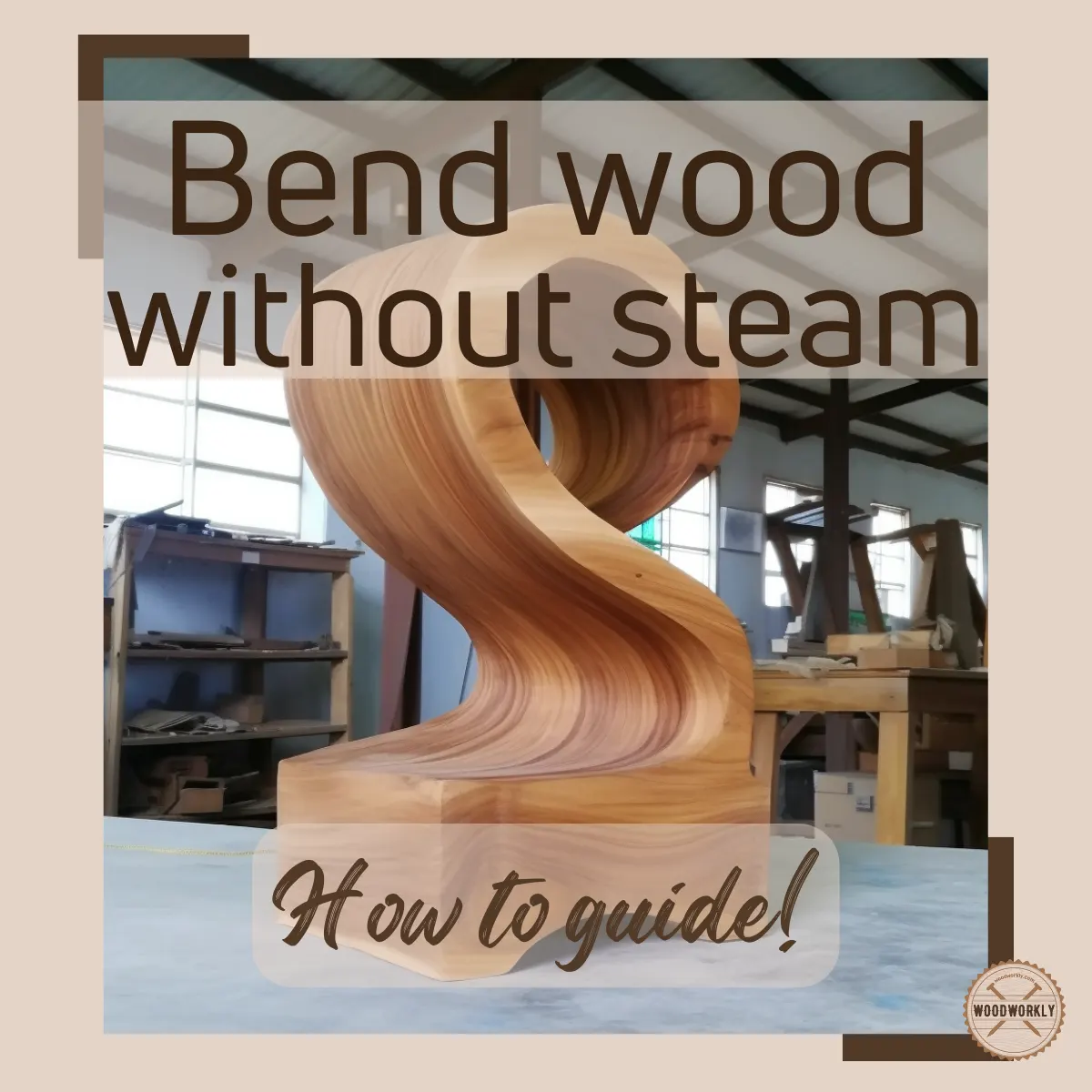

Ever wondered how to bend wood without the traditional steam method? Discover surprisingly simple yet effective techniques that take woodworking to a whole new level! Ready to curve the rules?

The traditional and most useful method of wood bending involves steam. In steam bending the wood fibers soften and made them pliable to achieve new forms and shapes.

But there’re times when the steam bending option is not practical or feasible since you don’t have the necessary equipment or the wood, you’re working with doesn’t respond well to the steam.

