Ever wondered if lacquer or polyurethane suits your project best? Dive in to discover the champion in the battle of finishes!

If you’re new to woodworking, I know that finding an ideal finish can take some time and money.

In the battle of lacquer vs polyurethane, it’s even I think it’s even harder to say which type is better.

Since they look and feel alike, I’ve seen a lot of people mistakenly call them the same thing.

But there are some important differences between them that make each one useful for different uses.

With yeast of experience, Let me give you a quick rundown of the differences between lacquer and polyurethane finishes.

Here are the main differences between lacquer and polyurethane,

- Lacquer is easy to apply

- Polyurethane is less harmful and safer

- Polyurethane is more durable

- Lacquer dries quickly

- Polyurethane is more versatile

- Lacquer cost less

- Polyurethane resists yellowing

- Lacquer is solvent-based

But there’s a lot more to know.

In this article I will tell you more about these lacquer vs polyurethane finishes and which one is better for your project.

Let’s get right to it!

What Is the Main Difference between Lacquer and Polyurethane?

The main difference between Lacquer and Polyurethane is the type of coat they create. Lacquer is a water-based finish made of chemicals that are based on solvents while polyurethane is an oil-based finish that forms a plastic-like coat.

Lacquer dries swiftly, so you don’t have to wait for long between coats. In my experience, you can put on multiple coats in simply a few hours.

Polyurethane, on the other hand, might be either water-based or oil-based, and I know it will still take a few hours to spread the layers needed to create a solid covering.

Polyurethane likewise is typically more lasting and less harmful than lacquer.

What Is Lacquer?

As you probably already know, the lacquer tree saps are where these resin leftovers come from.

After getting polished, these goods have a finish that is both bright and exceptionally strong.

For an ideal use, I suggest that you use a lacquer spray that offers both high volume and low pressure.

Most woodworkers generally agree that lacquer works best as a finish on wood furniture.

However, Because it has thin layers that dry easily, it is ideal for many different kinds of woodworking jobs, like wooden floors.

This tough layer makes the wood’s surface highly resistant to harm. Due to this, lacquer finishes are useful to help things remain a long time.

What Is Polyurethane?

Polyurethane finishes are created from liquid types of plastic parts. When polyurethane is used on a surface, it covers it with a firm, shiny resin.

In my experience applying it to wooden floors isn’t simple, yet I always solve that by blending it with a thinning agent.

Since it’s thicker, it can’t be sprayed, so using a bristle brush is an ideal way to use it.

I know that the finish itself takes different amounts of time to dry, but after it does, it creates a strong coat.

Read to know, Is Polyurethane Waterproof? Here’s the Truth!

Differences Between Lacquer and Polyurethane

I may be old, but I enjoy creating things out of wood. But once you commit to a project for weeks or days, it can be sad to see it come apart in a few weeks.

That’s why I think it’s crucial to pick the proper finish, particularly if you got paid to do the work.

Do you know that there are many differences between lacquer and polyurethane?

This deep comparison of lacquer and polyurethane can help you pick which one is best in nearly every scenario.

Here’s a table that shows how lacquer and polyurethane are different:

| Characteristics | Lacquer | Polyurethane |

|---|---|---|

| Durability | Less durable and simpler to damage | Very durable and capable to withstand damage from use |

| Price | Most of times, it’s cheaper | Sometimes more expensive, especially good oil-based ones |

| Drying Time | Solvent evaporates swiftly, so it dries quickly | It needs more time to dry between coats |

| Simple Application | Easy to apply and one can put on several coats in one day | Slower application, longer breaks between coats |

| Composition | Chemicals based on solvents | Oil-based or water-based chemicals |

| Safety and Hazards | Since it is created with solvents, it is more risky | Less dangerous, especially those that are water-based |

| Versatility | Suits some surfaces, but may not stick nicely to others | Versatile, can be used on different surfaces |

| Yellowing | Particularly likely to become yellow when facing UV light | Likely to turn yellow but keeps its brilliance over time |

Know I’ll explain the differences between lacquer and polyurethane one by one.

1. Durability

Wood coatings help furniture appear polished while shielding it from harm, marks, water, and more.

Lacquer and polyurethane thrive at this. Lacquer is Water-resistant, strong lacquer protects against damage. But nitrocellulose lacquer fades easily.

Also, most lacquers give limited heat and chemical safety. But polyurethane resists damage, scuffs, water, stains, and temperature.

I suggest you find UV-resistant outdoor polyurethane.

I use polyurethane since it endures greater damage than lacquer as it protects wood from multiple damages.

It also helps as it’s stronger than lacquer. It remains on the surface, making it difficult to harm the work for several years.

