Ever confused between a chop saw vs miter saw? Wondering which powerhouse tool to pick for your next big project? Let’s dive deep and discover the distinctions that make each unique!

The chop saw and miter saw are two important tools used for cutting wood and metal. There are many similarities and differences between these two tools.

I was curious to know the key differences between them to select one heavy-duty woodworking project.

So, I went for experts and got a good understanding of the uses, and features with a good comparison between chop saw and miter saw.

Now with years of experience, let me tell you the key areas that differentiate chop saw from miter saw.

Here are the differences between chop saw and miter saw,

- Chop saws make straight, 90-degree cuts only; miter saws can make a variety of angled cuts.

- Chop saws are more powerful and used primarily for cutting hard materials like metal; miter saws are preferred for woodworking.

- Miter saws offer precision and versatility; chop saws are known for their power and efficiency.

- Chop saws typically use abrasive cutting wheels; miter saws use carbide-tipped blades.

- Miter saws can be adjusted for bevel and miter cuts; chop saws cannot.

- Chop saws are generally larger and heavier; miter saws are more compact and user-friendly.

- Miter saws are safer and easier to use for DIY projects; chop saws are more industrial and require skilled handling.

But there is a lot more to know about each of the above difficulties.

So in this article, I will explain all the differences between the chop saw and miter saw, their uses, and more details in detail.

Furthermore, I’ll answer some frequently asked questions as well.

So, let’s get started.

What Is the Main Difference between Chop Saw and Miter Saw?

One of the most striking differences between these two machines is the difference in the materials cut by these two machines.

A chop saw can cut any material from wood to metal. But a miter saw can only cut wood.

But for cutting wood it is more suitable to use the miter saw. It can make smooth cuts. A miter saw is widely used for cutting metal.

