Ever pondered the secret behind enduring furniture finishes? Dive deep with us into the captivating Spar Urethane vs Polyurethane duel.

I encountered a friend of mine while I was on my way to a picnic. He was taking his small boat in for maintenance, as the wooden components were beginning to rot. He needed to treat them with wood preservatives.

During our conversation, he asked for my advice on the most suitable preservatives, knowing that I have expertise in this area.

I recommended two types to him which were Spar urethane and polyurethane.

He asked the differences between them and that’s when I thought to do research on this topic.

In the next couple of days, I went for experts and gathered lots of info about the differences between spar urethane and polyurethane.

So, here is the answer for the spar urethane vs. polyurethane,

The main difference between spar urethane and polyurethane is their resistance to environmental elements; spar urethane offers better moisture and UV resistance, making it ideal for outdoor projects, while polyurethane provides a harder finish, preferred for indoor furniture and flooring.

I have shared my experiences regarding these types of wood preservatives, so I thought I should share these experiences with you.

So, now let’s see what these wood preservatives are, their features, and details like differences.

Let’s jump in!

What is Spar Urethane?

In my experience, most people have heard of spa urethane. Spar urethane is a special type of finish used for boats.

“Spar” is the name given to the supporting wooden posts for the sails of ships and boats. These wooden posts must withstand high humidity, wind, and temperature.

Therefore, because this type of paint is applied to the wooden poles, it is called Spar urethane.

Studying the past gives a better understanding of how it should be used. It is made by mixing resins and solvents in high proportions.

In my experience, Spar Urethane is more resistant to water and UV rays, which is why it is so popular among carpenters who make outdoor furniture.

There are two main types of spar urethane.

- Oil-based spar urethane

- Water-based spar urethane

So, let’s talk about them in detail.

Oil-based Spar Urethane

Oil-based spar urethane is the most popular type of spar urethane.

Oil-based spar urethane is viscous, flammable, less environmentally friendly, slower drying, and more damaging.

But it protects against UV rays and provides a durable finish.

Care must be taken that unlike water-based spar urethanes, they smell good and turn yellow over time.

Water-Based Spar Urethane

The main difference is that water-based spar urethane dries faster than oil-based options.

Water-based spar urethane has many advantages such as being thin, non-flammable, environmentally friendly, and less harmful.

Pros and Cons of Spar Urethane

Now I’m going to share with you some pros and cons of spar urethane you might get when you’re working with it.

Most of them were based on my personal experience since I’ve finished many indoor and outdoor furniture with this awesome finish.

Pros of Spar Urethane

Multipurpose

Spar urethane can be used for indoor and outdoor applications, but it is mainly used for outdoor wood.

It can be applied to a variety of wood and wood-related materials and the more porous the surface, the easier it is for the spar urethane to hold, cure, and look great.

Lasting

In addition to being weatherproof and UV-resistant, spar urethane is generally a durable paint. That means it won’t dent, scratch, or dent easily.

Its durability is the main reason for applying it to surfaces that are at high risk of damage.

Easy to Apply

Spar urethane can be brushed, rolled, or sprayed, but the project should decide which method is best.

However, applying spar urethane is not difficult. The most challenging thing is being patient enough to let it dry completely.

Cons of Spar Urethane

Slow Curing Time

In my experience, spar urethane takes five to seven hours to dry mostly, but it takes about 30 days to fully cure.

However, if you choose a water-based spar urethane over an oil-based version, water-based Spar-based urethane takes a week or two to fully cure, so your project can be finished quickly.

High VOCs Content

Volatile organic compounds (VOCs) are harmful to humans, and spar urethane contains many of them.

Therefore, you should take precautions before working with this finish.

Sustained exposure to VOCs can cause adverse health effects, including eye, nose, and throat irritation, headaches, nausea, kidney failure, and liver damage.

Gives off Strong Fumes

Oil-based spar urethane emits strong fumes, which means you should only apply this finish in a well-ventilated space.

