Ever juggled between choosing a contractor saw or a cabinet saw? What makes them distinct, and which one will seamlessly align with your woodworking needs? Dive in!

In the world of woodworking, many woodworkers grapple with the question: is a contractor saw or a cabinet saw better?

If you are seeking an answer to this question, you have come to the right place.

I once had the same question and sought advice from experts to select the saw that best suited my needs.

Now, with my years of experience, here’s my opinion on the contractor saw versus cabinet saw

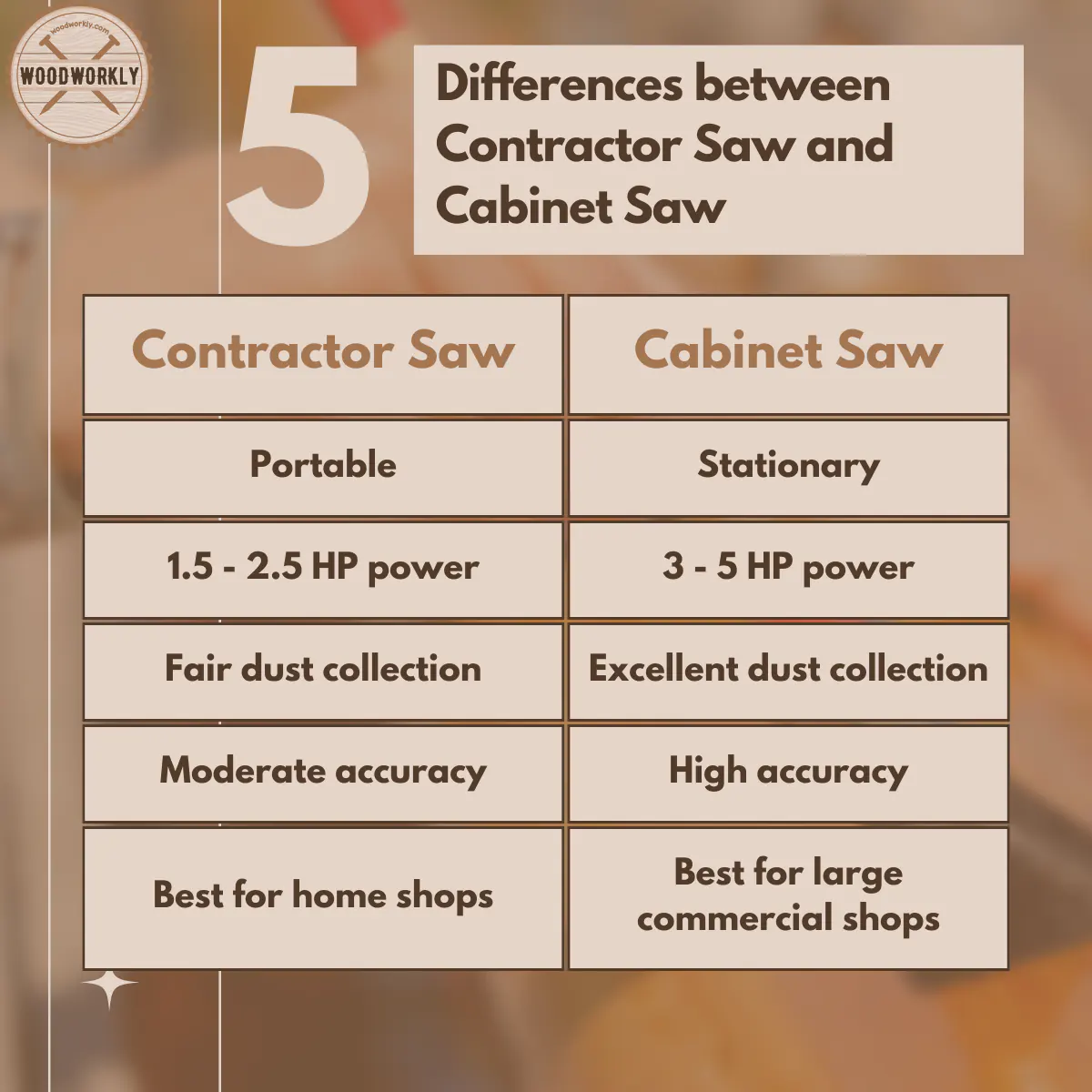

Here are the differences between contractor saw vs cabinet saw,

- Contractor saws offer more mobility and affordability than cabinet saws.

