Ever marveled at a beautifully curved wooden piece and wondered ‘How do they bend thick wood like that?’ Well, brace yourself for an enlightening journey into the craftsmanship behind bending thick wood!

Bending thick wood can be challenging because the bending technique can differ according to the thickness and the type of wood species.

Plus, it needs a lot of practice and patience to master the bending skills.

I was curious about bending thick wood boards for my projects and did deep research about it and found some useful information from my own experience over the past few years.

Here’s what I know about, How to bend thick wood?

To bend thick wood, use steam bending, kerf-cutting, or laminating. For steam bending, expose the wood to steam, then bend it around a form. In kerf-cutting, make multiple incisions with a saw to bend the wood. Laminating involves gluing thin layers of wood around a form to create a curve.

But that’s just a quick snapshot of the question.

So, in this article, I’ll explore how to bend thick wood with all possible techniques you can use for the job. I’ll discuss each technique in detail with their pros and cons.

Furthermore, I’ll answer some frequently asked questions as well.

Let’s jump in!

Can You Bend Thick Wood?

Yes, you can bend thick wood with no issues with specific techniques. You need to know how to handle and bend wood properly without cracking or breaking the wood in the process.

The characteristics of the wood you selected, and the appropriate bending method are the keys to success in this project.

Thick wood, depside its stiffness can be incredibly flexible under the right conditions.

One would not anticipate a tough slab of wood to be pliable, thus it is quite amazing to see it change into a material that can be bent into attractive curves and arcs.

Different types of wood need different bending techniques. For example, hardwoods like ash, oak, and hickory are great for steam bending since they have inherent flexibility and grain structure.

Ash, oak, and hickory woods possess a good balance of strength and flexibility, which makes them excellent for bending without cracking or splitting the wood.

But there’re some other types of wood as well which are great for bending. With the right technique, almost any type of wood can be pliable.

Let’s see what are the main techniques that can be used to bend thick wood.