Without physical or chemical damage, lacquer endures as long as polyurethane.

However, how likely is that? In the end, when it comes to durability, polyurethane is superior than lacquer.

2. Price

While choosing lacquer for woodworking, I suggest that you remember both the initial and long-term expenses.

Initial Lacquer Price:

- Lacquer kinds like nitrocellulose and acrylic differ in cost.

- A quart-sized lacquer may cost $10–$30, based on brand and kind.

- Spray guns run $20 to more than $200.

Permanent Lacquer Expenses:

I think the value of lacquer is also important.

- Lacquer offers a high-gloss look that might need less care.

- Given its durability, it’s an affordable option that can require certain repairs or refinishing.

Initial Polyurethane Price:

- Oil-based and water-based polyurethane are available.

- You may need $5–$20 brushes or applicators.

- According to kind and manufacturer, quart-sized polyurethane may cost $10–$20.

Permanent Polyurethane Expenses:

Polyurethane has cost-related benefits.

- It’s truly durable, so it will last for decades.

- This durability may save you money by lowering the need to restore or fix wood surfaces.

Overall, I advise you to examine your budget for polyurethane versus lacquer’s first purchase and upkeep over time.

Polyurethane can seem affordable at first, but lacquer’s longevity and easier upkeep can render it superior for certain uses.

The option you pick should match your task’s needs and permanent cost.

3. Drying Time

The situation is highly one-sided. Given polyurethane’s resilience, versatility, and richness, people hate its long drying time.

It’s so horrible that most woodworkers have shifted to water-based polyurethane completely.

Oil-based polyurethane sets to the feel in 4–6 hours but takes 12–24 hours to dry fully.

Water-based polyurethane alone can take three days since most projects need three coatings. Recoating in two hours, water-based polyurethane works well.

Although remarkable this is not lacquer. Ten minutes to dry the lacquer, and 30 minutes is prepare a different coat.

It takes the same amount of time to apply 4 or 5 coats of lacquer as it does to apply the second coat of the fastest-drying polyurethane.

So I suggest using lacquer if drying time matters to you.

4. Simple Application

When I’m picking a wood finish, one aspect is how simple it will be to put on.

At the end of the day, it’s nicer to have a good finish with a bad product than a bad finish using a good product.

Lacquer is light, simple, and dries swiftly, so a high-volume, low-pressure (HVLP). So you can use a sprayer to apply it.

It gives me a smooth end result. Lacquer may be put on with other tools, but that’s just an ideal choice for small jobs where renting or buying a sprayer makes no sense.

