Ever struggled with cutting a perfect groove in wood? Learn how a circular saw can make it easy and precise, as we reveal expert tips and tricks below!

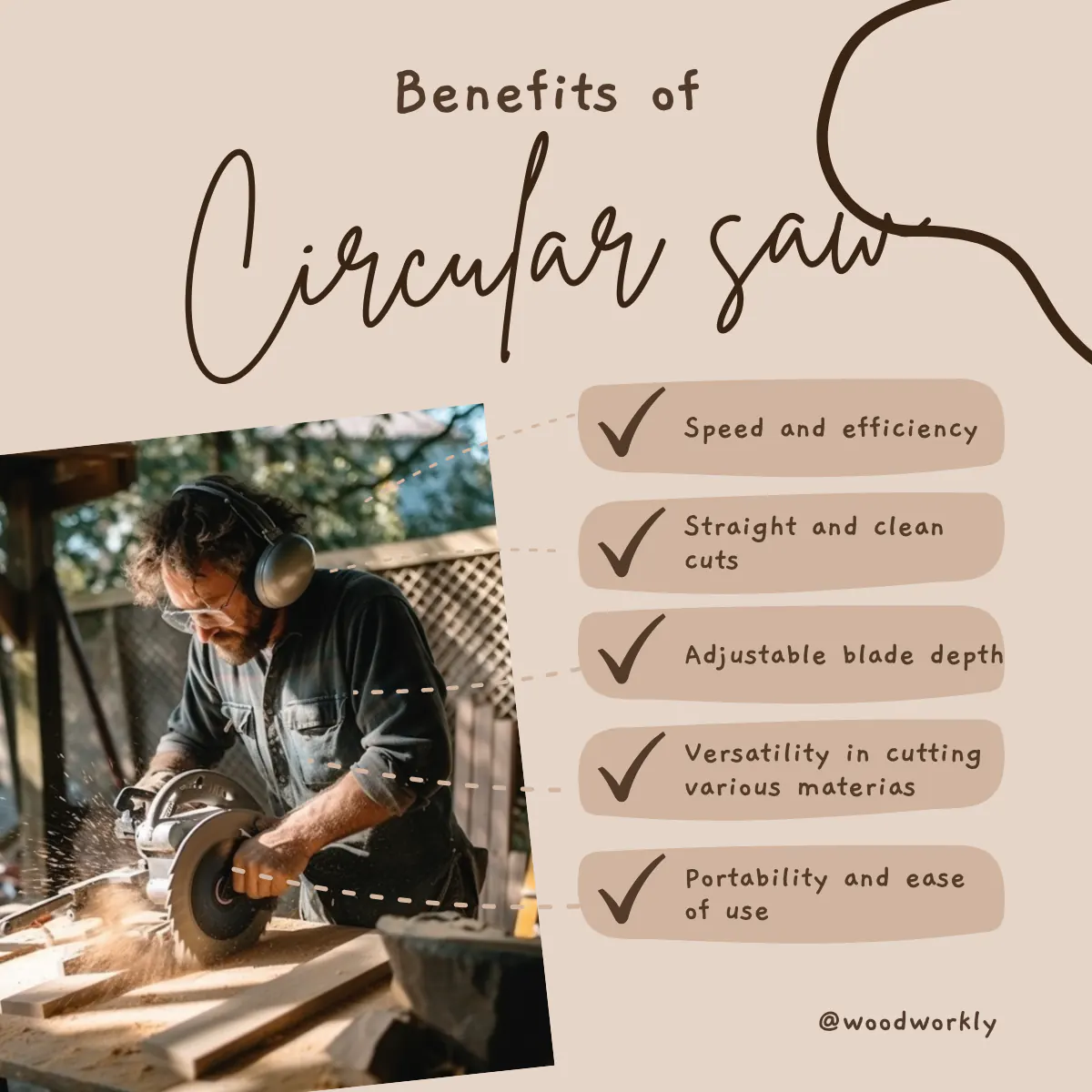

Circular saw is mainly used for cutting large lumbers to make furniture and other woodworking projects.

But have you ever thought of cutting grooves in wood using a circular saw?