- Cabinet saws offer unmatched precision, power, and stability over contractor saws.

- Contractor saws are less effective than cabinet saws in terms of dust collection.

- Contractor saws exhibit more vibration than cabinet saws.

- Contractor saws are more versatile than cabinet saws.

I know this information is not enough for you to know the difference between contractor saw vs cabinet saw and choose the best saw for your projects.

In this article, I’ll provide complete information about everything you need to know about that same contractor saw vs cabinet saw.

At the end of this article, you will know what contractor saw vs cabinet saw is, their uses, pros and cons, and everything you need to be aware of when working with these saws.

Let’s start the journey!

What Is the Main Difference between Contractor Saw and Cabinet Saw?

Did you know that the main difference between a contractor saw and a cabinet saw lies in their portability and construction?

These contractor saws are popular among contractors who need to move saws from one job site to another because of their portability.

Featuring lightweight construction with an easily transportable stand, these saws are also designed for job site mobility.

In contrast, cabinet saws are very heavy in weight, as they are designed for constant use in a workshop.

They often have a cast iron table and heavy cabinet base, providing more stability and reducing vibration during operation.

Typically, these cabinet saws are used more by projects where precision and power are a priority, and they are less portable compared to contractor saws.

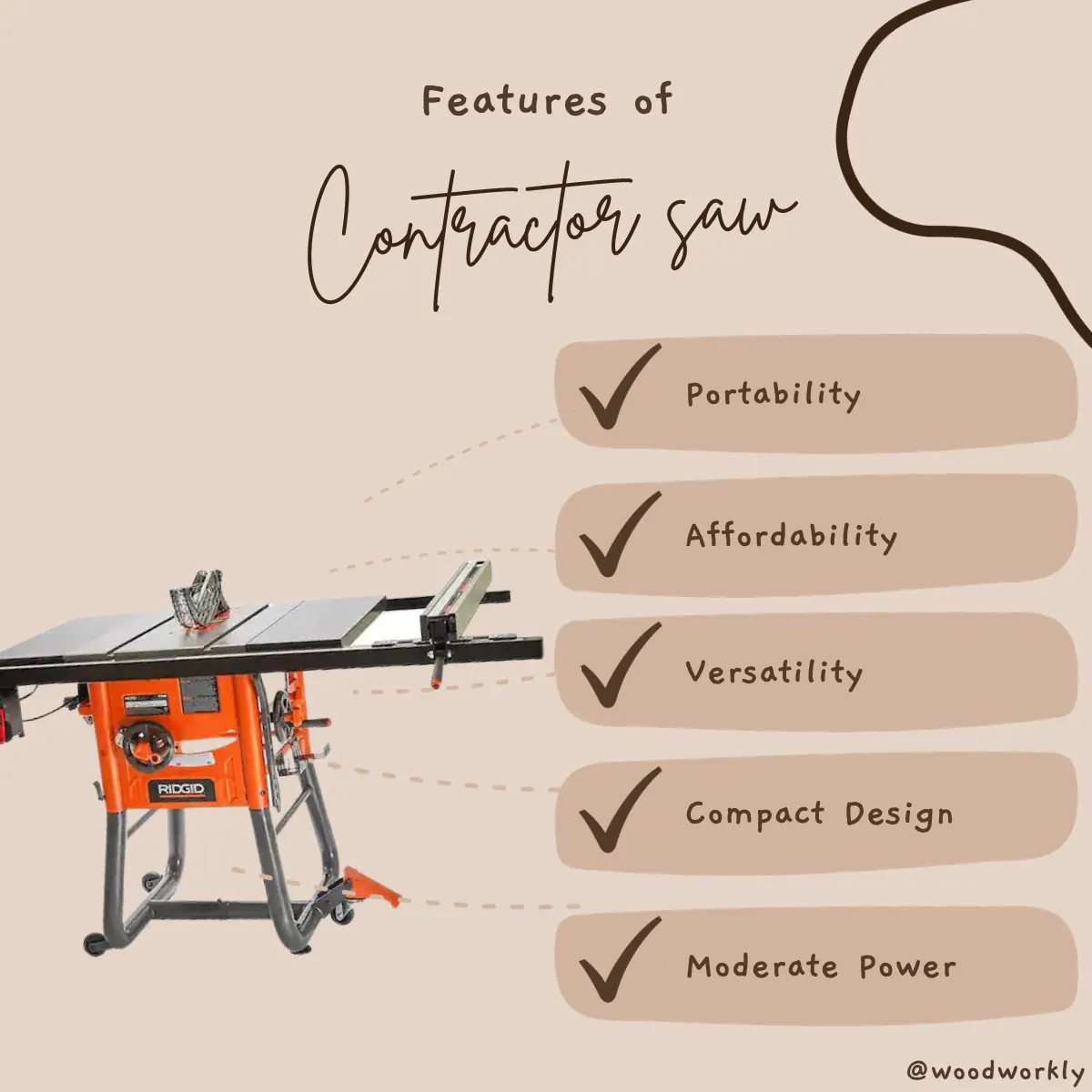

What Is Contractor Saw?

A contractor saw, variously known as a job site saw or a portable table saw typically consists of a lightweight stand, a folding base, and a powerful motor mounted beneath the table surface.

In particular, it is a table saw designed for versatility and portability, making it a popular choice among contractors and carpenters.

Contractor saws typically have a smaller table than cabinet saws and are more compact and mobile.

Before you use a contractor saw, you should have a good understanding of how to use it, its pros and cons, and its uses.