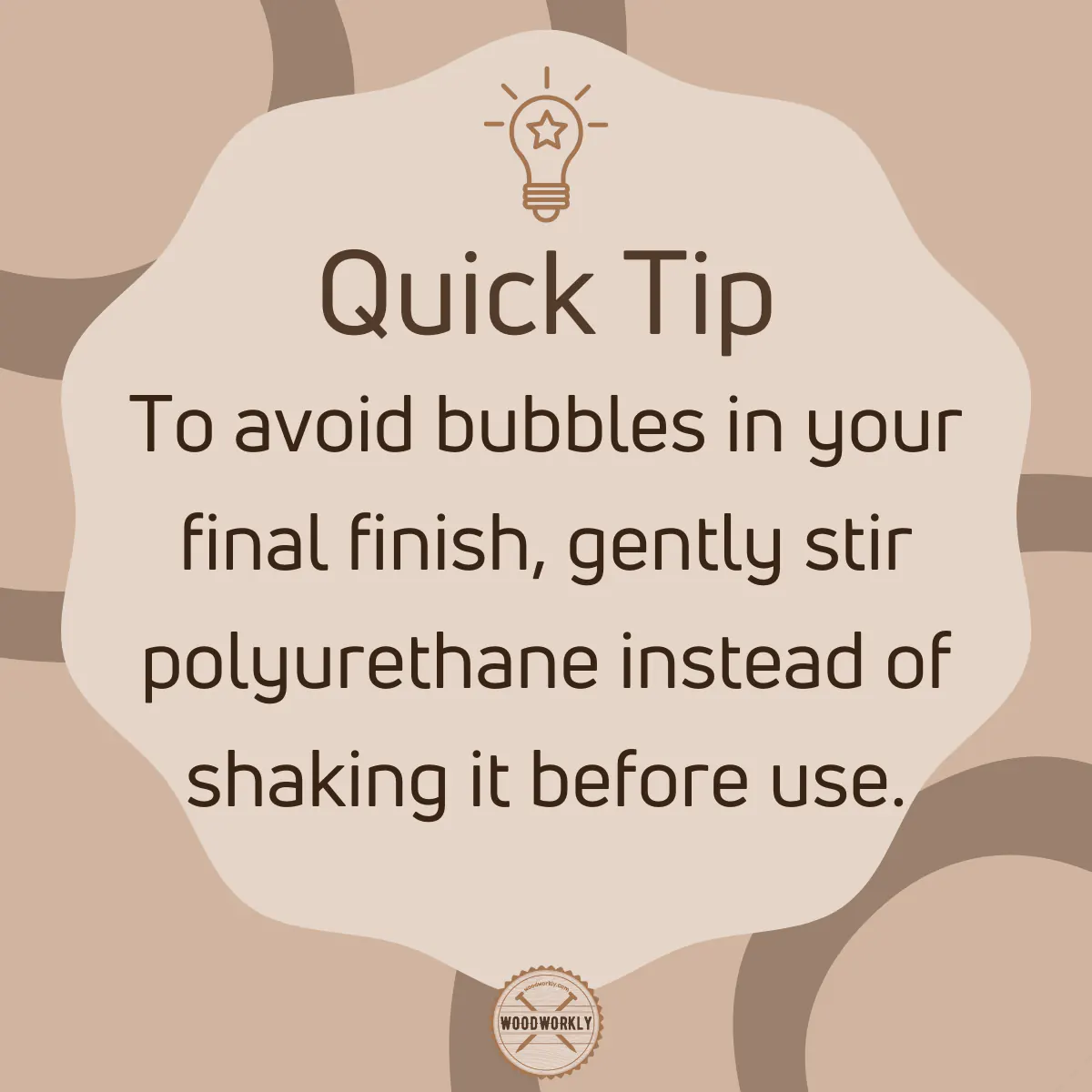

Polyurethane, on the contrary, is robust, so it’s ideal to use a brush to coat it.

Given the kind of polyurethane, sometimes you may need an HVLP sprayer, roller, or cloth to put it on; however, a brush is an excellent tool.

The trouble here is that brush traces and lines are often visible. When you use a cheap brush, it leaves hairs covering the surface of the wood.

Bubbles and dusty bits are additional things to keep an eye out for. Having to sand between coats of polyurethane is another issue.

Lacquer is a unique solvent, so every thin coat blends into the one underneath it.

This means you don’t have to sand unless there’s an issue with any of the coats underneath.

Each of these things may make it hard for newcomers to use polyurethane. But don’t worry; I suggest putting polyurethane on with a rag.

5. Composition

A popular wood finish, lacquer, is different. Let me show you a more detailed look into lacquer composition.

Composition of Lacquer:

- Solvents: Lacquer dissolves in acetone or lacquer thinner for easy application.

- Acrylic/Nitrocellulose Resin: This makes lacquer film.

- Major VOC Content: Certain lacquers have major VOC emissions, so airflow is vital during application.

- Quick Drying: Lacquer dries quickly since solvents dry quickly.

- Gloss and Simplicity: Lacquer improves wood’s essential brilliance with a high-gloss, simple finish.

Standard wood finish polyurethane has many vital elements. Therefore, knowing polyurethane composition is crucial.

Composition of Polyurethane:

- VOC Emissions: Water-based or oil-based polyurethane can have volatile organic compounds (VOCs) that impact the quality of the air homes.

- Polyols: Petrochemical or vegetable oil-derived substances offer polyurethane its film-forming ability.

- Solvents: These break and scatter polyols and isocyanates for use.

- Durability: It resists water, damage, and chemicals, so you can use it for many things.

- Curing Method: When curing, isocyanates and polyols create a protective coating in polyurethane.

- Isocyanates: Reactive substances form cross-links that make polyurethane strong.

Polyurethane and lacquer are chemically distinct.

Lacquer gives me a brilliant sheen that comes from nitrocellulose or acrylic resin, whereas polyurethane gives me ideal endurance that comes from polyols and isocyanates.

In my experience knowing these traits will help you select a coating for your woodworking project that suits your needs and tastes.

6. Safety and Hazards

I’ve seen a lot about the risks of household chemicals, with a valid reason.

Lacquer and polyurethane send off plenty of volatile organic compounds (VOCs), which make them dangerous to those with breathing problems.

Most of the risk lies in starting the process. When chemicals are released into the air, which is the suggested way to use lacquer, they get more dangerous.

This is why I always wear a mask when using chemicals.

But I have to tell you that the VOCs in polyurethane aren’t toxic once they dry, which is a positive thing.

To fix such issues, companies created water-based lacquer and polyurethane. Some give off a tiny amount of VOCs so they’re quite secure.

Since water-based polyurethane is applied regularly VOCs from lacquer are a major risk.

