Ever wondered how to achieve a flawless, even finish on your woodworking projects? Discover the secret of wood conditioner and learn how to use it effectively! Curious? Keep reading!

Wood conditioners are useful when preparing and finishing your furniture or woodworking projects.

They basically, penetrate the porous structure of the wood and avoid occurring blotches when staining and they prevent the wood from getting moisture damage and warping as well.

When I first heard about applying wood conditioner on wood, I was like what the heck is that? What does it do?

Then, I did some research about it with the help of experts and wood-finishing journals.

Now, with years of experience here’s what I know about, What does wood conditioner do?

Wood conditioner helps the wood to accept wood stain evenly by penetrating the wood grain. Wood conditioner helps uniform acceptance of stains and prevents stains from soaking too deep into the wood. It prevents wood from getting dark spots by sealing the wood temporarily at the rate of stain absorption.

So, basically, the wood conditioner helps the wood to stain uniformly without fewer issues.

But there’s a lot more to know about what does wood conditioner do, how does it help the wood to stain more evenly.

In this article, we’ve deeply discussed the advantages and disadvantages of wood conditioners, the types of wood conditioners, and how to use wood conditioner properly.

Furthermore, I’ve answered some frequently asked questions as well.

So, let’s get going!

First of all, let’s have brief look at what is a wood conditioner and what does it really do.

What Is Wood Conditioner?

A wood conditioner, also known as a pre-stain conditioner or wood sealer, is a solution applied to bare wood surfaces before staining or finishing.

Wood conditioner helps ensure a more uniform and even absorption of stains or finishes by preventing blotchy or uneven coloration.

This product is especially beneficial when working with softwoods or porous hardwoods, which can have inconsistent grain patterns and density.

By using a wood conditioner, you can achieve a more professional and aesthetically pleasing finish on your woodworking projects.

What Does Wood Conditioner Do?

- Prevents blotchy and uneven staining: Wood conditioner seals the wood’s pores and reduces the absorption of stains, ensuring a more consistent and even color across the wood surface.

- Improves adhesion: The conditioner creates a barrier that can enhance the adhesion of the stain or finish, resulting in a longer-lasting and more durable surface.

- Enhances wood grain appearance: By promoting even stain absorption, wood conditioner accentuates the wood’s natural grain pattern, making it more visually appealing.

- Reduces end-grain staining: End-grains tend to absorb more stain than other wood surfaces, leading to darker and more prominent staining. Wood conditioner minimizes this effect by partially sealing the end-grain.

- Works with various wood types: While primarily used for softwoods and porous hardwoods, wood conditioner can also be used on other wood types to achieve a more uniform stain or finish.

Does Wood Conditioner Make A Difference?

Yes, wood conditioner helps to avoid many common mistakes that can happen during wood staining.

Wood conditioner helps to even out the color of the wood when working with bare wood as a pre-stain wood conditioner.

Wood conditioners work well with new and fresh wood.

It penetrates the wood deep inside and covers up the porous structure of the wood with limited access to the wood stain. Wood conditioner controls the rate of absorption.

Wood conditioner avoids wood from getting stain streaks and darks spots. Normally wood conditioner is applied for most of the wood. But for some woods, applying wood conditioner is not necessary and can be skipped.

According to my experience, wood conditioner works well with porous, soft hardwoods than less porous hardwoods.

For example, soft hardwood like pinewood takes the wood conditioner well and seals the wood to prevent the wood stain from soaking too deep into the wood.

If you’re going to apply oil-based wood stain to get the color you want from the wood, I highly recommend applying wood conditioner before staining the wood to penetrate the wood stain evenly throughout the wood surface.

But if you’re willing to apply gel stains, unlike liquid stains, no need to apply wood conditioner before staining.

Because gel stains do not blotch like oil stains and no need for a pre-staining job.

Gel stains do not penetrate the porous structure of the wood like regular water-based and oil-based stains. It just sits on the surface and does the job.

According to my experience, wood conditioner works well with porous, soft hardwoods than less porous hardwoods.

For example, a soft hardwood pinewood takes wood conditioner well and seals the wood to prevent the wood stain from soaking too deep into the wood.

Advantages and Disadvantages of Wood Conditioner

There are many benefits you’ll get by applying wood conditioner before the staining job. But there’re some drawbacks as well.