How to Use a Contractor Saw?

If you have been looking for how to use a contractor saw, then don’t worry, below is how I use a contractor saw.

Always wear safety glasses and hearing protection when using a contractor’s saw to protect your eyes and ears.

Also, make sure the saw is placed on a stable surface or stand.

The second thing you should definitely do is adjust the height and angle of the saw blade as needed for your specific cut.

For that, you will find easy-to-use adjustment knobs on most contract saws.

Then set the rip fence to the desired width for your cut and lock it securely. You can use a miter gauge for cross cuts and miter cuts for this.

If you need to make narrow cuts, use a push stick to guide the material across the blade to keep your hands a safe distance away.

Pros and Cons of Contractor Saw

Pros

You can get the following benefits while using a contractor saw.

- Portability: Contractor saws are designed for mobility, making them ideal for jobsites and projects where you need to move the saw around.

- Affordability: Contractor saws are often more budget-friendly than cabinet saws, so they can be purchased by a wide range of users.

- Versatility: If you want to perform a wide range of cutting tasks including rip cuts, cross cuts, bell cuts and dado cuts, you can easily do it all with a contractor saw.

- Compact Design: These saws require less space in your workshop or job site, making them ideal for smaller workspaces.

Cons

As we all know, there is a good side and a bad side to everything. So you have to face the following disadvantages while using contractor saw.

- Accuracy: While contractor saws are versatile, they don’t offer the same level of accuracy and stability as cabinet saws due to their lightweight construction.

- Low power: Cabinet saws typically have relatively low-power motors, so your ability to handle heavy-duty tasks may be limited.

- Dust collection: Dust collection systems on contractor saws are less effective and can be difficult to clean after use

Uses of Contractor Saw

As you know, these contractor saws, which can be used for a wide range of woodworking and construction work, are used for a variety of uses and I have listed them below.