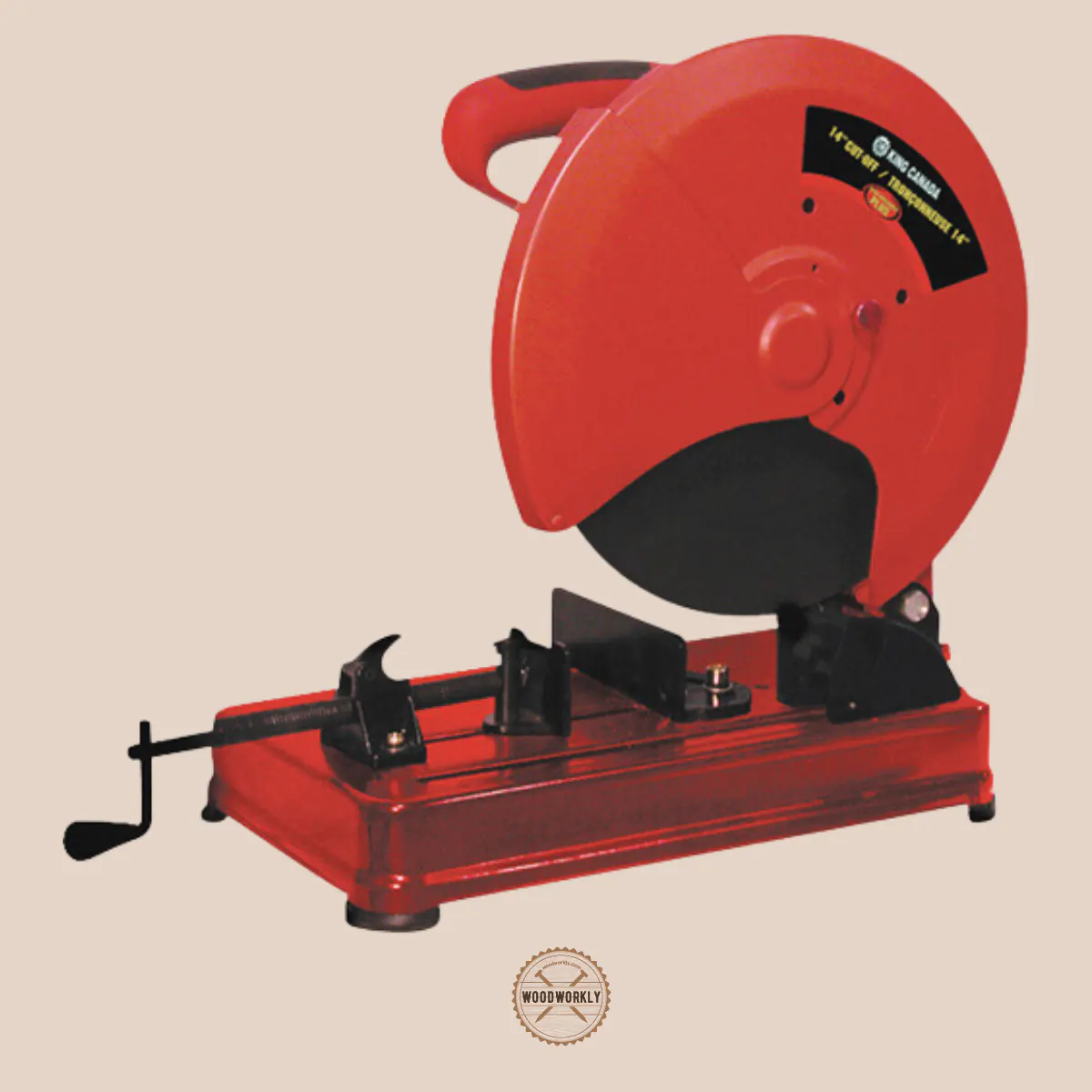

What is Chop Saw?

A powerful tool designed to create straight and accurate cross-cuts is called a cut-off saw.

A key feature of chop saws is their ability to cut a variety of materials, from wood to metal.

Another feature is that a precise 90-degree cut can be made. Unlike other saws, chop saws are only used for cross cuts and are not suitable for miter cuts, bevel cuts or curved cuts.

The device consists of a cutting area with a table and a back fence that fully contributes to the safe holding and support of the material during cutting.

Most chop saws are equipped with clamps to ensure that the material stays in place while making straight cuts. This tool makes cuts by moving the saw blade up and down.

The efficiency of these saws is especially important in engineering and welding shops.

How to use a Chop Saw?

There are a few steps to follow before using a chop saw.

- First, the tool should be kept stationary on a horizontal surface.

- Then place the material to be cut on the device and hold it firmly.

- Always keep the cutting line vertically below the plate.

- Then turn on the machine and bring down the rotating blade.

- Release the trigger button to stop the blade rotation.

- It returns to its original position when released slightly loosely.

- This procedure allows you to make finer cuts.

It should be remembered that chop saws are designed for straight cutting at an angle of 90 degrees.

Advantages and Disadvantages of Chop Saw

| Advantages | Disadvantages |

| Can cut various materials (metal, wood) | Limited to 90-degree cuts |

| Produces precise and accurate crosscuts | Cannot make angled cuts, bevel cuts, or curves |

| Sturdy and reliable construction | No provision for rip cuts |

| Equipped with clamps for secure material hold | Takes up considerable space |

| Suitable for high productivity in workshops |

Uses of Chop Saw

A chop saw is a versatile tool that is widely used in a wide range of applications. Such as,

- Cutting metal rods (e.g., rebar, angle iron)

- Metal and plastic pipe-cutting

- Working with metal building materials (e.g., studs, gutters, posts)

- Wood processing with embedded nails, screws, or other metal components

What is a Miter Saw?

Also known as a miter saw, this tool is a versatile tool designed for making precise cuts in wood. It is especially useful for creating angled cuts.

This tool is especially useful for tasks such as installing crown molding or framing pictures.

The distinguishing feature of the miter saw is its rounded front and the ability to swivel up to 45 degrees in both the left and right directions on its mounted stand.

In addition, many models are equipped with an angle gauge to facilitate accurate cuts. There are different types of miter saws. Each miter saw is designed for different cutting needs.

Types of Miter Saws

Conventional Miter Saw

Allows turning for angled cuts but does not slide forward or backward.

Sliding Miter Saw

Equipped with a sliding mechanism, the blade can move forward and backward, facilitating cutting on wide boards.

Compound Single Bevel Miter Saw

Offers both turning and tilting for bevel cuts, allowing for a versatile cutting range.

Compound Dual Bevel Miter Saw

Made in the same way as the single bevel but with the added ability to tilt up and down for both sides of the bevel cut.

Compound Dual Bevel Sliding Miter Saw

An advanced product that combines sliding and double bevel capabilities for maximum versatility in woodworking.

How to Use a Miter Saw

Follow the steps below to operate the miter saw properly,

- First position the saw securely in a horizontal position.

- Use the protractor to select the desired angle for cutting.

- Select the desired angle and adjust the miter saw accordingly.

- Turn on the saw and carefully lower the blade onto the workpiece to make the cut.

- Release the trigger button to stop the blade rotation.