Don’t worry I faced the same situation a long time ago and now I have diverse ways of bending wood without steam.

Each technique holds its unique allure and challenge.

So, let’s find out, How to bend wood without steam?

To bend wood without steam, you can use methods such as kerf-cutting, laminated bending, hot pipe bending, or applying chemicals like ammonia. Each technique involves carefully manipulating the wood’s flexibility, often by adding moisture or heat, to achieve the desired shape without causing breakage.

But that’s just the tip of the iceberg!

So, in this article, I’ll explore how to bend wood without steam by explaining the steps you need to follow in each and every method while identifying their properties, pros, and cons.

Furthermore, I’ll answer some frequently asked questions as well.

Let’s jump in!

Can You Bend Wood Without Steam?

Yes, you can bend wood without steam since steam bending can be challenging with some wood types and it requires specialized equipment and a considerable amount of time.

Steam bending is a popular method of bending wood and steam box plays a crucial role in it.

You need to have a keen understanding of how different wood species react to heat and moisture when following the steam bending method.

Who can forget the heartbreak of seeing a beautifully crafted piece crack or split during the steaming process? It’s in these moments that we find ourselves wondering, “Isn’t there another way?”

Don’t worry! there’re many different methods you can try to bend wood without using steam.

So, let’s have a look at them in detail.

Methods to Bend Wood Without Steam

There’re several methods you can try to bend wood without steam. Each method holds a unique charm and offers a solution to a specific challenge in wood bending.

Explore each one of them and select the one that suits you the most.

Here’re the best methods to bend wood without steam,

- Kerf bending

- Laminated bending

- Hot pipe bending

- Using ammonia for bending

- Cold bending

- Bending with vinegar

- Bending with heat guns

- Using a bending iron

- Bending with a bag press

- Bending using a mold and clamps

So, let’s discuss each one of them in detail with their properties, procedures with pros and cons.

1. Kerf Bending Method

Kerf bending method or kerf cutting is an excellent way to bend wood without occurring cracks and splits.

The Kerf bending method means cutting a series of notches along the length of the wood to make it more pliable. Pliable woods are easy to bend.

Plus, it allows for precise control over the bend radius by adjusting the depth and spacing of the kerfs.

Generally, the kerf bending method is best suited for bending plywood or thin, flat pieces of wood.

You only need a table saw, clamps, and wood glue for this method.

The kerfs created in the process must be filled after bending, using a mixture of glue and sawdust. This helps to maintain the structural integrity of the piece.

If the kerf bending method is not properly followed, it can weaken the wood, potentially causing it to crack or break.

Kerf Bending Procedure

- First, you’ll need to cut notches, also known as kerfs, which are about 2/3 of the wood’s thickness. These kerfs should be placed on the curve’s inside you wish to bend.

- Ensure the kerfs are spaced at least 1/2 inch (1.3 cm) apart for even spacing, creating a harmonious pattern along the length of your wood.

- Once the kerfs are cut, it’s time to bend the wood. The magic of this method lies in the simplicity of this step—just compress the wood’s ends.

- Reinforce the bent shape and fill in the kerf gaps by applying a mixture of glue and sawdust to fill in the spaces.

- Wait for the glue to harden, and you’ve got your bent wood piece!

Pros and Cons of the Kerf Bending Method

| Pros | Cons |

| Offers precise control over the bend radius | Improper execution can weaken the wood |

| Enables bending of flat or thin pieces of wood | Potentially leads to cracks or breaks |

| Can be utilized without special tools or setups | Requires additional steps of filling kerfs after bending |

| Allows for complex shapes and bends | Not suitable for thick or dense woods |

| Does not require heat or steam | The final appearance may be impacted by visible kerf marks |

2. Laminated Bending Method

Laminated bending is almost similar to the kerf bending method. but it relies on the concept of making small adjustments to gain a big impact.

The laminated bending method uses adhesives to apply in between thin wood strips. Since multiple layers are glued together, you can make sturdy and strong-bond bent wood pieces with this method.

You can make a wide range of shapes and curves by bending strips over the curves in this method.

Since this is a layering method, it takes some time compared to other methods.

You can achieve promising results by bending wood with the laminated bending method by using quality adhesives and keeping the application very even.

