Ever marveled at the rich hues of Padauk wood? But do you know its downsides? Dive in to uncover some surprising facts!

Padauk wood is useful in making high-end furniture, cabinets, flooring, and many other indoor and outdoor woodworking projects. It is a hardwood with excellent strength and durability.

But on the other hand, there’re some disadvantages as well. I did some research and found some main disadvantages of Padauk wood.

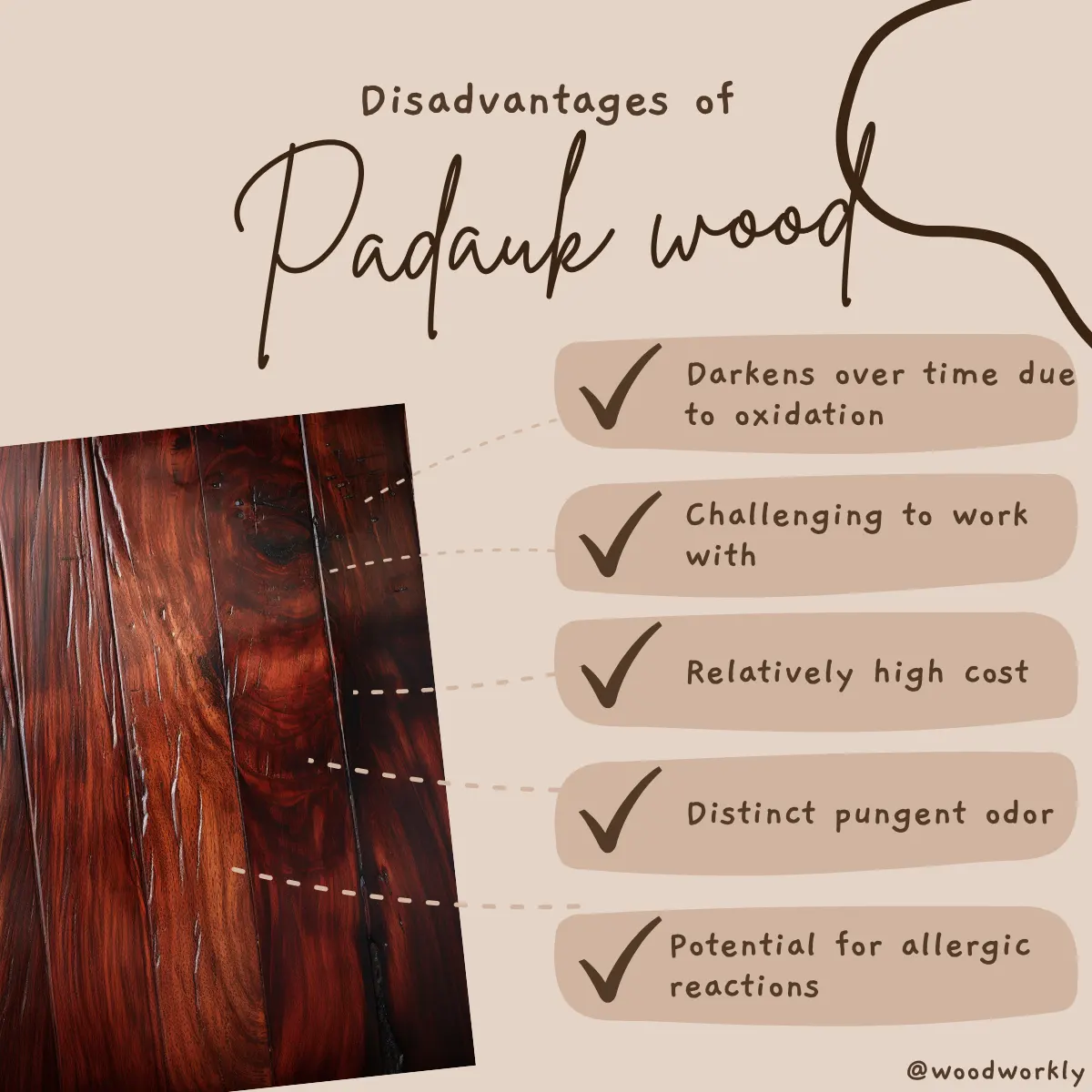

Here’s the list of Padauk wood disadvantages,

- Interlocked grain structure

- Darken with age

- Difficult to work with

- Expensive

- Distinct odor

- Allergy problems

In this article, I’ll explore all the above Padauk wood disadvantages in-detail and how to fix them with simple methods and tricks.

