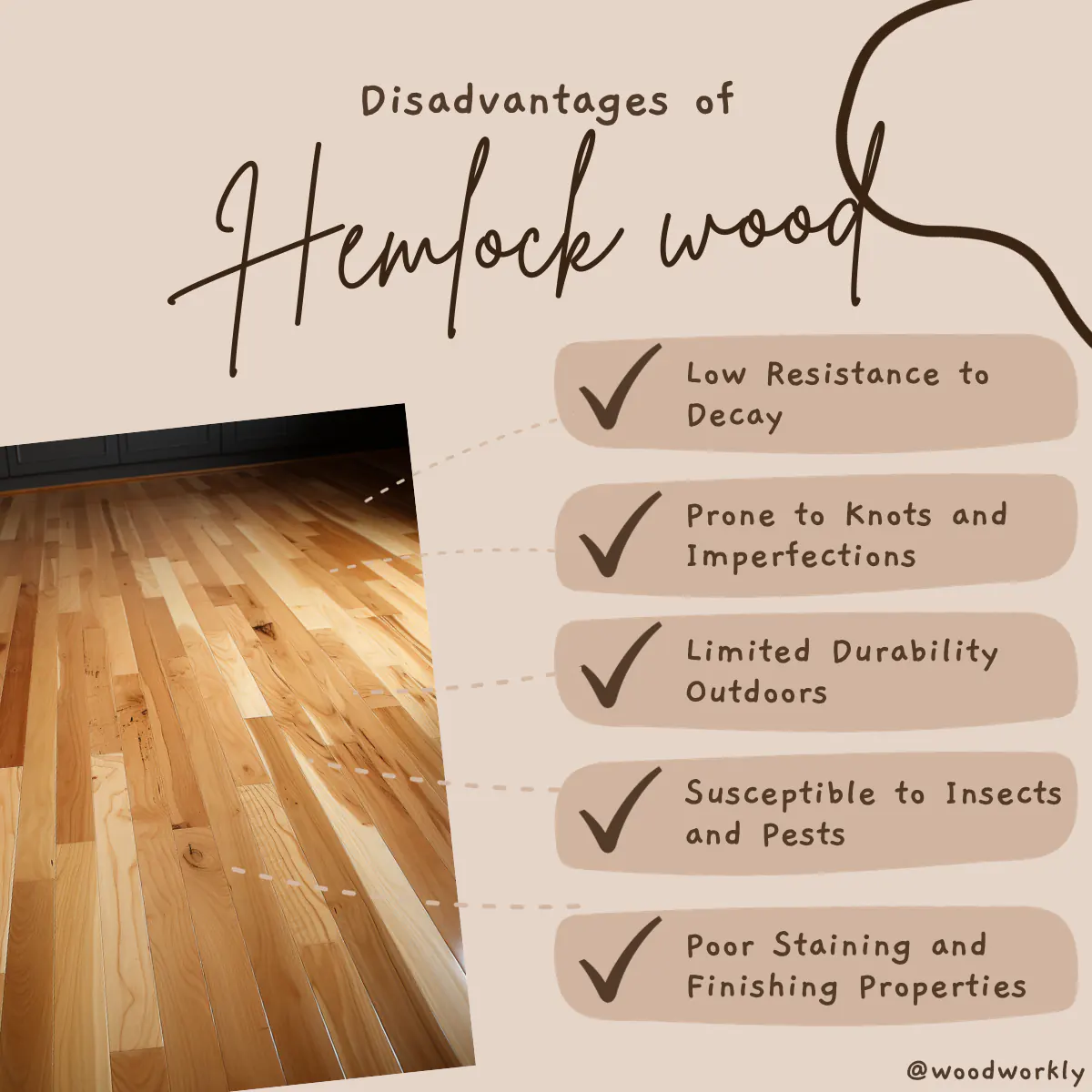

Here’s the list of Hemlock wood disadvantages,

- Prone to dents and scratches

- Need regular maintenance

- Poor durability

- Hard to identify

- Susceptible to insect attacks

- Prone to splinters

- Difficult to work when dry

- Darken with age

But there’s a lot more to know!

In this article, I’ll discuss each of the above Hemlock wood disadvantages in detail to give you better knowledge about how the wood behaves and how to fix those disadvantages to get the best out of it as well.

Furthermore, I’ll answer, some frequently asked questions as well.

First, let’s see the main advantages of Hemlock wood in brief.

Advantages Of Hemlock Wood

- Strong compared to other softwoods

- Resistance to warp

- Easy to work with

- Easy to stain and finish

- Affordable

- Lightweight

- High machinability

- Attractive

As you can see Hemlock is wood with lots of benefits. That’s why it has become so much popular among woodworkers.