Let’s have a look at some common pros and cons of using wood conditioner.

| Advantages | Disadvantages |

| Prevent blotches and streaks | Lighter than stain |

| Prevent dark spots | Sometimes give a splotchy or blotchy surface |

| Help to stain evenly | Application and drying time is high |

| Can skip many kinds of wood staining mistakes | Not necessary for less porous hardwood types |

| Helps to get the perfect finish we want |

Best Woods To Work With Wood Conditioner

Almost any type of woodwork is perfect with a wood conditioner.

But softwoods have a better chance of absorbing conditioner and minimizing the mistakes that commonly happen during wood staining such as surface blotchiness.

Here’s the best wood to work with wood conditioner,

- Walnut

- Alder

- Pine

- Birch

- Fir

Here’re the woods that don’t require wood conditioner,

- Maple

- Mahogany

- Poplar

- Red oak

- White oak

Above woods are highly porous and soft.

Therefore, they have the ability to take wood conditioner so well and seal the wood successfully before applying wood stain.

Types of Wood Conditioners

There are main two types of wood conditioner. They are,

- Oil-based wood conditioner

- Water-based wood conditioner

So, let’s discuss each type of wood conditioner separately with their specifications.

Oil-Based Wood Conditioner

The oil-based wood conditioner is used when you’re planning to work with oil-based wood stain.

An oil-based wood conditioner helps the oil-based wood stain to spread evenly throughout the wooden surface by limiting access to the porous structure of the wood fibers.

Oil-based wood conditioner help to prevent dark spots, surface blotchiness, and many other wood staining mistakes.

Here’re some of the best commercial oil-based wood conditioners available in stores.

- Minwax pre-stain wood conditioner

- Beeswax oil-based wood conditioner

- Copper Greenwood preservative

Water-Based Wood Conditioner

Water-based wood conditioner work well with water-based wood stains.

A water-based wood conditioner helps wood stain for uniform penetration of wood stain all over the wooden surface with fewer staining mistakes.

Here’re some of the best commercial water-based wood conditioners available in stores.

- Minwax water-based pre-stain wood conditioner

- General finishes water based pre-stain conditioner

To identify what is the best wood conditioner according, you need to have a clear idea about the wood type and type of the wood stain that you’re planning to.

By having a better understanding of those factors you can minimize the mistakes that most people commonly do.

Make sure not to apply water-based pre-stain wood conditioner, if you’re planning to apply an oil-based stain. They’re just incompatible with each other.

Let’s see what tools and materials you need to have before applying wood conditioner on wood.

Supplies You Will Need To Apply Wood Conditioner

- Wood conditioner: Choose a product that is compatible with the type of stain or finish you plan to use.

- Clean, lint-free cloth or brush: Use these for applying the conditioner to the wood surface. Brushes work well for detailed or intricate areas, while cloths are suitable for flat surfaces.

- Sandpaper: Use fine-grit sandpaper (around 180-220 grit) to smooth the wood surface before applying the conditioner.

- Tack cloth: This sticky cloth is used to remove dust and debris from the wood surface after sanding, ensuring a clean surface for the conditioner.

- Gloves: Wear gloves to protect your hands from the chemicals in the wood conditioner and keep your hands clean.

- Respirator or dust mask: Use a respirator or dust mask to protect your lungs from any harmful fumes or dust during the application process.

- Eye protection: Safety glasses or goggles help shield your eyes from any accidental splashes or dust.

- Drop cloths or plastic sheeting: Use these to protect the surrounding area from spills and drips during the application process.

- Stir stick or paint paddle: You’ll need this to mix the wood conditioner thoroughly before applying it to the wood.

So, let’s find out how to apply wood conditioner correctly in order to get the finishing outcome from our loving woodwork.

Tip: Even though we’re able to make DIY wood conditioners by mixing a 1;1 ratio of white vinegar and hot water, I highly advise you to go for commercial products.

Because they’re specially designed without contamination. The user manual is pretty much important to get an idea about how to apply and what type of woodwork well the conditioner.

