Ever torn between a track saw vs table saw for your next project? Dive in to discover which tool reigns supreme!

At the beginning of my journey of woodworking, I only had a table saw which was from my father. I was unable to do asymmetrical edge cutting properly.

So, I needed to buy a new saw machine with modern features and with safe and easy cutting.

Then, I did deep research on different saw machines with the help of industry experts.

Here, I am going to discuss how modern features assist in the safety and ease of track saws compared with table saws.

Here are the differences between track saw and table saw,

- Portability: Track saws are portable; table saws are stationary.

- Best Use: Track saws excel with large sheet goods; table saws are ideal for repeated rip cuts.

- Plunge Cuts: Track saws can make plunge cuts; table saws generally cannot.

- Safety: Track saws pose less risk of injury compared to table saws.

- Splintering: Track saws often produce splinter-free edges.

- Cut Limit: Table saws have cutting width limits due to their fence; track saws don’t.

- Setup: Track saws require setting up a guide for each cut; table saws have a fixed fence for consistent cuts.

- Depth: Table saws generally have a deeper cut capacity than track saws.

- Dust Management: Table saws often offer better dust collection systems.

- Versatility: Table saws can accommodate various accessories like dado blades; track saws are more limited.

But there’s a lot to know about each above!

In this article, I’ll explain track saw and table saw separately with their pros, cons uses, and differences of them.

Furthermore, I’ll answer some frequently asked questions as well.

First, let’s see what track saw and table saw separately.

What is a Track Saw?

A track saw, also known as a plunge saw or rail saw, is a popular tool that is used in the woodworking industry for the portable cutting of wood, plywood, MDF (medium-density fiberboard), as well as certain metals and polymers.

A track saw consists of a circular saw mounted on a guide rail or track, and there is a splinter guard for splinter-free cuts.

It is a portable machine. The circular saw blade can be plunged to the appropriate depth.

The track saw operates along a saw track, making it extremely simple to get absolutely straight cuts, and angled cuts of up to 45 degrees are also possible.

How to Use Track Saw?

Using a track saw is simple, but it needs some care and attention to guarantee correct and safe cuts.

Here’s a step-by-step instruction to efficiently use a track saw.

1. Get Safety Precautions

First, you need to take safety precautions before starting the cutting. Wear, safety Glasses to keep dust and debris out of your eyes and ear protection.

Since the track saw is very noisy, it’ll damage your ears.

A dust mask or respirator and Gloves to protect from dust particles.

2. Set up the Machine

For this, you need to find the appropriate blade type.

For example, for plywood, blades with finer teeth are better, and for rough lumbers blades with coarser teeth are better.

Then, you need to set your material down on a firm work surface with clamping and ensure it prevents moving during the cut, in other words, keep the wood stationary.

Place the track on top of the material, aligning it with the desired cut line while making sure to prevent the track from moving during the cut.

For this, some have anti-slip strips on the bottom of the track.

3. Make the Cut

To start the cut, you need to adjust the depth of the track saw blade to match the thickness of your wood.

There are depth adjustment knobs or levers in track saws for this purpose.

Now, place the track saw on the track with the blade guard up. Check that the blade is exactly aligned with the cut line of the wood.

Start the Saw by handling the saw with both hands. Before making contact with the wood, start the saw and allow it to reach full speed. Here, your body should keep to the side of the saw’s path.

Slowly insert the saw blade into the wood, keeping it against the track’s edge. To create the cut, move the saw along the track with mild and uniform pressure.

Continue sliding the saw along the track until you’ve cut the entire length of the wood. After finishing the cut, release the trigger to bring the saw to stop.

Raise the saw blade out of the material and allow it to completely stop before removing it from the track.

For softwoods higher speed and for hardwood lower speed is applied.

If you need to make plunge cuts (cuts beginning in the center of the material), however, before beginning the saw, ensure the blade is raised above the wood. Insert the blade into the wood at the specified starting point until it has reached the entire depth and then cut the wood.

Types of Track Saws

There are some common track saws designed for specific applications and user preferences as follows.

