Ever considered using poplar wood for your next project? While it’s popular, it has its pitfalls. Curious about the downsides? Let’s dive in!

Poplar wood is a quality wood that can be used in the making of cabinets, furniture, toys, carvings, and many woodworking projects.

But on the other hand, there’re some drawbacks of popular wood which only highlight in some scenarios.

I was curious about this and did deep research to find out the cons of poplar wood.

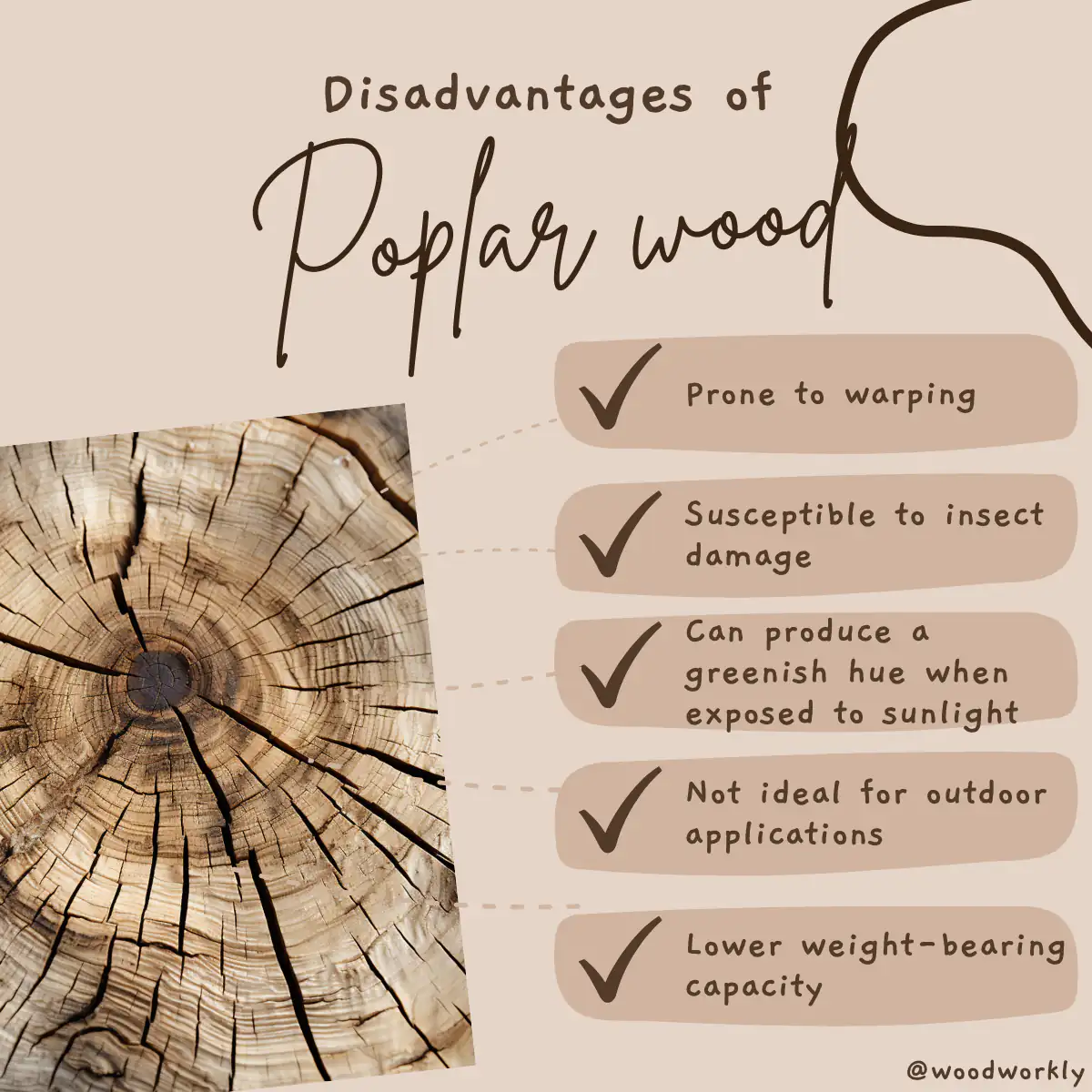

Here’s the list of, Poplar wood disadvantages

- Dent and scratch easily

- Need regular maintenance

- Difficult to stain

- Poor stability

- Poor durability

- Require more sanding

- Irritant

- Darken over time

- Expensive than softwoods

- Prone to warping

- Susceptible to insect damage

- Can produce a greenish hue when exposed to sunlight

- Not ideal for outdoor applications without proper treatment

- Lower weight-bearing capacity

- Emit a distinct odor

From this article, I’ll explain deep down each of the above poplar wood disadvantages and all you need to know about poplar wood.

Furthermore, I’ll answer some frequently asked questions as well.

Let’s jump in!

First of all, let’s have a quick look at the Advantages of poplar wood.

Advantages Of Poplar Wood

- Hardwood

- High workability

- Lightweight

- Uniform texture

- High availability

- Inexpensive

- High machinability

- Poplar wood is strong

As you can see poplar wood is filled with lots of advantages that we can use in various woodworking projects.

This is why it has become so popular among woodworkers.

So, let’s find out the disadvantages of poplar wood and discuss them in detail.

Disadvantages Of Poplar Wood

Let’s have a look at the disadvantages of poplar in detail and how to fix them.

1. Dent and Scratch Easily

This is the main disadvantage of poplar wood. Even though poplar wood is considered a hardwood, it is significantly softer than many other hardwoods.

Being so soft causes poplar wood to dent and scratch easily.

Janka hardness test is the standard method of testing the hardness of particular wood by considering its resistance to wear and tear.

For example, if a particular wood has high wear and tear resistance, it has a high Janka hardness rating.

