Ready to master the art of applying Bulls Eye Shellac for a stunning finish? Ever wondered how professionals achieve that flawless gloss? Let’s dive right into the 7 easy steps!

Shellac is a natural finish that is using for thousands of years. It gives a warm color finish to your woodworks while enhancing the natural wood grain.

Bulls Eye Shellac is a popular Shellac product that is widely used for many wood finishing purposes.

Since I got friends and wood-finishing professionals working closely with Rust-Oleum Corporation, I got an opportunity to know about the perfect way of using Bulls Eye Shellac.

So let’s discuss, How to apply Bulls Eye Shellac?

To apply Bulls Eye Shellac, stir well and apply it evenly on the wood surface with a natural bristle brush, following the grain. After drying for an hour, sand lightly, remove dust, and apply a second coat. Repeat the process for additional coats. Clean up with alcohol or ammonia and water.

But there’s more to know about the best way to apply Bulls Eye Shellac.

So, in this article, I’ll explore how to apply Bulls Eye Shellac in very simple ways, the number of coats you should use, and how to sand between coats as well.

Furthermore, I’ll answer some frequently asked questions regarding the application of Bulls Eye Shellac with its properties and qualities.

Just keep reading!

What Is the Best Way To Apply Bulls Eye Shellac?

Bulls Eye Shellac gives a naturally enhanced mid-gloss finish to your woodwork and furniture while giving a super smooth finish.

Most importantly, Bulls Eye Shellac won’t dark over the years, is non-toxic, and is easy to repair wood damage.

There’re main two methods of applying Bulls Eye Shellac. They are,

- Brushing on Shellac

- Padding on Shellac

Brushing is the common method of applying Bulls Eye Shellac. The application is pretty much simple and easy to use.

The Supplies You Will Need to Bulls Eye Shellac

- Bulls Eye Shellac

- Fine bristled brush

- Clean glass jar

- Lint-free polishing cloth

- Denatured alcohol

- 400 grit sandpaper

- 200 grit sandpaper

- Cotton cloth rag

- Measuring cup

Grab the above supplies from quality manufacturers and start the application process.

How To Apply Bulls Eye Shellac?