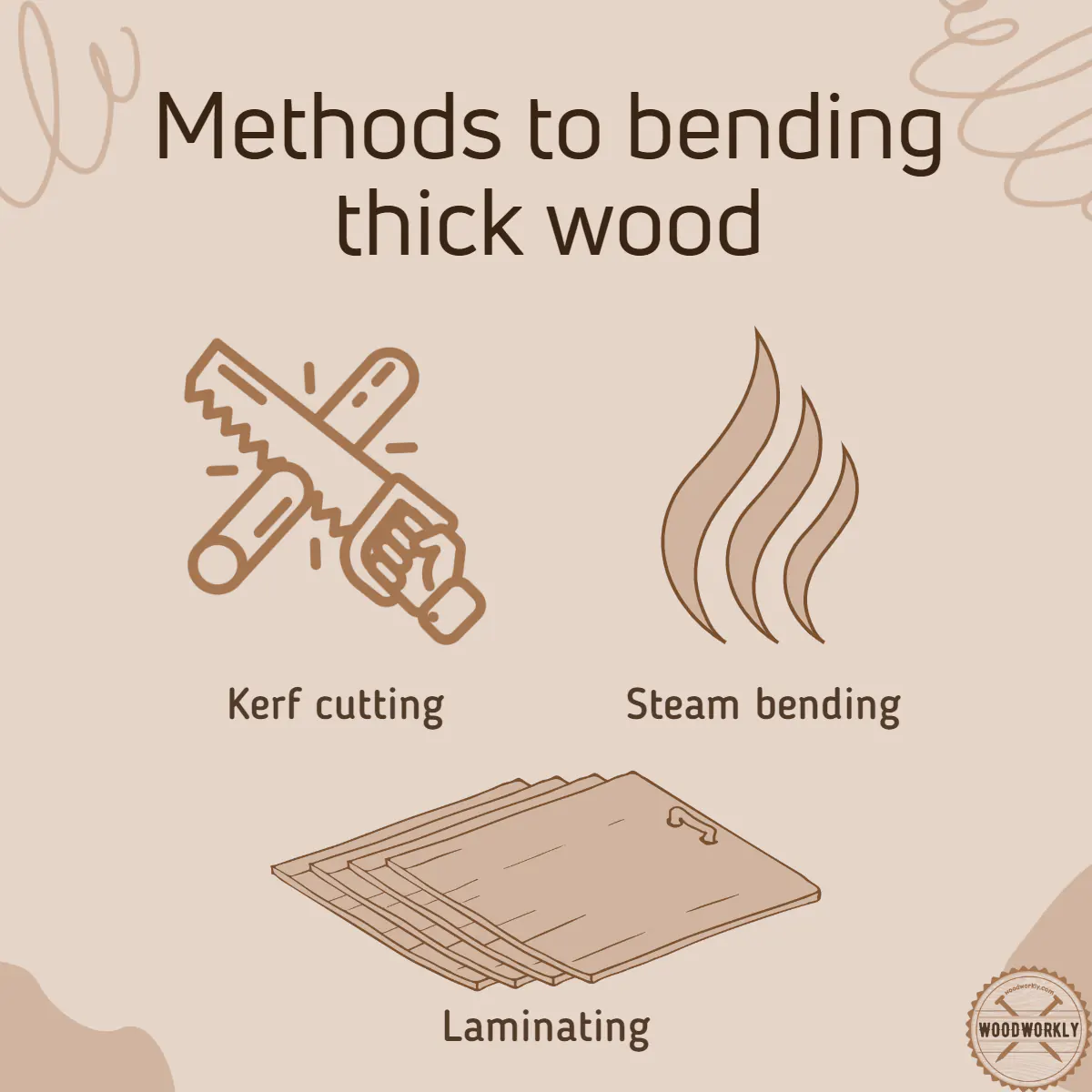

Techniques for Bending Thick Wood

The best methods for bending thick wood are laminating thin layers together, steam bending, and kerf cutting.

Each of those thick wood bending techniques has its own pros and cons.

The choice of the right technique for your project depends on the type of wood you’re working with, its thickness, and the degree of bend you want.

Let’s discuss each of those thick wood bending techniques in brief.

1. Laminating

Laminating is a wood bending process where thin layers of wood splices are glued together while being clamped in a bending form.

Over time, the glue will be dried, and the layers will retain the shape of the form resulting in a sturdy piece of bent wood.

This method is great for creating complex or gentle curves with thick wood, but it is time-consuming due to the drying time of the glue.

2. Steam Bending

Steam bending is one of the best methods to bend thick wood. in this method, the wood is placed in a steam box, where hot steam makes the wood fibers pliable.

After steamed, the wood is bent carefully by applying force little by little into shape using a jig.

The steam bending method is popular among furniture makers and woodworkers to handle thicker wood pieces.

You can make large, smooth bends with the steam bending method.

3. Kerf Cutting

Kerf cutting is also an ingenious method to bend thick wood. here we’ll make a series of cuts (kerfs) along the back of the wood piece. These kerfs make the wood flexible enough to bend.

The Kerf cutting method is clean, and quick, and allows more control over the bending process.

But the cuts are visible on one side after making cuts which can affect the look of the woodworking project especially when the back of the wood piece is not hidden in the final product.

Speaking from my experience, each of these methods has its charm and challenges.

Laminating feels like crafting a sculpture, bit by bit, layer by layer.

Steam bending, on the other hand, feels like performing magic, turning seemingly inflexible into flexible.

Kerf cutting is more like a neat engineering trick that never ceases to amaze.

As a woodworker, there’s a deep sense of satisfaction that comes with mastering these techniques and the unique results they offer.

It takes practice, patience, and a bit of trial and error, but the results are often more than worth it!

Let’s see how thick your wood should be able to bend for each of the above techniques. This helps you to decide the best technique for your wood preference.

