Ever been torn between a jack plane and a smoothing plane for your woodwork project? Let’s delve into their unique roles to unveil which tool truly suits your needs!

Jack plane and Smoothing plane are popular hand planes in woodworking.

They use muscle power to force the cutting blade over the wooden surface to reduce the thickness of the wood and achieve a smooth and well-shaped wood piece.

Because of having similar properties, I was curious about the differences between the Jack plane and the Smoothing plane.

So, I did some research and found lots of useful info about their differences.

Let’s review, Jack plane vs Smoothing plane

Jack plane shapes the lumber to finer dimensions while the Smoothing plane smoothens further out the surface by making it ready to finish. The rounded dull cutting blade of Jack plane can use for any task while the sharp blade of the Smoothing plane that does a better job at smoothing.

But there’s a lot more to know about Jack plane vs Smoothing plane.

So, in this article, I’ll explore an in-depth look at the 6 differences between Jack plane and Smoothing plane.

I’ll discuss what is jack and Smoothing plane and what are they good for with pros and cons and I’ll answer frequently asked questions as well.

Let’s dive in deeper!

What Are the Differences Between Jack Plane and Smoothing Plane?

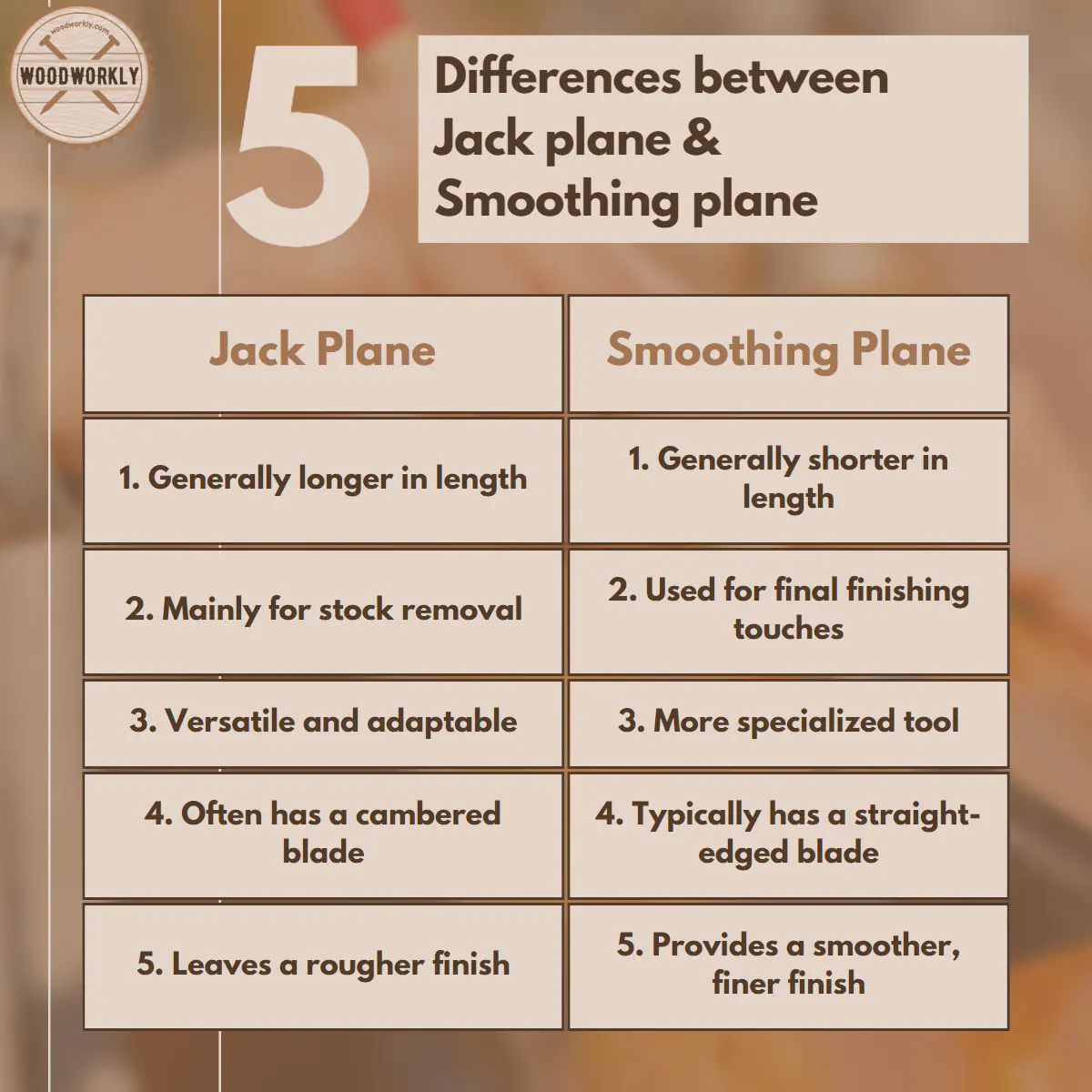

Jack plane and Smoothing plane differ in terms of functionality and their physical appearances.