Corded Track Saws

They are powered by electricity and they can be used for a variety of woodworking jobs which are typically seen in professional and workshop settings.

Cordless Track Saws

These are powered by rechargeable lithium-ion batteries, providing portability and cord-free operation.

Most suitable for construction sites without easy access to electricity and come in a variety of voltage ranges, with higher-voltage models typically offering more cutting power and a longer runtime.

Compact Track Saws

These are lightweight and portable, most commonly used for DIY projects or small woodworking jobs.

Full-Size Track Saws

Full-size track saws are larger and more powerful, making them ideal for heavy-duty and professional use. They can easily handle heavy and dense materials.

Pros and Cons of Track Saw

There are some advantages and disadvantages you need to know when using a track saw for your project.

Pros

Accuracy

The guide rail in the machine provides a precise path and gives smooth, splinter-free cuts. Just you need to align the track with the mark that you need to cut.

The plastic edge in the track indicates exactly where the blade will cut. No need to double-check and test cuts.

Furthermore, every cut is completed. There will not be re-cutting.

Versatility

Track saws are capable of rip cuts, crosscuts, bevel cuts, and plunge cuts. This is because of their adaptability, for a wide range of woodworking and construction jobs.

Portability

Moving between workspaces is much easier and safer than bigger stationary instruments like table saws.

It can be carried under one arm.

Clean Cuts

Track saws reduce tear-out and splintering when cutting materials like plywood or veneered boards and as a result provides smooth and professional-looking edges.

Fewer Space Requirements

Track saws take up less storage space than bigger stationary saws, making them ideal for small workshops or garages.

Dust Collection

The shroud on a track saw acts as both enclosing the blade and trap that effectively collects dust particles during the cutting.

Safety

Track saws are safer to use because of the enclosed blade and the guided cutting path. This is important for people who aren’t familiar with woodworking.

Long Cut Potential

Do you need long cuts? You can use connectors that can easily lock two tracks with their dead squares at the end in order to do long supercuts.

Asymmetrical Edges Cutting

The track saw guide is simply adjustable and positioned to facilitate cutting asymmetrical edges on plywood which will save you time and money.

Cons

Limited Capacity

Track saws are designed to cut thinner materials, and their cutting depth may be limited when compared to table saws.

This type may not be suitable for more thick and dense materials.

Narrow boards are more difficult to tear with a track saw because the track can tip. You may require scrap wood to keep the track at the same level as the workpiece.

Cost

As with all others, high-quality track saws are expensive. Nevertheless, they are, less expensive than other high-end table saws.

Not Ideal for All Cuts

While track saws are experts at straight cuts, they may not be a good solution for some applications, such as complicated curved or dado cuts (three-sided channel cuts across the grain of the wood).