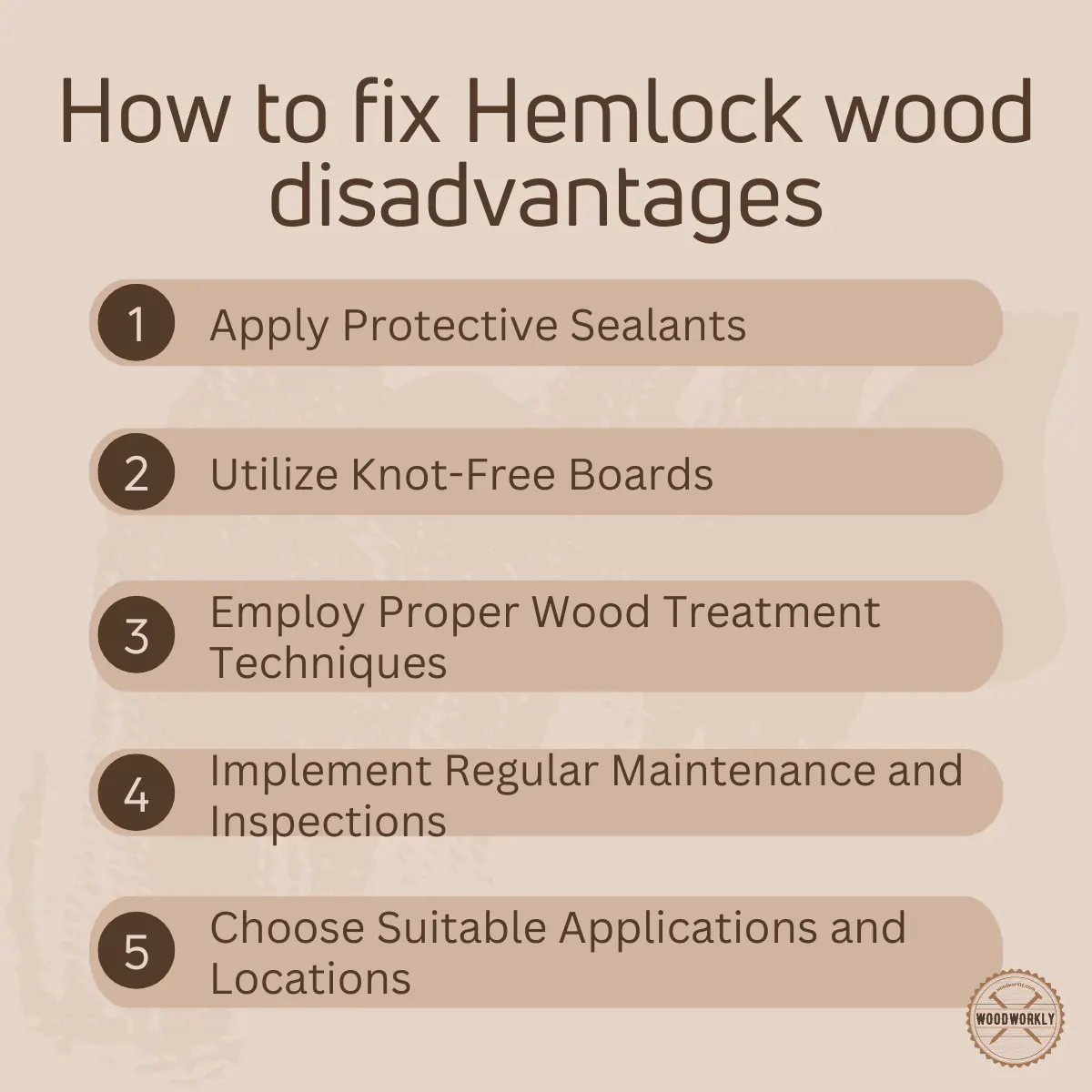

So, let’s head into the key topic, Hemlock wood disadvantages, and how to fix them easily with simple steps.

Disadvantages Of Hemlock Wood

Let’s have a look at the disadvantages of Hemlock wood in detail and how to fix them.

1. Prone To Dents and Scratches

Hemlock is a softwood that cannot withstand dents and scratches due to its soft fiber structure.

Scratches on Hemlock are extremely visible and hard to remove since they usually go deep into the wood.

The reason for being prone to dents and scratches is because of its less hardness and density.

According to the Janka hardness scale Hemlock wood has a hardness of 540 lbf (2,402 N) which is significantly less hard than many other kinds of wood.

Janka hardness test is the standard method of testing the hardness of wood by considering its resistance to wear and tear.