Both Jack plane and Smoothing plane are hand tools that belong to the bench plane family.

They are really important for many woodworking activities. Each plane is specialized for its functions.

Differences between Jack plane and Smoothing plane can be discussed under the following factors,

- Functionality

- The shape of the blade

- Planes size

- Planes frog

- Camber

- Mouth opening

Here is a comparison table showing the differences between a Jack Plane and a Smoothing Plane based on the latest information:

| Attributes | Jack Plane | Smoothing Plane |

|---|---|---|

| Purpose | Mainly utilized for general tasks such as resizing, reshaping, and initial smoothing of wood. | Primarily used to smooth surfaces, particularly as the final step in woodworking projects. |

| Cutting Edge | It has a dull, rounded, cutting edge. | It has a sharp, crown-shaped, cutting edge. |

| Blade Edge | Tooth-shaped. | Smooth, softened. |

| Opening (Mouth) | Wide. | Narrow. |

| Size (Number) | Number 5. | Number 4. |

| Sole Size | 14 inches. | 9 inches. |

| Length | 12-18 inches. | 7-10 inches. |

| Blade Angle | Typically 45 degrees. | Between 45 – 50 degrees. |

| Frog (Blade’s Position) | Tooth-shaped iron edge with a 45-degree angle. | Smooth edges with a frog angle of 50 degrees. |

| Camber (Curve of the cutting edge) | Can use a couple of iron cambers. Heavily-cambered iron can take narrow and deep scoops out of the wood. A less-cambered iron performs similar to a smoothing plane. | Minimal camber with straight-nicked and softened corners. |

| Mouth Opening | Can adjust up to 1/16 inch or 1.6 mm for typical woodworking. | Smaller than the jack plane, suitable for thinner shavings. |

| When to Use | Generally used at the beginning of woodworking projects for resizing, reshaping, and initial smoothing. | Used towards the end of woodworking projects for creating maximum smoothness. |

Now you have general ide about those the differences of those bench planes.

First of all let’s give a quick look at both planes to know their features with some pros and cons.

What is a Jack Plane?

A jack plane, commonly referred to as a ‘bench plane’, is a tool that’s as fundamental to woodworking as a hammer is to carpentry.

It’s a hand tool used to smoothen and flatten surfaces, reducing them to the desired thickness.

Anatomy of a Jack Plane

Let’s start by understanding its structure. The body of a jack plane typically consists of a wooden or metal base, known as the sole.

A long, wide blade—or iron—sits inside the body, usually at an angle between 40 to 45 degrees.

The iron, controlled by a depth-adjustment knob, can be set to protrude slightly from the base, allowing for a varying depth of cut.

The chip breaker, positioned on top of the blade, helps in curling and breaking the wood chips.

Additionally, the plane has a front knob and a rear handle for control and comfort during use.

Key Features of a Jack Plane

- Versatility: Jack planes can be used for various tasks, from rough dimensioning of lumber to final smoothing.

- Depth of Cut Adjustment: The depth-adjustment knob allows you to control the cutting depth, depending on the task at hand.

- Frog Mechanism: This controls the angle of the blade, allowing you to adjust the plane for harder woods or intricate tasks.

- Durable: Given the robust materials they’re made of—usually high-grade steel and hardwood or sturdy cast iron—a jack plane can last for generations if properly cared for.

Pros and Cons of Using a Jack Plane

Pros

- Satisfaction: There’s an unrivaled satisfaction in using a hand tool and physically engaging with the wood. You’re truly a part of the crafting process.

- Control: A jack plane gives you the ultimate control over your workpiece, which can often result in a higher quality finish.

- Sustainability: It’s a manual tool, so it doesn’t use electricity, making it an environmentally friendly choice.

Cons

- Physical Effort: It requires a considerable amount of physical strength and stamina, especially for large projects.

- Skill: Operating a jack plane efficiently takes practice and patience to learn the right techniques.

- Time-Consuming: Compared to electric planers, hand planing is more time-consuming.

As you can see, the jack plane is a tool steeped in tradition, offering an incomparable sense of satisfaction. It connects the craftsman to their work in a way that few tools can, a tactile experience that’s both rewarding and intimate.