How Thick to Bend Wood?

Determining the right thickness for your project is important to bend the wood without making any cracks or splits.

The answer to this question isn’t one size fits all. The ideal thickness of the wood for bending depends on the type of wood, the bending technique you’re using, and the specifics of your project.

Wood Thickness and Flexibility

When bending wood, the thickness of the wood plays a key role in its flexibility.

Generally, thinner wood pieces are more flexible, and they are easy to bend while thick wood pieces are less flexible, and can be challenging to bend without forming cracks.

But with proper technique, you can bend thicker woods like butter with no issues at all.

Let’s look at how the thickness can affect different bending techniques.

Laminating Technique and Wood Thickness

In the laminating method, the thickness of each wood layer you’re going to glue together matters.

Mostly, thin wood strips around 1/6 to 1/8 inch thick are great for laminating technique.

In laminating technique, thinner wood strips are easier to bend around the form and they’ll dry quicker than thick wood.

Steam Bending Technique and Wood Thickness

In steam bending, the thickness of the wood is critical.

According to my personal experience, steaming can effectively bend wood that’s up to 1 inch thick.

After steaming for about an hour the wood becomes pliable and able to bend into your desired shape.

Generally thicker wood needs to be steamed for more than an hour and multiple steaming sessions to become pliable enough for bending.

Kerf Cutting Technique and Wood Thickness

In kerf cutting, the thickness of the wood is not an essential thing to consider since you’re physically altering the wood to make it more bendable.

Therefore, the kerf-cutting technique is the best bending method for thick wood since it allows you to bend considerably thicker wood than other methods.

However, please be careful about the depth of the kerfs you make and ensure not to cut through the front of the wood since the cuts will be visible outside.

Choosing the Right Thickness for Your Bending Project

Choosing the right thickness for your bending project depends on the bend radius you’re going to make and the type of wood you’re going to use.

As a rule of thumb, the tighter the desired curve, the thinner the wood needs to be.

Plus, keep in mind that wood gets stronger when it is bent, so you might not need as much thickness as you first thought.

Over the years, I’ve experimented with various wood thicknesses and bending techniques.

There’s always been something exhilarating about bending a thick piece of hardwood using steam. It feels like taming a stubborn piece of nature.

With laminating, the control you have with the thin strips is always satisfying, like molding clay into a sculpture.

Kerf cutting, on the other hand, gives a certain thrill, especially when dealing with thick pieces that defy all traditional bending methods.

Determining how thick your wood should be for bending largely depends on your project and the method you’re planning to use.

Don’t be afraid to experiment and test out different thicknesses and techniques.

Now let’s begin to talk about the thick wood bending procedures in detail by taking all 3 bending techniques.

How to Bend Thick Wood?

Bending thick wood might seem like an intimidating task. But with a little bit of patience, some careful steps, and the right techniques, it’s achievable.

Here’re the best methods to bend thick wood,

- Laminating

- Steam bending

- Kerf cutting

Here, we’ll delve into all three methods discussing the procedures, materials needed, and their pros and cons.

Laminating Thick Wood

Laminating is an ingenious way to bend thick wood. It involves gluing together several thin layers or strips of wood, then clamping them around a form or a mold.

As the glue dries, it bonds the strips together, taking on the shape of the mold.

Materials Needed

- Thin strips of wood

- Wood glue

- Clamps

- A form or mold in the desired shape

Laminated Bending Procedure

- Preparation: Start by cutting your wood into thin strips. Aim for about 1/16 to 1/8 inch thick.

- Applying Glue: Apply a generous amount of wood glue on one side of each strip, making sure to cover the whole surface.

- Clamping: Stack the glued strips on top of each other and clamp them onto your form or mold.

- Bend the wood: Apply even pressure along the curve to ensure a smooth bend.

- Drying: Leave the wood to dry. This could take several hours or even overnight, depending on the type of wood and glue used.