When it comes to poplar wood, it has a Janka hardness rating of 540 lbf (2,402 N) which is significantly lower than most other hardwoods.

For example, yellow pine has a Janka hardness rating of 870 depsides of being a softwood.

So, as a hardwood, poplar wood is extremely soft. Because of having soft fibers, poplar wood scratch and dent easily.

Because of prone to dents and scratches, poplar wood needs to be well finished, sealed, or stained before use for any woodworking application.

When it comes to flooring, never use bare poplar wood since it cannot bear foot traffic, and dog scratches and you may end up having deep scratches on the floor.

Staining or finishing is a must for poplar wood.

Even though poplar is a paint-grade wood, it is so difficult to paint popular because it dents easily. This makes poplar bad for painting.

Poplar wood is not good for kitchen applications since it dents easily. It is too soft and cannot use in hard and harsh environments like the kitchen, bathroom, and outdoor environment.

Plus, you need to put extra focus on the finishing step. MDF is a better choice than poplar since it doesn’t dent easily.

Overall, poplar wood is too soft, and it dent, scratch and tear up easily. But with proper finishing, sealing, or staining, you can make it resistant to dents and scratches.

2. Need Regular Maintenance

Poplar wood needs regular maintenance and care to keep the food lasting long for many years.

Even though it belongs to the hardwood family, poplar is too soft, and it cannot tolerate extreme impacts without proper maintenance.

Poplar wood is too porous, soft hardwood. Water particles are able to penetrate inside of the wood through its porous structure and cause the wood to rot.

In order to prevent the wood from rotting and to keep it waterproof, you need to apply sealant or finisher often before the previous coat fades away.

Especially when it comes to outdoor applications, poplar cannot withstand harsh weather conditions, temperature variations, and high humidity without proper maintenance.

Clean poplar furniture and other woodwork frequently and make them dust and dirt-free and reapply to finish oil like tung oil, teak oil, or Danish oil to increase the lifetime of the wood.

Plus, poplar is susceptible to insect and bug attacks. Applying paint, polish, varnish or any other wood finisher helps to repel bugs and keep the wood protected.