Furthermore, I’ll answer some frequently asked questions as well.

As a fresh start, first, let’s briefly have a look at Padauk wood’s advantages that are useful in woodworking and furniture making.

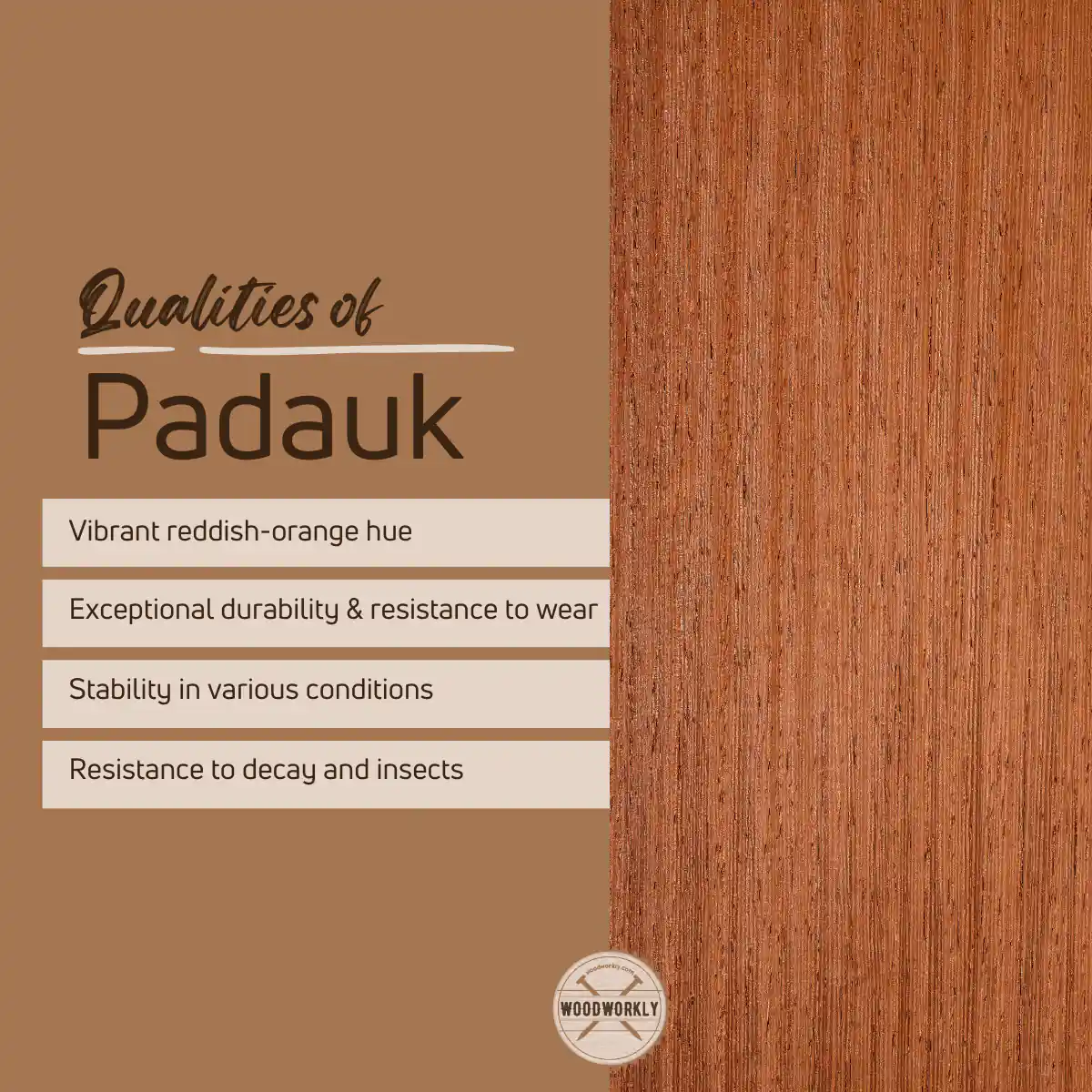

Advantages Of Padauk Wood

- High durability

- High strength

- Hardwood

- Rot-resistant

- Resistant to termites

- Has many colors options

- Straight open texture

- Attractive

As you can see Padauk wood is filled with lots of significant benefits. That’s why it has become popular among woodworkers.

So, let’s head into the main topic of Padauk wood disadvantages in-detail with fixes.

