Ever wondered how to protect and enhance your cedar treasures? Discover the wonders of Linseed oil on cedar – a game changer in wood care!

Linseed oil, also known as flaxseed oil, is one of the top-tier wood finishes among oil finishes.

It enhances the wood’s appearance while providing excellent protection from weather elements.

I was curious about finishing cedar wood furniture with Linseed oil, so I conducted research with the help of experts over a decade ago.

This research focused on how raw and boiled linseed oil should be applied to cedar.

Thanks to that, I have learned the proper application techniques and have been practicing them for a long time now.

Let’s discuss, using Linseed oil on cedar.

Yes, you can use Linseed oil on cedar. Linseed oil cures and hardens to a protective coat over wood by protecting cedar furniture from moisture. Linseed oil enhances the cedar wood grain’s depth of texture and color. Apply Linseed oil on cedar along cedar wood grain light sand between coats.

But there’s more to know about using and applying Linseed oil on cedar.

So, in this article, I’ll explore whether can you use Linseed oil on cedar and how to apply Linseed oil on cedar wood furniture and woodwork properly.

Furthermore, I’ll answer some frequently asked questions as well.

Let’s jump in!

Can You Use Linseed Oil On Cedar?

Yes, Linseed oil works perfectly on cedar. It enhances the wood’s appearance by improving the natural look of cedar wood while protecting wood from environmental humidity, moisture, and sunlight.

Linseed oil sits and penetrates deep into the cedar wood surface to make a coating above the wood.

After you applied Linseed oil over the cedar, it will cure and harden to a protective layer by solidifying upon the reaction with outside air.

Atmospheric oxygen reacts with Linseed oil and goes through a polymerization reaction process to form solidified and hardened Linseed oil layer.

Once the Linseed oil gets cured and hardened, it makes a barrier between the wood and the outside world.

Water and moisture are unable to get into the wood through the Linseed coat and this helps to get cedar wood protected from water damage and rotting.

Apart from that, Linseed oil is able to protect cedar wood from damage from direct sunlight and other outdoor elements. With Linseed oil, cedar wood furniture won’t discolor.

It reduces sunlight damage. This makes Linseed oil great even the cedar wood outdoor furniture, fences, and woodwork.

Linseed oil is a non-toxic and environmentally friendly finisher. It contains no VOC or no harmful chemicals like most other finishers.

Linseed oil is mostly used for following applications of cedar wood,

- Cedar furniture

- Cedar fences

- Cabinets

- Flooring

- Wood carving projects

- Cutting boards (only raw Linseed oil)

As you can see Linseed oil can literally use for any cedar wood applications.

Read to know Does Cedar Need To Be Sealed? (Ultimate Guide!)

So, let’s see how the main two variants of linseed oil work on cedar wood in different cases.

Raw Linseed Oil and Boiled Linseed Oil On Cedar

There are main 2 types of Linseed oil that can be used over cedar wood.

- Raw Linseed oil

- Boiled Linseed oil

Both raw Linseed oil and boiled Linseed oil work well on cedar wood. But boiled Linseed oil dries and is cured faster than raw Linseed oil since it contains drying components.

Raw Linseed oil typically takes 5 to 6 days to dry on the cedar wood surface while boiled Linseed oil generally dries within 2 to 3 days after application.

Boiled Linseed oil makes by a special vacuum cooking process at a really high-temperature level. This process will increase the viscosity and shorten the drying time of Linseed oil.

But Linseed oil has hazardous toxic compounds since it is man-made and contains harsh chemicals inside. Therefore, better to use raw Linseed oil on food and kitchen applications of cedar.

Therefore, woodworkers love to use boiled Linseed oil over raw Linseed oil on cedar wood. It dries and cures faster than a finishing coat.

Here I made a simplified table of raw linseed oil vs boiled linseed oil on cedar,

| Raw Linseed Oil on Cedar | Boiled Linseed Oil on Cedar |

|---|---|

| Takes 5 to 6 days to dry | Dries within 2 to 3 days |

| Ideal for food-related applications (non-toxic) | Contains drying components and is less food-safe |

| Applied in slender coats, requires 2 to 10 weeks curing | Dries and cures faster due to added chemicals |

| Environmentally friendly, no VOCs | Emits VOCs while drying |

| Enhances the wood’s appearance naturally | Provides a more durable finish but with chemicals |

| Used mostly in applications where long drying times are acceptable | Preferred for quicker project completion |

Can You Use Linseed Oil On Exterior Cedar?