Excessive exposure to fumes can cause headaches, nausea, and loss of consciousness.

Applying Spar Urethane on Wood

In my personal experience, the best way I recommend applying spar urethane is to use a natural brush. This will also work with a wood finish paint sprayer.

If you don’t have those tools, you can use a clean rag to wipe the spar urethane solution over the surface.

All you must do is mix equal parts of oil-based spar urethane and mineral spirits.

Follow the following techniques when using spar urethane on wood,

- Whether it’s an interior or exterior project, apply at least three coats of spar urethane to the surface.

- You can apply spar urethane to the unfinished wood materials.

- For a finishing material, two layers of spar urethane will be enough.

- After applying the final coat, allow the spar urethane to dry thoroughly before using the surface for about a day.

The ideal temperature for spar urethane application is 50 to 90 degrees.

When should Spar Urethane be used?

- Spar urethane is best used for outdoor wood projects, outdoor furniture, etc. because it can take advantage of weather resistance. And it resists UV rays well so you don’t have to worry about sun damage or discoloration at all.

- Spar urethane can be used to coat cabins, vanities, and other indoor furniture.

- Spar urethane is also ideal for marine applications such as offshore structures, boats, and docks.

- In addition, spar urethane is ideal for surfaces that do not discolor from its oily nature, but can benefit from its durability.

Now you have a crystal clear knowledge about spar urethane. So, let’s talk about Polyurethane and its qualities as well before heading into the differences between them.

What is Polyurethane?

Polyurethane has been used for some of my projects. It is indeed an excellent type of sealer to keep your wood projects for a long time.

You have seen many of these types of sealers in the market before. Polyurethane can be considered a multi-purpose sealer and can be purchased in a variety of forms.

For those interested in polyurethane, it is a synthetic resin that is transparent in color.

There are two main types of polyurethane.

- Oil-based polyurethane

- Water-based polyurethane

Oil-based Polyurethane

Many wood experts, myself included, highly recommend oil-based products for interior wood surfaces because of their shine and scratch resistance.

A disadvantage of this is that oil-based polyurethane darkens or turns yellow after drying.

However, it creates a durable finish that can fight against external elements such as mold and moisture.

Oil-based polys produce toxic fumes because they contain combustible components.

Water-based polyurethane

Water-based polyurethane is an excellent option for the environmentally conscious.

It is relatively safe to use and generally has less fumes than solvent-based polyurethane (often sold as oil-based polyurethane).

Water-based poly dries very clear and stays clear.

However, both oil-based and water-based polyurethane can be used to protect wood surfaces for over a decade when applied and maintained correctly.

Does Water Based Polyurethane Yellow? Here’s The Truth!

Pros and Cons of Polyurethane

Now I’m going to share with you key advantages and disadvantages you might get working with Polyurethane.

This will help you to decide whether you should go with polyurethane or not for finishing your furniture.

Pros of Polyurethane

Resistant to Elements

Both oil and water-based polys are resistant to many degrading elements such as water, heat, chemicals, fungi, and solvents.

In addition to being weatherproof, polyurethane is UV-resistant, so it can be used outdoors to great effect.

Read to know, Is Polyurethane Waterproof? Here’s the Truth!

High durability

The durability of polyurethane is a major reason for its application to a range of wood surfaces.

It resists dents, and scratches and goes well, and its durability ensures it lasts long no matter what it’s forced to endure.

Bold Seal

Applying polyurethane can be considered a good measure when you want to prevent water seepage through wooden joints.

This is an excellent sealer.

Easy to Apply

You can apply polyurethane with a roller, foam brush, or even spray. All you need to apply this finish is sandpaper, one of the above applicators, a clean cloth or two, patience, and time.

By applying polyurethane correctly, you can avoid brush strokes, air bubbles, and many other mistakes that can ruin your project.

Cost-effective Finish

Polyurethane is a cost-effective finish, mainly due to its durability and longevity.

You will never regret spending $20-$30 on protecting an expensive piece of furniture. Polyurethane comes with a good warranty.