Disadvantages Of Padauk Wood

Let’s have a look at the disadvantages of padauk wood in detail and how to fix them

1. Interlocked Grain Structure

Having an interlocked grain structure is the main drawback of Padauk wood. Interlocked grain structure makes Padauk wood extremely difficult to work with.

Wood tear outs can occur due to interlocked structure since it is not machine friendly.

If you’re a beginner in woodworking, I highly recommend you not to start with Padauk wood since it gives you nightmares, especially when working with woodworking hand tools.

Screwing, nailing, drilling, cutting, and shaping Padauk wood is hard because of the interlocked grain structure.

Padauk wood tends to split and tear easily compared to other kinds of wood because of its unusual, interlocked grain pattern.

This issue is not common for Padauk wood only, Sapele wood also has these types of issues. Interlocked grain structure occurs usually with the growth of the tree.

Working with hand tools can be extremely difficult and your toolset needs to be well-sharpened to prevent Padauk wood from chipping.

Personally, I hate to work with Padauk wood since its interlocked grain structure, blunt and damaged woodworking tools and making shapes and cuts can be extremely difficult in furniture-making and wood carving projects.

Because of this interlocked grain structure, staining Padauk wood is also difficult since the wood stain is unable to penetrate the wood to make a smooth coat.

Due to the interlocked grain structure, staining and painting along the direction of the Padauk wood surface cannot be done and that may cause a blotchy surface with lots of wood staining mistakes.

The only solution for its interlocked grain structure is selecting a Padauk wood species with a less interlocked grain pattern when purchasing.

2. Darken With Age

Padauk wood has a unique reddish-brown discoloration over time. It comes in various colors like pale pink, orange, and more with white to yellowish brown sapwood color.

But after some time, it will turn into dark color due to direct sunlight, UV light, and the aging process of wood.

The more it is exposed to sunlight; more it gets darker.

You can prevent Padauk wood from darkening by applying a proper stain or finish that contains UV inhibitors in its ingredients.

For example, Cedar finishes have UV inhibitors that stop UV light from hitting the wooden surface which causes discoloration.

UV inhibitors absorb and dissipate UV light that comes to the wooden surface. They absorb and turn UV radiation into heat by protecting wood from harmful rays.

Apply sealer, stain or finish with UV inhibitors to the entire Padauk wood surface and keep using it under an open environment to see how finishing coats help Padauk wood to remain the same as its original color without darkening.

Here’re some finishes you can use for Padauk wood to stop wood darkening,

- Tung oil with UV inhibitors

- Wood stain

- Lacquer

- Varnish

You ‘ll have to apply the wood finish at least once per year to keep Padauk wood for so long without turning into dark reddish brown.

As soon as the finishing coat fades away over time, the wood gets exposed to direct sunlight and starts darkening.

Tip: Make sure not to use regular oil-based finishes with no UV inhibitors on Padauk wood since they cause instant darkening in Padauk wood.

Or you can place Padauk wood inside or cover it up from direct sunlight. But finishing is recommended to keep the original color for the long run.

3. Difficult To Work With

Padauk wood is difficult to work with because of its interlocked grain structure and extremely high hardness.

Wood tends to split and chip because it is so brittle and making smooth shapes can be a nightmare for many people.

The only fix for its working difficulty is using woodworking tools with sharp edges and using fresh sandpaper.

This is why power tools and recommend when working with hardwoods like Padauk.

Being heavy, strong, and stiff is great when it comes to wood durability. But not great when working since you need to put in extra effort always.

4. Expensive

Padauk wood is significantly more expensive than other hardwoods that have similar properties to Padauk.

They’re around 29 species of Padauk wood that are expensive in the US because of their less availability.

Because of its great durability and strength, Padauk wood has high demand in the woodworking world.

But supplying rate is slow and that’s the main reason for its expense and less availability.

5. Distinct Odor

During woodworking, Padauk wood release a distinct odor that can cause breathing problems. it has a faint, pleasing odor that is extremely harsh and causes issues.

This awful Padauk wood odor occurs mostly when cutting and drilling the wood.

Therefore, always wear a mask when working with Padauk wood since that can cause respiratory irritations.

6. Allergy Problems

Padauk wood is popular for causing allergies. When working with Padauk wood wearing, goggles, a mask, and latex gloves is a must.

Because Padauk wood oils and other wood particles can damage the eyes, skin, and respiratory system.

When sanding with Padauk wood, you need to have a proper dust collection pipe system to remove sawdust immediately without letting them roam free in the working area since it can damage your skin.