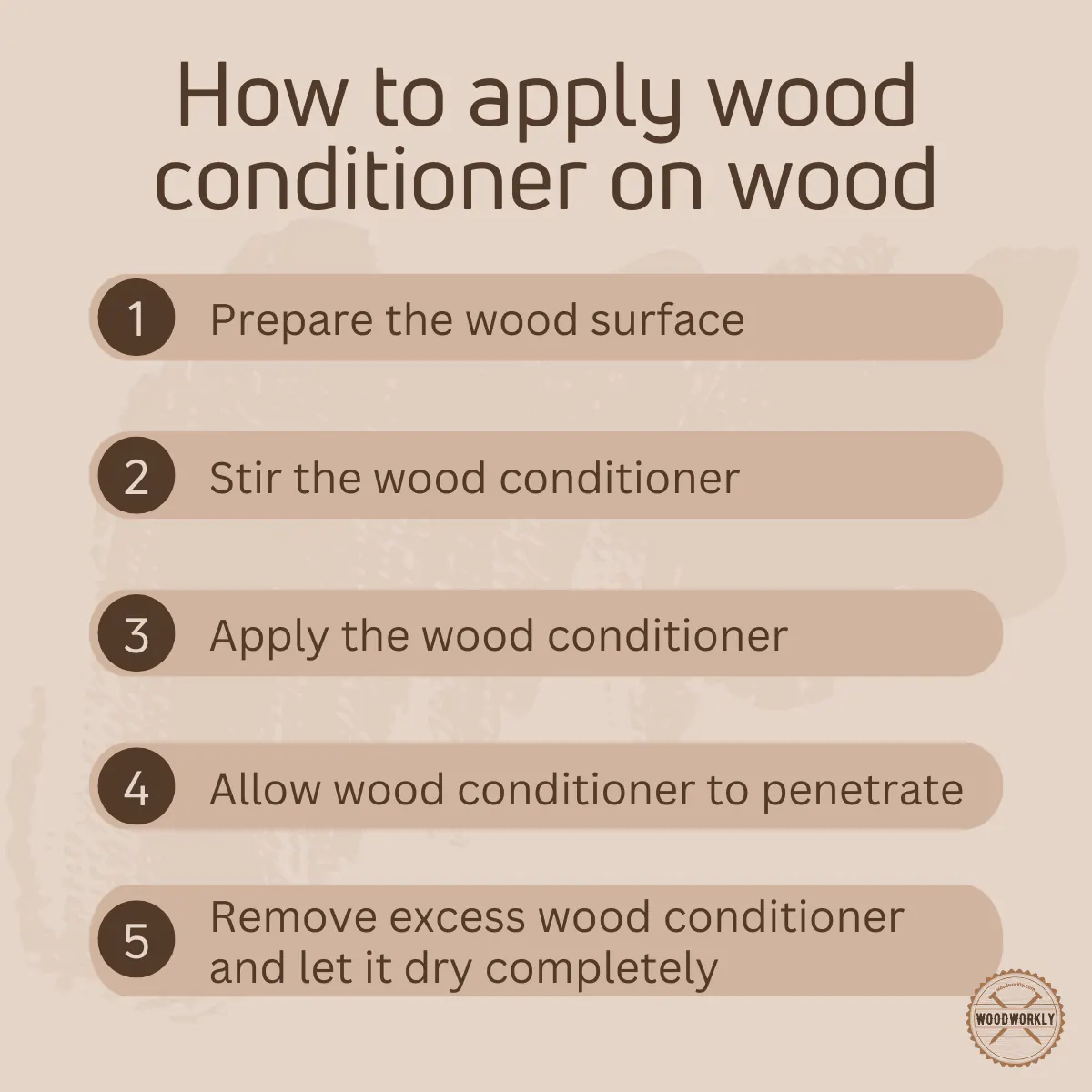

How To Use Wood Conditioner?

Here’re the steps you need to follow when applying wood conditioner on wood,

- Prepare and clean the wood surface.

- Stir the wood conditioner.

- Apply wood conditioner on the wood.

- Allow the wood conditioner to penetrate.

- Remove excess wood conditioner.

- Allow the wood conditioner to dry.

Let’s discuss each of the above steps in detail to find out how to use wood conditioner properly on wood without messing things up.

1. Prepare And Clean The Wood Surface

First you need to prepare the wood surface before conditioning by sanding the entire surface with such as 120-grit.