- Finishing Up: Once dried, remove the clamps and the form. The wood should maintain the shape of the form.

Pros and Cons of Bending Thick Wood by Laminating

| Pros | Cons |

| Allows for precise control of the curve | Time-consuming |

| No specialized equipment needed | Might require a lot of clamps |

Steam Bending Thick Wood

Steam bending is an age-old practice used by many cultures. This technique softens the wood fibers by exposing them to steam, making them pliable enough to bend.

Materials Needed

- Wood of up to 1-inch thickness

- Steam box or large PVC pipe

- Steam source (a Wagner Steamer, for instance)

- Clamps

- Form or mold in the desired shape

Steam Bending Procedure

- Prepare the Steam Box: If you don’t have a steam box, a large PVC pipe can do the trick. Insert some dowels to allow steam to reach all sides of the wood.

- Soaking the Wood: Although not always necessary, soaking the wood can help the steaming process.

- Steaming the Wood: Place your wood in the steam box and let it steam for about an hour per inch of thickness.

- Bending the Wood: Immediately after steaming, bend the wood around your form or mold using clamps. Be cautious as the wood will be very hot!

- Drying: Let the wood dry while still on the form. This can take a few days.

Building a Steam Box

A steam box can be made from various materials, but plywood is commonly used. If you prefer, a large PVC pipe with caps on both ends can serve as an effective steam box.

Pros and Cons of Bending Thick Wood by Steaming

| Pros | Cons |

| Suitable for thicker woods | Requires a steam box and a steam source |

| Creates strong, long-lasting bends | Can be a slow process |

Kerf-Cutting Thick Wood

Kerf-cutting is an effective method for bending thicker wood. It involves making several cuts (kerfs) on one side of the wood, enabling it to bend.

Materials Needed

- Thick wood

- Miter saw table saw, or radial saw

- Kerf saw blade

- Pencil for marking

Kerf Cutting Procedure

- Marking the wood: Mark the locations where you’ll be making the kerfs on your piece of wood.

- Making the Kerfs: Using your saw, cut the kerfs into the wood, being careful not to cut through to the other side.

- Bending the wood: Carefully bend the wood along the kerf lines.

- Finishing: If desired, you can fill the kerfs with wood glue for added strength.

Pros and Cons of Bending Thick Wood by Kerf Cutting

| Pros | Cons |

| Quick | Requires a miter, table, or radial saw |

| Can bend very thick wood | Only one side of the wood will be presentable |

| No need for steam or heat |

As you can see, bending thick wood can be a journey full of trials and triumphs.

But with the right technique, patience, and a bit of practice, you’ll be able to achieve the perfect bend for your woodworking project.

Congrats folks! Now you know how to bend thick wood using 3 different techniques.

Practice the above methods with scrap wood and select the one that suits you the most according to your purpose.

Now I’m going to share with you some tips that I have learned by bending thick wood with all the methods above.

These tips will make your job a lot easier since I learned them from experience.

Tips for Bending Thick Wood

Follow the below tips to bend your thick wood projects easily without making any mistakes.

Understand the Wood Grain

When it comes to bending wood, it’s crucial to understand the role of the grain.

Wood tends to bend easier along the grain. So, always try to orient your cuts or your bends in a way that follows the wood grain.

Know your Wood Species

Different types of wood react differently to bending. For example, oak and ash are great for steam bending, while pine and cedar are generally more difficult.

Research the properties of your chosen wood species and choose your bending method accordingly.

Patience is Key, Don’t Rush the Process

Whether you’re laminating, steam bending, or kerf-cutting, patience is a virtue. Rushing through the process can lead to mistakes or even wood breakage.

Allow enough time for the glue to dry when laminating and for the wood to steam when using a steam box.

Practice Makes Perfect

Don’t be disheartened if your first few attempts aren’t successful. Wood bending is a skill that takes time to master.