I was curious about this since I didn’t have a router in the early days and my father had a circular saw I was curious about cutting grooves for my cabinet using that circular saw.

I did some research and practiced with it for few times. Finally, I was able to cut grooves precisely with the circular saw.

Now with my years of experience and the information I collected, here’s, How to cut a groove in wood with a circular saw?

To cut a groove in wood with a circular saw, mark the groove edges and set the saw blade depth according to the wood thickness. Then, align the saw blade with the outline and cut the groove with the circular saw. Finally, hollow out, clean up and smooth the groove.

But there’s a lot more to know about cutting grooves with the circular saw.

So, in this article, I’ll explore how to cut a groove in wood with a circular saw by describing each and every step in detail.

Plus, I’ll provide you with useful information for suitable blade selection, tips, and tricks to make your cutting process a lot easier.

Furthermore, I’ll answer some frequently asked questions as well.

Let’s jump in!

Can You Cut a Groove with a Circular Saw?

Yes, you can cut a groove with a circular saw without any issue since it is a versatile woodworking machine with lots of useful properties.

Circular saws can use basically for almost any woodworking project. but you need to know how to handle it to make precise cuts and get the best out of it.

Don’t worry! I’ll teach you how to handle the machine so well when cutting grooves without making any mistakes.

Circular saws can handle a variety of cuts including cutting straight lines and curves.

Circular saw is mostly used for making clean, straight cuts in various materials.

But in my experience, it can also be used for cutting curves if we follow the appropriate technique and guidance.

After setting it up properly, you can use a circular saw for rip cuts, crosscuts, bevel cuts, and even miter cuts. Groove cutting is another example of the adaptability of circular saws.

Limitations and Precautions

Apart from its versatility, there’re some limitations and precautions you need to obey when working with circular saws for cutting grooves in the wood. Let’s talk about them,