With proper cleaning and maintenance, you can keep poplar wood furniture for even more than a decade.

3. Difficult To Stain

Poplar wood is too porous and soft. Therefore, it absorbs wood stains like a sponge.

This can be a waste of wood stain since poplar absorbs a lot of stain without letting stain sit on the surface to make a protective coating.

You’ll probably need to apply at least 5 coats of stain to make a top layer of stain, but it can make the surface looks blotchy since applying too many coats slow down the drying time.

To minimize this issue, you can apply a wood conditioner before staining poplar wood to slow down the stain absorption rate and to spread the stain evenly throughout the surface.

Wood conditioner controls the absorption rate of poplar wood fibers and lets stains sit on the surface making a protective shield to protect the wood against environmental elements like moisture, UV light, insect attacks, and much more.

Applying stain on bare poplar wood is not recommended since it develops a blotchy and tacky surface with an unpleasant visual appeal.

You should always use proper staining methods to hard staining woods like poplar to make the finish as you want.

4. Poor Stability

Poplar wood has poor dimensional stability compared to other hardwoods. Poplar wood shrink, expand, warp, and twist with environmental changes which lose the stability of the furniture and lose their strength.

Even though all the woods expand and contract upon environmental humidity levels, poplar wood shows too many movements upon humidity and temperature changes.

Poplar tree grows so fast, and it has less dense, wide annual rings which reduce the wood stability.

Because of having unstable wood structure poplar wood has less tolerance against temperature and humidity changes. That’s the main reason for its poor stability.

Poplar expands and contracts due to humidity changes. When the environmental humidity is less, water will evaporate from the poplar wood and the wood will start to shrink.

In high environmental humidity, the wood starts to expand.

Poplar wood expands and contracts upon temperature variations. It expands because of thermal expansions of wood fibers.

Because of the irregular movements of the poplar wood, it may warp, twist and crack.

In order to prevent poplar wood from warping, you need to apply a proper finisher or sealant to stop wood from absorbing or releasing moisture into the air.

Plus, you need to make sure to use the correct finishing and sealing methods when drying poplar wood slices since it cracks upon humidity variations of the atmosphere.

Wood finish or sealants work as a barrier to prevent poplar from releasing or absorbing moisture under humidity variations of the environment.

Therefore, wood movements will be minimized and able to improve the stability of poplar wood.

5. Poor Durability

Because of being a soft hardwood, poplar wood is not durable as regular dense hardwoods.

It is prone to environmental impacts like moisture, insect attacks, temperature variations, and harsh weather conditions.

Poplar woodworks and furniture are more fragile than furniture made with other hardwoods.

They tear up easily and cannot use for hard work. Wood may crack, or split when cutting, nailing, drilling, and other woodworking activities.

Poplar wood is prone to insect and fungi attacks. They can damage the poplar wood surface quite easily and cause wood to decay.

Plus, the growth of mold and mildew may occur in moist environments.

You can repel insects, fungi, and bugs by applying a proper sealer or stain on the poplar wood surface using the correct methods to improve the wood’s stability and keep it much longer.

Overall, poplar is a non-durable wood species that rot and decay easily and is prone to insect attacks. Proper finishing is the key factor to improve its durability.

6. Require More Sanding

Poplar is a soft hardwood that is unable to sand with coarse grit sandpapers since they may damage and scratch the wood.

Therefore, fine grit sandpapers are required to sand and smooth the poplar wood surface.

With fine-grit sandpapers, you need to sand for too long to get the smooth surface you wish.

Plus, poplar wood tends to fuzz up during the sanding process. You’ll notice the fuzzed-up poplar wood surface sooner or later after sanding is done.

Poplar is labor intensive, and you need to sand it for so long since it is so soft and has tiny marks, and can be easily visible.

Sand along the direction of the poplar wood grain to get a smooth surface quickly and to keep fuzzing up in a minimum amount.