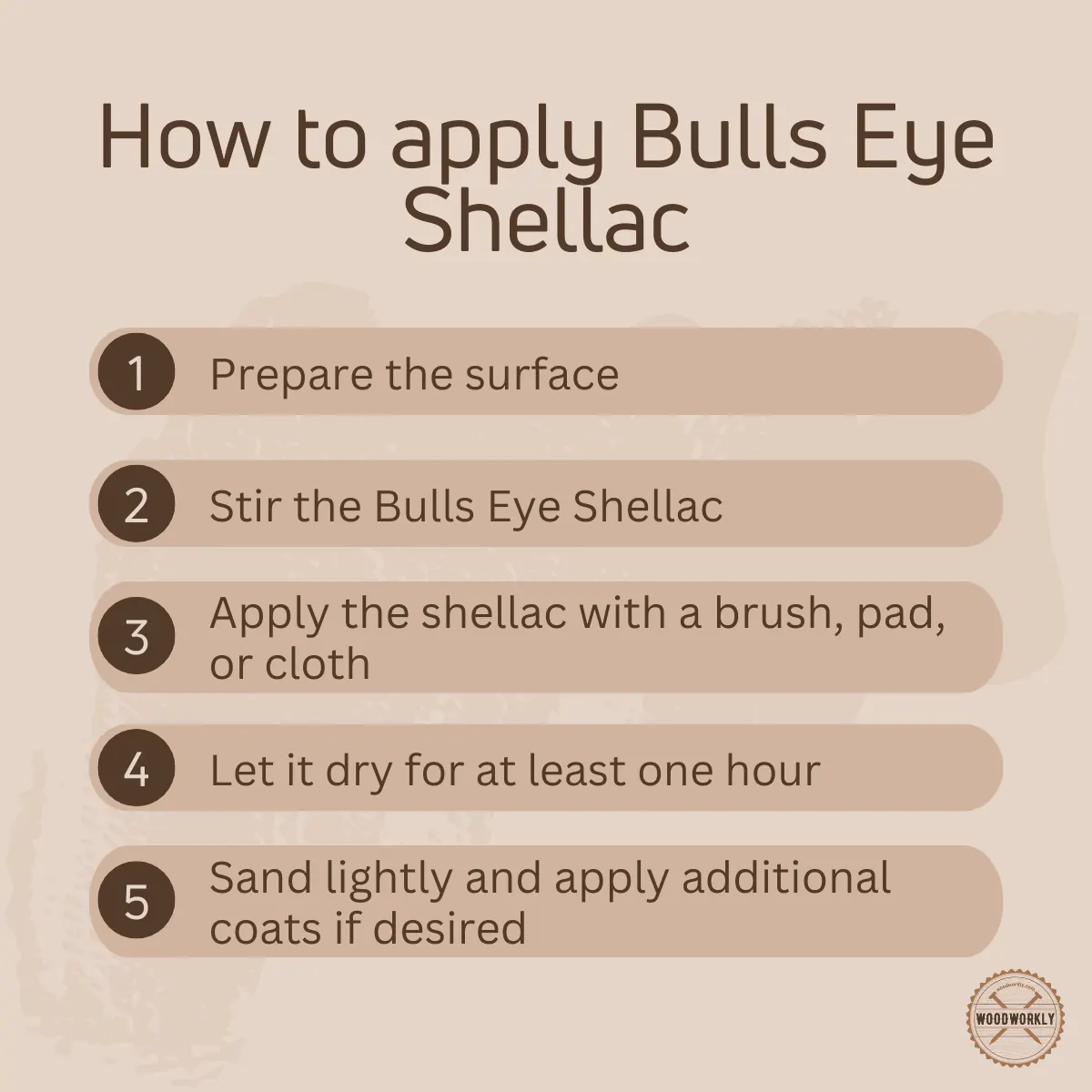

Here’s the procedure of applying Bulls Eye Shellac,

- Prepare and thin Bulls Eye Shellac

- Test Bulls Eye Shellac

- Surface preparation

- Apply Bulls Eye Shellac

- Let it dry completely

- Buff with sandpaper

- Recoat and let it dry

So, let’s discuss each of the above steps in detail to get a clear idea of applying Bulls Eye Shellac.

1. Prepare and Thin Bulls Eye Shellac

Usually, Bulls Eye Shellac comes in a high Shellac ratio (3 – 4 pound cuts) which can result in thick coats after the application.

As I have noticed thick coats of Shellac won’t dry quickly and if you couldn’t let it dry properly, that’ll cause surface blotchiness and streaks.

Therefore, I highly recommend you apply thin coats of Shellac to get the ideal finish.

To achieve thin coats of Shellac with a super smooth finish, Bulls Eye Shellac should be thinned.

To do that, take a glass jar and pour a sufficient amount of Bulls Eye Shellac. Then pour denatured alcohol using a measuring cup and stir the mixture slowly to thin out Bulls Eye Shellac.

The ratio of mixing Bulls Eye Shellac to denatured alcohol should be 1:4. That means 1 part of Shellac to 4 parts of denatured alcohol.

The glass jar should clean well with warm soapy water before adding Shellac. Otherwise, the reaction will be contaminated and you won’t get the best results out of it.

2. Test Bulls Eye Shellac

After mixing Shellac and denatured alcohol, never apply it directly to your main project without testing with a piece of scrap wood.

Once you have thinned Bulls Eye Shellac, take a small amount to a dry cloth, and apply to scrap wood.

After the application test wait until Shellac dries to see the true colors.

If the resulting Shellac layer has no imperfections, no bubbles, or color variations, congratulations, you have successfully thinned the Bulls Eye Shellac.

- If you feel the Shellac layer is too thin, add Shellac a little more to the mixture, stir, and do the test again.

- If you notice the Shellac layer is still too rough, add denatured alcohol a little more to the mixture, stir and do the test again.

Once you’re done with testing and making some adjustments to the mixture, you’ll get Bulls Eye Shellac that is perfect for your wood finishing application.

Now keep the mixture in a dust-free environment until we prepare the surface to take the Shellac well.

3. Surface Preparation

Surface preparation is important to remove contamination that interferes with Bulls Eye Shellac.

The surface should be, Clean, free of dust, dirt, mildew, grime, grease, wax, oil, chalky material, and adhesives.

Here’s how you should clean bare woods and finished surfaces before applying Bulls Eye Shellac.

For Bare Woods,

- Clean the wood surface with household ammonia and water solution.

- Let the woo dry completely

- Sand bare wood with 200 grit sandpaper or sanding bock to remove weathered wood fibers and smoothen the surface.

- Sanding dust should wipe off or vacuum

- Fill holes and scratch marks with wood filler that matches exactly the wood color.

For Finished Woods,

- Add denatured alcohol and or mineral spirit and dissolve them.

- Once it softens, remove the peel and the coatings.

- Let it dry completely

- Sand the remaining stains and paint coatings with 200-grit sandpaper to smoothen up the surface.