Safety Concerns

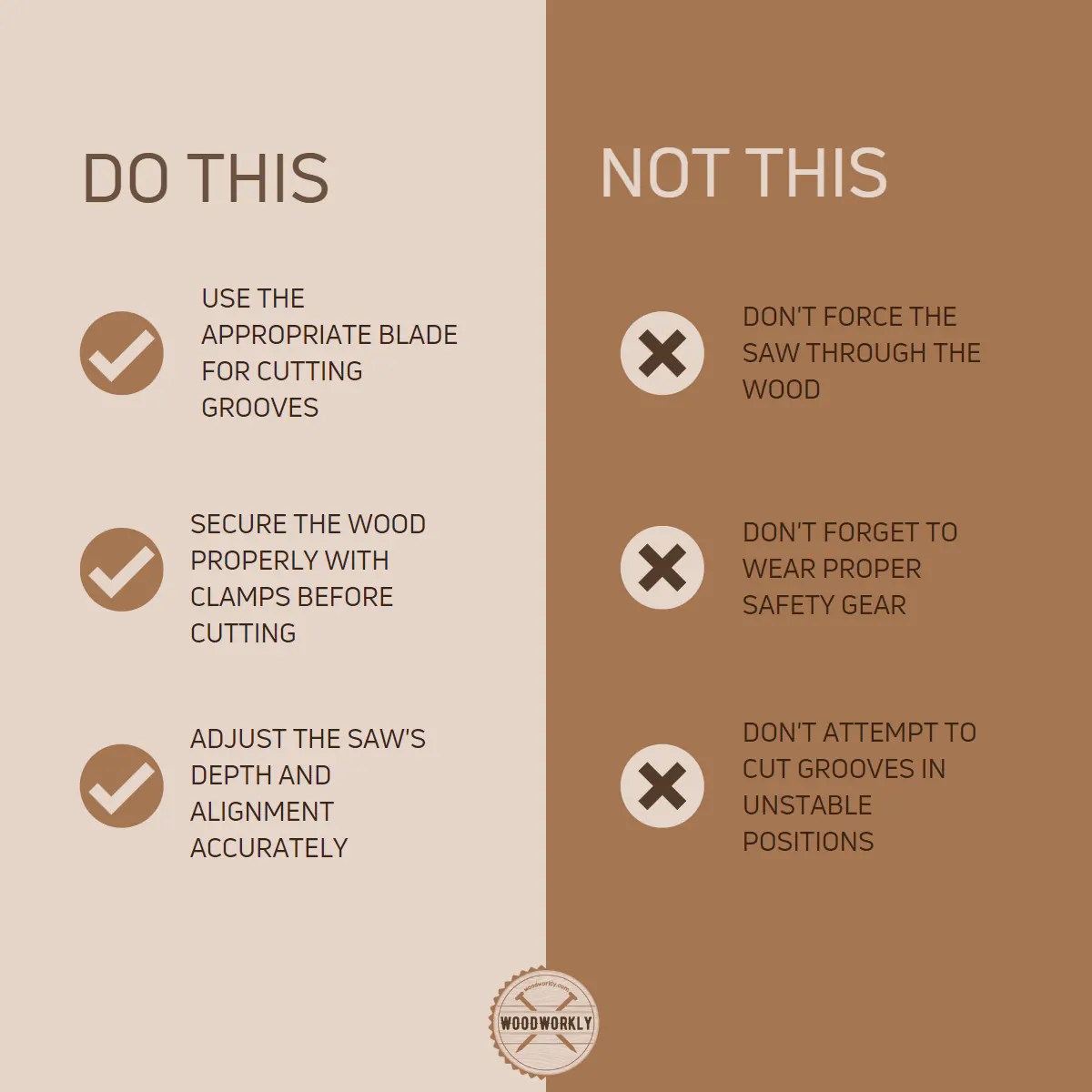

Working with a circular saw is a dangerous task if it is not used properly. You need to follow the manufacturer’s safety guidelines properly.

Plus, use personal protective equipment (PPE) such as safety goggles, ear protection, and gloves.

Make sure your working area is clutter-free, well-lit, and well-ventilated and the wood is clamped securely before cutting.

Proper Technique

You should use a specific technique to cut a groove in wood with a circular saw.

That involves adjusting the blade depth, making a series of parallel cuts, and then cleaning up the groove with a chisel.

It is super important to practice the groove-cutting process first with scrap wood before heading into the actual project to avoid mistakes from happening.

As you can see cutting a groove in wood is a possible thing with a circular saw.

But should always follow the proper technique and safety guidelines to get promising results for various woodworking projects.

Note that, practice is what makes you perfect, so give it a try on scarp wood first until you become a pro at this game before cutting grooves like a champ in your main project.

Factors To Consider When Cutting a Groove in Wood With A Circular Saw

Before starting to cut a groove in wood with a circular saw, there’re several things you need to consider about the wood, and the machine setup to achieve more precise, uniform, and accurate cuts.

Read to know the Best Circular Saw Guide Rails (Tested & Reviewed!)

They are helpful to maintain the safety and efficiency of the projects.

Here’re the factors you need to consider when cutting a groove in wood with a circular saw,

- Wood type and thickness.

- Blade selection.

- Saw the setup and adjustments.

Let’s discuss each of those factors in detail to get the desired outcome.

Wood Type and Thickness

First, you need to understand the characteristic features of the wood type you’re going to cut for achieving the best results.

Hardwoods (oak, maple, etc,)and softwoods (pine, cedar, et,) have different properties that affect how they work with the circular saw.

Usually, hardwoods need slower cutting speeds, while softwoods can be cut faster.

Therefore, make sure to get a good understanding of the properties of the wood material you’re going to cut.

Plus, it’s essential to avoid cutting too deep into the wood to prevent weakening or breaking the wood.

As a rule of thumb, avoid cutting grooves deeper than half the wood’s thickness.

Blade Selection

Circular blades with more teeth produce smoother cuts, while blades with fewer cuts offer faster cutting speeds.

When cutting groves, a blade with a higher tooth count is usually great to achieve clean and smooth edges.

Plus, make sure to consider tooth design such as flat top grind (FTG) or alternate top bevel (ATB), to optimize cutting performance for grooves.

Blade material is also important to know when cutting grooves in wood for excellent performance.

Carbide-tipped blades are great for cutting grooves since they stay sharper longer and are able to handle hardwoods effectively than standard steel blades.

I’ll talk about this blade selection process deeper in the next section since it’s super crucial for precise groove cutting.