One thing you must know is that added to the danger that can’t be seen, comes an issue of flammability. Lacquer is very simple to ignite a fire.

Never use it near an open flame, and you should only use it if it’s a space with plenty of airflow. Polyurethane can be easily ignited, yet it isn’t as vulnerable.

For instance, the flashpoint of Rust-Oleum woodcare lacquer is below 20°F, but the flashpoint of Minwax Fast-Drying polyurethane remains 102.2°F, which is usual for polyurethane.

So in terms of safety, polyurethane is better than lacquer since it does not contain high VOC content.

7. Versatility

Ultimately, the most crucial factor in choosing lacquer or polyurethane. In my opinion, lacquer is better for premium furniture and hardwood surfaces that won’t get used much.

Polyurethane is excellent for floors, tables, countertops, and bars with frequent use.

Project size is a further factor. Lacquer dries fast, so I believe it’s impractical for big jobs.

Lacquer over hardwood floors is probable, but drying time leaves it problematic.

Polyurethane won’t be damaged.

Interestingly, polyurethane’s versatility makes it tough to use. If it comes down to versatility polyurethane is much better.

8. Yellowing

Oil-based coatings are known for fading. This may give color to oak and other woods, but not everyone likes it, so it’s fair.

When picking a wood color, I usually want it to remain nice for 5 to 10 years. Polyurethane and lacquer fail as time passes.

Both polyurethane and lacquer turn yellow, but polyurethane yellows faster. Water-based lacquer and polyurethane won’t yellow.

For painting, make sure to apply non-yellowing exterior polyurethane. They become clear and bright.

You can also put polyurethane over the painted surfaces.

Since water-based lacquers are uncommon while others claim they shouldn’t be called lacquer, I favor polyurethane more.

Types of Lacquer

Did you know there are 5 types of lacquer? They are,

- Acrylic Lacquer

- Water-based Lacquer

- Catalyzed Lacquer

- Urushiol lacquer

- Nitrocellulose lacquer

I’ll tell you much more about these five types of lacquer.

1. Acrylic Lacquer

The greatest feature of acrylic lacquer is its yellowing resistance, paired with its shiny looks. I will always get a clear coat from this lacquer.

For higher flexibility, use a longer-lasting CAB-acrylic lacquer. Its damage and scratch resistance is based on its lower brittleness than acrylic lacquers.

The sole drawback is its higher cost. I spray this chemical with thinner. It also doubles the price over brushing lacquer on wooden surfaces.

2. Water-based Lacquer

Water-based lacquer is safer and smelly than tung oil. It lasts 5 years more than nitrocellulose lacquers because of its resiliency.

This lacquer dries quicker on wood. This usually saves me cash and time.

3. Catalyzed Lacquer

This blend will outlast various oil-based finishes. An acid catalyst must be added to liquid lacquer to cure it.

I like purchasing a pre-catalyzed lacquer over mixing it. Using post-catalyzed lacquer is okay. Check labels and directions closely to prevent miscalculating amounts.

4. Urushiol lacquer

I use urushiol lacquer for coating furniture, tableware, and decor. It sticks to metals, wood, and ceramics, so I favor it.

But urushiol can cause grave allergic responses, especially for poison ivy and oak-sensitive people.

This lacquer is part of ancient Japanese lacquerware, which I adore for its quality and skill.

The elegance and endurance make urushiol lacquer distinct and culturally crucial, yet its allergic traits need careful handling.

5. Nitrocellulose lacquer

Nitrocellulose resins vanish, but they don’t remain as long as water-based lacquers.

Use it on wooden furniture because it gives a color boost as it blends well with light and dark paint.

Nitrocellulose lacquer prevents wood from deterioration. Given its flammability, I advise against applying lots of finish. Spray it lightly in a well-ventilated area.