- Rip Cuts – Rip cuts are used for long straight cuts and are especially useful for sizing lumber or plywood for various projects.

- Bevel Cuts – A contractor’s saw allows you to tilt the blade so you can use it for chamfers or angled cuts used to join pieces at specific angles.

- Crosscuts – Can also be used to make cross cuts and by using a miter gauge or sled you can make precise cross cuts for framing pieces, trim and other woodworking components.

- Miter Cuts – With the help of a miter gauge or miter sled, a contractor saw can make miter cuts and is used to create frames, corners and precise angles in various woodworking projects.

- Dado Cuts – Used to make slots for joints and racks because a contractor saw can make dado cuts.

- DIY Projects – These contractor saws are used as versatile tools for DIY enthusiasts working on home improvement projects, craft projects, and general carpentry.

Remember; while contractor saws are versatile and portable, they can have limitations compared to larger stationary table saws.

What Is the Cabinet Saw?

Cabinet saws also known as cabinet table saws are stable and heavy-duty table saws known for their precision, power, and stability.

Unlike contractor saws, cabinet saws are designed to be a permanent fixture in a workshop.

Did you know that they usually feature a large cast iron table, powerful motors and sturdy construction?

However, before you use cabinet saws, you should pay close attention to how they are used, their pros and cons, and how to use them.

If so, I will tell you the details about it now.

How to Use a Cabinet Saw?

If you are hoping to use a cabinet saw, I advise you to pay special attention to your safety and accuracy.

Below is how I use the cabinet saw.

The first thing you should do is to make sure about your security. I use safety goggles, hearing protection, and appropriate clothing when using cabinet saws.

Second, in particular, I make sure my workspace is well-lit, clutter-free, and properly ventilated. It can prevent accidents.

Then plug the saw into a suitable power source and turn the power switch “off” before plugging it in.

I adjust the height and angle of the saw blade as needed for my cut, usually using adjustment wheels or knobs.

When starting work make sure you have the workpiece flat on the table and firmly pushed into the rip fence or miter gauge for straight and precise cuts.

Then turn on the saw using the power switch and allow the blade to reach full speed before making the cut.

Normally you should continue to push the material through the blade until the cut is complete.

Pros and Cons of Cabinet Saw

Pros

You can get the following benefits from using a cabinet saw.

- Accuracy: Cabinet saws are ideal for fine woodworking and carpentry because of their accuracy and stability.

- Power: Cabinet saws typically have powerful motors that can handle heavy duty tasks and heavy wood.

- Durability: Cabinet saws are built to last with sturdy construction and components.

- Dust Collection: The closed cabinet design allows for effective dust collection while keeping the work area clean.

Cons

While using a cabinet saw you have to face the following cons.

- Cost: Cabinet saws are more expensive than portable saws, making it a significant investment.

- Space: You will need a dedicated workshop space for cabinet saws due to their large size and weight.

- Immobility: Because cabinet saws are not designed for portability, they are less versatile for on-site work.

Uses of Cabinet Saw

Cabinet saws are a powerful and precise stationary woodworking tool widely used in professional woodworking shops and by serious woodworking enthusiasts.

So let’s now look at some common uses of cabinet saws.

- Precision Joints – Cabinet saws help you a lot in creating precise and tight-fitting joints like dovetail joints, box joints, and mortise-and-tenon joints.

- Furniture Making – Cabinet saws are essential for high quality furniture making and can be used to ensure a clean and precise cut for a professional finish.

- Cabinet Making – As the name suggests, cabinet saws are especially well suited for cabinet making.

- Trim Work – Cabinet saws are often used for cutting and molding work in home construction and remodeling projects.

- Fine Woodwork – You can use this saw for delicate and intricate woodwork such as setting wooden ornaments, intricate inlays or detailed carvings.

Cabinet saws are very popular among woodworkers for their precision, power and durability.