Plus, always make sure to choose a well-ventilated area to work with Padauk wood because good air circulation helps you to breathe fresh air with no wood residue and other bad chemicals that release when wood finishing.

That’s it, folks! Hope you have gained good knowledge about the Padauk wood disadvantages that occur during working and using Padauk wood furniture and other woodwork.

Plus, we have discussed how to overcome those cons as well.

Is Padauk Wood Toxic?

Padauk wood is non-toxic and food-safe wood. you can use Padauk wood for any woodworking project including kitchen utensils.

But always make sure to use non-toxic chemicals when treating Padauk wood because most of the finishes contain harmful chemicals that can be toxic.

Use natural non-toxic oil finishes like Linseed oil, and tung oil on Padauk wood furniture to get protected from environmental elements like moisture, UV light, and insect attacks.

Is Padauk Wood Safe For Cutting Boards?

Yes, Padauk wood is safe for cutting boards since it is food-safe, non-toxic wood with excellent strength and durability, Padauk wood has good resistance to scratches and decay resistance.

Padauk wood can tolerate sharp knife edges because of its high hardness and density.

What Is Padauk Wood Used For?

Padauk wood can use for any woodworking project.

It has some excellent features with so few drawbacks that can be fixed using the correct methods as we talked about earlier in this article.

Here’re some common uses of Padauk wood,

- High-end cabinets

- Furniture making

- Wood carving

- Flooring

- Boat building

- Wood joints

- Veneer

As you can see Padauk wood can be sued for anything including indoor and outdoor woodworking projects.

I highly recommend you apply a good finisher on Padauk furniture or woodwork before keeping them outside, because wood is wood and they get always damaged under harsh weather conditions and temperature fluctuations.

Is Padauk Wood Waterproof?

Padauk wood is not waterproof, but it has excellent water resistance. Therefore, you can use Padauk wood for the bathroom, kitchen, and even in swimming pools.

It doesn’t rot easily and has excellent stability to prevent water damage.

Padauk wood has oil that repels water particles and stops them from going inside the wood that causes rot.

Because of being water resistant, Padauk has become so popular and you don’t need to focus a lot more on the finishing step.

It has natural tolerance against environmental elements like moisture, humidity, and insect attacks.

Is Padauk a Good Wood?

Padauk wood is one of the most underrated wood types in the woodworking world.

It has excellent durability, strength, dimensional stability, water resistance, insect resistance, and a pleasing look that can use for any woodworking project.

Padauk wood is so good, and the only issue is its interlocked grain pattern, discoloration, and expensive.

But it is well worth the price and most of the disadvantages can be solved with a proper finisher.

Since you’re aware of all the disadvantages of Padauk wood, let’s answer some frequently asked questions.

FAQs

Does Padauk wood’s color stay vibrant over time?

No, Padauk wood naturally darkens over time due to oxidation, turning its reddish-orange hue to a subdued red-brown. While finishes can slow this process, they cannot stop it entirely.

Is Padauk wood challenging to work with?

Yes, due to its dense nature and interlocked grain structure, Padauk wood can be difficult to cut, plane, and sand, and it can dull blades quickly.

Is Padauk wood more expensive than other woods?

Yes, Padauk is considered a luxury wood and tends to be pricier than many other types of wood, making it an investment for many woodworkers.

Does Padauk wood emit an odor?

Yes, Padauk wood has a distinct and sometimes pungent scent that some people may find overpowering or unpleasant, and this odor can linger even after finishing.

How does Padauk wood fare in bending applications?

Padauk does not bend easily. Its density and resistance to warping make it unsuitable for projects requiring flexibility, like bending.

Did I cover all you wanted to know about: Padauk Wood Disadvantages

In this article, I’ve deeply discussed Padauk wood disadvantages and how to fix them easily.

Overall, Padauk wood is an excellent quality wood with lots of qualities and very few drawbacks that can be easily fixed.

Padauk wood’s disadvantages include its tendency to darken over time due to oxidation, challenges in working with its dense and interlocked grain structure, a relatively high cost, a distinct pungent odor, and potential allergic reactions caused by the chemical pterocarpum. It’s also not recommended for cutting boards due to these compounds.

Furthermore, I’ve answered some frequently asked questions as well.

Hope you have gained good knowledge about the disadvantages of Padauk wood and how to minimize them to get the best use of it.

Try to use Padauk for your next woodworking project and see how the wood behaves and try to escape its cons. Happy woodworking with Padauk wood!