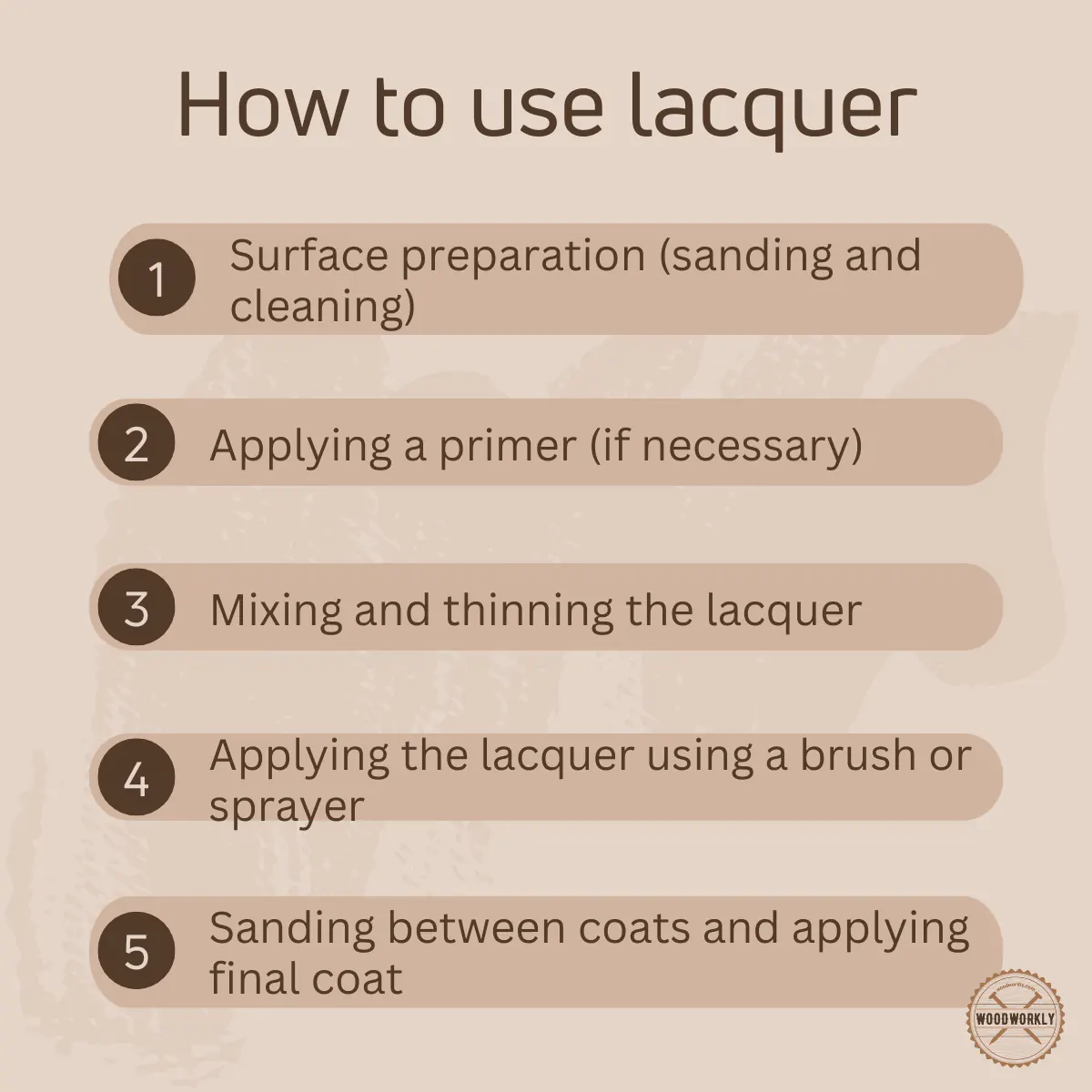

How to Apply Lacquer

I enjoy applying lacquer because of how it looks and feels once it dries smoothly. I’ll teach you how to do it.

Here are the things you need to apply lacquer:

- Lacquer

- Bristle Brush

- Empty Container

- Lacquer Thinner

- Tack Cloth

- 320-Grit Sandpaper

Here’s the method of applying lacquer,

- Put Sealer Coat

- Gently Sand

- Brush off Dust

- Apply Lacquer Properly

I’ll teach you more about these steps one by one about applying lacquer

1. Put Sealer Coat

Combine a cup of lacquer thinner with one cup of lacquer. Put this sealant coat on wood with a thick, soft-bristle brush.

This coat holds perched wood fibers, making sanding and the next tasks easy.

2. Gently Sand

When the sealer sets up, I softly sand using 320-grit sandpaper to clear raised wood fibers.

Once the surface feels silky, it’s finished.

3. Brush off the Dust

Before using lacquer, I wipe the sanded surface using a tack cloth.

4. Apply Lacquer Properly

I brush lacquer directly into the wood with long, unbroken strokes to avoid drying. Avoid back-and-forth brushing.

If the sealer layer is blotchy, let it dry and I reapply further coats until a consistent layer forms.

It usually takes 3 to 5 uses, depending on the lacquer and surface.

Types of Polyurethane

There are two main types of polyurethane that I use. They are,

- Oil-Based Polyurethane

- Water-Based Polyurethane

Let me tell you more about these types of polyurethane.

Oil-Based Polyurethane

Although oil-based polyurethane is more resilient, it needs 24 hours to dry.

Most woodworkers like me choose water-based polyurethane since it has a long drying period.

Use oil-based polyurethane for kitchen tabletops because it works well and resists heat.