Contractor Saw Vs Cabinet Saw: Differences

You already know that contractor saws and cabinet saws are two different types of table saws.

Each of them is designed for specific purposes and offers different features, but you should be aware of the differences before choosing between them.

So I will now share with you the key differences between a contractor saw and a cabinet saw.

1. Portability and Mobility

Contractor saws are designed for portability and job site mobility. They are relatively light and have foldable stands, making them easy to transport to different work sites.

On the other hand, cabinet saws are stationary and not designed for mobility. They are heavy and bulky and are meant to be in a fixed position in a workshop.

2. Table Size and Weight

Contractor saws typically have smaller table sizes compared to cabinet saws. They are compact and lightweight, contributing to their portability.

But cabinet saws have large and heavy tables and are often made of cast iron. The weight and size provide stability and support for precision woodworking.

3. Motor Power

Contractor saws typically have less powerful motors, ranging from 1 to 2 horsepower (HP). Although suitable for most tasks, they can struggle with extremely thick or dense materials.

On the other hand, cabinet saws usually include more powerful motors of 3 to 5 HP or even more.

This additional power allows them to handle heavy-duty cutting tasks effortlessly.

4. Dust Collection

Contractor saws may have less effective dust collection systems, which results in more cleanup after use.

But cabinet saws often have better dust collection capabilities because of their enclosed design, which helps keep the work area clean.

5. Precision and Stability

Contractor saws, although accurate, may exhibit more vibration during operation due to their lightweight construction.

This can affect the accuracy for delicate woodwork.

But cabinet saws are known for their stability and precision. Their heavy construction minimizes vibration, resulting in clean, accurate cuts, making them ideal for delicate woodwork and wine.

6. Versatility

Contractor saws are versatile and suitable for a variety of woodworking tasks, but their mobility makes them especially suitable for on-site work.

Also, cabinet saws are versatile, but their large size and stable nature make them ideal for dedicated workshops and professional woodworking environments.

7. Price

Contractor saws are generally more affordable than cabinet saws, making them accessible to a wider range of users.

But cabinet saws are expensive due to their large size, powerful motors and precision features. They are generally considered a significant investment.

8. Professional Vs Hobbyist Use

Contractor saws are often chosen by professionals who need a portable and versatile saw for on-site work. They are also suitable for woodworking hobbies.

But cabinet saws are favored by professional woodworkers and serious enthusiasts who prioritize precision, power, and quality in their woodworking projects.

Ultimately, choosing between a contractor saw and a cabinet saw depends on your specific needs and priorities.

Contractor saws offer mobility and affordability, making them suitable for a variety of tasks and job site use.

Cabinet saws, on the other hand, offer unmatched precision, power and stability, making them the top choice for professional woodworkers and those who want exceptional woodworking results in a specialized workshop setting.

Tips for Working with Contractor Saw

Working with a contractor saw can be a rewarding experience when you follow best practices and safety guidelines.

Here are some valuable tips I use to effectively and safely use a contractor saw:

- Always wear appropriate safety gear, including safety goggles and hearing protection.

- Make sure the saw is placed on a stable surface or on its built-in stand.

- By using a sharp, suitable blade, you can make a clean and safe cut.

- Adjust the height of the blade to the appropriate depth for your cut. That way you can reduce the risk of accidents.

- When making narrow cuts, use push rods to guide the material through the blade. By following this you can protect your hands from the blade.

- Maintain a balanced stance and a firm grip to prevent material from binding or kicking while cutting.

By following these tips, you will be able to successfully complete the job while minimizing risks.

Tips for Working with Cabinet Saw

Working with a cabinet saw, a powerful and precise fixed woodworking tool, requires careful attention to safety, precision and efficiency.

Here are some essential tips I’ve used to work effectively with a cabinet saw:

- Prioritize safety by first wearing appropriate personal protective equipment, including safety goggles, ear protection, and appropriate clothing.

- Ensure the cabinet saw is securely anchored to a stable surface in your workshop to reduce risk.