For example, if a particular wood has high wear and tear resistance, it has a high Janka hardness rating.

This is why you should be extremely careful when working with sensitive wood like Hemlock since once it got scratched or dented, it is so hard to cover up the marks since the wood gets damaged from both outside and inside.

Because of being a soft wood with less dense, it cannot bare foot traffic and dog scratches.

Therefore, Hemlock wood is not a good option for flooring applications and hard-using applications like kitchen cabinets due to poor tolerance against impacts.

You can prevent Hemlock wood from scratching and denting by applying sealant or a proper finisher before using it.

By finishing and sealing the Hemlock furniture and other woodwork properly, it gets the ability to bear little dents and scratches.

Hemlock wood is an excellent paint-grade wood. But because it dents easily, it can be difficult to paint and finish.

Once the Hemlock wood is properly sealed and finished, it can use for flooring, desk countertops, and many other traffic surfaces since it will get the ability to tolerate impacts better.

But think what should we do if the Hemlock wood is already dented or scratched?

Here’s the solution,

If the Hemlock wood surface got scratched, you can fix them by rubbing the scratched area with fine-grade steel wool until the scratch marks are gone, and wipe it off and buff it with a dry cloth.

Sealing and finishing Hemlock wood make a protective shield above the wood surface and prevents it from denting and scratches while enhancing the wood’s appearance.

2. Need Regular Maintenance

Even though you have applied good sealant, finisher, or stain on hemlock wood surfaces to protect the wood from environmental elements, you need to keep eye on it.

Once the shield starts to fade away, the wood gets attacked by elements such as moisture, insect attacks, UV light, fungi, and many more.

Regular maintenance is a must for sensitive softwood like Hemlock since it cannot bare high forces and extreme temperature levels and environmental changes.

Generally, you should reapply the wood finisher on the Hemlock wood furniture surface by removing the previous ones at least once per year for proper maintenance.

Proper maintenance and care are required to keep your Hemlock furniture, woodwork, and woodcarvings for so long without getting damaged.

Once the wood gets finished properly, it will be protected from UV light and moisture. UV light causes wood to split and crack.

Moisture causes wood to rot. Therefore, keeping the finishing coat alive is essential for the constant protection of the wood.

Hemlock wood has no natural resistance against moisture and bugs. Therefore, as soon as the top finishing coat went away, the wood gets exposed to the outside world.

Once the moisture penetrates inside of the wood, they cause the wood to rot internally.

Once the wood starts to rot, there is no use in applying a finisher on top of the surface.

The best method to fix rotted wood is restoration by removing the rotted area and applying a quality product like Flex Seal to stop wood from rotting further.

Keep the Hemlock wood furniture surfaces always clean by removing dust and debris since they give a dull appearance to the wood while damaging the beautiful wood surface.

Ultimately, proper care and maintenance are a must to keep your Hemlock wood furniture and woodwork even more than decades with no issues.

3. Poor Durability

Hemlock is not as durable as you think since it may lose its dimensional stability and strength quickly because of the wood movements under temperature variations, hazardous chemicals, and other environmental impacts.

Even though Hemlock wood does not warp or twist like many other softwoods, it expands and shrinks due to temperature variations.

When the outside temperature is high, Hemlock wood fibers will get thermally expanded, and when they shrink with cold temperature levels.

These wood movements impact so badly on the durability of Hemlock wood furniture.

When we look at the internal cross-section structure of softwoods, we can notice resin canals instead of pores.

Resin canals are tubular-shaped passages that exude resin or pitch to seal off wounds that occur due to mechanical damage.

But surprisingly, there’re no resin canals in the cross-section.

In other words, it indicates that Hemlock has poor resistance against mechanical damage than softwoods with resin canals such as Pine, Spruce, and Douglas Fir.

Plus, Hemlock is prone to rot and decay quickly.

Therefore, you cannot use Hemlock furniture and woodwork outdoors since they get easily damaged when exposed to the air.

If you live in an area with damp weather, I highly recommend you, not to use Hemlock woodwork or furniture for outdoor projects even after finishing the wood properly.

Because wood finish or sealants cannot protect the wood for so long and that takes a lot of time and effort.

Go for alternative woods like cedar, oak, mahogany are the best options you should you wish to avoid the poor durability of Hemlock wood especially if you live in an area with harsh weather conditions.

4. Hard To Identify

There’re several species of Hemlock wood species and they are so hard to identify because all look so similar, but they have wide differences when it comes to their characteristics.

This can be frustrating since finding quality Hemlock wood for your project can be so difficult.