Cons of Polyurethane

Release Harsh Fumes

Polyurethanes, especially oil-based products, typically emit strong fumes.

Therefore, the room you are in should be well-ventilated when you apply this so that you don’t inhale too much fumes and experience the effects.

Discolor the Wood

Oil-based polyurethane can discolor wood and wood-based materials, especially softwood.

Polyurethanes with higher viscosity, i.e. those with higher oil content, will turn yellow or amber after fully curing and may discolor the applied paint or stained material.

High VOC Content

Especially oil-based polyurethanes have a lot of VOCs. So if you coat a frequently used piece of furniture here, you are more likely to be exposed to these VOCs (in vapor form) in the long term.

Again, excessive exposure to VOCs can cause a number of health problems so be sure to use proper protective gear when applying polyurethane.

Slow Curing Time

Like spar urethane, it takes five to seven hours to dry 70-80%. However, it takes several weeks for the polyurethane to reach this state to fully cure.

Using Polyurethane on Wood

The great thing about polyurethane in my experience is that you can apply it by spraying, brushing, and wiping, no matter how many coats your material needs.

If it is water-based or oil-based, this process should be done in a well-ventilated area.

The application and drying procedures take several hours. Something I always do is work in a dust-free space and wear a mask to avoid inhaling VOCs.

The following are the mandatory steps that you should keep in mind when working with polyurethane,

- The workpiece must be well prepared with an even surface. You must ensure that there are no missed spots on the wood.

- You should sand the wood surface with sandpaper (minimum 220 grit) to remove dents and scratches.

- When applying polyurethane, the surface must be checked for dust particles. If there are dust particles, remove them immediately before polyurethane dries.

- Allow the polyurethane to dry according to the drying time recommended on its label.

- Polish the applied surface for smooth results.

- ·Use a high-quality brush for polyurethane applications.

Read to know, How To Fix Polyurethane Mistakes!

When Should Polyurethane Be Used?

- To my knowledge polyurethane is best suited for indoor applications. These don’t need strength and security as much as visual appeal.

- Polyurethane is an effective sealer, which means that if it is applied to cabinets, drawers, vanities, tables, shelves, etc., these furniture items do not have to worry about water damage.

- In short, it is practical to apply this finish to any indoor wooden surface that is especially prone to dingy, scratches, etc.

- Exterior polyurethanes can be used outside to great effect, and even these polyurethanes won’t hold up well for long if you’re in an area with frequent temperature and humidity fluctuations.

Differences Between Spar Urethane and Polyurethane

From what I’ve said, you now have a basic understanding.

Let’s take a closer look at their differences to determine which finish is better overall.

1. Ease of application

The first thing you need to know when working with a new product is how easy it is to apply. It looks great and the method you know is perfect for this.

Many people say that spar urethane is easier to apply than polyurethane, but that is a bit misleading.

The application process for both products is the same in every way.

Brush the underlying surface, clean it, add the first coat, wait for it to dry, then add the second coat and repeat as needed.

Some people give spar urethane the edge because brush strokes are less visible compared to polyurethane.

This is true because spar urethane is a softer material so it can be leveled better.

However, that only happens when you apply oil-based polyurethane. There are no such problems when applying water-based polyurethane.

2. Drying time

Ask anyone who has used these two products before, and they will tell you that spar urethane dries faster than polyurethane.

Polyurethane is known to dry very slowly; one coat can take up to 24 hours before you can apply the next one. One day per coat? After 4 hours of spar urethane, the second coat can be applied.

However, that’s only when you’re referring to traditional oil-based polyurethanes, not the fast-drying types. Fast-drying, oil-based polyurethane dries in as little as 4 to 6 hours, which is a huge improvement.

For the water-based versions of both products, they are both ready for a new coat in 2 hours.

Even cure times are similar for water-based alternatives such as oil-based spar polyurethane and fast-drying oil-based polyurethane.