Sanding removes any rough spots, mill marks, and minor imperfections, creating a smooth and even surface for the wood conditioner and subsequent stain or finish.

Sand along the grain pattern to avoid creating scratches or cross-grain marks on the wood.

After the initial sanding, switch to a finer grit sandpaper, such as 220-grit, to further smoothen the surface and remove any remaining scratches or imperfections.

After sanding, it’s essential to remove any dust, debris, or dirt from the wood surface.

Dust and debris can affect the adhesion and absorption of the wood conditioner, stain, or finish.

Use a tack cloth, which is a sticky cloth designed to pick up fine dust particles, or a soft brush to remove dust from the wood surface.

You can also use a vacuum cleaner with a brush attachment to remove larger debris.

2. Stir The Wood Conditioner

This step is what many beginners skip. But stirring is essential to achieve consistent results and to ensure that the conditioner performs as intended.

Over time, the ingredients in wood conditioner can settle and separate, which can affect its performance and consistency.

Stirring the wood conditioner ensures that all the components are well mixed and evenly distributed throughout the product.

First, you need to, open the container and use a clean stirring stick or a paint stirrer. Avoid using any tools that could introduce contaminants or debris into the conditioner.

Now, gently stir the wood conditioner in a circular motion, making sure to reach the bottom and sides of the container.

Make sure not to stir too vigorously, as this can create air bubbles that may affect the application and final appearance of the conditioner. Simple as that!

Following the same procedure, continue stirring until the wood conditioner has a uniform consistency and color.

This may take a couple of minutes, depending on the specific product and how long it has been sitting.

3. Apply wood conditioner on the wood

Now, apply the wood conditioner evenly throughout the wooden surface without missing any spot after dipping the lint-free tack cloth in the wood conditioner.

Make sure to apply wood conditioner along the direction of the wood grain to take the conditioner easily into the wood.

I advise you to go with a thin coat of wood conditioner to dry out quickly. Because if you use thick coat of wood conditioner, you’ll have to wait so long to dry the surface completely to apply wood stain on top of it.

Sometimes, people tend to apply wood stain before the completion of the drying process of wood conditioner and ended up the blotchy surface by ruining their woodwork.

Also make sure to apply wood conditioner with even pressure throughout the surface, to avoid the surface getting splotchy with random color spots.

4. Allow the wood conditioner to penetrate

Now, let the wood conditioner soak into the wood for the recommended time indicated on the product’s label, typically 5 to 15 minutes.

The time that takes to penetrate completely into the wood differs according to the type of wood conditioner.

Oil-based wood conditioner takes 5 -15 minutes to penetrate the wood while water-based wood conditioner penetrates within 1 – 5 minutes.

Not like oil-based wood conditioners, when you’re using water-based wood conditioners make sure to remove excess after 1 to 5 minutes of penetration duration.

Because the excess amount of water-based wood conditioner tends to swell wood fibers and cause a lot of trouble.

5. Remove the excess wood conditioner

After the recommended penetration time, wipe off any excess wood conditioner using a clean, lint-free cloth.

Removal of excess wood conditioner is super important to prevent a sticky or uneven surface.

6. Allow the wood conditioner to dry

Allow the wood conditioner to dry completely before applying any stain or finish.

The drying time of wood conditioners can range from 15 minutes to 2 hours, depending on the wood type, temperature, and humidity.

Refer to the manufacturer’s instructions for specific drying time recommendations.

This time can vary according to the place you live, the humidity of the environment, the climate, and many other factors.

However, make sure to wait until the wood conditioner is completely dried before stepping into the next step.

How Long After Wood Conditioner Can I Stain?

Application is recommended to apply wood stain after 2 hours of applying wood conditioner.

Apply just one coat of wood conditioner to gain the best results with a good seal over the bare wood surface.

But remember to let the wood conditioner dry completely between each coat.

After the final coat of the wood, conditioner is completely penetrated, you can apply wood stain.

At the end of the staining and drying process, you’ll probably get a nice evenly colored wood stain with a better outcome.

Can wood conditioner be left on too long?

Never left the wood conditioner on wood for too long since it may interfere with the staining or finishing process.

The recommended penetration time for each wood conditioner product is typically between 5 and 15 minutes, while the recommended drying time might be anywhere from 15 and 2 hours.