Here are some popular species of Hemlock wood,

- Eastern Hemlock

- Mountain Hemlock

- Western Hemlock

Some woodworkers are confused about identifying the right Hemlock and they face lots of troubles when making furniture with bad wood.

Eastern Hemlock is the wood that you should mostly go for woodworking because of its excellent features over other Hemlock species.

Here are some tips to identify eastern Hemlock without getting confused,

- Eastern Hemlock also known as Canadian Hemlock

- Eastern Hemlock tree is 30 to 50 meters tall

- The tree has a dark green tone with the needle leaves

- Needles are flat and attached to the branches

- Needles are arranged in separate rows

- Cultivated as an ornamental tree

- It is the state tree of Pennsylvania

There’s a Hemlock species called poisonous Hemlock which looks like parsley or carrot. Never use it for any woodworking project or never try to smell it.

Better to ask for eastern Hemlock wood from local stores for any woodworking project.

5. Susceptible to Insect Attacks

Because of being a softwood with no resin canals in cross-section, Hemlock is prone to insect attacks. It does not have bugs and insect repellant ability like Cedar.

Therefore, if you keep Hemlock untreated for so long, the wood will get eventually damaged and start to decay because of insect attacks.

Insects love Hemlock wood since provides a watershed, a perfect microenvironment with such a cool habitat.

Once the wood gets attacked by insects it is so hard to eliminate them since they start to grow quickly because of the healthy environment inside of the Hemlock wood.

Hemlock woolly adelgid is the most famous insect that kills Hemlock wood since they are specialized for Hemlock. They are the reason for the root diseases of the Hemlock tree.

Other than that, the wood can get attacked by many other insects as well.

In order to stop wood from insect attacks, you need to treat the wood chemically. You can apply oil finisher like teak oil, tung oil, or Danish oil which is able to build a protective beautiful coating over Hemlock while not letting insects attack the wood.

Wood finishers repel insects and prevent them from laying eggs on the surface.

Finishing Hemlock is essential for outdoor woodworking projects like making garden beds since those areas are kingdoms of insects.

6. Prone To Splinters

Hemlock produces tiny needle-like splinters when sanding, drilling, and screwing. Once the splinters get landed on your skin, they can damage it and cause a lot of pain.

Always do a light sanding along the direction of the wood grain to prevent the wood from splintering. Drill Hemlock wood without splintering using pilot holes.

Splinters not only damage the wood itself but also damage the woodworker as well.

Hemlock splinters are annoying and so painful because of their needle-shaped structure.

Sanding is a must before touching Hemlock wood to avoid splintering. Splinters mostly appear when the wood is raw.

When you’re making Hemlock wood furniture, sanding is essential to get rid of splinters while using them.

Splintering is not a critical issue of Hemlock since it can be easily fixed with light sanding. Cover Hemlock wood when it is in the raw state.

7. Difficult To Work When Dry

When the Hemlock wood is dry, it gets so hard, sturdy, and resilient. When the wood is too hard, working and shaping the wood can be challenging.

This happens when the wood is fully cured and dried.

Because of being so hard when dry, your woodworking hand tools get damaged easily and you’ll probably have to go for power tools when drilling and carving the wood.

To prevent the wood from going hard, use the wood for woodworking projects when it is in the raw state.

Hard Hemlock wood cracks and splits easily and has a high tendency to scratch and tear off when working with tools.

Nailing, sawing, drilling, and cutting can be extremely difficult when the Hemlock is too dry and hard.

You cannot the shape of your woodworking project or Hemlock furniture once it gets too dried and hard since wood tends to crack and peel without giving smooth edges.

8. Darken With Age

Hemlock wood darkens with time.

Hemlock wood will turn into a chocolate brown color as it ages due to sunlight, UV light, and other environmental elements.

Sunlight darkens the Hemlock wood by changing its natural composition over the years. You can notice hits of natural burgundy tones bleed through the Hemlock wood.

In order to prevent Hemlock wood from darkening, you can apply a proper finisher over it.

A proper sealant or finisher helps to protect the wood from UV light and minimize the color discoloration of the wood.

By applying a proper sealant, you can only slow down the darkening process since darkening of Hemlock wood over when it ages is a natural process that hard to avoid.

If you keep the Hemlock wood untreated, it will eventually turn almost black, a very dark color. Sunlight makes the darkening process faster.

In order to slow down the darkening process of Hemlock wood over ages,

- Apply proper finisher over wood

- Cover up Hemlock furniture or woodwork

- Place Hemlock furniture away from direct sunlight

- Use UV filter glasses for windows

Hemlock wood darkens faster when placed outside than inside because of the direct sunlight and other environmental elements.