Now let’s look at the smoothing plane.

What is a Smoothing Plane?

A smoothing plane is a type of bench plane primarily used in woodworking to smooth the surface of a workpiece.

The most delightful thing about a smoothing plane is its ability to deliver an impeccably smooth finish that even the finest sandpaper might struggle to achieve.

The Design of a Smoothing Plane

The smoothing plane usually has a similar structure to other planes, but it’s typically smaller in size.

It consists of a flat sole, which can be made of wood or metal, and a sharp, broad blade (or iron) set at a low angle.

This configuration allows the tool to cut a very thin layer off the surface, resulting in a smooth, clean finish.

The tool also features a chip breaker to help prevent tear-out, and a frog mechanism to adjust the blade angle.

It has a front knob and a rear handle for comfortable grip and control.

Key Features of a Smoothing Plane

- Size: Smoothing planes are typically smaller in size, offering better control and precision.

- Blade Angle: The low-angle blade setting is perfect for achieving smooth finishes on hardwoods.

- Frog Adjustment: This feature allows you to control the angle of the blade to match the grain of the wood, preventing tear-out.

- Comfortable Handling: Due to their size, they’re generally more comfortable and less tiring to use over extended periods.

Pros and Cons of Using a Smoothing Plane

Pros

- Fine Finish: The smoothing plane can deliver an ultra-smooth finish that can be challenging to achieve with sandpaper.

- Control: You have complete control over the depth of cut, allowing you to tailor the finish to your liking.

- Efficiency: It’s a great tool for tackling small-scale projects quickly.

Cons

- Learning Curve: Just like other hand tools, mastering the smoothing plane takes practice and time.

- Physical Effort: While it’s not as demanding as larger planes, it still requires physical effort.

- Limited to Smaller Projects: Due to its size, a smoothing plane may not be the best option for larger pieces of timber.

The smoothing plane is a remarkable tool that allows you to achieve a superbly smooth finish on your woodworking projects.

It offers a great way to interact with your workpiece, and provides a gratifying, tactile experience that’s sure to enrich your craftsmanship.

So, let’s discuss Jack plane vs Smoothing plane under each of the above factors.

Functionality Of Jack Plane Vs Smoothing Plane

Jak plane and Smoothing plane mainly differ because of their functionalities. Both are important in their own way.

Let’s take a deeper look at the differences in functions between Jack plane and Smoothing plane. The results might surprise you!

Jack Plane

Jack plane is considered as the “Jack of all trades” because it can basically use for anything. Jack plane is used to shape and resize roughhewn lumber to finer shapes.

If can remove bowing or cupping of the wood by adjusting in 38 total angles which is quite impressive. Common Jack plane angle is 45-degrees.

Jack plane is mostly used at the beginning of woodworking projects for shaping and resizing the wood and providing the required smoothness to the surface.

According to my experience, Jack plane is a combination of jointer planes, Smoothing planes, and fore planes.

It can basically use for any task, and it is an essential hand tool for every woodworking expert.

Jack plane can be used to flatten the surface. But that needs a lot of skills to find the high spots on a wood surface and flatten them with the short plane.

Even though Jack plane is capable of anything, it is too short to be a good joint plane. Plus, the sole is too long to be good at smoothening.

But when it comes to rough works, no plane can beat Jack plane. It can hog any wood quickly.

As a conclusion, here’re what Jack plane is good for,

- Shape the wood

- Resize the wood

- Flatten large surfaces

- Smoothen the wood

- Jointing work

Smoothing Plane

In terms of functionality, Smoothing plane is specialized for smoothing the surface.

The smoothing plane is mostly used in the final stages of woodworking projects to smoothen the surface without using any sandpapers.

That means you don’t have to sand the wood prior to a final finish. Smoothing plane does the job perfectly.

It keeps the natural grain of the wood to avoid splintering. It makes the surface ready to finish. The common angle of Smoothing plane is 45-degrees.

Smoothing planes can remove fine shavings from the wooden surface and create a super smooth surface for staining or sealing the wood.

As a conclusion, here’re what Smoothing plane is good for,

- Smoothing the surface

- Remove fine shavings

- Avoid splintering

- Make the surface ready to finish

That’s all about the functionality of Jack plane vs Smoothing plane. So, let’s jump into the next factor, the shape of the blade.

Shape Of the Blade of Jack Plane Vs Smoothing Plane

Jack plane and Smoothing plane differ not only in functions but also in the physical appearance of the cutting edges of blades.

Way Jack plane a Smoothing planes work differ when the shapes of the cutting edges are different.