7. Irritant

Even though poplar wood is a non-toxic wood, it can be an irritant and cause allergies in the eyes and skin.

The sawdust and small saw particles can go into the eye and cause issues.

Therefore, always make sure to use goggles and rubber latex gloves when working with poplar wood.

It is softwood that chips easily and releases lots of sawdust that can be bad for the skin.

Always chose well-ventilated are to minimize issues. Wood dust can be a huge problem for asthma patients.

Hiding eyes and skin is important and using proper dust collection pipes to remove sawdust quickly before them spreads all over the area.

8. Darken Over Time

Poplar wood gets darkened and yellow over age because of the sunlight and chemicals.

Poplar is a lightwood that is able to absorb chemicals like mineral spirits from the ground which can cause wood to get darkened with age.

The green streaks of poplar wood get deep brown color with age. Direct sunlight darkens the poplar wood color.

Some people think getting darker colors on poplar is a benefit but if you have taken poplar considering its light color to match the theme, it is a nightmare to see how your poplar furniture and woodwork get darker and darker over time.

You can minimize the darkening of poplar by staining the poplar back to its original color or placing poplar wood furniture away from direct sunlight and chemicals.

Green in poplar fades to a brown color within a few months.

But this can be slowed down by sealing the wood properly.

Color changing of poplar happens due to the oxidation with atmospheric oxygen.

This is a natural process that happens in most other woods as well. Staining is the best option to color the wood as you want without losing its beautiful grain texture.

9. Expensive than Softwoods

Even though poplar wood is considered a soft hardwood, it is more expensive than many other softwoods. It is only cheaper than hardwoods. For example, poplar is more expensive than Pine.

Poplar has become expensive not because of its features, but for its less availability.

Because of having so many alternatives like MDF which provide exactly the same features as Poplar wood with extra benefits, growing poplar has become less than early days.

This has caused the wood to cost more than most softwoods.

But if you are looking for hardwood for a cheap price, poplar is the best option you should go with.

Even though it is expensive compared to other softwoods, it is a lot cheaper than hardwoods.

10. Prone to Warping

Warping is one of the most notorious and pesky issues faced by those working with woods like poplar.

If you’ve ever crafted something with wood and noticed it becoming distorted over time, then you’ve seen warping in action.

Let’s dive deeper into this issue, especially concerning poplar wood, and discover ways to combat it.

What is Warping and Why Does It Happen?

Warping refers to the distortion or deformation in wood due to moisture and uneven drying.

Essentially, wood cells absorb and release moisture, leading them to expand and contract.

This change in size isn’t uniform and can cause the wood to bend or twist out of shape.

Poplar wood, despite its numerous benefits, is particularly susceptible to warping.

The primary reason is its growth pattern. Poplar trees grow rapidly, resulting in less dense, wider annual rings.

These characteristics reduce the wood’s stability and make it less tolerant of changes in humidity and temperature.

In simpler terms, think of poplar wood as that friend who is a tad more sensitive to sudden changes in plans—only in this case, the plans are environmental conditions!

Example: I once used poplar for an outdoor project, thinking its light color and texture would be perfect.

But after a few months of fluctuating weather, the panels started to twist and bend. If only I’d known better!

Steps to Avoid Poplar Wood from Warping

If you love Poplar as much as I do, don’t be disheartened!

There are steps you can take to reduce the risk of warping.

1. Proper Drying:

Before using poplar, ensure it has been adequately dried.

Properly dried wood is less likely to warp since it’s already adapted to a stable moisture content.

2. Sealants and Finishers:

Applying a proper finisher or sealant is vital. These act as barriers, preventing the wood from absorbing or releasing excess moisture.

Remember my twisted panels? A good sealant would have made a world of difference.

3. Storing in a Controlled Environment:

Always store poplar wood in an environment where you can control the temperature and humidity.

It’s like giving your wood a comfortable room to rest in before it’s put to use.