Now, when you consider options like one-coat poly and wipe-on poly, the drying time shrinks even further, making it slightly faster than spar urethane.

So, overall, this is a tougher race than expected.

3. Poisoning

Polyurethane is great for many and many things, but the environment is not one of them

Polyurethane contains isocyanates and other products that emit highly volatile organic compounds (VOCs).

Some VOCs are known carcinogens, such as benzene – they can also irritate the eyes, lungs and skin when used.

As a result, you should be more careful when using polyurethane, especially oil-based. After the polyurethane dries, it is no longer harmful.

As far as I know, spar urethane also emits high VOCs, although not as high as polyurethane. This is true for both water-based and oil-based versions.

If we compare water-based spar urethane vs. polyurethane, we can find some water-based versions that emit less VOC than water-based spar urethane, but this is not common.

Spar urethane is generally safer for people and the environment.

4. Durability

As you probably know by now, polyurethane is the toughest topcoat available for interior woodwork.

Its unique resin and solvent combination make it dry so hard that it will maintain this hardness for years to come.

This is true for both oil-based and water-based polyurethanes. Some people say that oil-based polyurethane is tougher.

Spar urethane, on the other hand, hardens, but it does not dry as hard as polyurethane. Since these products are made for both indoor and outdoor use, they maintain quite a bit of flexibility.

Outdoor wood can expand and contract as the weather changes, so the topcoat should be able to do without cracking or peeling.

As a result, spar urethane does not dry as hard as interior poly. As a result, spar urethanes are not very durable.

Polyurethane can last 1 to 2 decades, water-based spar urethane can last five years, and oil-based up to three times as long.

Long before that time, the spar urethane is more likely to suffer irreparable damage.

5. Protection from the Elements

As mentioned earlier, spar urethane was originally developed for boats and is more weather-resistant than polyurethane finish.

Spar urethane can handle UV rays, and it can be abused by water without burning a grey color.

However, this is a slightly softer finish than polyurethane, so spar urethane can take on a milky appearance when exposed to moisture.

This might make you think the finish isn’t working anymore, but once it dries it clears up once again.

Polyurethane does not have such a problem, but it certainly cannot withstand moisture or sunlight.

Only exterior polyurethane usually comes with UV blockers. Therefore, if you need to apply a topcoat on interior wood that is exposed to sunlight all day, you are better off with spar urethane.

6. Ambering

The primary reason you might want to change undamaged wood finishes is ambering. Oil-based finishes have an amber color that darkens over time.

While this may not be a problem in dark woods, it can be unpleasant in light wood or light paint colors.

But then, even with dark woods, you may not complain for the first few years, but it may eventually get on your nerves.

So, it would be safe to say that ambering should also be considered as part of durability.

Oil-based polyurethanes don’t have a leg to stand on in this argument. It has an undeniable yellow color that increases with age. The same goes for oil-based spar urethane.

We have a difference with water-based options. Water-based poly is very clear and stays that way until the end of time. The same cannot be said for water-based spar urethane.

It’s technically a clear coat, and it’s amber on light stains and wood.

Therefore, before you use it in this way, you first need to test it on an inconspicuous part of the surface to ensure that it is not yellow.

7. Versatility

Due to the versatility of polyurethane, it is a very resistant product, so it can be used on any wooden surface.

Unfortunately, it is not the same with spar urethane. The significant difference between the way both products are used is the floors.

While you can apply polyurethane to wood floors, the same cannot be done with spar urethane. Because spar urethane is quite soft, it will wear out quickly in high-traffic areas.

It gets damaged by constant pounding from feet, furniture, shoes, golf clubs, falling chairs and everything else.

Polyurethane, on the other hand, dries hard and is strong enough to handle any type of abuse for years without weakening.

Besides floors, you may not want to use spar urethane on any surface you want to be stone.

Spar urethane is so great that it can’t be used on some of the surfaces that need it the most.