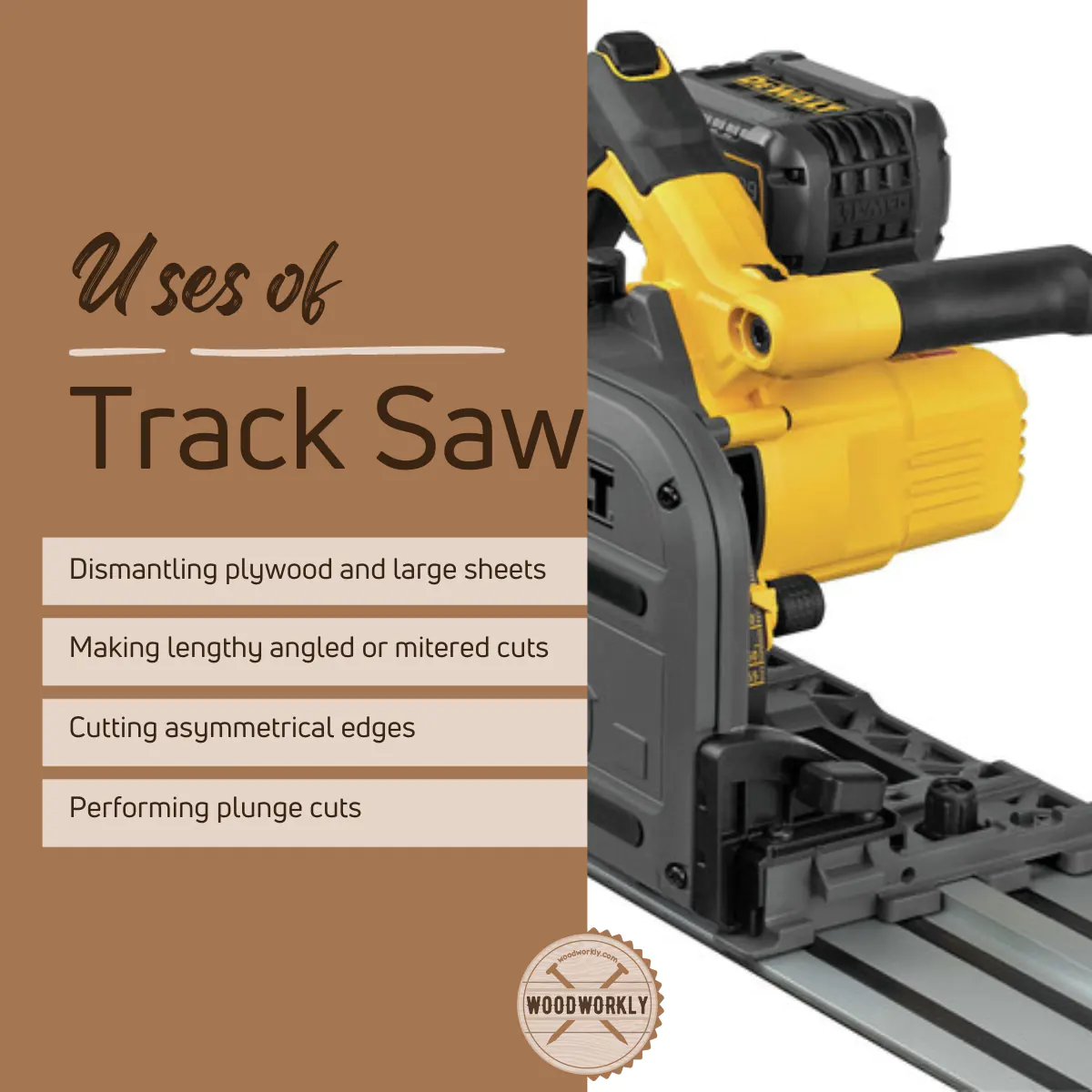

Uses of Track Saw

Track saws are flexible cutting tools that are often used in woodworking and building projects.

Their accuracy, portability, and ability to make clean cuts make them useful in a variety of applications such as,