- It returns to its original position when released slightly loosely.

- This procedure allows you to make thin cuts.

- Always wear appropriate safety gear, including safety glasses and ear protection.

Advantages and Disadvantages of Miter Saw

| Advantages | Disadvantages |

| Enables precise angled cuts | Limited to linear cuts along the grain |

| Versatile for various woodworking projects | Not suitable for cutting wide sheet material |

| Eliminates the need for multiple saws | May produce dust and require dust extraction |

| Saves time and effort in making angled cuts | Can be bulky and may require dedicated space |

Uses of Miter Saw

A versatile tool, the miter saw is basically used for many projects. Such as,

- Making straight cross cuts in wooden sticks and trim pieces.

- Cutting wooden floorboards to length.

- Creating angles for framing windows, doors, and picture frames.

- Design of bevelled hip joints for extra strength.

- Obtaining compound angles in crown moulding.

Chop Saw VS Miter Saw Differences

Chop saws and miter saws are two tools that are made to make precise cuts.

There are similarities and differences between these two devices.

1. Function

A chop saw is a specialized tool designed for cutting wood to metal. It’s the choice when you want a straight cut that’s as straight as you want it to be.

A Miter Saw is a woodworking cutting tool that is most commonly used by those working on woodworking projects.

2. Cutting Speed

When it comes to speed, chop saws have more speed. It has an impressive range of 3,000 to 4,000 revolutions per minute (RPM). This speed allows efficient cutting.

The Miter Saw operates at a speed of about 1,500 RPM, making it a more controllable speed.

3. Materials Cut

Chop saws are capable of cutting hard materials such as metal, pipes, rods, sheets and various building materials, making it a versatile tool.

Miter Saws are used to cut materials such as wood and plastic. This is why this tool is popular among woodworkers.

4. Motor power

Chop saws are equipped with larger and more powerful motors, making them suitable for heavy-duty tasks, especially metalworking and heavy construction projects.

Miter Saws are designed for precision woodworking projects where finesse and precision are critical. Miter Saws do not have as powerful motors as chop saws.

5. Movement

The chop saw has an edge when it comes to mobility. It is compact and lightweight. It makes it the perfect companion for on-site work.

Miter Saws are incredibly versatile but are generally less portable, making them ideal for stationary workshops.

6. Cutting Options

Chop saws are known for their ability to deliver straight, high-speed cuts, ideal for producing clean, straight cuts with ease.

Miter Saws feature a variety of cutting options, including straight, bevel, miter and compound cuts, essential for projects that require different angles and precision.

7. Common Uses

Chop saws are used for metalworking and heavy-duty construction projects where their power and precision are essential.

Miter Saws are often used for woodworking tasks such as cutting baseboards, corner beads, and intricate cuts such as wood flooring and miter saws.

Chop Saw vs Miter Saw Comparision Table

The differences discussed above are summarized in the table below

| Aspect | Chop Saw | Miter Saw |

|---|---|---|

| Type | Specialized tool for direct and precise cuts | Versatile cutting tool for various materials |

| Speed (rpm) | 3,000 to 4,000 | Around 1,500 |

| Materials | Metal, pipes, rods, plates, building materials | Wood, plastic, some metals |

| Motor Power | larger and more powerful for heavy-duty tasks | Suited for precision woodworking projects |

| Mobility | Compact and lightweight for on-site work | Generally less portable |

| Cutting Options | Direct, high-speed cuts | Straight, bevel, miter, compound cuts |

| Common Uses | Metalworking, heavy-duty construction projects | Baseboards, corner beads, hardwood floors |

Now you have a good understanding of both chop saw and miter saw. Select the one that suits you the most based on the given details.

Now I’m going to share with you some tips that I’ve learned by working with chop saw and miter saw for a long time.

The below tips will help you to succeed in your projects without making any mistakes.

Just keep reading!

Tips for working with Chop Saw

Secure materials

Always use clamps or other safety devices to hold material while cutting to ensure safety and accuracy.

Proper Alignment

Take the time to precisely align the material with the desired cut line to achieve clean and accurate results.

Steady Hand

Maintain a steady hand while guiding the saw through the material to prevent any deviation from the intended cut.

Safety Gear

Wear appropriate protective gear including safety glasses, ear protection and gloves when working with this machine.

Clear the Workspace

Ensure that the work area is free of clutter and debris to prevent any obstructions while operating the chop saw.

Regular Maintenance

Keep chop saws in good condition by performing routine maintenance such as sharpening and cleaning the blade.