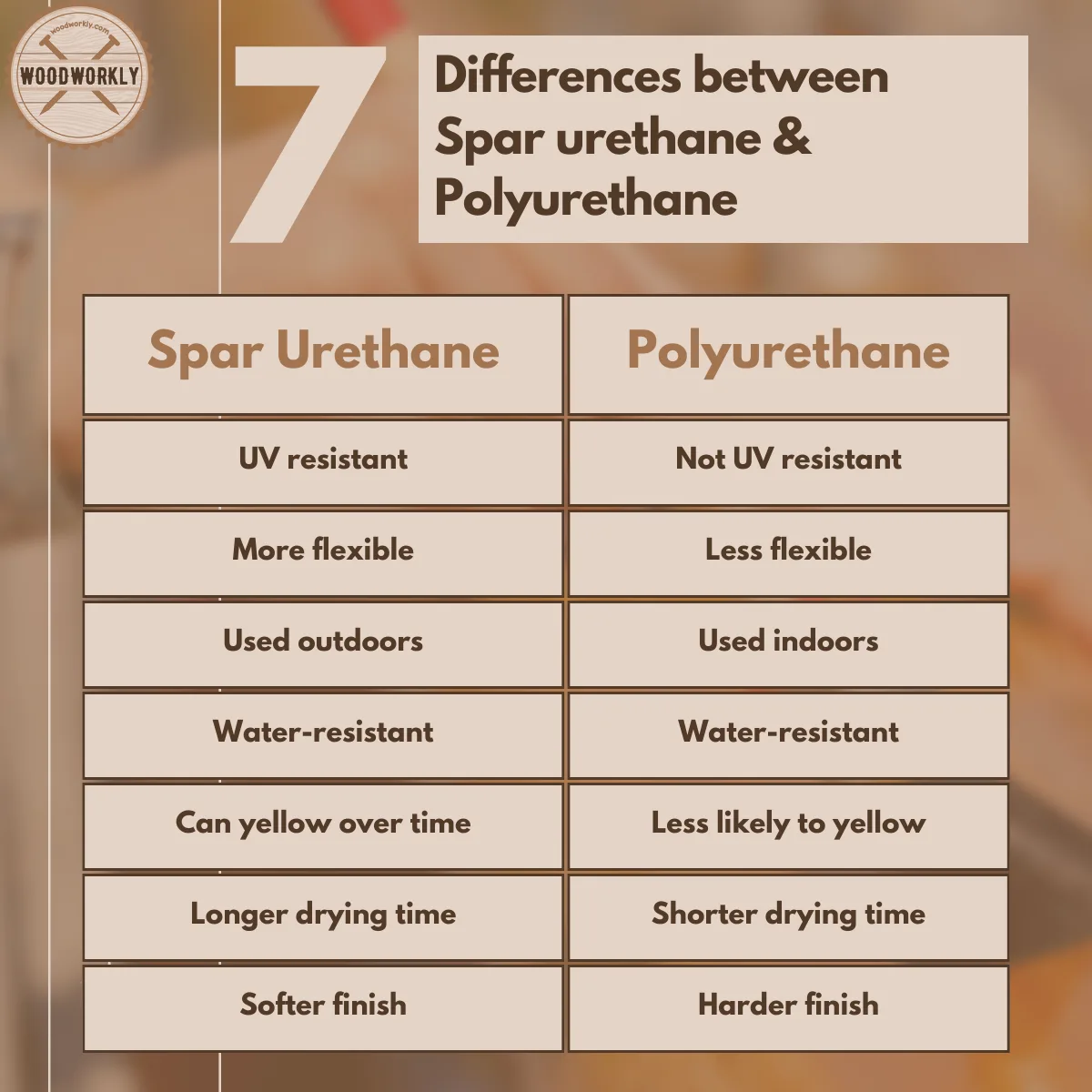

Based on the above details, I designed a comparison table to emphasize the key differences between spar urethane and polyurethane. This will help you to take a quick decision a lot quicker.

