Ever puzzled over choosing between a band saw vs scroll saw for your next project? Discover the distinct features and optimal uses of each, tailored to your crafting needs!

Both band saws and scroll saws are used for making precision cuts, including curves and complex shapes. They are favored for their ability to make intricate and detailed cuts.

However, I was curious about their differences in terms of their blade type and motion. So, I did research based on that with the help of experts.

Now with experience and the things that I learned from experts, here’s what I know about band saw vs scroll saw.

Here are the differences between band saw and scroll saw,

- Blade Type: Bandsaws have a continuous loop blade; scroll saws have reciprocating blades.

- Cutting Capacity: Bandsaws handle thicker materials; scroll saws are for thinner, delicate cuts.

- Precision: Scroll saws offer intricate, detailed cuts; bandsaws provide straight, uniform cuts.

- Motor Power: Bandsaws typically have more powerful motors.

- Learning Curve: Scroll saws require more skill for intricate designs; bandsaws are easier for straight cuts.

- Project Suitability: Bandsaws are versatile for various materials and cuts; scroll saws are ideal for detailed artistry.

But there’s a lot more to know about each of those machines.

So, in this article, I’ll explore band saw vs scroll saw in detail by taking their uses, how they work, and what makes them different from each other.

Furthermore, I’ll answer some frequently asked questions.

So, let’s dig in!

What is Bandsaw?