Saw Setup and Adjustments

Proper saw setup and adjustments are important to know since they improve the accuracy and the quality of your groove-cutting process.

Adjust the circular saw’s blade depth to match the desired groove depth accurately. This not only ensures a clean cut but also minimizes the risk of kickback and other safety hazards.

Using a rip fence or guide when cutting grooves can help maintain a straight, consistent cut.

Properly align your saw with the marked groove lines and secure the fence or guide to keep the saw on track.

By considering the above factors that I’ve talked about in deep, you’ll be well-equipped to cut grooves in wood with a circular saw confidently.

Understanding the wood type, selecting the appropriate blade, and setting up your saw correctly are all essential aspects of achieving clean, precise grooves for your woodworking projects.

As promised next I’m going to help you with the blade selection process with is super important.

Circular Saw Blade Suitable for Cutting Grooves in Wood

Selecting the right table saw blade for cutting a groove in wood is important for process efficiency.

The type of blade you need to use for a circular saw depends on your purpose and the wood type you’re working with.

Types Of Circular Blades

There’re many different types of circular saw blades available for different woodworking projects.

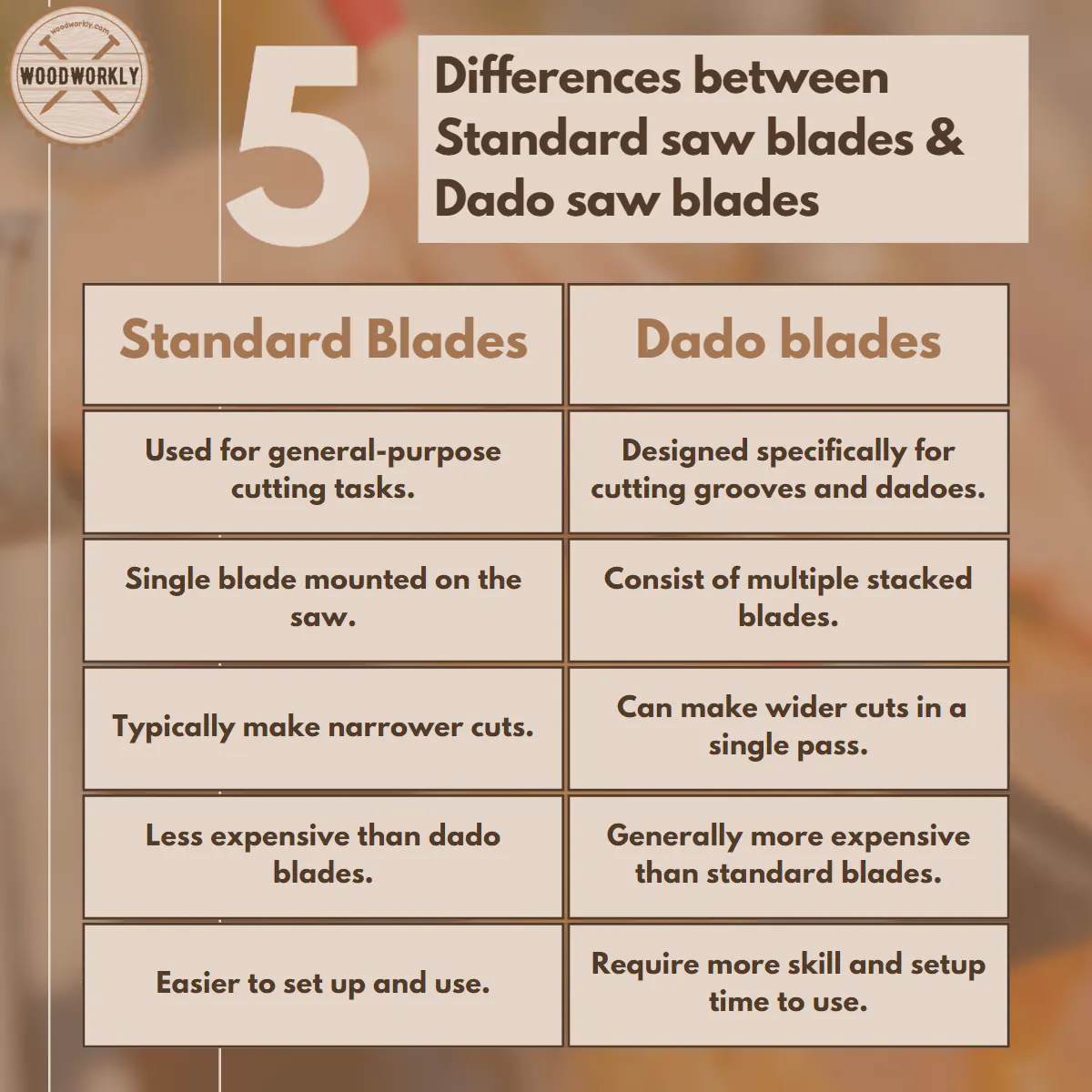

But for cutting grooves, two main types of blades are commonly used: standard blades and dado blades.

Standard Blades

Standard circular blades are also known as combination blades. They are versatile and able to use for a wide range of grove-cutting purposes.

Standard blades have a higher tooth count and are useful to create smooth, clean cuts suitable for grooves.

Make sure to use a blade with carbide teeth and a tooth design that minimizes the tear-out, such as ATB (Alternate Top Bevel) or TCG (Triple Chip Grind).

Here’re some pros and cons of standard blades you might face when groove cutting,

| Pros | Cons |

| Versatile | Require multiple passes to achieve groove width |

| Suitable for various cutting tasks | Less precise than dado blades for wider grooves |

| Compatible with a handheld circular saw |

Dado Blades

Dado blades are also known as dado sets. They are specially designed for cutting grooves, rabbets, and dados in wood.

Dado blades are consisting of two outer blades and multiple inner chipper blades that can be adjusted to achieve desired groove width.

As mentioned, dado blades are great for cutting grooves and they are mostly used with table saws and not useful for handheld circular saws.