- Wipe off sand dust

Never use TSP as a cleaner, because it harms the wood.

Once you’re done with surface preparation, you’re free to move on to the application process of Bulls Eye Shellac.

4. Apply Bulls Eye Shellac

Shellac can be applied using a fine bristled brush or cotton cloth rag. The common method is applying Bulls Eye Shellac using a brush.

But here we’re going to apply Bulls Eye Shellac with both brush and clean cloth to do the job precisely.

In my experience, use a clean cloth rag to apply Bulls Eye Shellac over large areas and use a brush to apply Shellac for tight edges and corners.

Dip a clean cloth rag into the mixture of Bulls Eye Shellac and apply all over the large wood surface without missing any spots along the direction of the wood grain.

Apply with even strokes and take a small amount of Shellac to get a thin layer of coating. Because thin coats dry faster and make less trouble without streaks and blotches.

Then grab the brush and take the little amount from the Bulls Eye Shellac mixture and apply for tight edges and corners with minimal brush strokes.

If you have noticed, the surface getting tacky during the application process, ignore that. It will naturally soak in.

5. Let the Coat Dry Completely

After the application of Bulls Eye Shellac with a clean cloth and brush wait for about 30 minutes before moving on to the next step.

30 minutes of waiting time are well enough because Shellac dries so much faster than most other finishing products.

Plus, the Shellac-denatured alcohol mixture dries so much faster than the regular Bulls Eye Shellac as well.

Because of this fast-drying capability of Shellac, you can apply more coatings in less amount of time. But on the other hand, you should work quickly during the application to avoid issues.

6. Buff with Sandpaper

After the first layer of Bulls Eye Shellac is completely dried, lightly sand the whole surface with 400 grit or fine sandpaper to remove raised wood grain, blotches, and uneven Shellac globes.

In between coats, sanding with 400 grit sandpaper is a must.

You can identify whether your previous coating is completely dried or not by getting a white color powder during sanding. Gummed-up sandpaper indicates that your previous coat is still wet.

After sanding, wipe off the white residue and sand dust with a cloth rag or vacuum the surface.

Apart from using 400 grit sandpaper, you can use a piece of superfine steel wool as well.

Buffing with sandpaper between the coats of Bulls Eye Shellac results super smooth surface.

Once you’re done with sanding try to identify areas that don’t reflect light as much as other areas.

Those non-reflective areas aren’t covered properly and make sure to pay special attention to those areas during the next coat.

7. Recoat and Let It Dry

Applying 3 to 4 coats of Bulls Eye Shellac is ideal to achieve a super smooth finish as you wish. Make sure to do light sanding between each coat.

Once you get an even, smooth surface with no imperfections, no bubbles, or color variations, no drips or streaks you can stop the application process and let it dry completely.

After the last coat of Bulls Eye Shellac, you can skip the sanding part to keep the surface with a glossy look.

Because once the white residue is gone with light sanding you won’t get the nice glossy appearance.

As you apply coats, you’ll notice the surface is getting less thirsty, and make sure not to apply final coats too heavy because they dry so quickly.

In the end, some people like to wax the surface to a nice feeling when touched.

But make sure not to apply wax until the final coat of Bulls Eye Shellac is completely dry.

How To Repair Shellac Finish that Damaged During the Process?

If your Shellac coatings get damaged during the application due to dings or scratches you can easily repair them. Dig a clean cloth rag in alcohol and gently rub it in the damaged area in a circular motion to remove the damaged Shellac layer.

Then do the light sanding with 400 grit sandpaper and recoat the area once or twice with Bulls Eye Shellac.

Fine scratches can be repaired by fine brush in low areas with Bulls Eye Shellac and buffing smoothly with a fine-grit sandpaper.

So, that is all you should know about how to apply Bulls Eye Shellac in easy steps.

Let’s answer some frequently asked questions about Bulls Eye Shellac to make fewer issues during the application process.

How Many Coats Of Shellac Should I Use?

Usually, 3 – 4 coats of Shellac are ideal to get an even, super smooth surface. Shellac coatings work as a protective layer that seals the wood completely with 3- 4 coats.

But this can vary according to the type of application and wood.

If the wood takes Shellac well, you’ll notice a difference even after the application of the first coat.

But it doesn’t take Shellac well you won’t notice any difference even after the application of 3 -4 coats.

Some woods need a higher number of coats because of their wood fiber structure and porosity.

First coat of Shellac seals and protect the wood and the second coat of Shellac gives it enough space to sand, level, and recoat.

Is Zinsser Bulls Eye Shellac Dewaxed?