Laminated Bending Procedure

- First, you need to prepare your wood strips. Cut them longer than your final measurement to account for any shortening that might occur during the process.

- Apply a special kind of glue or laminate onto your wood strips.

- Next, place your glued wood onto a form or pattern quickly before the glue sets.

- Secure your wood pieces with clamps and allow the glue to dry as per the manufacturer’s instructions.

- Once dried, cut the ends to match your desired measurements.

Pros and Cons of Laminated Bending

| Pros | Cons |

| Created very sturdy and strong bent wood pieces due to the multiple layers glued together. | Time-consuming because of the layering process. |

| Able to achieve a wide range of curves and shapes, allowing for great versatility in design. | Relies heavily on the quality and even application of adhesive |

| Able to use for a variety of wood types, even those not inherently flexible. | Incorrect cutting or alignment of the strips could lead to structural weaknesses. |

| Need relatively simple tools and does not necessarily require specialized equipment. | Resulting in a heavier end product because of the added weight from the adhesive. |

| The final product has a unique aesthetic because of the layered effect. | The glue lines can be visible in the final product |

3. Hot Pipe Bending Method

The hot pipe bending method is a traditional method of bending wood heating a pine and using it as a form to bend the wood.

The hot pipe bending method is good for thinner strips of wood since they can be easily wrapped around the pipe.

The heat that generates from the pipe makes the wood more pliable and you can easily bend the wood without cracking.

You can get your desired curvature when the wood is slowly worked around the pipe.

You don’t need to have additional material to use this method. just need clamps, adhesive and hot pipe for the bending process.

Hot Pipe Bending Procedure

- First, you need to create a container using an ABS pipe. Cement a cap on one end and ensure the other has a removable cap. ABS pipe is crucial because regular PVC pipe cannot withstand high temperatures.

- Next, mix one part fabric softener with twelve parts water.

- Heat this solution to boiling.

- Insert your wood into the container and pour the hot solution inside.

- Seal the open end.

- Keep the container warm. If you’re lucky to be in a sunny location, placing it in the sun should do the trick. If not, a sunlamp could help.

- Let the wood steep for at least an hour.

- Finally, take out the softened wood from the pipe. You’ll find it more pliable and ready for bending.

- It should hold its new shape well once it cools down.

Pros and Cons of Hot Pipe Bending

| Pros | Cons |

| It is a relatively simple and quick method. | It is not suitable for thicker pieces of wood. |

| No additional materials are required. | It may result in uneven bends. |

| The heat helps the wood to be more flexible. | There is a risk of burning or scorching wood. |

| It allows for small adjustments during bending. | It requires careful attention and skill. |

| Works well for small-scale projects. | It can be time-consuming for larger projects. |

4. Using Ammonia for Bending

Even if it seems a little bit odd, trust me, ammonia is an excellent chemical product for bending wood.

Ammonia bending utilizes anhydrous ammonia to plasticize wood, making it flexible for bending.

The method is widely used in commercial woodworking due to its ability to bend large, thick wood pieces.

Ammonia bending requires the wood to be exposed to ammonia fumes in a closed container, which alters the wood’s cell structure.

After the bending process, the wood retains its new shape as it dries and the ammonia evaporates.

This technique, while powerful, necessitates careful handling and safety precautions due to the toxicity of ammonia.

Ammonia for Bending Procedure

- Ensure you’re in a well-ventilated area and you have the necessary protective equipment.

- Soak the wood in a solution of ammonia. The ammonia softens the fibers, making the wood more pliable.

- After a sufficient soaking time, bend the wood into your desired shape

- Hold the wood in place until it dries.

Pros and Cons of Ammonia Bending

| Pros | Cons |

| Ammonia bending is highly effective for bending large, thick pieces of wood. | Ammonia is a toxic substance and requires careful handling and good ventilation. |

| The process allows for complex and intricate designs. | It can take a significant amount of time for the wood to soak in the ammonia fumes. |

| The bent wood retains its new shape once dried, providing lasting results. | The method can be cost-prohibitive due to the price of anhydrous ammonia. |

| It can be applied to a variety of wood types. | It may darken the color of some types of wood. |

| The technique is a well-established, commercial woodworking method. | Special equipment (like a sealed container and protective gear) is required. |

5. Cold Bending Method

Cold bending requires a lot of patience but gives satisfying results in the end. This method is able to give the wood a desired shape by improving its flexibility while it is in its natural state without heating.