Yes, you can use Linseed oil on exterior cedar. Linseed oil increases the lifetime of exterior cedar furniture and works since protects it from moisture, environmental humidity, and rotting.

But it is not recommended to apply Linseed oil on exterior cedar in areas with harsh weather conditions.

Linseed oil repels the water and only provides some sort of water resistance and it is not completely waterproof.

Therefore, better to apply lacquer, varnish, or some other protective finisher over the cedar exterior if you’re willing to keep it under extreme weather.

Plus, proper maintenance is a must since over time Linseed oil coat will fade away, and the reapplication of Linseed oil on exterior cedar at least once per year.

By keeping exterior cedar in a safer place with fewer weather changes and maintaining the finish properly, you’ll be able to keep the exterior project as fresh as new in the long run.

If you’re interested in applying linseed oil on a Cedar outdoor deck, here’s a comprehensive guide about How to Use Linseed Oil on Decks (EASY Guide!)

Let’s see all the benefits you’ll get by using Linseed oil on cedar.

So, let’s have a look at the proper way of applying Linseed oil on cedar with no mistakes.

Supplies You Will Need to Use Linseed Oil on Cedar

- Linseed oil (Raw or Boiled Linseed oil)

- Mineral spirits

- Fine-Grit sandpapers (120 grit, 220 grit, 320 grit, 400 grit)

- Abrasive finishing pads

- Lint-free tack cloths

- Rags

- Bristle brush or sponge brush

- Latex gloves

- Facemask

Make sure to purchase the above supplies from quality manufacturers to get a promising nice and smooth finish.

Tip: Always check the shelf life of mineral spirits you’re going to use because Mineral spirits can go bad pretty quickly.

How to Apply Linseed Oil to Cedar?

Not like other oil finishes, you can apply Linseed oil on cedar easily using a few easy steps.

Cedar takes Linseed oil so well since it is porous wood and oil will easily penetrate into those porous to provide the finish you wanted.

Linseed oil enhances the wood color and provides excellent protection against weather elements

Choosing the right type of Linseed oil is important before application.

- If you’re going to apply Linseed oil on a cutting board or any other food-related woodwork, go for raw Linseed oil since it doesn’t contain hazardous chemicals

- If you want to do the finishing process quickly and efficiently, go for boiled Linseed oil since it dries and cures faster than raw oil.