Wood conditioner can become tacky or produce an uneven surface if it is left on the wood surface for too long before the excess is removed.

This can cause the stain or finish to adhere poorly and have an unattractive appearance.

The conditioner may also create a barrier that prevents the stain or finish from effectively permeating the wood if it is dried for a long time beyond the advised drying time.

A lighter color or uneven coverage may result from this.

It’s crucial to use the wood conditioner solution exactly as directed by the manufacturer to get the best results.

For the greatest results on your wood staining or finishing project, pay strict attention to the suggested penetration and drying times.

Do You Sand After Applying Wood Conditioner?

If you’re planning to use a water-based wood conditioner, sanding is necessary after applying each coat of wood stain to remove the excess amount.

Because the excess amount of water-based wood conditioner swell wood fibers and ruins the woodwork.

Therefore, we need to take action and remove excess water-based wood conditioner after 5 minutes of application. Because it takes 1 -5 minutes for the complete penetration into the wood.

But if you’re planning to use an oil-based wood conditioner, you don’t have to sand after the application.

Oil-based wood conditioner takes 15 -30 minutes for the complete penetration and doesn’t give issues as water-based one.

alternatives for wood conditioner

- Sanding sealer: A sanding sealer is a diluted finish that can be applied before staining to help seal the wood pores and provide a more even stain application.

- Shellac: A natural resin, shellac can be used as a wood sealer by diluting it with denatured alcohol, creating a barrier that promotes even stain absorption.

- Thinned-down polyurethane: By diluting oil-based polyurethane with mineral spirits, you can create a makeshift wood conditioner that can help prevent blotchy staining.

- Homemade wood conditioner: Mixing equal parts of your chosen stain with a compatible clear finish (like varnish or polyurethane) can create a homemade wood conditioner that provides a more uniform stain appearance.

That’s it, folks! hope you were able to know all you wanted to know about what does wood conditioner do and how to use it properly for promising results.

Let’s answer some frequently asked questions as well.

FAQs

Is wood conditioner necessary for all wood types?

While wood conditioner is primarily used for softwoods and porous hardwoods, it can also benefit other wood types, ensuring a more even and consistent stain or finish.

Can I use wood conditioner with water-based stains?

Yes, wood conditioner can be used with both water-based and oil-based stains, but make sure to choose a compatible conditioner for the type of stain you’re using.

How long should I wait between applying wood conditioner and staining?

Follow the manufacturer’s instructions for the specific drying time, which can range from 15 minutes to 2 hours, depending on the wood type and environmental conditions.

Can I apply multiple coats of wood conditioner?

Applying multiple coats is generally not recommended, as it can create a barrier that prevents the stain or finish from penetrating the wood properly.

Will wood conditioner change the natural color of the wood?

Wood conditioner may slightly alter the wood’s natural color, but its primary purpose is to ensure even stain absorption and enhance the wood’s appearance.

Can I use wood conditioner on previously stained or finished surfaces?

Wood conditioner is designed for bare wood surfaces; applying it on previously stained or finished surfaces will not yield the desired results.

Is wood conditioner the same as wood sealer?

While both products serve to prepare the wood surface, wood conditioner is specifically formulated for pre-stain application, while wood sealer is typically applied after staining to protect the wood from moisture and damage.

Does wood conditioner make stain darker?

Wood conditioner does not typically make the stain darker; instead, it helps achieve a more even and consistent stain by preventing excessive absorption and blotchy appearance on porous wood surfaces.

Did I cover all you wanted to know about: What Does Wood Conditioner Do?

In this article, we have mainly discussed what does wood conditioner do and what kind of characteristics you can gain by applying wood conditioner before applying wood stain.

We dive into the advantages and disadvantages of wood conditioner, the best types of wood conditioners, and what type of woods work well with wood conditioner, and what doesn’t as well.

Furthermore, I’ve answered some frequently asked questions as well.

Wood conditioner is a solution applied to bare wood surfaces before staining or finishing. It prevents blotchy and uneven staining, improves adhesion, enhances wood grain appearance, reduces end-grain staining, and works with various wood types.

I hope you have gained good knowledge about what does wood conditioner do and how helpful it is to get the perfect finish for our loving woodwork.

So, let’s start the next woodworking project and make sure to apply wood conditioner according to the guidelines as we discussed. Have fun!