Several coats of oil-based polyurethanes must be applied properly to avoid surface processing troubles.

Water-Based Polyurethane

In my opinion, oil-based polyurethane is more hazardous and slower to dry.

Water-based polyurethane doesn’t smell or become yellow when dried, making it more environmentally friendly.

Many of these coatings have oil- and water-based polyurethane qualities.

Apply it with a foam roller, bristle brush, as well as synthetic polymers. The only downside with water-based polyurethane finishes is heat.

Thus, I wouldn’t suggest them for outdoor furniture.

Oil-based polyurethane vs. Water-Based Polyurethane

Choosing between oil-based polyurethane and Water-based polyurethane can be hard but here is a table to help you decide.

| Characteristics | Oil-Based Polyurethane | Water-Based Polyurethane |

| Durability | Strongly durable | Durable |

| Price | Usually higher priced | Affordable |

| Color Changes | Ambering over time | Color Changes |

| Drying Time | Slow drying | Quick drying |

| Odor | Intense smell | Lower smell |

| Application and Cleaning | Needs solvents | Easily cleaned with water |

| Environmental Effects | High VOCs | Low VOCs |

| Yellowing | Likely to yellow | Resists turning yellow |

The choice between oil-based and water-based polyurethane relies on your demands.

I personally use oil-based polyurethane since it’s resilient and safe for areas with heavy use. But it has a strong odor, slows drying, and an amber, changing the wood’s color.

I like water-based polyurethane as it dries faster, smells less, and keeps the wood in color.

The lowered VOC level makes it more eco-friendly.

Though less durable than oil-based, it’s I use it for applications inside requiring quick drying and low odor. The decision relies on project needs and personal interests.