That’s it, folks! Now you have a clear idea about the Hemlock wood disadvantages and how to fix them with simple tips and tricks.

Is Hemlock Good for Outdoor Use?

Hemlock wood is good for outdoor use only after it is finished and treated properly. After applying a quality sealant or finisher Hemlock wood will be able to get protected from outdoor elements such as moisture, UV light, insect attacks, and more.

But proper and regular maintenance is a must for Hemlock outdoor furniture and woodwork since the wood is highly sensitive to temperature variations, and climate changes and it has no natural weather resistance.

Clean Hemlock outdoor furniture frequently to remove dust and debris and reapply the finisher or sealant on Hemlock wood at least once per year before the previous coat fades off completely.

Is Hemlock Wood Water Resistant?

Hemlock wood has no water resistance since there’re no resin canals inside of the wood and the wood is too soft and has poor density.

Water will easily penetrate through Hemlock wood fibers and cause wood to rot.

Hemlock wood can be water resistant by applying a proper sealer.

The sealing coat prevents water from going inside the wood and stops the wood from rotting and decaying.

Because of having no water resistance, you cannot keep Hemlock wood untreated.

Proper sealing and finishing are a must to get protected from water.

What Is Better Hemlock or Pine?

Hemlock wood is harder and stronger than Pine. Hemlock is a durable and better wood than most other softwoods like Pine.

But pine has better water resistance than Hemlock since it has resin canals which Hemlock doesn’t have.

According to the Janka hardness ratings, Hemlock is harder than Pine with 580 lbf hardness while Pine has a 380 lbf hardness level.

Both Hemlock and pine are softwoods with excellent workability and stability, and they can be used for many woodworking projects after sealing and finishing properly.

Is Hemlock Wood Poisonous?

Not every Hemlock wood is poisonous, but there is a variant called poison Hemlock which is toxic to animals and humans in many ways.

Never use poison Hemlock for any woodworking project.

Never touch or smell poison Hemlock since they contain toxic alkaloids that can be fatal for us.

Best Finish For Hemlock

As we already know by applying a wood finish properly on Hemlock, we’re able to solve lots of its disadvantages like poor water resistance, rotting, insect attacks, and much more.

So, let’s find out what are the best finishes for Hemlock to get protected from environmental elements like moisture.

The best finishes for Hemlock are as follows,

- Oil finish (Teak oil, Danish oil, Tung oil, Linseed oil)

- Lacquer

- Paint

- Varnish

- Wood stain

By applying the above finisher before using Hemlock furniture, you can protect the wood from environmental elements while getting an enhanced wood appearance.

So, let’s answer some frequently asked questions as well.

FAQs

Is hemlock wood resistant to rot and insects?

Hemlock wood is not naturally resistant to rot and insects, which makes it imperative to treat the wood if it is to be used for outdoor purposes or in moist environments.

How does hemlock wood respond to staining and painting?

emlock wood can be challenging to stain evenly due to its uneven grain patterns, and it might require additional preparation work for painting to achieve a smooth finish.

Is hemlock wood a durable option for flooring or furniture?

Hemlock is softer compared to other types of wood like oak or maple, making it less durable and more prone to scratches and dents when used for flooring or furniture.

Can I use hemlock wood for outdoor structures?

Due to its low resistance to rot and insects, hemlock wood is not the best option for outdoor structures unless it is properly treated and maintained.

How does hemlock wood compare in cost to other types of wood?

Hemlock wood is generally less expensive than hardwoods like oak or maple, but this cost advantage might be offset by the need for additional treatments to protect the wood from rot and insects.

Is hemlock wood an environmentally friendly option?

While hemlock is a fast-growing species and can be a more sustainable option compared to slow-growing hardwoods, the need for chemical treatments to protect the wood from decay can have environmental impacts.

Does hemlock wood have any particular odor or allergenic properties?

Some people might find the natural odor of hemlock wood to be unpleasant, and the wood dust produced during cutting and sanding can be an allergen for certain individuals.

Did I cover all you wanted to know about: Hemlock Wood Disadvantages?

In this article, I have deeply discussed the Hemlock wood disadvantages and how to fix them quite easily using simple techniques.

Hemlock wood disadvantages include being prone to rot and insect damage, requires treatment for outdoor use, and can be difficult to stain evenly. It is also softer and less durable than harder woods, making it susceptible to scratches and dents in flooring or furniture applications.

Furthermore, I’ve answered some frequently asked questions as well.

Hope you have gained good knowledge about Hemlock wood disadvantages with solutions.

Try Hemlock on your next woodworking project and try to minimize its cons and get the best advantages out of it. Happy woodworking with Hemlock!