The cold bending method is suitable for thin strips of wood and it is less likely to crack.

You need to have a form or mold to get the desired curve and shape for the wood with right angles.

Overall, the method is a combination of gluing multiple thin strips and bending. Then, glue them together to maintain the form.

Clamps are essential in the cold bending method to keep the wood strips steady while bending to get a steady new shape.

Cold Bending Procedure

- First, select the right type of wood. Softer woods, which have more flexibility, are usually best suited for this method.

- Slowly apply pressure to bend the wood, holding it in place using clamps and a form.

- Allow the wood to adapt to its new shape over time, often several days.

Pros and Cons of Cold Bending

| Pros | Cons |

| Does not require any special equipment like steam boxes or heat sources. | Cold bending may not be suitable for thick pieces of wood as it could lead to cracks. |

| It allows for great precision as the wood is bent slowly and carefully. | This method is time-consuming due to the careful process and drying time needed for glue. |

| This method can yield very strong structures because of the use of multiple layers and glue. | A considerable amount of patience and skill is needed to successfully bend the wood without causing any damage. |

| Cold bending is ideal for creating complex, unique shapes. | Some types of wood may not bend well using this method. |

| The cold bending method is quite safe as it doesn’t involve the use of heat or chemicals. | Without proper clamping and care, the wood may spring back to its original shape. |

6. Bending with Vinegar Method

Yes, you can use household vinegar to bend wood. It is an easy and cost-effective method.

Vinegar makes the wood flexible since it contains softening properties. You need to soak the wood in vinegar for a certain period of time to make it malleable for bending.

You can bend wood soaked with vinegar quickly after raking it out from vinegar and then let the wood dry to get the new form.

The vinegar wood bending method is an environmentally friendly method since it does not require harsh chemicals.

Vinegar contains a weak acid called acetic acid which penetrates the wood and weakens the lignin compound which holds wood fibers together. Therefore, wood becomes flexible and easy to bend.

Bending with Vinegar Procedure

- First, Mix vinegar with an equal part of water.

- Soak your wood in this solution. The acid in the vinegar helps to break down the wood fibers, making it more flexible.

- Once soaked, bend the wood into your desired shape.

- Use a form or mold to help hold the shape until it fully dries.

If you want to know more information about this process, read my latest comprehensive guide about, How to bend wood with vinegar!

Pros and Cons of Bending with Vinegar

| Pros | Cons |

| Vinegar is a readily available substance. | The process can be time-consuming as the wood needs to be soaked for a long period. |

| Environmentally friendly method | Not suitable for all types of wood, particularly those with high natural resistance to bending. |

| Affordable method of bending wood. | The wood might develop an odor from the vinegar. |

| Suitable for small-scale or home projects. | Vinegar may potentially discolor the wood. |

| Vinegar weakens the lignin in the wood, making it easier to bend. | May not yield as precise results as some other methods. |

7. Bending with Heat Guns Method

Bending wood with heat guns is super easy and allows for the precise application of heat to specific areas of wood.

You don’t need to soak the wood or treat the wood with any kind of solution if you have a heat gun. This is why woodworkers love this method.

Heat gun releases the heat quickly which helps to speed up the bending process and you don’t need any substantial setup or preparation materials for this method.

Bending with Heat Gun Procedure

- Use a heat gun to evenly heat the area of the wood you wish to bend.

- Once heated, the wood becomes more malleable, and you can bend it to your desired shape. Be careful not to heat it too much, or you may burn the wood.

- Once in shape, allow the wood to cool, maintaining its new form.

Pros and Cons of Bending Wood with Heat Gun

| Pros | Cons |

| Precise heat application for specific areas | Risk of scorching or burning the wood |

| No need to soak or treat the wood | Requires careful handling and safety measures |

| Quick heat application speeds up the process | Not ideal for large or complex bends |

| Ideal for minor bends or adjustments | The learning curve involved to avoid uneven bends |

| No substantial setup or material preparation required | Can dry out the wood, leading to potential cracking |

8. Bending with Bending Iron

The bending iron method is mostly used for the construction of musical instruments such as violins, guitars, and other items since it is able to make smooth and consistent curves.