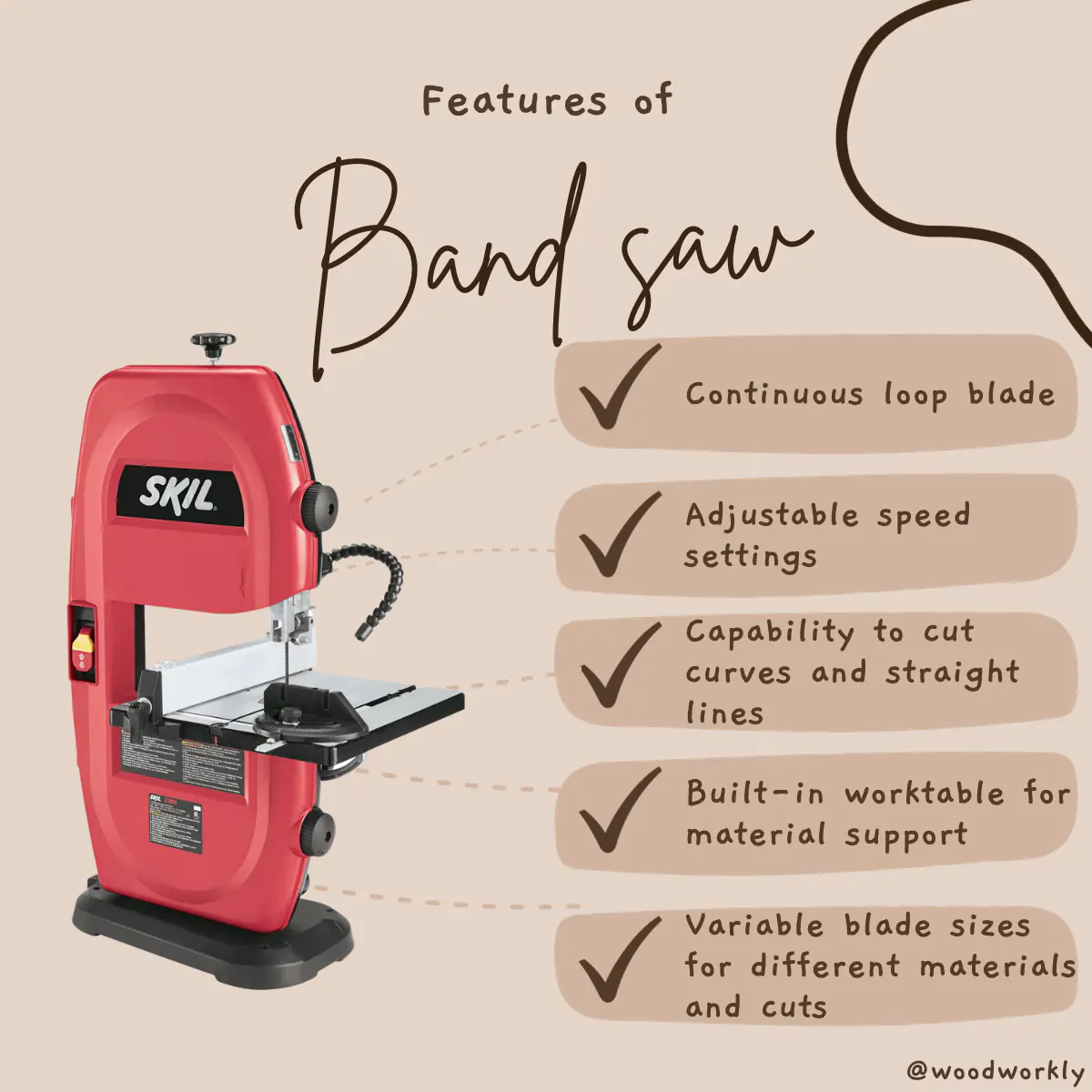

A bandsaw is a versatile tool used to cut a variety of materials. Primarily used for cutting wood, it can also be used for cutting metal, plastic, and more.

It consists of a continuous, toothed metal blade that moves in a continuous loop around two wheels, an upper wheel, and a lower wheel.

A cutting action occurs when the material is fed into the path of the moving blade.

Bandsaw is a well-known tool among many because of its strong power.

Equipped with high RPM motors, it is capable of handling solid and bulky materials with ease.

How to Use Bandsaw?

Here are the steps that I follow when using a band saw for any woodworking project.

1. Follow Safety Precautions

Always wear the appropriate safety gear, including safety glasses and hearing protection, before using a band saw.

Then check to make sure the machine is in good working order.

2. Adjust Blade Tension

Check and adjust the blade tension according to the manufacturer’s guidelines.

3. Set the blade guides

Adjust the blade guides and thrust bearings to properly support the blade.

This prevents blade deflection when the machine is turned on and sawing wood.

4. Prepare the Cutting Table

If you want to make belt cuts, set the cutting table at the desired angle.

Most bandsaws allow you to tilt the table for angled cuts.

5. Place the Materials

Place your material on the cutting table and adjust the fence or miter gauge to ensure a straight cut or desired angle.

6. Start Bandsaw

Turn on the band saw and wait for it to come up to full speed before making any cuts.

7. Feed Materials

Insert the material systematically into the moving blade. The blade should be allowed to cut.

Avoid pushing too hard. Otherwise, a rough cut may damage the blade.

8. Follow the Cutting Line

Carefully guide the material through the blade, keeping your eye on the cut line. Control of the material must be maintained throughout the cut.

9. Disable Bandsaw

After the cut is complete, turn off the band saw and wait for the blade to come to a complete stop before removing your cut. Then remove the cut.

10. Clean up

Always dust off the machine after use to keep your work area clean and tidy.

Uses of Bandsaw

Woodwork

A bandsaw is an excellent tool for cutting intricate shapes and curves in wood, ideal for crafting furniture, decorative items, and wooden toys.

Metalworking

Metal cutting bandsaws are an essential piece of equipment in manufacturing and metalworking shops because they can cut through a variety of metals.

Rereading

Bandsaws are used to turn solid wood back into thin boards.

This is expected to maximize the use of wood and minimize waste.

Teardowns

Bandsaws are ideal for making long, straight cuts in a variety of materials.

Curved cuts

Bandsaws are essential for cutting complex curves and are a popular tool among woodworkers for scrollwork and intricate designs.

Advantages and Disadvantages of Bandsaw

| Advantages | Disadvantages |

| Versatile – can cut various materials | Larger and bulkier than some other saw types |

| Precise and accurate cuts | The learning curve for beginners |

| Can make intricate curved cuts | Requires periodic blade replacement |

| Resawing capability for maximizing wood usage | Generates more sawdust than some tools |

What is a Scroll Saw

A scroll saw is a specialized tool used to make complex and precise cuts in wood in various materials.

It has a flat worktable with a vertical bar behind it.

A horizontal arm extends from the bar, holding a thin, reciprocating blade that moves up and down to make cuts.

A tool popular among many for its ability to create delicate designs.

How to Use Scroll Saw?

1. Follow Safety Precautions

Always remember to wear safety glasses and hearing protection when using a scroll saw.

Then check the machine to make sure it is in good working order.