- Breakdown sheet goods

- Cutting Plywood

- Trimming door bottoms

- Flooring installation

- Custom furniture making

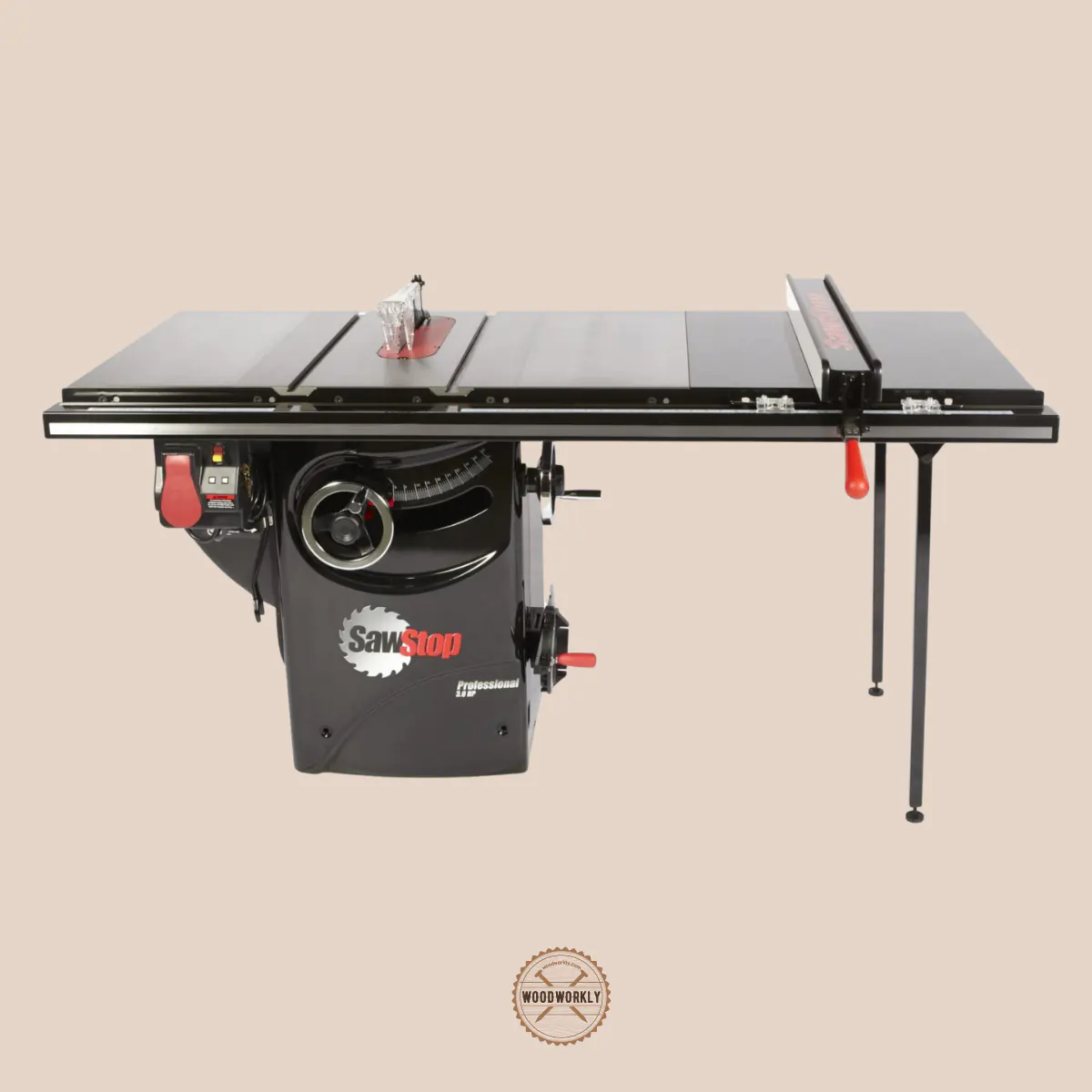

What is a Table Saw?

A table saw is a stationary woodworking machine that is used to make accurate and straight cuts in a variety of materials, most notably wood.

A table saw mainly consists of a Tabletop, Circular Saw Blade, Fence, Riving Knife, Miter Gauge and Blade Guard.

Tabletop is a large, flat surface that serves as a stable work area for the material being cut. It is typically a smooth and low-friction surface.

There is a circular saw blade that is mounted on an arbor and protrudes through an opening in the tabletop.

This can be adjusted into different heights, and angles in order to make different cuts including cross-cuts (cuts made perpendicular to the wood grain), rip cuts (cuts made parallel to the wood grain) etc.

There is a blade cover around it to protect the user’s hand and to prevent debris from being thrown back at the user while cutting.

The fence acts as a straight guide that runs parallel to the blade and aids in the accuracy and consistency of the cuts. This can be adjusted to achieve the necessary width for rip cuts.

For angled cross-cuts and bevel cuts, there is a tool called miter gauge, a guide that can be adjusted to various angles to achieve exact angled cuts.

A safety device, a riving knife is positioned behind the blade which reduces kickback by keeping the workpiece from binding on the back of the blade and there is a power source most probably this is the electricity.

Types of Table Saws

Depending on the size there are three types of table saws.

Benchtop Table Saw

These are smaller, portable table saws designed for use on the job site. These can be used on a workbench or a stand.