4. Use in Suitable Applications:

If possible, avoid using poplar wood in places where it’ll be exposed to frequent moisture or drastic temperature changes.

For instance, it might not be the best choice for an outdoor shed but could be perfect for indoor furniture.

5. Keep Away from Direct Sunlight:

Direct sunlight not only darkens poplar wood over time but can also contribute to warping.

If using poplar for furniture, place it in a spot where it’s shielded from the sun’s intense rays.

11. Susceptible to Insect Damage

Just like how some of us can’t resist a chocolate cake, some insects simply can’t resist poplar.

Let’s dive into this peculiar attraction and find out how to keep these unwelcome guests at bay.

Why Are Insects Attracted to Poplar Wood?

Poplar wood has a light, somewhat porous grain, making it quite appealing to certain insects.

The wood’s organic compounds and moisture content act like a siren call to these pests.

Wood-boring insects, in particular, find poplar wood to be an excellent place to lay their eggs and let their larvae thrive.

For instance, a friend of mine once crafted a gorgeous poplar bookshelf, only to discover small holes and sawdust trails a few months later.

The culprits? Woodworms! They had made a feast of the bookshelf, turning what was once a solid structure into something resembling Swiss cheese.

It’s a heartbreaking sight for any wood enthusiast!

Steps to Protect Poplar Wood from Insect Damage

Fear not!

While insects might be drawn to poplar, there are ways to ensure your poplar projects remain bug-free.

1. Proper Treatment:

Before putting poplar wood to use, make sure it’s treated with insect-resistant chemicals.

These chemicals deter pests and protect the wood’s integrity.

2. Regular Inspections:

Every once in a while, inspect your poplar items for any signs of insect activity. Look for small holes, sawdust trails, or even larvae.

Early detection is key to stopping an infestation in its tracks.

3. Maintain a Dry Environment:

Most wood-loving insects are drawn to moisture.

By ensuring that your poplar wood is kept in a dry environment, you’ll make it less appealing to these pests.

Think of it as setting the right ambiance that says, “This isn’t the place for you!”

4. Use Natural Repellents:

Certain natural substances, like cedarwood chips or essential oils (e.g., eucalyptus or tea tree oil), act as repellents for many insects.

Consider placing these near your poplar items for added protection.

5. Seek Professional Help:

If you do spot signs of an infestation, it might be worth calling in the experts.

Pest control professionals can offer solutions tailored to the specific bug you’re dealing with.

12. Can Produce a Greenish Hue When Exposed to Sunlight

Sun-kissed skin might be a desirable trait for many of us, but when it comes to poplar wood, the sun can play some unexpected tricks.

Have you ever seen a beautifully crafted poplar piece gradually transform into a shade that reminds you of a mildew-infested wall?

I know I have, and it’s quite a surprise, to say the least.

Let’s delve into this sun-induced phenomenon and explore how we can prevent our poplar wood from turning green.

The Sun-Tanned (or Sun-Burned?) Poplar

Poplar, despite its many virtues, has this quirky tendency to adopt a greenish hue when it spends too much time in direct sunlight.

This is due to the specific chemical compounds present in the wood.

When these compounds interact with the ultraviolet (UV) rays of the sun, a chemical reaction occurs, leading to this greenish discoloration.

I remember walking into a friend’s house and admiring a poplar coffee table they had just acquired.

The table, sitting right next to a large window, was basking in the afternoon sunlight.

A month later, what was once a light, creamy wood was now exhibiting streaks of green.

It looked unique, sure, but it wasn’t the look they had initially bought it for!

Ensuring Your Poplar Stays True to Its Color

It’s not all gloom and doom, though. With some precautionary measures, we can ensure that our poplar wood remains as vibrant and genuine as the day we got it.

1. Change Location:

The simplest way to avoid the green hue is to position your poplar furniture or items away from direct sunlight.

If you have a piece near a window, consider relocating it to a shadier spot.

2. UV Protective Finishes:

There are a plethora of finishes available on the market that come with UV protection.