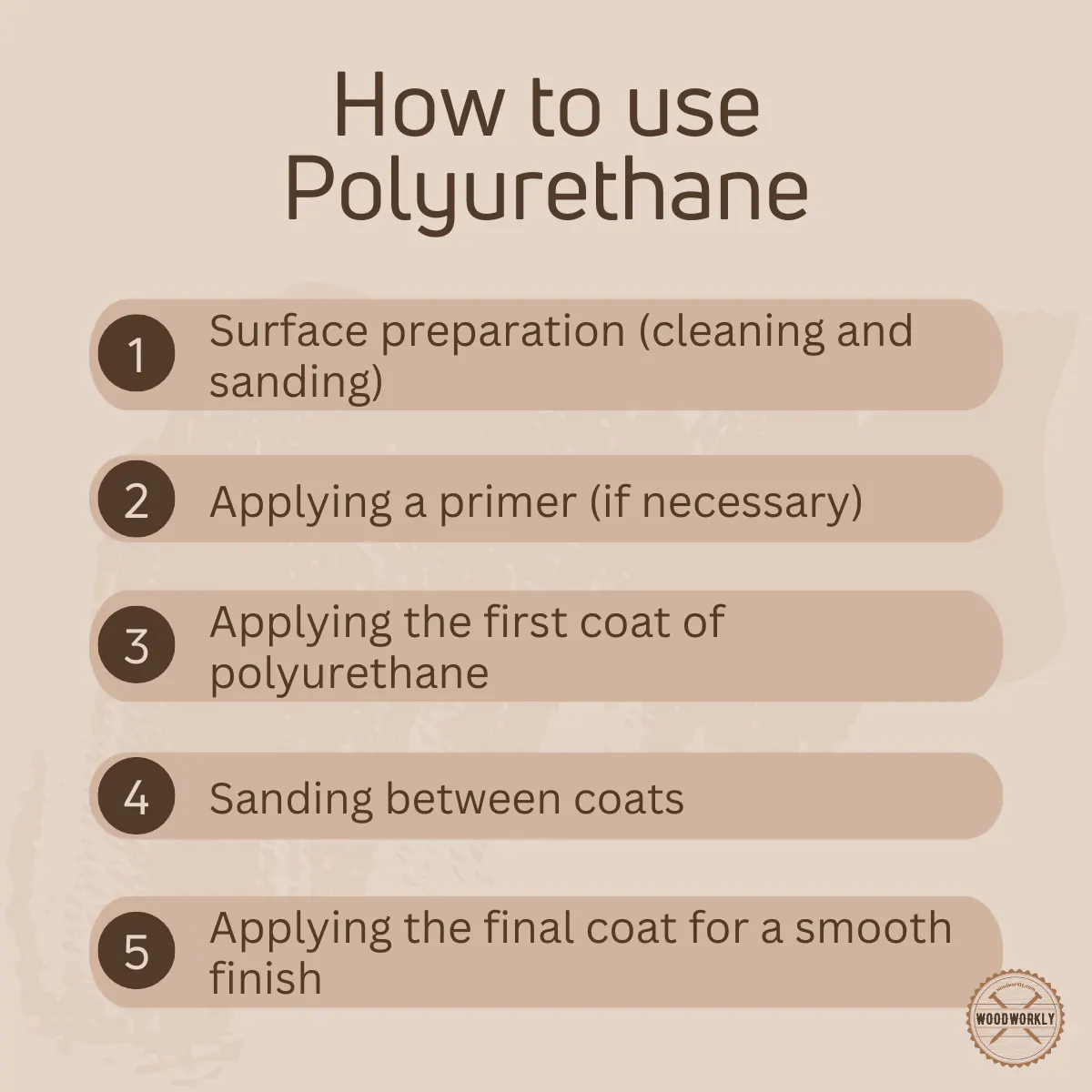

How to Apply Polyurethane

The polyurethane application method is like applying lacquer, but there are a few key distinctions.

These are the things you will need to apply polyurethane:

- 320-Grit Sandpaper

- Vacuum

- Mineral Spirits

- Clean Cloth

- Brush

- Warm Water

- Dish Soap

These are the steps I use to apply polyurethane.

- Smooth the Surface

- Clean the Surface

- Use the Polyurethane

- Allow the Polyurethane Dry Out

- Clean Up

Now I’ll explain these steps in detail for applying polyurethane

1. Smooth the Surface

Use 320-grit sandpaper to smooth the wood’s surface and get rid of any flaws.

You’ll want sandpaper and a vacuum to get rid of the dust.

2. Clean the Surface

Mineral spirits, a clean cloth, and a brush can be used to clean the sanded area and make sure the paint sticks well.

Always check that there is plenty of ventilation.

3. Use the Polyurethane

You’ll want polyurethane and a brush for this stage. I normally use a lot of polyurethane and long, smooth strokes that go with the wood grain.

Make sure to apply thin and even coats of polyurethane to get the perfect finish you want to get.

Read to know how to fix mistakes that happen when applying polyurethane finish.

4. Allow the Polyurethane Dry Out

Let the polyurethane dry entirely for 6 to 12 hours. Drying time can change upon the environmental humidity.

Having good ventilation is a must for a fast and efficient drying process.

Then, continue the steps until the number of coats you want is met.

5. Clean Up

Clean your hands, and polyurethane brushes swiftly after using them.

For oil-based polyurethane, apply mineral spirits, and for water-based polyurethane, use hot water with dish soap.

Now I’m going to share with you the pros and cons of lacquer finishes based on my own experiences.

Pros and Cons of Lacquer

Do you know the advantages and disadvantages you get from using lacquer?

By applying lacquer or polyurethane as a finish I get a lot of its pros and cons.

Before picking which finish you’ll be using, look at the pros and cons of each one.

Pros of Lacquer

- Makes a Thin Coat

- Easy Application

Let me explain these pros of lacquer in more detail.

Thin But Works

In contrast to polyurethane, the coating of the lacquer finish makes it tricky to see since the lacquer absorbs into the pores of the wood.

But although the lacquer coating is thin, it remains strong and remains a long time if it’s used correctly and kept in excellent shape.

Easy Application

I simply put on this finish since it is far simpler than putting on polyurethane, no matter if I use a brush or a spray.

I only need an hour or two to apply multiple thin coats of lacquer, nevertheless, it can take anywhere from a few hours to a few days to create a strong polyurethane shield.

Cons of Lacquer

- Difficult To Use

- Dents and Scrapes Are Tricky To Get Rid Of

Now I’ll tell you more about these cons of lacquer in great detail.

Difficult To Use

It is difficult to put on a glossy look compared to a polyurethane coat. It’s mostly because when you apply spray lacquer, I always need plenty of space and suitable safety gear.

And if you’ve got a brush or foam roller for applying lacquer, it’s essential to make long, smooth strokes so the lacquer won’t dry too fast.

Dents and Scrapes Are Tricky To Get Rid Of

While the lacquer finish is resilient, it can still get dented and scratched. And it could be tricky to fix either one.

On the contrary, I believe polyurethane is simple to repair.

Pros and Cons of Polyurethane

Although polyurethane is extremely durable, that doesn’t imply you can just pick up any good off the shelf.

I recommend that you think about these pros and cons to figure out if it’s worth the cost.

Pros of Polyurethane:

- Robust

- Lasting a Long Time

Now, I will tell you more about these helpful pros of polyurethane.

Robust

Based on the way it dries, the polyurethane finish is particularly robust.

Also, you can put multiple coats to make sure the covering is robust and thick.