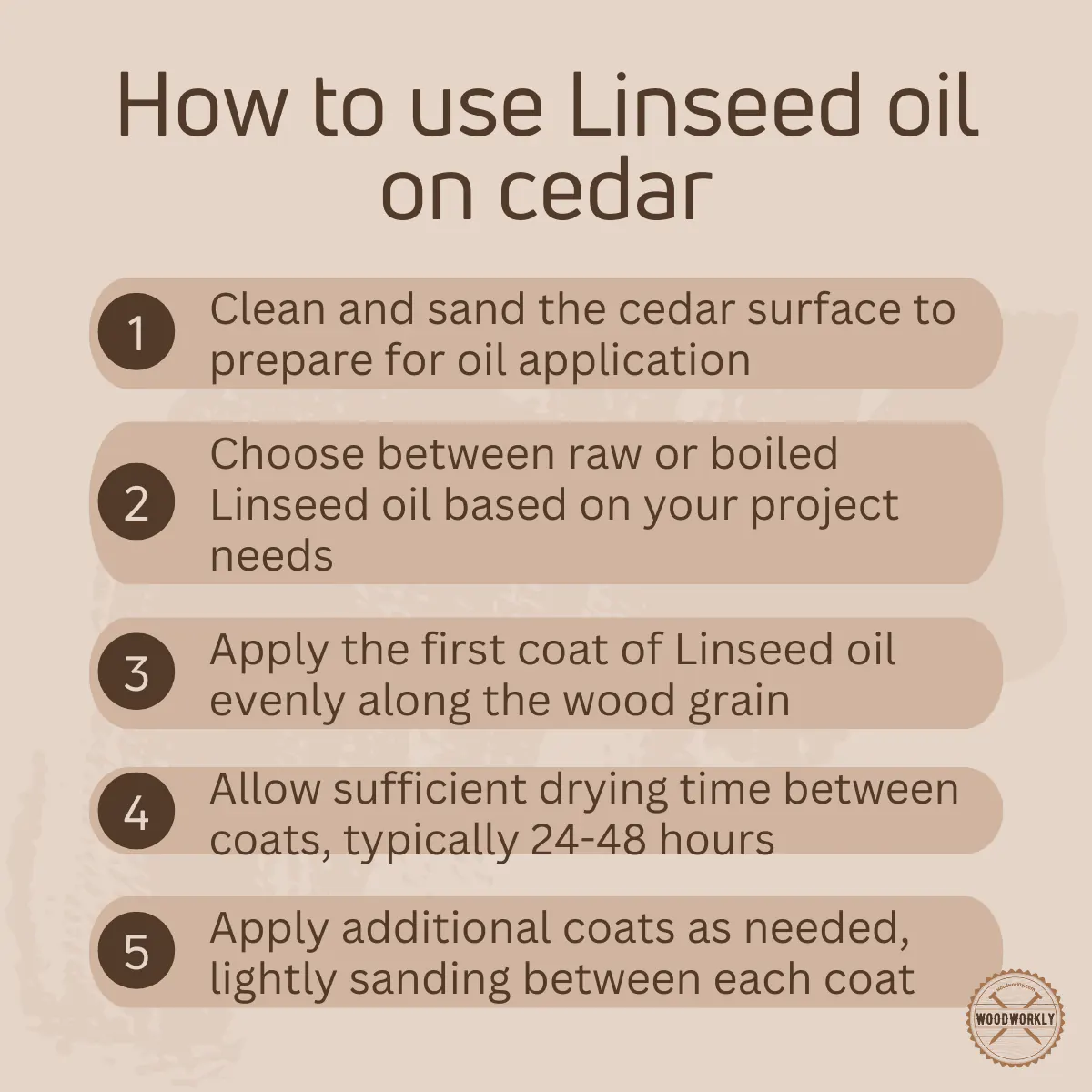

Here’re the steps you need to follow when applying Linseed oil to cedar,

- Prepare the cedar wood surface

- Thin the Linseed oil

- Apply the first coat of Linseed oil

- Let the coat dry well

- Light sanding

- Apply more coats

- Let the final coat dry and cure properly

So, let’s discuss each of the above steps separately to get a better idea about the application process.

1. Prepare The Cedar Wood Surface

First, you need to take cedar wood furniture or woodwork to a well-ventilated area since having proper air circulation is a must for efficient drying.

You can open windows in your working area.

Plus, in this process, we’re going to use harsh chemicals like mineral spirits, and boiled Linseed oils, and lots of sawdust will be released.

These can issue eye and skin irritations with breathing issues. Therefore, proper air circulation is a must for any wood-finishing project.

After that, take a clean cloth and clean the cedar wood surface that is going to be finished with Linseed oil properly.

Remove dust, sawdust, dirt, and debris by wiping the surface or using a proper dust collection pipe system.

Sawdust, dirt, and other contaminants prevent Linseed oil penetration, and you may end up with never drying tacky and splotchy surfaces when the dust is on the surface.

Or you can use Tri-sodium phosphate to remove dirt that is difficult to remove with tack cloths.

After cleaning the wood, sand the entire wood surface using 120 grit or fine sandpaper to eliminate dumps, and surface randomness and smoothen the surface to take the Linseed oil well.

Plus, sanding helps to remove previous finishes from the surface and make it nice and clean.

Sand along the direction of the cedar wood grain to prevent the wood from scratching during the process. Then, clean and remove sawdust from the surface using a clean rag.

Now your cedar wood surface is ready to take on Linseed oil.

2. Thin The Linseed Oil

Thinning Linseed oil is an optional step.

When you’re sealing cedar wood with tung oil, you’ll have to go through a thinning process.

But, in this case, you don’t need to be worried about thinning since Linseed oil is good to apply on cedar as it is.

Note: Thinning Linseed oil is good to improve the adhesion between coats and to make the coats dry faster. It is an optional step.

Thinned Linseed oil also increases the absorption rate of Linseed oil on cedar.

To thin Linseed oil, open the Linseed oil can add pour a sufficient amount into a glass jar.