Applying these to your poplar wood can act as a sunscreen, preventing those UV rays from causing any discoloration.

3. Window Treatments:

If you’re adamant about keeping your poplar piece next to a window, invest in UV-blocking window films or blinds.

Not only do they protect your wood, but they can also keep your indoor space cooler in the scorching summer months.

4. Regular Maintenance:

Over time, any applied finishes can wear off.

Make it a routine to check the finish on your poplar items and reapply when necessary to maintain that UV shield.

5. Embrace the Change:

For some, the greenish hue adds character. If you’re one of those people, let nature take its course and enjoy the evolving beauty of your poplar piece.

13. Not Ideal for Outdoor Applications Without Proper Treatment

Ah, the great outdoors! Birds chirping, the smell of fresh air, and… poplar wood furniture turning into a spongy mess?

Wait, that’s not part of the idyllic scene we pictured! Many of us have had dreams of setting up that rustic wooden sitting area in our garden.

And poplar wood, with its smooth grain and light color, often seems like a prime candidate.

But as I’ve learned from some personal misadventures, not all woods are cut out for outdoor escapades.

Let’s dive into why untreated poplar isn’t the best pick for the elements, and of course, how to make it work if your heart is set on it.

When Poplar Plays Outside: The Downside

Poplar, in its natural state, is a bit like that friend who loves indoor board games but wilts at the thought of a strenuous hike.

The wood is soft and relatively porous. Here’s what that means for our garden dreams:

- Moisture Magnet: Poplar tends to absorb moisture from the environment. This makes it susceptible to rot, decay, and the all-too-familiar warping when left outside.

- Insect Affinity: As with the previous point on insects, untreated poplar is a bit of a snack for pests. Termites, beetles, and other wood-loving critters find it particularly delectable.

- Sun Sensitivity: We already touched on how poplar can take on a greenish hue in the sun, but there’s also the risk of the wood becoming brittle over time due to UV exposure.

I once had this dreamy vision of setting up a poplar wood bench in my backyard.

Needless to say, without proper treatment, the dream quickly turned into a saggy, slightly green-tinted reality. Lesson learned!

How to Prep Poplar for the Great Outdoors

Fear not, fellow Poplar enthusiasts! With some TLC, we can make Poplar ready for the wild (or, at least, the backyard).

1. Seal the Deal:

Start with a good quality outdoor wood sealer.

These sealers create a protective barrier that keeps out moisture, ensuring your wood remains dry and decay-free.

2. Repel Those Critters:

Opt for insect-repellent treatments.

These treatments make the wood less appealing to pests, ensuring it remains bite and burrow-free.

3. Sunscreen for Wood:

As with the greenish hue problem, a UV-protective finish is crucial.

This will prevent the wood from losing its structural integrity and color under the sun’s harsh rays.

4. Routine Checks:

Nature is unpredictable. Regularly inspect your outdoor poplar pieces for signs of damage, wear, or insect activity.

Early detection means easier fixes.

5. Cover Up:

If possible, invest in covers for your outdoor poplar furniture.

These covers can protect against rain, direct sunlight, and pests, prolonging the life of your wood.

14. Lower Weight-Bearing Capacity

Have you ever watched one of those movies where the protagonist takes a daring leap onto a fragile bridge, only to have the bridge buckle under their weight, leading to a nail-biting sequence of near-misses?

Well, think of poplar as that fragile bridge in the world of woods. Now, don’t get me wrong.

I absolutely adore poplar for its versatility and aesthetics, but it has its limitations.

One of which is its lower weight-bearing capacity. Let’s embark on this journey to understand this trait of poplar and how to circumnavigate it.

Poplar wood, as beautiful and smooth as it is, isn’t the Hercules of woods when it comes to strength.

Its cellular structure is relatively less dense compared to some of its more muscular wood counterparts, such as oak or maple.

What does this mean in practical terms?