Contractor Table Saw

These are large and more powerful table saws that come with a stand.

Cabinet Table Saw

These can be seen in professional woodworking shops and used for heavy duty. These are more durable, accurate and have greater power.

How to use Table Saw

- First, you need to wear the appropriate safety gear mentioned above before starting the cutting.

- Set up the saw by keeping the saw on a flat, stable surface and the blade height should be adjusted according to the thickness of the material being cut.

- For rip cuts, set the fence to the correct width, and for cross-cuts or slanted cuts, adjust the miter gauge.

- Make sure to keep your hands and body to the side of the blade rather than directly in front of it.

- Adjust safety accessories, such as push sticks or feather boards.

- Then turn on the saw and wait until it reaches full speed. Once you get high speed, start cutting as your necessity.

- If you need a rib cut, push the workpiece against the fence by keeping it flat against the table.

- Use the miter gauge to guide the workpiece through the blade for cross-cuts or angled cuts.

- You need to maintain a constant feed rate by moving the workpiece slowly and smoothly across the blade for perfect cutting.

- After finishing the cut, allow the blade to come to a complete stop before removing the cut pieces.

- Finally, clean the saw after disconnecting the power supply.

- Make sure to fully reset and be ready before starting a new cut.

Pros and Cons of Table Saw

Pros

Versatility

They can make a variety of cuts, including rip cuts, cross-cuts, bevel cuts, miter cuts, dado cuts, and more, making them useful tools for a variety of woodworking projects.

Repeatable Cuts

The use of a fence, miter gauge, and other accessories enables consistent and repeatable cuts,

which is necessary for manufacturing uniform components in woodworking projects.

Powerful

Many table saws have powerful motors that can cut through hardwoods and thicker materials with ease.

Joinery Work

Table saws are necessary for producing precise joinery such as dadoes, rabbets, tenons, and mortises, which are required for the construction of furniture and cabinets.

Safety Mechanisms

To reduce the danger of accidents, modern table saws frequently include safety features such as blade guards, riving knives, and anti-kickback mechanisms.

Cons

Cost

High-quality table saws can be expensive, especially with advanced features.

Space Requirements

A dedicated workspace and enough floor space are required to accommodate a table saw.

Less Portable

It is inconvenient because it is less portable. Rather than bringing the saw to your project, bring the workpiece to the equipment.

Low Cutting Power

Its cutting power is limited by the fence. It is sufficient to place it between its fence and blade.

Uses of Table Saw

A table saw is a flexible woodworking instrument that may be used to cut a variety of materials including wood.

Here are some popular applications of table saws.

- Cross-cutting against the grain of wood

- making rip cuts for sizing boards and panels.

- kerfing cuts for making tight angles

- angled bevel woodcuts for adding chamfers, beveled edges, and other aesthetic elements.

- Rabbet Cuts

- Resawing

- Trim Work

- Tapering for making tapered table legs, chair legs, or other components

Track Saw Vs Table Saw Differences

A track saw and a table saw differ primarily in their design, portability, and intended usage.

The differences between a track saw and a table saw can be explained as follows.

1. Portability and Design

The track saw comprises a circular saw mounted on a rail or track. The track acts as a guide, allowing for straight and exact cuts.

Track saws are highly portable and can be used on a variety of work surfaces, including on-site and in tight places.

Comparatively, a table saw is larger and heavier than a track saw and is intended for use in a workshop or dedicated workspace.

Table saws are well known for their strength and ability to make precise and fast repetitive cuts, unlike track saws.

2. Cutting Ability

Normally track saws are designed for making straight cuts, especially when breaking down large panels, plywood sheets, or other large materials, and produce clean, splinter-free cuts.

While table saws are designed as they can make a variety of cuts such as,

- Rip cuts

- Crosscuts

- Bevel cut( angle cuts, made through the thickness of a board)

- Miter cuts(angle cuts made across the width).

In addition to that, the cutting depth of a track saw is often limited to around 2 inches, whereas a table saw can typically cut about 3 inches.