Practice on some scrap wood first until you feel comfortable moving on to your actual project piece.

Safety First

Both steam bending and kerf-cutting come with their own set of safety precautions.

Always handle steam carefully, using heavy gloves and eye protection. When kerf-cutting, ensure you’re following all safety requirements for working with electric saws.

Preserve the Bend

Once you’ve achieved the bend, you’ll want to maintain it. If you’ve used steam bending or laminating, keep the wood clamped to your form until it’s fully dried.

This helps the wood hold its new shape.

Fine-Tune with Heat

If the bend isn’t quite perfect, you can fine-tune it with some gentle heat. A heat gun can be used carefully to soften the wood and allow for minor adjustments.

Remember, bending wood isn’t just about following steps; it’s about understanding the material you’re working with.

The best woodworkers are those who learn to listen to the wood, adapting their techniques to the unique properties of each piece.

Hope you’ve learned everything you wanted to know about, how to bend thick wood properly without breaking.

So, let’s answer some frequently asked questions as well.

FAQs

What is the best type of wood for bending?

Oak and ash are highly recommended for bending, especially when using the steam bending method, due to their pliable nature. However, it’s crucial to remember that every wood species has unique characteristics that can affect the bending process.

Can you bend wood without steam?

Yes, it’s possible to bend wood without steam; this can be accomplished through kerf-cutting or lamination, both of which are effective alternatives to steam bending, and can cater to different types of projects and wood species.

How long should wood be steamed for bending?

Typically, a rule of thumb for steam bending is to steam the wood for one hour per inch of thickness. However, this can vary depending on the wood species and the degree of bend required.

Is it necessary to soak wood before steam bending?

While not always necessary, soaking wood before steam bending can increase its pliability and improve the outcome of the bending process. This can be especially beneficial for harder or thicker pieces of wood.

What are the risks of kerf-cutting?

Kerf-cutting requires precision and comes with a few risks including potential wood breakage if not done carefully. Moreover, one side of the wood will show the cuts, so it might not be suitable for projects where both sides of the wood are visible.

Can all types of wood be kerf-cut?

Nearly all types of wood, even composite materials like particleboard or Masonite, can be kerf-cut. However, the aesthetic and functional results may vary depending on the wood species and its grain structure.

How can I maintain the bent shape of the wood?

After bending, the wood should be clamped to a form and left to dry completely. This will help the wood maintain its new shape. For steam bending or laminating, this drying process is crucial for preserving the bend.

How do you bend a 2×4 wood?

For 2×4 wood, steam bending or kerf-cutting can be effective. For steam bending, you’ll need to steam the wood for an hour per inch of thickness, then bend it around a form. For kerf-cutting, precise cuts are made in the wood with a saw, enabling it to bend.

How do you bend 4×4 wood?

Bending 4×4 wood can be challenging due to its thickness. Steam bending would require an extended steaming time – around 4 hours. Alternatively, kerf-cutting can be used, but it would need to be done carefully to prevent splitting.

Did I cover all you wanted to know about How to Bend Thick Wood?

In this article, I’ve dived deep into finding how to bend thick wood properly without damaging the wood. I’ve shared with you step by step procedure you need to follow with some useful tips to make your bending project succeed.

You can bend thick wood by steam bending, kerf-cutting, and laminating. Steam bending involves heating the wood in a steam box, kerf-cutting requires making precise cuts with a saw, and laminating involves shaping multiple thin layers with glue and a form.

Furthermore, I’ve answered some frequently asked questions as well.

Hope you were able to know all you need to know about how to bend thick wood like a pro!

Practice the methods I provided with scrap wood and make beautiful creations with complex shapes for your furniture.

I enjoyed reading your nice website. I see you offer priceless info. stumbled into this site by chance but I’m sure glad I clicked on that link. You definitely answered all the questions I’ve been dying to answer for some time now. Will definitely come back for more of this.