- Choose the right saw blade for your specific cutting task.

- Feather boards help hold your workpiece against the fence and table, thus improving stability and accuracy when cutting.

- Do not overload the saw by attempting to cut material that exceeds the saw’s capacity.

Following these tips can ensure your safety and the quality of your work.

Which is Better Contractor Saw or Cabinet Saw?

Choosing between a contractor saw and a cabinet saw ultimately depends on your specific needs and priorities when it comes to woodworking.

Contractor saws are ideal for those who need on-site mobility and versatility on projects.

In contrast, cabinet saws are ideal for professional woodworkers working in workshop settings and serious enthusiasts.

The decision depends on your level of woodworking expertise, the scale and type of projects you undertake, and whether you prioritize portability or precision in your woodworking tools.

That’s it, folks! Now you have a crystal clear knowledge about contractor Saw vs cabinet saw with their features, uses, and main differences based on experts’ opinion.

So, let’s answer some frequently asked questions.

FAQs

What is the primary difference between a contractor saw and a cabinet saw?

A contractor saw is designed for portability and is generally more affordable, making it ideal for job sites and DIY enthusiasts. In contrast, a cabinet saw is stationary, offers greater precision and power, and is typically used in professional woodworking environments.

How do the power and precision of contractor and cabinet saws compare?

Cabinet saws boast more power and precision due to their sturdy build and advanced features, making them ideal for intricate and heavy-duty tasks. Contractor saws, while versatile, offer less power and precision.

Is a contractor saw suitable for professional woodworking?

Contractor saws are often chosen by professionals for on-site work due to their portability but may lack the precision and power needed for intricate woodworking tasks typically accomplished with a cabinet saw.

Why might a hobbyist choose a contractor saw over a cabinet saw?

Hobbyists often prefer contractor saws because they are more affordable and portable, making them suitable for smaller workspaces and a variety of tasks, despite the lower precision compared to cabinet saws.

Can cabinet saws be easily transported between job sites?

No, cabinet saws are typically heavy and designed to be stationary, making them unsuitable for transportation between job sites, unlike the lighter and more portable contractor saws.

How do contractor and cabinet saws differ in terms of dust collection?

Cabinet saws generally have superior dust collection systems due to their enclosed design, keeping the workspace cleaner, while contractor saws often have less effective dust management.

Are contractor saws less expensive than cabinet saws?

Yes, contractor saws are generally more budget-friendly, making them a popular choice among DIY enthusiasts and professionals needing a portable option, while cabinet saws are a significant investment due to their advanced features and capabilities.

Is it easy to adjust the settings on a contractor saw?

Contractor saws are user-friendly, with easily adjustable settings making them versatile for a range of cuts, although they might lack the precision adjustments available on cabinet saws.

Which saw is better for making precision cuts?

Cabinet saws are known for their precision, stability, and power, making them the preferred choice for tasks that require highly accurate cuts, while contractor saws are more suited for general cutting tasks.

Can I use a contractor saw for heavy-duty tasks?

Contractor saws are versatile but may struggle with extremely heavy-duty tasks due to their lower power compared to cabinet saws, which are designed to handle rigorous and precise cutting requirements.

Did I cover all you wanted to know about: Contractor Saw vs Cabinet Saw

In this article, I’ve deeply discussed contractor saw vs cabinet saw in detail by taking their various features to help you to select the one that suits you the most.

Contractor saws are portable, affordable, and ideal for light-duty tasks, featuring 1.5-2.5 HP motors and moderate precision. Cabinet saws are stationary, more expensive, and built for heavy-duty, precision work, equipped with 3-5 HP motors and excellent dust collection systems.

Furthermore, I’ve answered some frequently asked questions as well.

Hope you’ve learned everything you wanted to know about contractor saw vs cabinet saw with tips and techniques.

Now it’s time to go through this article several times select the one that suits you the most and visit the store to pick it up. You won’t go wrong! Happy woodworking!