Read to know, How to Cut a Groove in Wood With a Table Saw.

3. Safety and Control

Track saws are lightweight and easier to control, and the blade is mostly enclosed by the track.

Therefore, this safer type is encouraged for people with less experience or beginners.

Comparatively, because of the exposed blade and the possibility of kickback (the workpiece is thrown back toward the operator), table saws provide a higher risk of injury.

They are heavy compared with track saws.

4. Cost and Space Requirements

Track saws are less expensive than table saws and take up less storage space.

They are an excellent option for individuals with limited budgets or workspaces.

To purchase table saws you need to bear large investments that demand an appropriate space in a workshop or garage due to its size.

They are better suited to experienced woodworkers and experts.

Tips for Working with Track Saw

- Engage the safety trigger if your saw has one before starting it. This prevents accidental beginnings.

- To prevent splintering or tear-out at the start and conclusion of the cut, use support blocks on both sides of the track.

- Strongly adhere to the manufacturer’s instructions and recommendations in the user manual in order to safe and clear cuttings.

Tips for Working with Table Saw

- Wear safety gear.

- Make sure to avoid freehand cutting and to guide the workpiece, always use the fence or miter gauge.

- While using the table saw, focus on your job and avoid distractions. Maintain your hands and mind on the task at hand.

Can a Track Saw Replace a Table Saw?

Although a track saw can perform many tasks, in some situations it may not be able to completely replace a table saw.

Consider the following aspects when deciding whether a track saw can replace a table saw for your specific needs

- Versatility

- Portability and Jobsite Use

- Precision of Cuts

- Breaking down large sheet goods

- Space limitation

However, the choice between the two is determined by your individual woodworking requirements and budget.

Some woodworkers even keep both tools in their toolbox to optimize versatility.

That’s it, folks! Now you have a crystal clear knowledge about track saw vs table saw in detail with their features, uses, and key differences.

So, let’s answer some frequently asked questions.

FAQs

What are the primary differences between a track saw and a table saw?

A track saw is mobile and glides over material with the help of a track, ideal for large sheet goods and plunge cuts. In contrast, a table saw is stationary, with material pushed through its blade, perfect for repeated rip cuts and narrower stock.

Is a track saw safer than a table saw?

Yes, track saws are generally considered safer than table saws due to their design and method of operation.

Can a track saw replace a table saw in a workshop?

While track saws offer advantages like splinter-free cuts and easy handling of large sheet goods, they can’t fully replace the versatility and repeatability of cuts offered by table saws.

Which saw is better for making mitered or angled cuts on large materials?

Track saws are preferable for lengthy, slanted cuts across large materials, offering precision and ease.

Are there limitations to the width of cuts possible on a table saw?

Table saws have a limitation based on the distance between the blade and the fence, while track saws can cut wider materials without such constraints.

How do dust management capabilities compare between the two saws?

Table saws typically have superior dust management systems, while track saws allow for vacuum attachments to keep the workspace clean.

Which tool is more portable?

Track saws are more mobile and easier to transport compared to stationary table saws.

Can you make plunge cuts with a table saw?

No, plunge cuts are specific to track saws, where the blade can be lowered into the material at any point.

What type of saw is better for repeated rip cuts?

Table saws excel at repeated rip cuts, allowing for consistent widths without needing to reset the guide after each cut.

Are there different types of track saws available?

Yes, there are various track saws, including standard track saws, cordless track saws, and circular saws that can be converted with a track guide rail.

Did I cover all you wanted to know about: Track saw vs Table saw

In this article, I’ve deeply discussed track saw vs table saw in detail with their key differences, properties, and tips based on experts’ opinions.

A track saw is portable and designed for precision cuts on large sheet goods, while a table saw is stationary and ideal for repeated rip cuts. Track saws excel in plunge cuts and handling large materials, whereas table saws offer more versatility for various woodworking tasks.

Furthermore, I’ve answered some frequently asked questions as well.

I hope this post helped to clarify all the differences you wanted to know about between a track saw and a table saw. Happy woodworking with these two amazing power tools!