- Not a Heavy Lifter: Poplar isn’t the go-to choice for projects that need to bear significant weight. Think large bookshelves filled to the brim with books or heavy-duty workbenches.

- Dents and Scratches: Because of its softer nature, poplar is also more prone to dents and scratches. I remember once placing a slightly heavier vase on my poplar table, and oh boy, that left a mark!

- Structural Limitations: For those who are into DIY or home construction, poplar isn’t the ideal candidate for structural applications where weight-bearing is crucial.

Making Poplar Stronger: It’s Possible!

While poplar may not be naturally suited for heavy-duty tasks, there are ways to maximize its strength and mitigate its weight-bearing limitations.

1. Choose the Right Project:

First and foremost, be aware of what you’re using poplar for.

It’s fantastic for decorative pieces, lightweight furniture, and interior moldings.

2. Reinforce with Stronger Woods:

If you’re adamant about using poplar but are concerned about its strength, consider combining it with stronger woods.

For instance, a poplar bookshelf can have oak or maple reinforcements on its edges or corners.

3. Use Proper Joinery:

The type of joints you use can significantly enhance the strength of your poplar creation.

Dovetail or mortise-and-tenon joints, for example, can distribute weight more effectively.

4. Thicker Cuts:

If using poplar for a weight-bearing application, consider using thicker cuts of the wood. The added thickness can help it withstand more weight.

5. Protective Finishes:

While finishes won’t necessarily increase weight-bearing capacity, they can shield the wood from dents and scratches.

A quality finish can add a layer of protection against minor bumps and accidents.

15. Emit a Distinct Odor

Have you ever been on a long hike, and as you traverse through the woods, your senses get tickled by a unique aroma that’s neither fresh pine nor blooming flowers?

That, my friend, might just be the signature scent of poplar wood. For some, it’s an aromatic whisper of nature, while for others, it’s an unwanted perfume.

Let’s delve into this olfactory tale of poplar wood and find out why it emits that distinct odor and how you can navigate this characteristic if it’s not quite your ‘scent of choice’.

A Whiff of Poplar: The Good, The Bad, and The Musky

Poplar wood, like a good vintage wine, comes with its own bouquet. Here’s a glimpse into its aromatic profile:

- Natural Resins: All woods contain natural resins that give them their characteristic smell. In the case of poplar, these resins produce a somewhat musky scent, especially when freshly cut.

- The Age Factor: I once worked with an old piece of poplar, and it had a more pronounced aroma than the newer pieces. Just like us, wood ‘matures’ and so does its smell!

- Environmental Influences: Believe it or not, the environment where the poplar tree grows can influence its scent. Soil types, rainfall, and other trees around it can add nuances to its aroma.

Navigating the Aromatic Journey of Poplar

So, you’ve got this beautiful piece of poplar, but you’re not too keen on its natural perfume?

Fear not! Here’s how you can minimize or embrace this distinct feature:

1. Air It Out:

Before starting your project, consider placing the poplar wood in a well-ventilated area.

This can help dissipate some of the stronger odors.

2. Seal the Deal:

Sealing the wood with finishes can lock in the scent.

Varnishes, paints, or even clear sealers can form a barrier that prevents the odor from escaping.

3. Mask with Essential Oils:

If you’re into DIY solutions, consider using essential oils.

A light touch of lavender or cedarwood can mask the scent and add a touch of personal flair to the piece.

4. Embrace the Aroma:

Sometimes, it’s all about perception. Instead of seeing it as a drawback, consider the scent as a unique characteristic of poplar.

Just like the smell of old books or fresh rain, it has its own charm.

5. Mix with Other Woods:

If you’re crafting a piece that uses multiple types of wood, the aromas of other woods can help neutralize or mask the distinct odor of poplar.

That’s it, folks! Now you know the poplar wood disadvantages in detail.

As you can see most of the above disadvantages of poplar can be easily fixed with proper finishing and sealing of the wood.

Does Poplar Wood Crack Easily?