So, let’s take a deep look at the differences in the shape of the blade between Jack plane and Smoothing plane.

Jack plane

The cutting edge of Jack plane is rounded, honed straight, and dulled.

Therefore, you don’t have to worry about sharpening the plane before use. Cutter width can be 1” – 2”. Blade angle is 45-degrees.

Cutting width is important to get an idea about the flatness of the resulting wood surface and how much work should be done to get there.

Wider planes make flatter surfaces, but it takes time.

Narrower planes make flatter surfaces quickly if wielded precisely.

Because of having a rounded cutting edge, Jack plane can avoid wood from cracking and splitting which is wider than the iron of the plane.

Smoothing plane

Smoothing plane has a slightly cambered or crown-shaped, sharp blade. Therefore, the blade needs to be sharpened before use.

A properly sharpened blade is important to get the super smooth surface and you can use water stones to sharpen it.

Because of having a cambered-shaped blade, Smoothing plane can work on minimal curves that are hard to see because of the overlapped cuts.

Recommended blade size for the Smoothing plane is 70mm.

Planes Size of Jack Plane Vs Smoothing Plane

Both Jack plane and Smoothing plane come under the bench plane family. Plane sizes of bench planes range from number 1 to number 8 according to their sizes.

The functionalities of each plane differ based on their plane size as well.

So, let’s take a deep look at the differences in plane size between Jack plane and Smoothing plane.

Jack plane

Even though you are able to use single planes for all the tasks, I recommend using multiple plane sizes that are set up differently to get finer dimensions.

Number 5 and Number 3 are the most common plane sizes for Jack plane. Number 5 plane is cheap and can use for scrub works.

You can use one plane for aggressive work and while other for smoothing work.

Number 5 Jack plane has a 2” cutting width and 14” sole length for rough and finishing tasks. It has a heavily cambered iron to dress stock.

It is powerful and useful for almost any woodworking plane activity.

Smoothing plane

Number 4 is the most common Smoothing plane size with a sole length of 9” and the latter is 10” long. Smoothing plane iron width ranges from 1” – 2”.

It has a perfectly balanced cutter width and sole length which is important to smooth furniture and other woodwork parts.

Number 4 Smoothing plane is popular for cabinet making which is heavy and won’t wear out easily.

Smoothing plane is smaller in size than Jack plane. Number 1 and 2 bench planes are Smoothing planes with 5 1/2” and 7” long. They cannot be used for smoothing tasks because the plane size is too small.

Therefore, they’re called kids bench plane.

Number 3 Smoothing plane is also recommended for smoothing small parts (stiles, narrow rails, and mullions) and removing tear-outs in large panels. But the size is short and narrow.

Planes Frog of Jack Plane Vs Smoothing Plane

Planes frog is helpful to eliminate the need for scrapers. The frog angle of a plane directly affects its functionality. 45-degree and 50-degree frogs are popular for most woodworking activities.

So, let’s have a deep look at the plane frog differences between Jack plane and the Smoothing plane. The results might surprise you.

Jack plane

Jack plane has tooth-shaped edges (iron) that teeth into the wooden surface.

Number 5 jak plane frog angle is 45-degrees which helps Jack plane to move more easily through the wood than high-angle planes.

Smoothing plane

Smoothing plane has smooth edges that help to gain a smooth finish as you wish. The iron of the Smoothing plane has no sharp rough edges like the Jack plane.

This is the key reason why Smoothing plane is specialized for smoothing the surface than Jack plane.

Even though Jack plane is good for smoothing, it cannot surpass Smoothing plane due to teeth-shaped edges on the blade.

Number 4 Smoothing plane has a frog angle of 50-degrees which helps to reduce the tearing of curly woods.

Camber of Jack Plane Vs Smoothing Plane

Cambered iron is useful for light shaving and makes the wood smooth. Plus, camber can remove the stock quickly.

Let’s take a look at the differences in camber between Jack plane and Smoothing plane.

Jack plane

Camber is powerful and efficient in smoothing the wood surface.

You need a couple of irons to get the full functionality from the Jack plane. Heavily cambered iron is used to take deep narrow scoops of wood pieces out. A less cambered one does a similar job like a smoother plane by smoothing the surface.

Plus, by inserting another iron in between, you can have the last iron with no camber or very little camber and the edges can be slightly loosened.

Smoothing plane

Smoothing plane has minimal camber because it is used to smoothen the wood. Smoothing plane irons are straight with softened corned which are useful as true camber.

Because of having a thin maximum projection, shavings might be transparent. Smoothing plane cambers corners are nicked to prevent tacks in woodwork.