Zinsser Bulls Eye Shellac is not dewaxed. It has natural wax substances that react with oil-based polyurethane and water-based finishes.

But there is Zinsser Bulls Eye dewax Shellac that is free from wax. The wax is removed manually. But the regular Bulls Eye Shellac contains wax.

- Zinsser Bulls Eye Seal coat is dewaxed

- Zinsser Bulls Eye Shellac contain wax

The product that doesn’t contain wax(dewaxed) is used as an undercoat or finishing coat.

But the product that contains wax is used only as a finishing coat.

To check whether the Shellac product is dewaxed, better to check the label before purchasing. Because nowadays most Shellac manufacturers release products that are waxed and dewaxed.

Shellac is able to apply over stained or painted surfaces as well.

Is Zinsser Bulls Eye Shellac Oil-Based?

Zinsser Bulls Eye Shellac is alcohol-based. It has Shellac, denatured alcohol, ethanol, and water as substances.

Because of being alcohol-based, Zinsser Bulls Eye can be thinned with denatured alcohol.

Self-Life of Bulls Eye Shellac

Bulls Eye Shellac has a low shelf life of 3 years. However, this is an estimated value and it can be decreased if you haven’t stored Shellac can in a temperature-regulated environment.

If the Shellac can is placed in an air-free environment with controlled temperature and humidity, it can live much longer than 3 years.

Drying Time of Bulls Eye Shellac

Under 70F (210C) and 50% of relative humidity drying times of Bulls Eye Shellac are as follows,

- The first coat of Bulls Eye Shellac should let dry for about 30 minutes.

- The drying time of the Shellac recoats is about 1 hour.

- The full curing time of Bulls Eye Shellac is around 24 hours.

Above estimated drying times can be varied along with the temperature fluctuations and humidity levels.

That’s it, folks! Now you know everything you need to know about, how to apply Bulls Eye Shellac basically on any application.

If you need to know more information about Bulls Eye Shellac, contact Rust-Oleum

Let’s answer some frequently asked questions.

FAQs

Can I apply Bulls Eye Shellac on any existing wood finish?

Yes, Bulls Eye Shellac can be applied over soundly adhered existing furniture finishes, including lacquer, polyurethane, and varnish.

What’s the ideal way to apply Bulls Eye Shellac?

Bulls Eye Shellac can be applied using a brush, pad, or lint-free wiping cloth, with multiple thin coats often producing a better finish than a single thick one.

What is the coverage rate for Bulls Eye Shellac?

One gallon of Bulls Eye Shellac can approximately cover 400 to 600 square feet, though this may vary depending on surface porosity and application method.

How should I clean up after applying Bulls Eye Shellac?

Clean up tools and brushes with denatured alcohol or a solution of household ammonia and water. For dried product, soak tools overnight in the same solutions.

Is Bulls Eye Shellac toxic?

No, once dried, Bulls Eye Shellac is non-toxic and hypoallergenic, making it safe for use on children’s toys, craft items, and furniture.

Can I apply Bulls Eye Shellac in colder or warmer temperatures?

Warmer temperatures can accelerate and colder temperatures can prolong the drying time. The product is not recommended for use when the relative humidity is greater than 85% or the temperature is within 10º of the dew point.

Is Bulls Eye Shellac durable for floor surfaces?

While it can be used on floors, shellac is not as durable or scratch-resistant as other finishes specifically formulated for floor surfaces, such as polyurethane.

Is Bulls Eye Shellac flammable?

Yes, Bulls Eye Shellac is flammable as it contains alcohol. Always use it with adequate ventilation and keep it away from heat, sparks, and flames.

Did I cover all you wanted to know about: How To Apply Bulls Eye Shellac?

In this article, I have deeply discussed how to apply Bulls Eye Shellac in 7 simple steps.

This detailed guide is important for all woodworkers that are curious about applying Shellac to their woodworking projects.

To apply Bulls Eye Shellac, first, stir well and apply light coats of Bulls Eye Shellac with a brush, pad, or lint-free wiping cloth and let it dry for about 1 hour. Then sand with 400 or finer grit sandpaper between each coat while wiping the dust away. Recoat until you achieve a super smooth finish.

Bulls Eye Shellac should thin with denatured alcohol before applying to get an even, nice, and super smooth finish.

It is a 100% natural product with super-fast drying time, is non-toxic, has no yellowing with age and so many other great qualities.

Hope you have gained good knowledge about how to apply Bulls Eye Shellac accurately without making any issues.

This same procedure can be applied to other Shellac products as well. Practice it with scrap wood first and then for the big one.

Happy woodworking!