Spar Urethane Vs. Polyurethane – Comparision Table

| Spar Urethane | Spar Urethane |

|---|---|

| UV resistant | Not UV resistant |

| More flexible | Less flexible |

| Used outdoors | Used indoors |

| Water-resistant | Water-resistant |

| Can yellow over time | Less likely to yellow |

| Longer drying time | Shorter drying time |

| Softer finish | Harder finish |

Can You Use Polyurethane Over Spar Urethane?

Never put polyurethane over spar urethane because oil-based polyurethanes or interior varnishes have a lower oil content than spar urethanes.

You should take off the old finish and apply the finish the same way you removed it. This will give you a nice finish with no extra work required.

Can You Use Spar Urethane Over Polyurethane?

Yes, you can put spar urethane over polyurethane as long as it dries completely.

Spar urethanes can be a little tricky to use. It is best to test on a small, inconspicuous area before starting your project.

Congrats folks! Now you know all about Spar urethane vs. Polyurethane in detail with practical examples.

So, let’s answer some frequently asked questions.

FAQs

What are the key differences between Spar Urethane and Polyurethane?

Spar urethane is generally more flexible, handles UV rays and moisture better, and is slightly easier to apply due to less visible brush strokes, while polyurethane offers a harder, more durable finish, suitable for high-traffic areas and is less prone to yellowing, especially the water-based variety.

Is Spar Urethane suitable for floors?

No, spar urethane is not recommended for floors, as it is softer and can wear out quickly in high-traffic areas. Polyurethane, which forms a harder finish, is more suitable for flooring applications.

Does Spar Urethane yellow over time?

Yes, spar urethane, especially the oil-based varieties, can turn yellow over time. The rate of yellowing can be influenced by factors like exposure to sunlight and the type of wood it’s applied on. However, you can opt for a water-based spar urethane to minimize the yellowing effect.

Which finish offers quicker drying times?

The drying times can vary; traditionally, spar urethane dries quicker (in about 4 hours) compared to oil-based polyurethane. However, fast-drying and water-based variants of polyurethane can dry in as little as 2 to 6 hours, making it comparable to or even quicker than spar urethane in some cases.

Are there any environmental concerns associated with Polyurethane?

Yes, polyurethane contains higher quantities of volatile organic compounds (VOCs), including some known carcinogens, making it less environmentally friendly and potentially irritating to the eyes, lungs, and skin during application compared to spar urethane.

Which one should I choose for a project exposed to a lot of sunlight?

For projects that will be exposed to significant amounts of sunlight, spar urethane is the better choice due to its superior UV resistance which prevents the wood from turning gray, compared to standard interior polyurethane varieties.

Can I use spar urethane instead of polyurethane?

Yes, you can use spar urethane instead of polyurethane, particularly for outdoor furniture and projects that will be exposed to elements like water and UV rays, as spar urethane offers better resistance to these factors. However, for indoor furniture or flooring, polyurethane may be preferred due to its harder finish.

Is polyurethane better than spar urethane?

Whether polyurethane is better than spar urethane depends on the specific requirements of your project. Polyurethane, known for its hard and durable finish, is generally better for indoor furniture and flooring, where wear and tear are significant concerns. Spar urethane, on the other hand, shines in outdoor applications due to its flexibility and better resistance to water and UV rays. The best option would depend on the nature of your project.

Did I cover all you wanted to know about: Spar Urethane Vs. Polyurethane

In this article, I’ve deeply explored all the key differences under, spar urethane vs. polyurethane. I’ve mentioned the qualities of each finish and explained what differs from each other.

The main difference between spar urethane and polyurethane is their resistance to environmental elements; spar urethane is more resistant to water and UV rays, making it ideal for outdoor use, while polyurethane is typically used for indoor projects due to its harder, more durable finish.

Furthermore, I’ve answered some frequently asked questions as well.

Hope you’ve learned everything you wanted to know about spar urethane vs. polyurethane.

Now it’s time to go through all the differences again and again and select the one that suits you the most. Happy wood finishing!