Here’re some pros and cons of dado blades you might face when groove cutting,

| Pros | Cons |

| Designed for cutting grooves | Mostly used with table saws |

| Adjustable width for custom groove sizes | Not suitable for handheld circular saws |

| May be overkill for simple groove-cutting |

Choosing the Right Blade

Selecting the right blade type for your circular saw depends on several factors, including wood type, required groove width, and your saw’s compatibility.

- Wood type: Hardwoods may require a blade with more teeth and a specific tooth design, such as ATB or TCG, to minimize tear-out.

- Groove width: For wider grooves, a dado blade may be ideal, but remember, they are primarily used with table saws.

- Saw compatibility: Ensure that your saw can accommodate the chosen blade and make the necessary adjustments for cutting grooves.

Overall, as you can see, standard blades are versatile and compatible with handheld circular saws, dado blades offer specialized performance for grooves but are primarily compatible with table saws.

According to the given information choose the circular saw blade you’re going to use for making grooves wisely as per your preference for a nice result.

Before heading into the groove-cutting process, there’re several supplies you need to gather. Let’s talk about them first.

Basic Tools For Cutting a Grooves in Wood

- Circular saw

- Clamps

- Chisel

- Mallet

- Speed square

- Sandpaper

- Pencil

- Rip fence or straight edge

- Personal protective equipment (safety glasses, dust mask, ear plugs, or ear muffs)

After gathering the above equipment, you’re all good to start the groove-cutting with a circular saw.

How To Cut a Groove in Wood with a Circular Saw?

Cutting a groove in wood with a circular saw is easy if you follow the correct procedure with the right guidelines.

Here’re the steps you need to follow when cutting a groove in wood with a circular saw,

- Mark the groove edges.

- Secure the wood.

- Set the saw blade depth.

- Align the saw blade with the cut outline.

- Cut the groove edges.

- Hollow out the groove.

- Clean up leftover wood.

- Smooth the groove with sandpaper.

Let’s discuss each of the above steps in detail to cut a groove in wood with ease, ensuring accuracy and a smooth finish.

1. Mark the Groove Edges

First, you need to measure and mark the edges of the groove you want to cut on a wood workpiece using a pencil and a speed square.

Be precise with your measurements since wrong measurements and non-straight lines can directly affect the accuracy of the groove you’re going to cut.

Even though this looks like a simple step, this is the one you should do 100% accurately to get promising results.