Like in the heat gun method, the bending iron method allows you to heat and bend precisely the specific area of the wood to be bent.

Using a Bending Iron often involves a metal pipe or solid iron that is heated either electrically or traditionally with a heat source.

The wood is usually soaked or steamed and then applied to the heated surface of the iron to bend it.

The Bending Iron method requires careful handling and patience to avoid scorching or damaging the wood.

Bending with Bending Iron Procedure

- Heat the bending iron.

- Press the wood against the heated iron.

- Move the wood slowly across the area you wish to bend.

- Once sufficiently heated, you can bend the wood to your desired shape.

Pros and Cons of Bending Wood with Iron

| Pros | Cons |

| Provides precise application of heat to specific areas, allowing for greater control over the bending process. | Risk of scorching or damaging the wood if not handled carefully or if too much heat is applied. |

| Allows the creation of smooth, consistent curves, ideal for musical instruments and fine furniture. | Requires a significant amount of skill and practice to master, making it not as suitable for beginners. |

| Can be used with various heat sources including electricity or traditional heating methods. | The need for a heat source can make this method potentially dangerous if safety precautions are not strictly followed. |

| Suitable for different types of wood, expanding the scope of projects that can be undertaken. | Depending on the heat source, it may not be as energy efficient as other methods. |

| Can be a very effective method for intricate designs. | Requires additional tools like a metal pipe or solid iron, which can increase the overall cost of the woodworking project. |

9. Bending with a Bag Press Method

The bag press method uses vacuum pressure to bend wood which is useful for making complex shapes.

In the bag press method, atmospheric pressure is used to create a clamping force that can press the wood against the mold.

The pressure will distribute evenly all over the wood avoid wood from deforming.

The bag press method is great for making various shapes and is able to use for various sizes of wood.

It does not require heat, steam, or any other treatment method.

Bending Wood with Bag Press Procedure

- The wood to be bent is placed in a bag with a bending form.

- The air is sucked out of the bag, creating a vacuum that presses the wood tightly against the form.

- The wood is left to take the shape of the form.

Pros and Cons of Bending Wood with Bag Press

| Pros | Cons |

| Provides precise application of heat to specific areas, allowing for greater control over the bending process. | Risk of scorching or damaging the wood if not handled carefully or if too much heat is applied. |

| Allows the creation of smooth, consistent curves, ideal for musical instruments and fine furniture. | Requires a significant amount of skill and practice to master, making it not as suitable for beginners. |

| Can be used with various heat sources including electricity or traditional heating methods. | The need for a heat source can make this method potentially dangerous if safety precautions are not strictly followed. |

| Suitable for different types of wood, expanding the scope of projects that can be undertaken. | Depending on the heat source, it may not be as energy-efficient as other methods. |

| Can be a very effective method when other methods are not feasible, especially for intricate designs. | Requires additional tools like a metal pipe or solid iron, which can increase the overall cost of the woodworking project. |

10. Bending Using a Mold and Clamps Method

Bending using clamps and molds helps you to gain precise control over the shape of the bend. Plus, it uses a wooden form or mold which use to clamp the wood.

You can easily get your desired shape with it.

Bending wood using a mold and clamp method is versatile and able to make different sizes and shapes without using heat, steam, or other bending methods.

Clamps are useful to keep the wood steady upon drying and to avoid wood from deforming.

Bending Wood with Mold and Clamps Procedure

- Prepare a mold or form in the shape you want your wood to bend.

- Wet the wood lightly to make it more pliable.

- Carefully bend the wood around the mold using clamps to hold it in place.

- Allow the wood to dry completely, maintaining the shape of the mold.

Pros and Cons of Bending Wood with Mold and Clamps

| Pros | Cons |

| Provides precise application of heat to specific areas, allowing for greater control over the bending process. | Risk of scorching or damaging the wood if not handled carefully or if too much heat is applied. |

| Allows the creation of smooth, consistent curves, ideal for musical instruments and fine furniture. | Requires a significant amount of skill and practice to master, making it not as suitable for beginners. |

| Can be used with various heat sources including electricity or traditional heating methods. | The need for a heat source can make this method potentially dangerous if safety precautions are not strictly followed. |

| Suitable for different types of wood, expanding the scope of projects that can be undertaken. | Depending on the heat source, it may not be as energy-efficient as other methods. |

| Can be a very effective method when other methods are not feasible, especially for intricate designs. | Requires additional tools like a metal pipe or solid iron, which can increase the overall cost of the woodworking project. |

Congrats folks! Now you know all the alternative methods you can use to bend wood without using steam.