Lasting a Long Time

Compared to lacquer, Polyurethane finish lasts for a longer time mainly because it fades away slowly as time passes.

Also, it’s less likely to receive dents or scratches, so I don’t need to fix it as often.

I know that it is able to endure big changes in temperature and long-term exposure to the outdoors.

Cons of Polyurethane:

- Application Takes Some Time

- More Obvious

There is a lot to know about these cons of polyurethane.

Application Takes Some Time

A drawback that can’t be avoided with polyurethane finish is that it takes quite a while to put on.

In a nutshell, a Polyurethane coat needs time to dry and become stronger.

In my experience a strong barrier needs a while to form, there’s a greater chance that something will go wrong and slow down the healing process.

More Obvious

I recommend it because the polyurethane layer is made above the surface of the wood, it’s thicker and more visible, though it is clear.

So lacquer is an excellent choice if you don’t want a strong shield.

But I sometimes enjoy the sparkle that a polyurethane finish offers, so this might also be viewed as a benefit.

Can You Use Polyurethane Over Lacquer?

Yes, polyurethane can be used over lacquer; however, it’s vital to follow certain steps for an effective finish.

Always check to see that the lacquer is totally dry, clean, and clear of any dirt or other debris.

Briefly sand the lacquer surface to help it stick better, and if you’d like to be extra sure, you might try a suitable primer.

Before putting polyurethane on the whole surface, I suggest trying for compatibility in an unnoticed place.

Keep in mind that the qualities of both finishes can impact how the end look turns out and that the process of application needs to be done in a well-ventilated area.

Following the above steps, you get a finish that lasts and looks excellent.

Can You Use Lacquer Over Polyurethane?

Yes, but I recommend that you don’t use lacquer over polyurethane since the two don’t work well together.

Lacquer is a solvent-based finish, so adding it on top of polyurethane can cause issues with sticking, drying out, and the general quality of the finish.

In my experience, the solvents in lacquer may soften or dissolve the polyurethane coat underneath, which can make the finish less durable and maybe not even.

For optimal results, I advise you to use just a single kind of finish on the work or to completely remove the old finish before putting in the fresh one.

Polyurethane and lacquer work well in various tasks and conditions, as shown by the head-to-head comparison.

I recommend considering your needs instead of comparing these items based on their abilities. Consider which option does your job properly.

That’s it, folks! Now you know what are the main differences between lacquer and polyurethane finish under lacquer vs polyurethane to select the one that suits you the most.

So, let’s answer some frequently asked questions.

FAQs

What are the primary differences between lacquer and polyurethane?

Lacquer dries faster than polyurethane and offers a glossy finish, while polyurethane takes a bit longer to dry but provides a durable and resistant coat.

Is lacquer or polyurethane better for furniture?

The better choice depends on the project; lacquer is known for its smooth finish and is easy to work with, while polyurethane offers a tough and resistant surface ideal for furniture pieces that will receive heavy use.

Can I apply lacquer over a polyurethane finish?

Generally, applying lacquer over polyurethane is not recommended as it can lead to cracking or peeling due to the different drying times and chemical compositions of the two finishes.

What is the drying time for lacquer compared to polyurethane?

Lacquer typically dries much faster, often in under an hour, whereas polyurethane can take several hours to a day to fully dry.

Which is more durable, lacquer or polyurethane?

Polyurethane is generally more durable compared to lacquer, providing a finish that is resistant to abrasions, impacts, and chemicals.

How do I choose between lacquer and polyurethane for my project?

Your choice between lacquer and polyurethane should depend on the specific needs of your project, including the expected wear and tear, desired finish, and your level of expertise with each material.

Is it easier to repair a lacquer finish or a polyurethane finish?

Lacquer finishes are generally easier to repair as they can be smoothly recoated or touched up, whereas polyurethane finishes may require more preparation to achieve a seamless repair.

What safety measures should I take when working with lacquer and polyurethane?

Ensure good ventilation in the workspace, and use proper personal protective equipment including gloves and respirators to protect against harmful fumes and chemicals.

Did I cover all you wanted to know about: Lacquer Vs Polyurethane

In this article, I’ve deeply explored lacquer vs polyurethane finish by taking their main differences, and application process with expert tips.

Lacquer dries faster, offers a glossier finish but is less durable, while polyurethane takes longer to dry, provides a more durable finish and is available in various sheens. Both are popular wood finishes with distinct advantages and downsides. Choose based on your project’s specific needs.

Furthermore, I’ve answered some frequently asked questions as well.

Now you have to go through the article again and again and select the finish that suits you the most based on your project type and your personal preferences.

Share your feedback in the comment section to let others know about lacquer vs polyurethane and which one is better as wood finishes.