2. Choose the Right Blade

Choose the right palette for your project. Smaller blades are suitable for complex cuts and larger blades are better suited for thicker materials.

3. Blade Installation

Install the selected blade following the manufacturer’s instructions.

Properly tension the blade to prevent deflection during cutting.

4. Prepare the Materials

Secure your material to the workbench with clamps or double-sided tape. Make sure it is flat and stable.

5. Set the Speed

Adjust the speed of the saw based on the material and the type of cut you are making.

Slow speed is often used for complex work.

6. Start Cutting

Turn on the scroll saw and start making your cuts.

Gently guide the material along the cut line. Remove your hands from the blade.

7. Practice Control

Scroll saws are known for their ability to make tight curves and complex cuts.

By practicing controlling the material to follow the pattern you want, you can achieve a good finish.

8. Disable Scroll Saw

After completing your cuts, turn off the scroll saw and wait for the blade to stop moving before removing your workpiece.

9. Sanding and Finishing

Depending on your project, you may need to sand the edges of your cut to remove any roughness.

10. Clean up

After using the machine, wipe off the dust and clean it.

Uses of Scroll Saw

Intarsia

It is used to create complex wooden mosaics with different pieces of wood.

Fretwork

Creating fine decorative designs from wood.

Inlay work

Precise insertion of wooden surfaces.

Jigsaw puzzles

Cutting intricate puzzle pieces out of wood.

Scrollwork

Creating beautiful patterns and designs

Advantages and Disadvantages of Scroll Saw

| Advantages | Disadvantages |

| Exceptional for intricate, detailed work | Limited to thinner materials |

| Can make very tight curves | Slower cutting speed than other saws |

| Minimal waste of material | Not suitable for heavy-duty or rough cuts |

| Relatively safe due to the small, fine blade | Limited in versatility compared to other saws |

Bandsaw VS Scroll Saw Differences

Now I’m going to share with you the key differences between band saw and scroll saw in detail.

They will help you to select the one that suits you the most.

1. Working mechanism

A scroll saw works by rapidly moving its blade up and down, like how a sewing machine works.

It consists of a short, fine blade guarded in both upper and lower arms, which oscillates together while cutting.

In contrast, band saws use a continuously looped blade attached to two wheels that move in one direction.

The blade moves continuously downward to cut through the material.

2. Types of cuts

Scroll saws are great for circular, angled, and straight cuts.

They offer a unique feature that allows you to remove and insert the blade in the center of the workpiece to carve shapes and circles.

Bandsaws are known for their straight and angled cuts.

They are powerful and suitable for cutting large pieces of plywood but cannot cut internal circles like scroll saws.

3. Clearances

Scroll saws have clearance limitations due to the frame that supports the blade.

They do, however, offer unlimited side-to-side clearance. Allows cutting at various angles and curves along the width.

Bandsaws have side-to-side clearance limitations due to the throat measurement.

Although longer boards with extra support can be handled, cutting wider boards can be challenging due to the limited throat distance.

4. Feeding speed

Bandsaws typically cut faster than scroll saws when using particularly aggressive blades.

5. Cut the radius

Based on the scroll saw technology, comes with thin blades that allow complex cuts without radius restrictions.

Bandsaws have wide blades and can cut up to a ¼” radius.

However, the width of the blade makes the radius tighter when moving slowly.

6. Thickness capacity

When cutting solid materials, scroll saw blades can overheat and break if they exceed recommended thicknesses (e.g., up to 1-1/2″ for softwoods and up to ¾” for hardwoods).

Bandsaw blades are designed to cut through thick stock from ½” to 1 inch or more.

7. Fret Work

Scroll saws excel at cutting decorative patterns, allowing detailed cuts to be made within the boundaries of a workpiece without having to cut across the edge.

Bandsaws are not suitable for complex or detailed projects such as fretwork.

8. Veneer Cutting or Rereading

Bandsaws can be used for resawing or veneer cutting, making thin edge-to-edge cuts in solid stock.

Scroll saws are not designed for these types of projects.

9. Cut-Finish

Scroll saw blades provide a smooth and shiny finish without marks and are ideal for complex designs.

Bandsaw cuts may require additional sanding for a similar finish.

10. Safety

Scroll saws are generally considered safer because of their low power and small size.

They often come with foot pedals for added control.