Mouth Opening of Jack plane Vs Smoothing plane

Mouth opening means the gap between cutting edge and plane. Body. Smaller opening makes thinner the shaving.

Mouth opening is another main factor that differs according to the type of the plane.

Let’s have a deep look at the mouth opening differences between Jack plane and Smoothing plane.

Jack plane

Jack opening mouth opening can be adjusted 1/16” (1.6mm) for general work and finer woodworking activities.

Mouth opening should be set according to the thickness of the shaving. The thickness of the Jack plane shavings is large; therefore, Jack plane mouth is open wider.

Mouth opening of Jack plane can be controlled by loosening the front button and turning the lever that moves the twisted plate to the front plane.

Smoothing plane

The mouth opening of the smooth plane is small because the shavings are too thin.

By making the mouth opening of the Smoothing plane small, you’ll be able to reduce wood tearing off.

When you use Smoothing plane for heavy rough smoothing tasks, the mouth opening will be wider. The mouth opening makes it large enough to shave the wood surface without clogging and choking the plane.

If you’re using Smoothing plane on a non-rough surface with very few defects, better to adjust mouth opening small to reduce tear-out.

That’s all about Jack plane vs Smoothing plane.

So, let’s have a look at the summarized table of differences between the Jack plane and Smoothing plane to get a direct idea of what suit you the most.

Differences Between Jack Plane and Smoothing Plane

| Jack plane | Smoothing plane |

| Useful for general purposes | Useful only for smoothing the surface |

| Rounded dull cutting edge | Crown shaped sharp cutting edge |

| Number 5 plane size with a sole length of 14” | Number 4 plane size with a sole length of 9” |

| Tooth shaped blade edge | Smooth softened blade edge |

| Mouth opening is wide | Mouth opening is narrow |

Ultimately both are awesome hand tools and planes in woodworking.

Can You Use Jack Plane as A Smoothing Plane?

I know you’re probably wondering, why we can’t use Jack plane as a Smoothing plane if it’s capable of smoothing the wood.

Yes, you’re correct, we can use Jack plane as a Smoothing plane. But there’re some exceptions.

If you need a super smooth finish, Jack plane is not the ideal plane you should go with. Because Jack plane can never replace Smoothing plane in terms of smoothing.

Smoothing plane is specialized for smoothing the wood. it makes the wood ready to finish while Jack plane is used at the beginning of most woodworking projects.

If you use Jack plane at the end to make the wood ready to finish, you might probably ruin the wood grain or make the wood tear off.

Jack plane is designed for rough works, not for finer tasks.

Therefore, I highly recommend going for Smoothing plane if smoothness is a critical factor in your woodwork because Jack plane can ruin the wood with its dull blade, and better not to take risks at the end of your beautiful woodworking project.

That’s it folks! now you know all you need to know about Jack plane vs Smoothing plane.

Let’s answer some frequently asked questions.

Why is a smoothing plane typically smaller than a jack plane?

A smoothing plane is typically smaller to provide better control and precision when working on smaller-scale projects or performing detailed work, while the larger jack plane is better suited for quickly roughing and flattening longer or larger pieces of wood.

Is it necessary to have both a jack plane and a smoothing plane in my tool kit?

Yes, having both a jack plane and a smoothing plane in your tool kit is beneficial because they each serve unique purposes in the woodworking process, from initial shaping and sizing to final finishing.

Which one should I use first: a jack plane or a smoothing plane?

You would typically use the jack plane first to get your piece of wood to near its final shape, removing any rough spots and twists, and then follow up with the smoothing plane for the final finish and smoothness.

Can a smoothing plane replace sandpaper?

A well-tuned smoothing plane can often achieve a smoother finish than even the finest grit sandpaper, especially on hardwoods. However, it does require more skill and practice to master.

Did I cover all you wanted to know about: Jack plane Vs Smoothing plane

In this article, I have deeply looked at Jack plane vs Smoothing plane under various factors such as functionality, the shape of the blade, plane size, plane frog, camber, and mouth opening.

I have discussed how the Jack plane and Smoothing plane contribute to those factors with differences.

A jack plane is a versatile woodworking tool typically used for roughing and straightening wood. On the other hand, a smoothing plane, usually smaller, is designed for providing the final finish and smoothness to a wooden surface, effectively replacing the need for sandpaper in many cases.

Furthermore, I have answered a frequently asked question as well.

That’s it, folks! Hope you have gained good knowledge about the differences between Jack plane and Smoothing plane with pros and cons of each plane.

Keep practicing with those planes to sharpen your woodworking skills. Have fun!