Follow the above methods carefully to get promising results.

Now I’m going to share with you some useful tips and tricks which are important when bending wood without steam.

I have learned those tips with experience by working on different woodworking projects for years.

Just keep reading!

Tips for Bending Wood Without Steam

Let’s have a look at some useful tips you can follow to bend wood easily without using steam.

Select the Proper Wood

The flexibility of various types of wood varies.

Ash, oak, and hickory are examples of hardwoods that are often more malleable and suitable for bending.

Although they might need more caution and effort to avoid breaking or cracking, softwoods like pine and spruce can also be bent.

Patience is the Key

Haste causes waste when it comes to bending wood.

Rapidly exerting stress might cause cracks or possibly break the wood.

The better your results will be, the slower and more gradually you may exert pressure.

Moisture Content

In the process of bending wood, moisture is an essential component. Moist wood is more malleable and less likely to crack than dry wood.

To make the wood more malleable, think about employing moisture-inducing techniques like soaking in a vinegar solution or a solution of hot water and fabric softener.

Even Heat Distribution

Applying heat evenly throughout the portion you want to bend is crucial if you’re employing a heating method. The wood may distort or bend unevenly as a result of uneven heating.

Practice Regularly

For wood bending to become second nature, practice is necessary. If your initial attempts don’t produce flawless outcomes, don’t give up. You’ll get better at it the more you practice.

Wear Appropriate Protective Gear

The safety of the project’s participants should always come first. Make sure you are using the appropriate safety gear when bending wood. This could include safety eyewear to shield your eyes from flying wood chips and gloves to protect against heat and splinters.

That’s it, folks! Hope you were able to learn everything you wanted to know about, how to bend wood without steam.

Let’s answer some frequently asked questions as well.

FAQs

What is the best method for bending wood without steam?

There isn’t a “best” method as such, as it often depends on the type of wood, the desired shape, and the tools at your disposal. Techniques such as kerf-cutting, lamination, or using a hot pipe or chemicals like ammonia are all effective, each with its own advantages.

Does bending wood weaken it?

If done correctly, bending wood should not significantly weaken it. However, aggressive bending or improper techniques can lead to cracking or breaking, compromising the wood’s structural integrity.

What’s the role of moisture in bending wood without steam?

Moisture increases the wood’s flexibility, making it less prone to cracking during the bending process. Techniques that don’t use steam often incorporate moisture in some form, like soaking in a vinegar solution or a fabric softener and hot water mixture.

Can I bend dry wood without steam?

Dry wood can be bent without steam, although it may be more challenging as it tends to be more brittle. Moisture-inducing methods or the use of heat can help make dry wood more pliable.

How long does it take to bend wood without steam?

The time it takes to bend wood without steam can vary greatly depending on the method used and the type of wood. Some methods, like lamination, may take several hours or even days, while others like kerf-cutting or hot pipe bending could be completed in a shorter time.

How do I prevent the wood from cracking when bending?

Preventing wood from cracking when bending involves a combination of choosing the right wood, ensuring it’s adequately moist, applying force gradually, and evenly distributing heat if a heat method is used.

What safety measures should I take when bending wood?

Always wear proper protective gear when bending wood, including gloves to protect against heat and splinters, and safety goggles to shield your eyes from wood particles. Also, be mindful when handling chemicals or heated tools.

Did I cover all you wanted to know about How to Bend Wood Without Steam?

In this article, I have widely discussed how to bend wood without steam by taking 10 different methods with step-by-step procedures of each with pros and cons.

Bending wood without steam can be achieved via methods like kerf-cutting, lamination, hot pipe bending, or chemical methods. These techniques manipulate the wood’s natural flexibility, usually with added moisture, heat, or chemicals, to shape it as desired, preventing any damage or breakage.

Furthermore, I’ve answered some frequently asked questions as well.

Hope you were able to learn all you wanted to know about, how to bend wood without steam.

Practice the methods that I’ve learned above with scrap wood before heading into the main project. Select the one that suits you the most and be a pro at it!