2. Secure The Wood

Before starting anything with the workpiece, you need to place it on a stable workbench and secure it with clamps to avoid happening any individual movement during the cutting process.

This step is essential to do for safety and to achieve precise and clean cuts.

3. Set the Saw Blade Depth

Now, adjust the saw blade depth according to the depth of the groove you’re willing to cut.

To do that, first, you need to have a good understanding of the size and depth of the groove you’ll make.

Make sure not to exceed the depth of the groove you’re going to cut, than half of the wood’s thickness.

Saw blade depth adjusting part is usually done by loosening the depth adjustment level on your circular saw and moving the base plate up or down until the blade’s teeth extend slightly below the workpiece.

Secure the lever of your circular saw to lock in the depth.

4. Align the Saw Blade with the Cut Outline

Now carefully align the saw blade with the marked edges of the groove you drew.

If you’re using a rip fence or straight edge, attach it to your saw and position it alongside the marked line to get a straight cut.

A rip fence or straight edge helps to achieve straight cuts when cutting the groove.

5. Cut the Groove Edges

Now start to cut the groove edges using the circular saw after aligning it properly and the blade depth is set.

Start cutting along the marked line carefully by moving the saw at a steady pace and applying even pressure to maintain control and accuracy.

Make sure to wear your personal protective equipment during the process.

6. Hollowing Out the Groove

After you’re done cutting the edges of the groove with a circular saw, you need to hollow out the groove.

To do this, first, you need to make a series of parallel cuts between the two edge of the groove you cut. The parallel cuts should space about 18 to ¼ inch apart.

The closer the cuts, the easier it will be to remove the leftover wood in the next step.

7. Clean Up Leftover Wood

After making the parallel cuts, you need to remove the leftover wood from the groove using the chisel and mallet.

First, place the chisel in one of the parallel cuts and gently tap it with the mallet to break the wood fibers and take the wood out.

Repeat this process until all the excess wood has been removed, leaving a clean, even groove bottom.

Now you’re done with making the groove.

8. Smooth the Groove with Sandpaper

Now you’ll notice there’re some irregularities and rough areas on the surface of the groove and the surroundings.

Therefore, finally, you need to smooth out any rough edges and imperfections in the groove.

Start with a coarser grit sandpaper and work your way up to a fine grit sandpaper until you achieve a super smooth surface.

And that’s it. This is how you should achieve a clean, precise groove cut in wood with a circular saw.

By following the above steps you’ll be able to create any size of groove for your woodworking project with good confidence.

Let’s have a look at some tips and tricks that can be useful during the groove-cutting process to make your job a lot easier.

Tips for Cutting A Groove in Wood with a Circular Saw

Cutting a groove in wood with a circular saw need not only the right technique but also attention to detail and safety precautions.

Here’re some useful tips for cutting a groove in wood with a circular saw for effective results,

- Take your time when cutting a groove, don’t rush the process.

- Select the right blade for clean and accurate results.

- Keep the blade sharp to cut with ease.

- Clamp your workpiece firmly to prevent movements when cutting.

- Be gentile when removing excess wood with a chisel, rushing can damage the wood.

- Keep your working area well-ventilated and clean to avoid irritations and breathing issues due to sawdust.

By following the above steps, you’ll be able to make a clean, precise groove cut with your circular saw.

That’s it, folks! Hope you were able to know all you wanted to know about, how to cut a grove in wood with a circular saw properly without messing things up.

But what if you don’t have a circular saw with you or if your circular saw is already broken?

Are there any alternative methods to cut grooves in wood? Yes, there’re. So, let’s look at them and learn to use them in brief whenever your circular saw is not with you.

Alternative Methods To Cut A Groove in Wood

Even though a circular saw is an effective tool to cut a groove in wood, there’re some alternative methods as well you can get precise results.

Here’re some alternative methods you can use to cut a groove in wood,

- Using a router.

- Using a table saw.

- Using a drill.

- Using hand tools.

Let’s discuss each of those methods in detail to know how to cut a groove in wood properly.

Using a Router

A router is a versatile power tool specifically designed for shaping wood.

With the right bit and proper setup, it can efficiently and accurately create grooves in the wood.