Then add an equal amount of mineral spirit to it and mix them slowly without letting form air bubbles. Vigorous mixing can form air bubbles that are hard to remove once they are trapped inside the oil.

Generally, only the first coat of Linseed oil is thinned with the mineral spirit or odorless thinner. Having good adhesion makes the process easy.

3. Apply The First Coat Of Linseed Oil

Now apply the first coat of Linseed oil with the thinned Linseed oil that you prepared earlier. You can apply Linseed oil without thinning as well.

Apply a heavy, dripping Linseed oil coat on cedar wood along the direction of the wood grain using a paintbrush.

Applying along the wood grain helps for better absorption of finishing oil into the wood without forming blotches.

After applying the first wet coat of Linseed oil on the cedar let the oil sits and absorb into the wood for 30 minutes.

During this period, the oil will penetrate the wood fibers and the excess oil will settle on the surface by forming the coat.

Then spread Linseed oil evenly all over the wood along the wood grain using a lint-free tack cloth.

Make sure to wipe off excess amounts of Linseed oil before they harden.

Puddled areas should be wiped immediately before they hardened.

Mostly the first coat of Linseed oil saturates wood fibers and only the excess amount sits on the surface to make the protective coat.

Thinned Linseed oil absorbs easily into the wood and dries faster.

4. Let The Coat Dry Well

After applying the first coat of Linseed oil, let it settle for 30 minutes and wipe off the excess to get a wet-looking glossy finish.

After that let the coat dry and harden overnight.

Usually, raw Linseed oil coat takes 24 hours to dry completely. But I highly recommend you wait until 48 hours to get the maximum benefits without messing up the project with tacky surfaces.

Drying time depends on the humidity and the weather you live in. That’s why 48 hours consider the sweetest spot in the area you live.

Generally, Linseed oil takes more time to dry than other oil finishes.

Boiled Linseed oil dries faster than raw Linseed oil. Boiled Linseed oil coat dry within 12 hours.

Once the surface is fully dried you’re good to move on to the next step.

5. Light Sanding

Now sand the dried first coat of Linseed oil using fine-grit sandpapers or abrasive finishing pads.

Do light sanding using 220 grit or finer grit sandpaper along the direction of the wood grain to smoothen the surface and improve the adhesion properties of the Linseed oil coat.

Sanding along the wood grain doesn’t scratch the coat. apply even light pressure on sandpaper while sanding.

Or you can use abrasive finishing pads to knock off dust nibs. They don’t clog up like sandpapers.

6. Apply More Linseed Oil Coats

Once you’re done with light sanding, clean the surface and apply another coat of Linseed oil over the wood.

The second Linseed oil coat is not needed to be thinned before the application since we’ve already got the abrasion required by thinning the first coat.

The second coat of Linseed oil sits on the surface and contributes a lot to building the protective layer over the surface.

After applying the second coat of Linseed oil evenly all over the wood using a paintbrush and lint-free cloth, let it settle in and dry for about 24 hours.

Once the coat is fully dried do the light sanding only if necessary, just like the technique you used during the first coat.

Repeat the same procedure for another coat and limit the number of Linseed oil coats on cedar wood to 3 or 4 maximum coats.

The application time of Linseed oil is about 10 – 15 minutes, but this can vary on the area you’re going to cover.

7. Let The Final Coat Dry And Cure

After applying each coat of Linseed oil, let the coats dry for 24 – 48 hours. The final coat of Linseed oil should dry and cure for 5 to 6 days.

Boiled Linseed oil coats take 2 to 3 days to fully dry and cure. Raw Linseed oil coats take 5 to 6 days to fully dry and cure.

Boiled Linseed oil contains chemicals that accelerate the drying process more than the raw one.

But these drying times can vary upon weather changes, temperature changes, and environmental humidity.

Apply thin coats of Linseed oil to dry faster between coats.

During the curing process, the final coat of Linseed oil goes through a polymerization reaction process with the atmospheric oxygen to form, polymerized, solidified, tough Linseed oil protective coat over the wood.

This solidified coat helps the wood to get protected from environmental elements such as moisture, weather changes, temperature changes, sunlight, and insect attacks.

Here’s the basic process of applying Linseed oil,

- Wipe on

- Light sanding

- Wipe off

- Let it dry

- Scuff it

- Repeat

That’s it, folks! Now you know everything about applying Linseed oil on cedar without making any mistakes.