Bandsaws have more power and size and are a bit more dangerous. However, they can still be used safely with proper safety gear.

Tips for Working with Bandsaw

Here are the tips and techniques that I’ve learned by working with band saw over the past years which make the projects a lot easier.

- Always follow safety guidelines and wear appropriate protective gear.

- Choose the right type of blade for the material you intend to work with.

- Always keep the blade sharp for clean and efficient cuts.

- Check the blade tension guide and adjust it correctly to prevent blade drift.

- Avoid forcing the material into the blade.

- Use a fence or mitre gauge to make straight cuts.

- Keep the work area clean to avoid accidents and maintain accuracy.

Tips for Working with Scroll Saw

Here are the tips that I’ve learned by working with scroll saw over the years.

- Start with a simple project as you need to get used to the controls and blade when first using.

- Choose the appropriate blade for the complexity of your design and the thickness of your material.

- Practice controlling the material correctly to follow your pattern.

- Use light pressure. Let the blade cut.

- Keep the work area clean for better visibility and ease of control.

That’s it folks! Now you have a good understanding of band saw vs scroll saw with their key differences and features in detail.

So, let’s answer some frequently asked questions.

FAQs

What are the primary uses of a bandsaw compared to a scroll saw?

A bandsaw is typically used for making straight, uniform cuts in large or thick pieces of wood or other materials, and is adept at resawing and book matching. In contrast, a scroll saw is best suited for intricate, detailed, and complex designs in thinner materials, such as puzzles or intricate fretwork.

How do the blades differ between these two types of saws?

Bandsaws have a long, continuous blade ideal for straight cuts and curves in thicker material, while scroll saws feature a short, thin blade moving up and down, perfect for precise, intricate cuts in thinner materials.

Can bandsaws and scroll saws handle the same material thickness?

No, bandsaws are designed for cutting thicker materials thanks to their more powerful motors and robust blades. Scroll saws are tailored for thinner materials, often struggling with materials thicker than 1-2 inches.

Are scroll saws or bandsaws better for intricate designs?

Scroll saws excel at intricate designs due to their precision and ability to make complex, detailed cuts, while bandsaws are more suited for broader curves and straight cuts.

What is the learning curve like for operating these saws?

Operating a scroll saw requires more practice to maneuver the workpiece accurately for intricate designs, while a bandsaw is generally easier to use for making straight and uniform cuts.

What are the speed capabilities of a bandsaw compared to a scroll saw?

Bandsaws generally operate at higher speeds due to their powerful motors, ideal for cutting thick materials. Scroll saws offer variable speed settings, allowing for controlled, precise cuts in delicate, intricate designs.

Is it easier to make interior cuts with a bandsaw or scroll saw?

Interior cuts or pierced cuts are a specialty of the scroll saw, enabled by detaching and reattaching the blade through a pre-drilled hole in the material. Bandsaws are not capable of making such cuts.

Which saw is better suited for a beginner?

Scroll saws might be more approachable for beginners working on smaller, detailed projects due to their precision and control. Bandsaws, being powerful and versatile, are essential for broader woodworking applications but require adherence to safety precautions.

Can both saws cut metal and other materials besides wood?

Bandsaws can efficiently cut through a variety of materials including wood, metal, and plastics thanks to their robust build and powerful motors. Scroll saws can also cut different materials but are limited to thinner pieces.

Which type of saw is more cost-effective for small detailed woodworking projects?

For small, detailed projects, a scroll saw is often more cost-effective due to its precision and ability to handle intricate designs, while bandsaws are a more significant investment suited for a broader range of tasks including handling larger, thicker materials.

Did I cover all you wanted to know about: Bandsaw vs Scroll Saw

In this article, I’ve deeply discussed bandsaw vs scroll saw by taking their uses, and differences, and I’ve included the expert tips as well.

Band saw vs scroll saw include, bandsaws excelling in straight, uniform cuts and thicker materials, powered by robust motors while scroll saws are ideal for intricate, detailed designs in thinner materials, offering precision and complexity. The distinct blade designs and cutting motions define their varied applications in woodworking and material handling tasks.

Furthermore, I’ve answered some frequently asked questions a swell.

Hope you’ve learned all you wanted to know about band saw vs scroll saw without without missing anything.

Now it’s time for you to select the one that matches your project and make your awesome creation with it like a pro!