If you want to know more details about its groove-cutting process, read my latest comprehensive guide about cutting a groove in wood with a router step-by-step process.

Here’re some pros and cons you might bet by using a router for cutting grooves in wood,

| Pros | Cons |

| Clean and precise cuts | Require specialized bits for different tasks |

| Easy to control | More expensive than other methods |

| Can create various groove sizes and shapes |

Using a Table Saw

A table saw is another powerful tool that can be used to cut grooves in wood.

By adjusting the blade height and employing a Dado blade set, you can create a wide range of groove sizes and depths.

If you want to know more details about its groove-cutting process, read my latest comprehensive guide about cutting a groove in wood with a table saw step-by-step process.

Here’re some pros and cons you might bet by using a table saw for cutting grooves in wood,

| Pros | Cons |

| High level of precision | Requires a Dado blade set for grooves wider than the blade |

| Can create long straight grooves with ease | Can be less versatile than a router |

| Suitable for larger workpieces |

Using a Drill

While not the most conventional method, a drill can be used to create a groove by removing material in a series of overlapping holes.

This technique requires careful planning and a steady hand.

If you want to know more details about its groove-cutting process, read my latest comprehensive guide about cutting a groove in wood with a drill step-by-step process.

Here’re some pros and cons you might bet by using a drill for cutting grooves in wood,

| Pros | Cons |

| The accessible tool found in most workshops | Less precise than other methods |

| Can create grooves without specialized attachments | Time-consuming and labor-intensive |

Using Hand Tools

This is the traditional method of cutting groves in wood. Hand tools such as chisels and hand saws can be used to create grooves in wood.

Here’re some pros and cons you might bet by using hand tools for cutting grooves in wood,

| Pros | Cons |

| No need for power tools or electricity | Requires significant skill and patience |

| Provides a sense of craftsmanship and connection to the material | Less precise and slower than power tool methods |

If you prefer to know more details about using hand tools, Read my latest guide about, cutting a groove in wood by hand tools.

Tip: If you want to cut a groove in wood for decorative purposes, try the Dremel tool.

Here’s my latest comprehensive guide about cutting grooves in wood with the Dremel!

Now you know all the methods that are useful to make a groove in the wood.

Ultimately, the best method for your project will depend on your skill level, available tools, and personal preferences.

Let’s answer some frequently asked questions.

FAQs

Can A Standard Circular Saw Cut Grooves In Wood?

Yes, a standard circular saw can cut grooves in wood by adjusting the blade depth and making multiple passes along the marked groove edges.

What Type Of Blade Should I Use For Cutting Grooves With A Circular Saw?

Use a high-quality carbide-tipped blade with a suitable tooth count and design for the material and desired groove width.

How Can I Ensure Straight And Precise Grooves When Using A Circular Saw?

Utilize a rip fence or straight-edge guide to maintain consistent alignment while cutting, and take your time to ensure accuracy.

Is Cutting Grooves With A Circular Saw Suitable For Both Hardwood And Softwood?

Yes, cutting grooves with a circular saw is suitable for both hardwood and softwood, but proper blade selection and adjustments are crucial for the best results.

What Safety Precautions Should I Take When Cutting Grooves With A Circular Saw?

Wear personal protective equipment (PPE) such as safety glasses, ear protection, and gloves, and ensure the workpiece is securely clamped during the cutting process.

Did I cover all you wanted to know about: How To Cut a Groove in Wood with a Circular Saw?

In this article, I’ve deeply explained how to cut a groove in wood with a circular saw including my personal experience as a woodworker and the things that I’ve learned from my fellow woodworking experts.

I’ve provided how to select the right blade for this groove-cutting project with many tips which are useful to know to achieve precise and clean cuts.

To cut a groove in wood with a circular saw, mark the groove edges, set the blade depth, align the saw with the cut outline, and make multiple passes along the marked edges. Hollow out the groove by making additional cuts, remove leftover wood with a chisel, and smooth it with sandpaper.

Furthermore, I’ve answered some frequently asked questions as well.

Hope you were able to know everything you need to know about, how to cut a groove in wood with a circular saw in detail.

Keep practicing the things I taught you from this article with scarp wood using your circular saw until you become a pro at this game. All the best!