Advantages Of Using Linseed Oil On Cedar

- Raw Linseed oil is an environmentally friendly finisher

- Protect wood from weather elements

- Enhance wood appearance

- Water resistant finisher

- Raw Linseed oil is food safe

- Hide dents and scratches

- Protects wood from dents and scratches

- Prevent wood from rotting and decaying

- Protects wood from direct sunlight

- Easy to apply

- Non-toxic

- Protect wood from insect attacks

- Increases the wood durability

Now you can see why woodworkers consider Linseed oil as one of the best finishers for cedar wood furniture and woodwork.

But Linseed oil has both pros and cons when it comes to real-world application.

It provides excellent protection to cedar wood furniture and a beautiful glow with a shining natural look.

How Many Coats Of Linseed Oil Cedar?

Apply 3 coats of Linseed oil cedar to get a protective coating over the surface with an enhanced wood appearance.

Apply thin coats of Linseed oil for fast and efficient drying.

Never apply more than 4 coats of Linseed oil over any wood since when the number of coats gets higher, it may take forever to dry. probably you’ll end up with never drying tacky surface.

How Long Does Linseed Oil Last On Cedar?

Linseed oil lasts on cedar for about 2 to 3 years on use. Linseed oil on exterior cedar lasts for 2 years.

With proper maintenance and reapplying Linseed oil at least once per year you can keep Linseed oil on cedar forever.

Linseed oil will fade and peel away over time due to harsh weather conditions, high-humidity environments, sunlight, and other environmental impacts.

Plus, using Linseed oil on cedar for a long time with no maintenance or cleaning causes yellowing since it is an oil-based finish.

In order to keep your cedar wood furniture as fresh as new for a long time with high durability and strength, apply Linseed oil frequently once per year before the current Linseed oil coat starts to fade away.

What Is The Best Oil To Use On Cedar?

Here’re some of the best commercial oil finishes to use on cedar,

- Linseed oil

- Ung oil

- Teak oil

- Danish oil

- Spar Urethane

Will Linseed Oil Keep Cedar From Turning Grey?

Yes, Linseed oil keeps cedar from turning grey. Linseed oil helps cedar wood to keep its fresh natural color for a long time without discoloration.

Boiled Linseed oil slows down the natural aging process of cedar wood which turns cedar wood into a grey color.

You need to maintain the Linseed oil coat regularly by applying Linseed oil over cedar furniture at least once per year before the previous one fades away.

Otherwise, cedar wood will eventually turn grey upon exposure to environmental elements such as moisture and sunlight.

Let’s answer some frequently asked questions.

FAQs

Can Linseed Oil be Used on All Types of Cedar Applications?

Yes, Linseed oil is versatile and can be used for various cedar applications, including furniture, fences, and outdoor structures, providing enhanced protection and aesthetics.

How Often Should Linseed Oil be Reapplied to Cedar?

Reapply Linseed oil to cedar annually to maintain its protective qualities and appearance, especially for outdoor cedar items.

Does Linseed Oil Change the Color of Cedar Wood?

Linseed oil enhances cedar’s natural grain and color, deepening the wood’s texture and adding a slight amber hue over time.

Can Boiled Linseed Oil be Used on Food-Related Cedar Items?

Boiled Linseed oil is not recommended for food-related items due to its chemical additives; raw Linseed oil is a safer choice.

How Long Does Linseed Oil Take to Dry on Cedar?

Raw Linseed oil takes 5-6 days to dry on cedar, while boiled Linseed oil dries within 2-3 days, depending on environmental conditions.

Did I cover all you wanted to know about: Linseed Oil On Cedar

In this article, I deeply discussed whether can you use Linseed oil on cedar and how to apply Linseed oil on cedar properly using the correct method.

Linseed oil works well on cedar wood forming a protective layer to keep wood from water damage and rotting while increasing the wood’s appearance. Apply 3 coats of Linseed oil on cedar wood. Reapply Linseed oil at least once per year to keep the cedar furniture as fresh as new in the long run.

Furthermore, I’ve answered some frequently asked questions as well.

Hope you have gained good knowledge about; whether can you use Linseed oil on cedar with the relevant information.

Try to apply Linseed oil on cedar to experience the benefits of Linseed oil in the practical world.