Practice Safety Precautions

Follow the tool’s safety features and guidelines.

Always follow the recommended safety procedures when using the machine to achieve a safer and more efficient finish.

Tips for Working with Miter Saw

Choose the correct blade

Always choose the right blade for the material you are cutting.

Use protective gear

Always wear safety glasses and hearing protection when operating a miter saw.

Secure the workpiece

Hold the workpiece firmly to avoid accidents.

Maintain a clean workspace

Connect to a saw dust extractor to reduce clutter and increase visibility.

Practice safe cutting techniques

Familiarize yourself with the features of the saw and follow proper cutting procedures.

A miter saw is a valuable tool for any woodworker, and by using the correct working order, it can be used for many projects.

Gives a fine finish with good precision and efficiency.

Which is Better Chop Saw or Miter Saw?

Chop saws and miter saws should be chosen according to the project you are undertaking.

If you need straight cross cuts, chop saws are ideal and provide an affordable and effective solution.

A miter saw is ideal if more complex cuts with right angles are required. It is a versatile tool that can handle a wide range of tasks, making it suitable for both beginners and professionals.

Can I Use a Miter Saw as a Chop Saw?

Yes, a miter saw can be used as a chop saw, but there are a few important things to keep in mind.

Miter saws are designed to make accurate cross-cuts and miter cuts in materials such as wood, plastic, and some metals.

If you want to make straight and high-speed cuts in metal, a dedicated chop saw will be the ideal tool due to its high RPM and specialized blade designed for such tasks.

It is important to choose a blade that is specially designed for metal cutting, as standard wood cutting blades are not suitable for that purpose.

Be aware that miter saws are used for cutting metal because they are powered by a motor and apply more pressure on the blade.

Congrats folks! Now you know chop saw vs miter saw properties, uses, and their key differences based on experts’ opinions.

So, let’s answer some frequently asked questions.

FAQs

What is the main difference between a chop saw and a miter saw?

A chop saw is primarily designed for making straight, 90-degree cuts and is often used for cutting through materials like metal, whereas a miter saw has the ability to make angled cuts, making it ideal for woodworking tasks like cutting crown molding or picture frames.

Can a chop saw make angled cuts?

No, chop saws are designed to only make straight, 90-degree cuts, unlike miter saws, which can pivot to create various angled cuts.

Is a miter saw suitable for cutting metal?

While miter saws are primarily designed for woodworking, they can cut metal when equipped with the appropriate blade, but for thicker and harder metals, a chop saw would be more appropriate.

Which saw is better for a beginner in woodworking?

A miter saw is generally recommended for beginners due to its versatility, ease of use, and the ability to make precise angled cuts, which are commonly needed in woodworking.

Can I use a miter saw for straight cuts?

Yes, a miter saw can make straight cuts, and it offers the added flexibility of making angled and beveled cuts as well.

Why might someone choose a chop saw over a miter saw?

A chop saw is often chosen for jobs that require cutting through thick and hard materials, including metal, due to its powerful motor and abrasive cutting wheels.

What is a hybrid saw?

A hybrid saw combines features of both chop and miter saws, operating at slower blade speeds to accommodate carbide-tipped blades, making it suitable for cutting both metal and wood.

Is it safe to cut metal with a miter saw?

It can be safe when done correctly with the appropriate blade and safety precautions, though dedicated metal chop saws or hybrid saws are often preferred for cutting harder or thicker metals.

What are the typical blade sizes for chop and miter saws?

Chop saws typically have larger blades, ranging from 12-15 inches, while miter saws have smaller blades, usually between 7-1/4 to 12 inches.

Can a chop saw be used for woodworking?

While chop saws can cut wood, they are limited to straight cuts and lack the versatility of miter saws which can make various angled cuts essential in woodworking.

Did I cover all you wanted to know about: Chop Saw vs Miter Saw

In this article, I’ve deeply discussed chop saw vs miter saw by taking their importance in woodworking. Now you can select the one that suits you the most based on your preference.

Chop saw vs miter saw include chop saws make straight, 90-degree cuts and are often used for cutting metal and hard materials while miter saws can make angled, beveled, and straight cuts, ideal for woodworking. Chop saws have larger, abrasive blades, while miter saws have smaller, carbide-tipped blades.

Furthermore, I’ve answered some frequently asked questions as well.

Hope you’ve learned all you wanted to know about chop saw vs miter saw with experts’ tips and techniques.

Now go through this article again and take your final decision between the chop saw and the miter saw based on your project. Happy woodworking with saws!