Yes, poplar wood cracks easily especially when it is dry. poplar is too soft, and it has poor density. Therefore, it tends to crack and split easily by exterior impacts.

You can prevent the cracking of poplar wood when drying by sealing the wood before drying.

Always make sure to keep the moisture amount in the wood to an appropriate level since moisture increases the flexibility of the wood fibers and lets them stretch under pressure without making cracks.

On the other hand, because of the ability to crack and split easily, poplar wood is easy to work with woodworking hand tools.

It has good workability and even a beginner in woodworking can handle poplar pretty easily.

Is Poplar a High-Quality Wood?

Yes, Poplar wood is a high-quality wood since it has high compressive strength, bending strength, high workability, environmental friendliness, and attractive texture with lots of other hardwood characteristics.

Compared to most other hardwoods, poplar wood is cheaper and easy to work with. Therefore, poplar is excellent for carving.

With proper finishing and sealing, you can use poplar for any indoor and outdoor woodworking projects and with regular maintenance, they will last over decades.

Is Poplar Wood Rot Resistant?

Poplar wood has no rot resistance since it sucks up moisture like a sponge. Moisture penetrates inside of the poplar wood fibers and causes wood to rot.

You can prevent the wood from rotting by applying a protective sealer or stain before using poplar wood furniture and woodwork.

Once the wood gets started to rot there is no point in applying sealer to cover the outside area of the wood.

You should remove the rotted poplar wood and restore poplar wood using a quality product like FlexSeal.

But the restoration process is not an easy thing.

Therefore, better to seal your poplar wood furniture before moisture goes inside and damages the wood.

Does Poplar Wood Warp?

Yes, poplar wood warps due to irregular wood movements. When the wood is exposed to different humid levels, it gets to expand and contract because of the absorption and evaporation of the moisture.

When the moisture gets absorbed into poplar wood due to high environmental humid conditions, poplar wood gets expanded. Under low humid levels of the environment, poplar wood gets shrunk.

When the wood expansion and shrinkage happen unevenly all over the wood, it tends to get twisted and warped.

Wood warping loses the stability of the poplar wood and loses its strength.

Proper finishing is required to make a barrier between the poplar wood surface and the air and prevent moisture from going into and going out of the wood.

Sealing and finishing the wood will prevent wood warping.

Is Poplar Wood Weather Resistant?

Poplar wood is not weather resistant since it cannot tolerate temperature variations, humidity changes, moisture, and climate changes. The wood will rot and decay quickly under harsh weather conditions.

With proper finishing and regular maintenance, you can make poplar weather-resistant and keep it for so long with ease.

But that takes a lot of time and money.

So, let’s answer some frequently asked questions.

FAQs

Can I use poplar wood outdoors?

While poplar can be used outdoors, it requires proper treatment. Without protective finishes, poplar is not naturally resistant to the elements and may deteriorate faster.

Is poplar wood strong enough for heavy furniture?

Poplar has a lower weight-bearing capacity compared to hardwoods like oak or maple. Thus, it might not be the best choice for furniture pieces that need to support significant weight.

Is poplar wood a budget-friendly choice despite its disadvantages?

Absolutely! While poplar has its quirks, its affordability and versatility make it a popular choice for many woodworking projects, especially those where its disadvantages can be managed or are not a major concern.

Did I cover all you wanted to know about: Poplar Wood Disadvantages

In this article, I’ve deeply discussed most of the common poplar wood disadvantages and how to fix them with simple methods.

The main disadvantages of poplar wood are being too soft, dents and scratches easily, hard to stain, poor stability, poor durability, darkening over time, and being irritant to eyes and skin.

Most of the disadvantages of poplar can be fixed by finishing and sealing the wood properly before use.

Furthermore, I’ve answered some frequently asked questions as well.

Hope you have gained good knowledge about poplar wood disadvantages.

Use things you have learned about the other side of poplar wood to get the maximum out of the wood. Happy woodworking with Poplar!